®

Instalación

1. Para la instalación convencional de la montura para la salida

posterior colgable en la pared, se deberá usar un sistema

de soporte de 4 pernos para adaptar el tanque de agua al

sistema de soporte y al drenaje. Consulte las instrucciones

de instalación que se incluyen con el sistema de anclaje del

tanque para la instalación de la unidad.

2. Si va a instalar el inodoro sobre un sistema de anclaje

existente, asegúrese de que el mismo cumpla con los

requisitos locales y de que el sistema de soporte resista

el peso para los requisitos de la aplicación.

3. Los vástagos de montura deben sobresalir 5/16"(8mm) de

la pared terminada.

4. Colocar las tuercas de seguridad que se entregaron con el

soporte o el apoyo en el perno prisionero de la montura

# 1, # 3 y # 4. No se usa tuerca de seguridad en la montura

del perno prisionero # 2. Ajustar las dos tuercas inferiores

de tal forma que estén separadas 1/16"de la pared

terminada. Usando un nivel, ajustar la tuerca de respaldo

del perno de montaje # 1 hasta un plano vertical con el

perno prisionero de montaje N.º 3.

Nota: Si la pared está irregular, las tres tuercas y

arandelas de respaldo se deberán colocar de tal forma

que quede un espacio mínimo de 1/16"entre la montura

y la pared.

5. Nota: Las tuercas de respaldo también conocidas como

tuercas de conexión, se deben colocar de tal forma que

lleven toda la carga de la montura, dejando un espacio

de 1/6"entre la montura y la pared terminada. Siga las

recomendaciones del fabricante para la conexión de salida

del portador. Al colocar la montura en el portador no se

recomienda usar un anillo de cera, se recomienda usar

fieltro o neopreno. Al colocar la montura en el portador, el

empaque del drenaje se deberá comprimir lo suficiente

para asegurar un sellado positivo del gas y un sellado

impermeable.

6. Con ayuda de dos personas, instale la taza sobre los pernos

prisioneros del montaje. Coloque la arandela de fibra que se

incluye con la montura del portador, sobre los pernos #1,

#3 y #4. Coloque el tapón de la tuerca que se incluye en el

portador, sobre los pernos prisioneros de montaje #1, #3

y #4. Mientras que se sostiene la taza nivelada y usa una

llave ajustable, ajuste las tres tapas de las tuercas hasta

que estén ceñidas. ADVERTENCIA: EL PRODUCTO ES

FRÁGIL No ajuste demasiado. Solo debe quedar ceñido.

7. Instale la arandela de fibra y el tapón de la tuerca en el

perno de montaje #2, ajuste manualmente hasta que

la tuerca y la arandela toquen la porcelana. Ajuste

manualmente el tapón de tuerca firmemente contra la

porcelana. Eso es tolo lo que se necesita para montar la

tuerca y la arandela en el perno #2. Selle con silicona de

caucho la separación entre el inodoro y la pared terminada.

Nota: Si ajusta con llave el tapón de tuerca en el perno de

montaje #2, romperá la porcelana debido a que no hay

tuerca de respaldo en este perno.

8. Colocando la parte estrecha del empaque grande de goma

de cara contraria al tanque, deslice el empaque de goma

sobre la rosca de la válvula de desagüe al fondo del tanque.

Conecte el tubo flexible de suministro de agua (no incluido)

dentro de la válvula de llenado del tanque. Coloque el

tanque sobre la taza, con el lado estrecho del empaque de

goma grande viendo hacia la taza. Al mismo tiempo que

coloca el tanque sobre la taza, dirija el tubo de suministro

flexible a través de la apertura que se proporciona.

9. Coloque el empaque pequeño de goma sobre los pernos de

montura del tanque que se incluyen en el tanque. Coloque

la arandela metálica y la tuerca en el fondo de las tuercas

del tanque, y ajustarlas hasta que el tanque esté ceñido

contra la barra del tanque sanitario del tanque. Conecte

la línea de suminstro del tanque a la llave de paso y ajuste

firmemente todas las tuercas de acoplamiento. Abra

elsuministro de agua y permita que se llene el tanque.

Revise que no haya fugas y ajuste la montura como sea

necesario.

Nota: La perspectiva de esta ilustración es una representación

general y puede no necesariamente definir los contornos

exactos del producto.

A

B

C

D

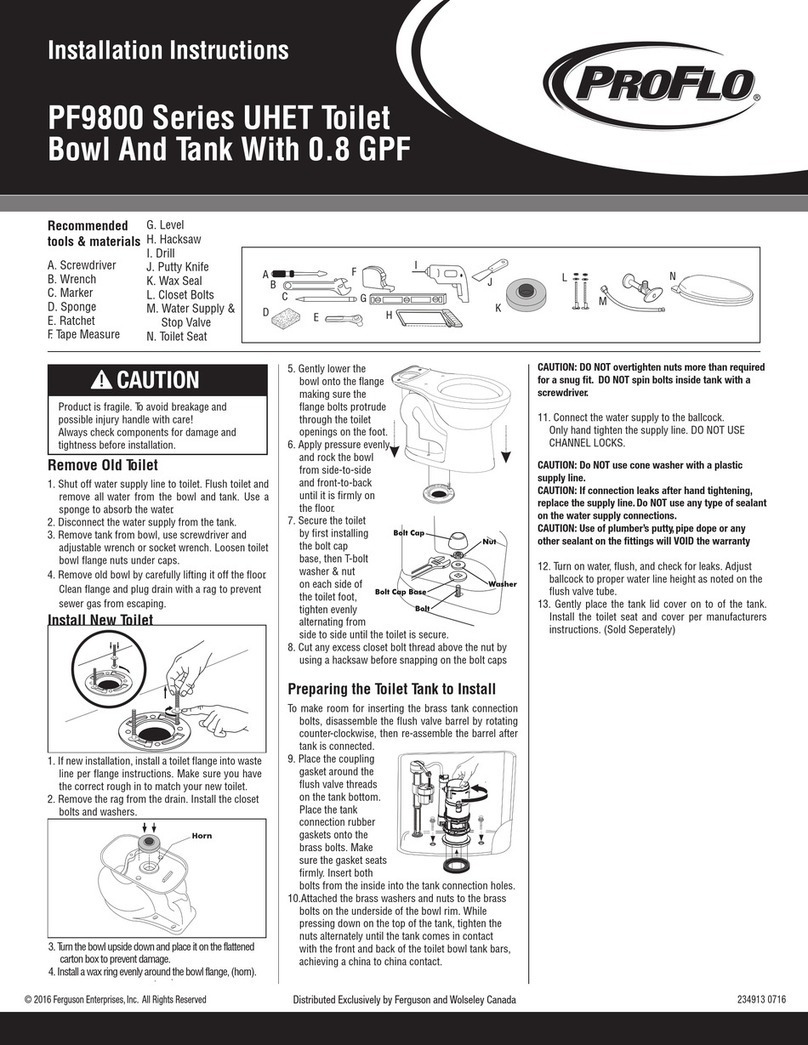

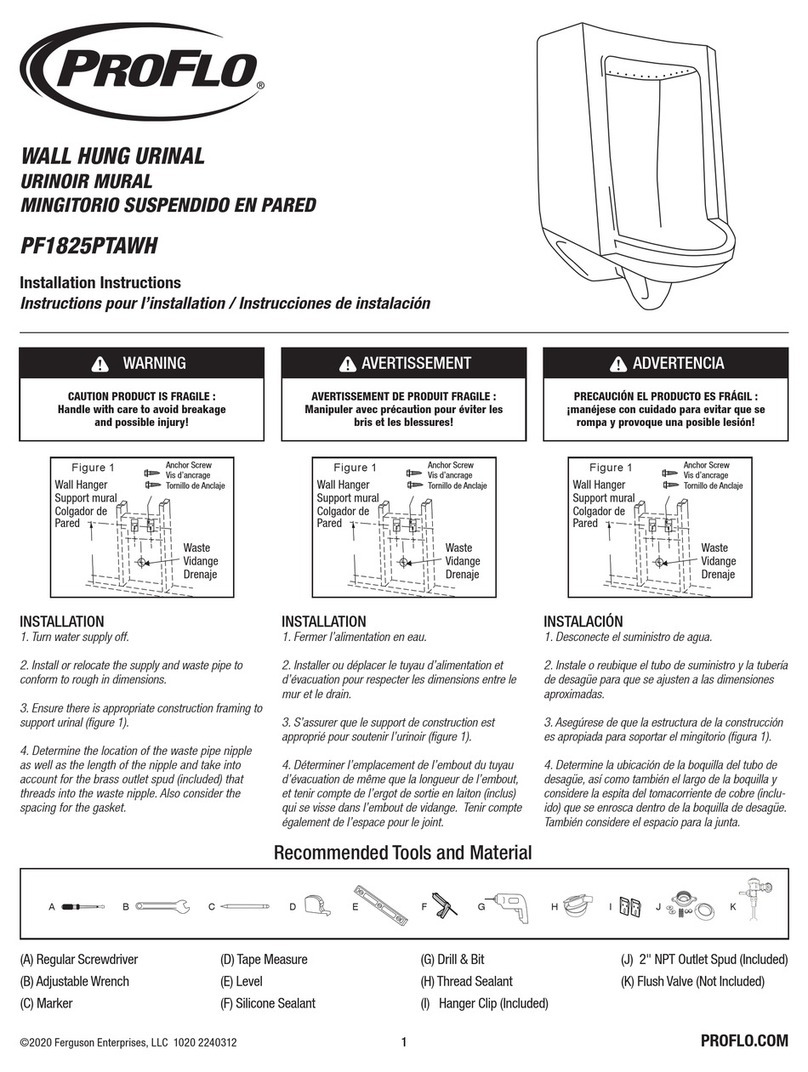

Recommended Tools & Materials

(A) Regular Screwdriver

(B) Adjustable Wrench

(C) Marker

(D) Tape Measure

(E) Level

(F) Silicone Sealant

(G) Putty Knife

(H) Flexible Supply Tube (Not Included)

(I) Closet Carrier/Support (Not Included)

CAUTION: PRODUCT IS FRAGILE

Handle with care to avoid breakage and possible injury!

When performance matters.

When performance matters.

Note: Views in this illustrations are for general representation

and may not necessarily define the exact contours of the product.

7730/7730HE

REV 10/2013

-1-

If you are installing the toilet on an existing support system,

make sure the system is in compliance with local code

requirements and the support system is weight rated for

the application requirements.

12

EG

F

If replacing an existing toilet be certain to shut off

water supply before removing old toilet.

SINK INSTALLATION:

34

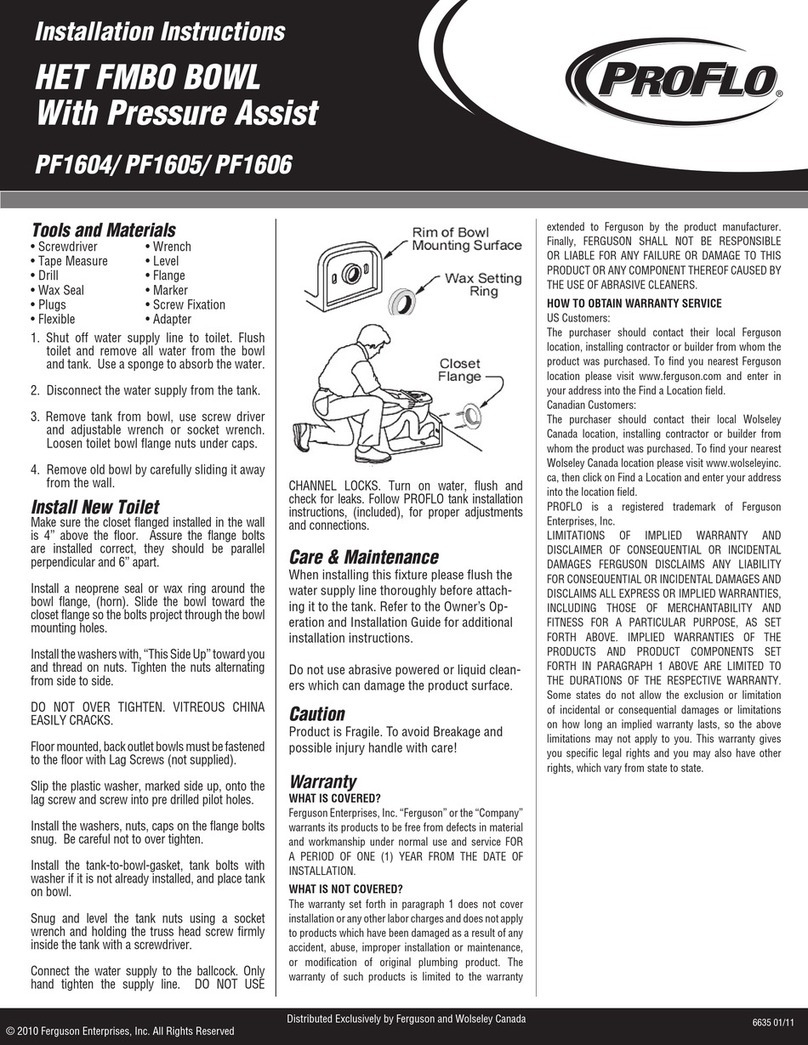

Wall Hung Back Outlet Toilet with Tank Installation

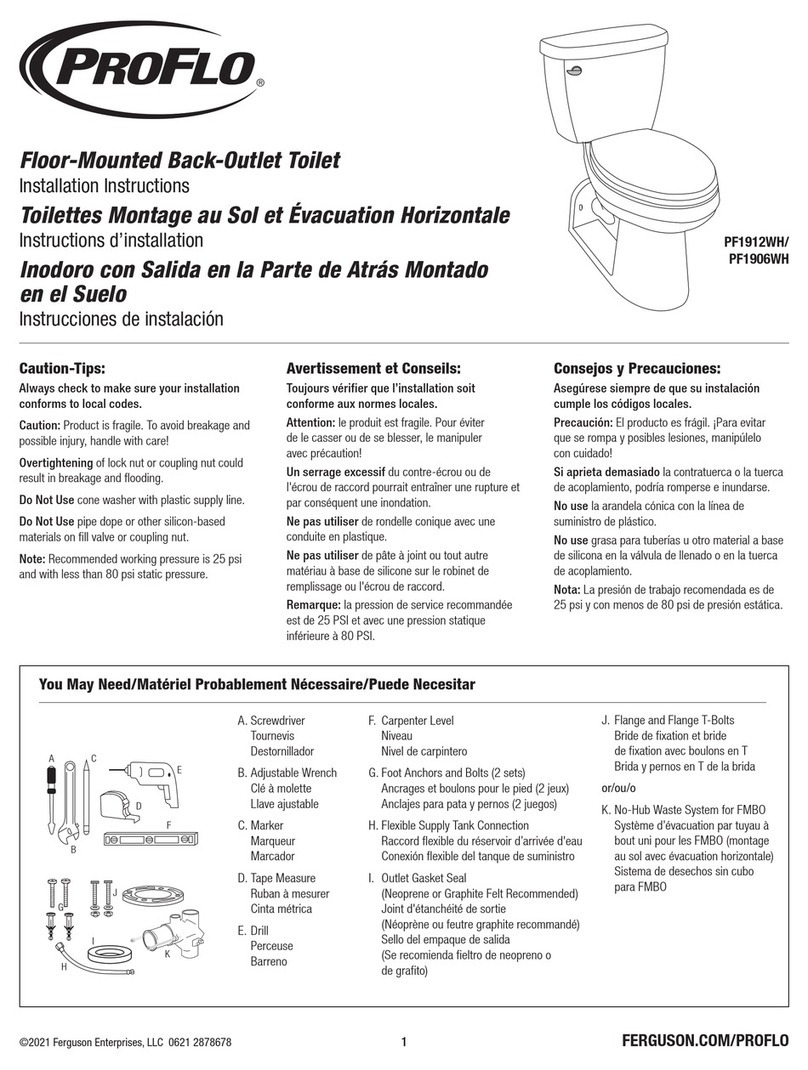

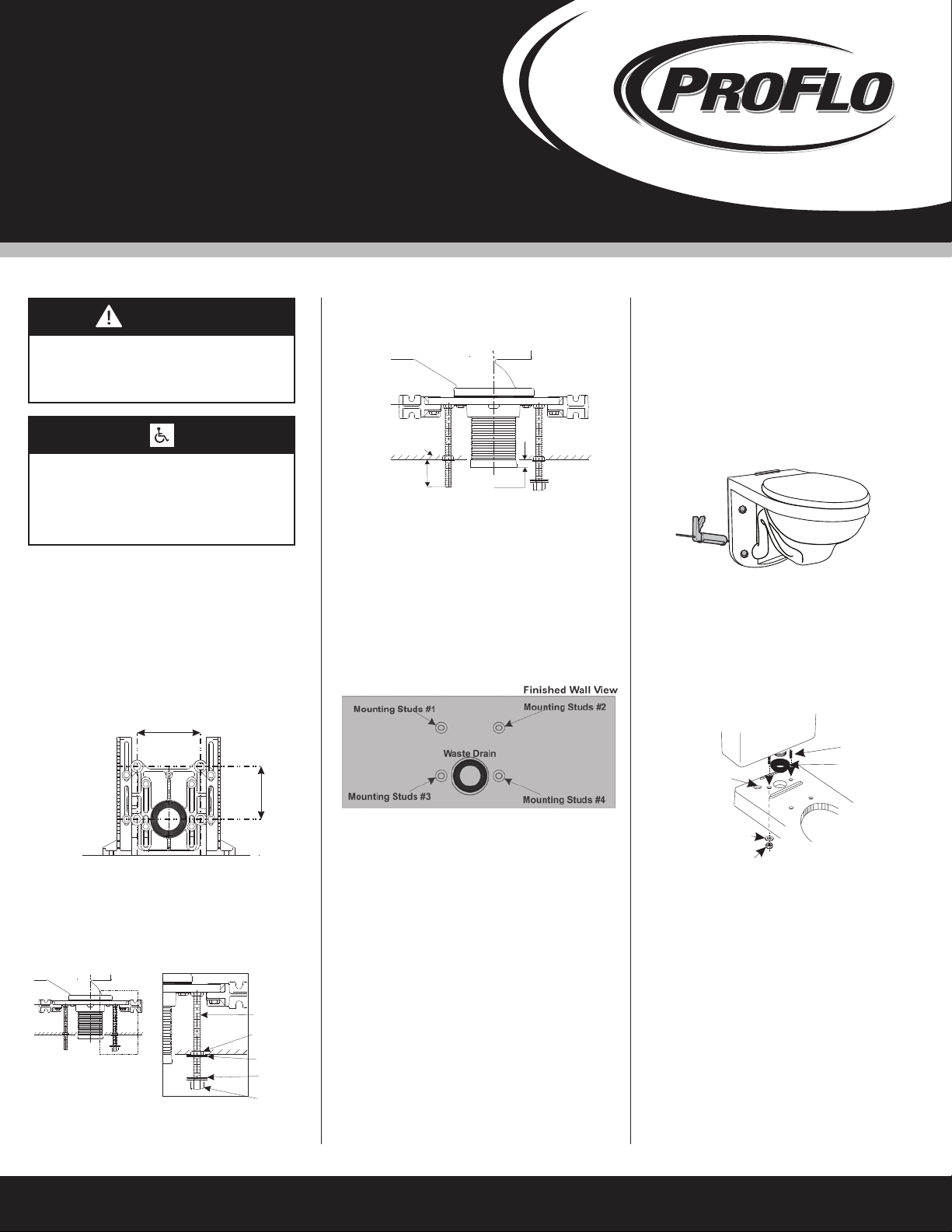

For typical installation of the wall hung back outlet fixture, a

4-bolt Carrier/Support system, (not supplied with this unit)

must be used for attaching the water closet to the carrier/support

system and waste drain. Refer to the Installation Instructions

that were supplied with the Closet Carrier/Support System for

installation of the unit.

H

Place back up nuts supplied with the carrier/support on mounting

stud #1, #3 and #4. No back-up nut is used on mounting

stud #2! Adjust the two lower back-up nuts so the front face of

the nuts are 1/16”away from the finished wall. Using a level,

adjust the back-up nut on mounting stud #1 to a vertical plane

with mounting stud #3. Place back-up washer on the three

installed back-up nuts.

Note; If the wall is irregular, the three back-up nuts and

washers must be positioned to allow a minimum of 1/16”

gap between the fixture and the wall.

7-1/2”

(190mm)

9”(228mm)

I

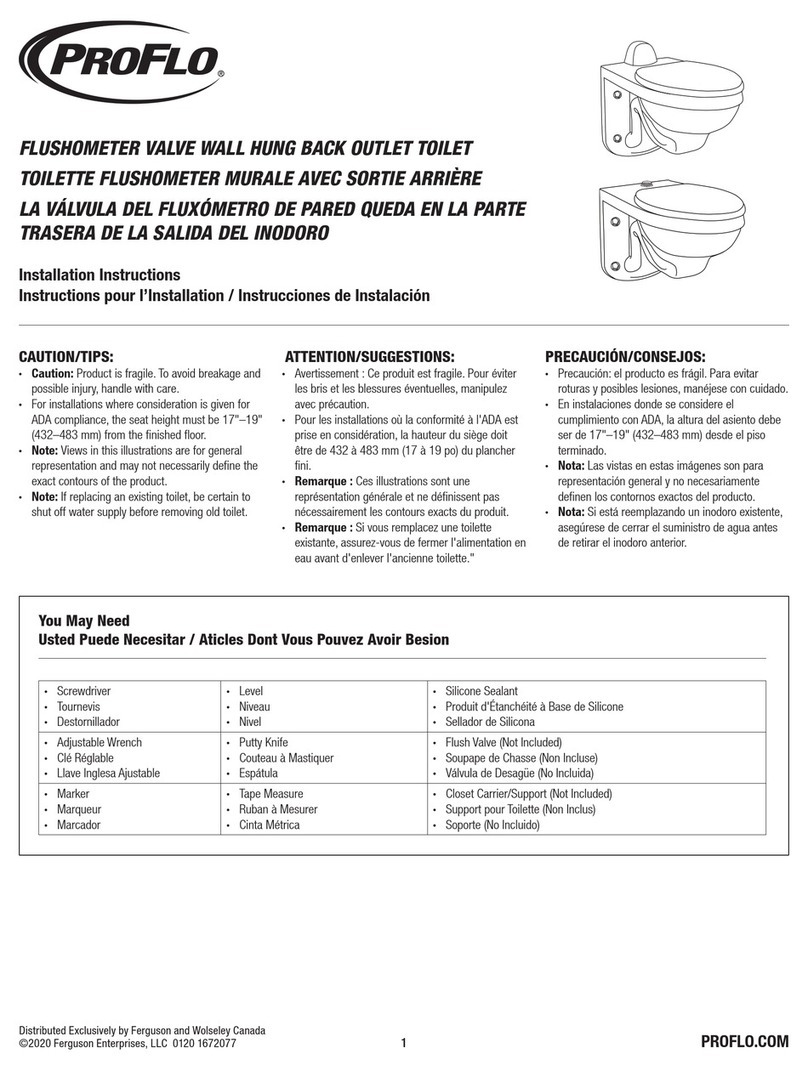

Vista frontal Corte de los accesorios de montaje

For installations where consideration is given for

ADA compliance, the seat height must be 17”to

19”(432 to 483) from the finished floor.

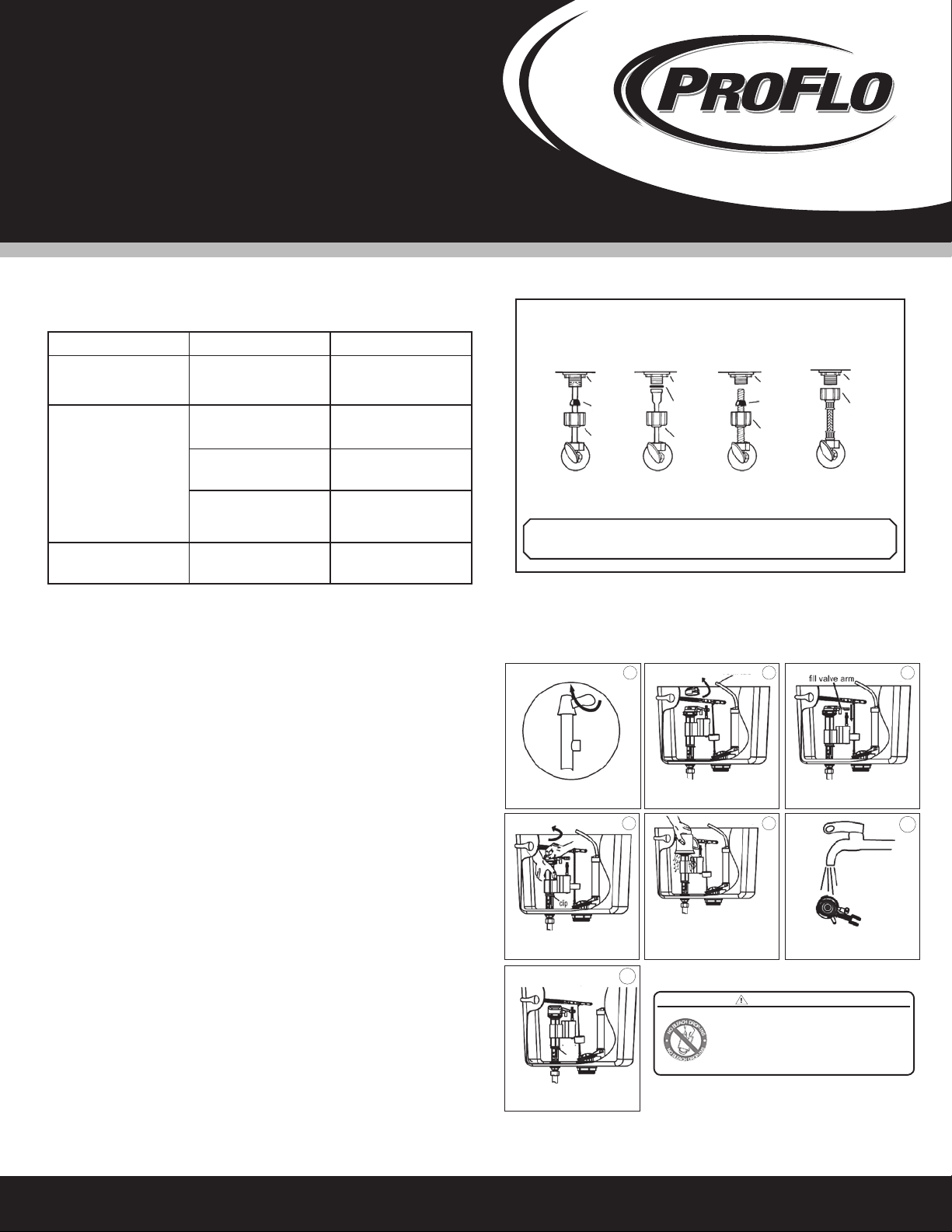

Pernos de montaje N.º 1

vista de la pared terminada

Pernos de montaje N.º 2

Pernos de montaje N.º 3 Pernos de montaje N.º 4

Drenaje residual

pernos de

montaje

2-1/8”

(54mm)

tuerca de

respaldo

tuerca de

respaldo

arandela de

fibra

tapa de la

tuerca

cabezal de

desague

5/16”

(8mm)

Mounting studs should extend 2-1/8”(54mm) beyond the

finished wall.

The waste horn should extend 5/16”(8mm) beyond the

finished wall.

pared terminada

vista superior

del transportador

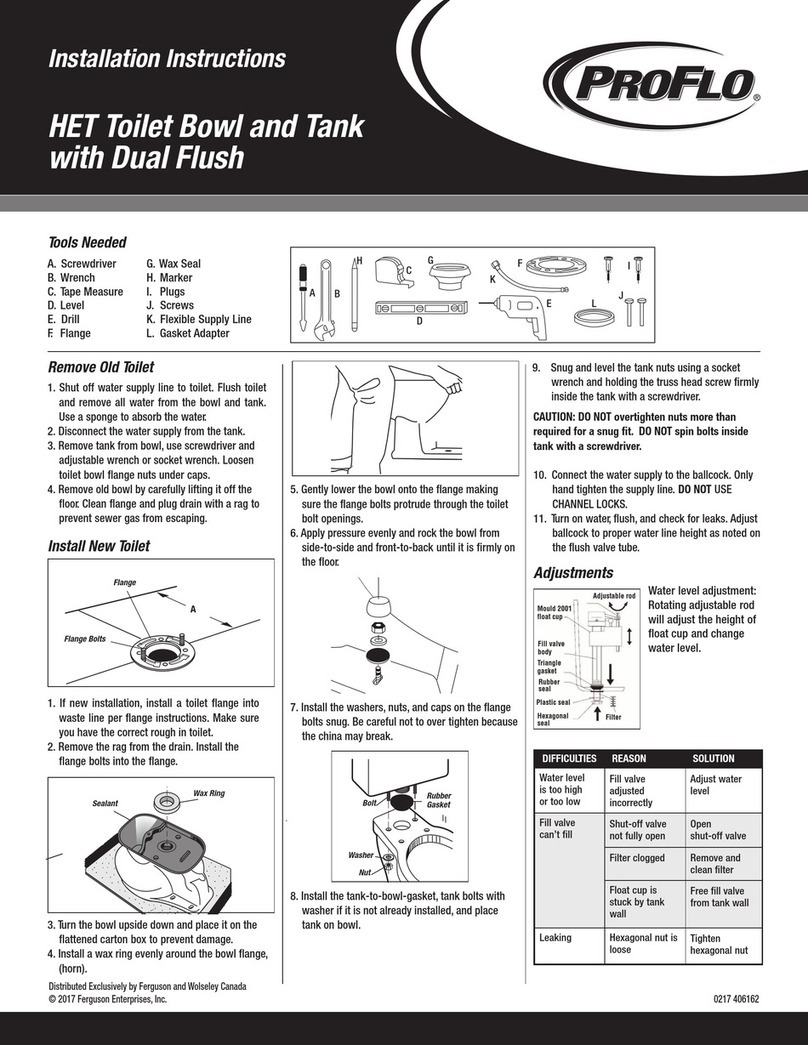

Rubber

Gasket

Tank

Bolts

Tank

Washers

Tank Nuts

-2-

Note: The back-up nuts, also referred to as the

bearing nuts, must be set to take the full loading

from the fixture while allowing a 1/6”clearance

between the fixture and the finished wall.

Follow the carrier manufacturer’s recommendation

settings for the outlet connection.

When setting fixture onto the carrier, it is not

recommended to use a wax ring, felt or neoprene

are recommended.

When setting the fixture to the carrier, the waste

gasket must be compressed sufficiently to assure

a positive gas and watertight seal.

56

78

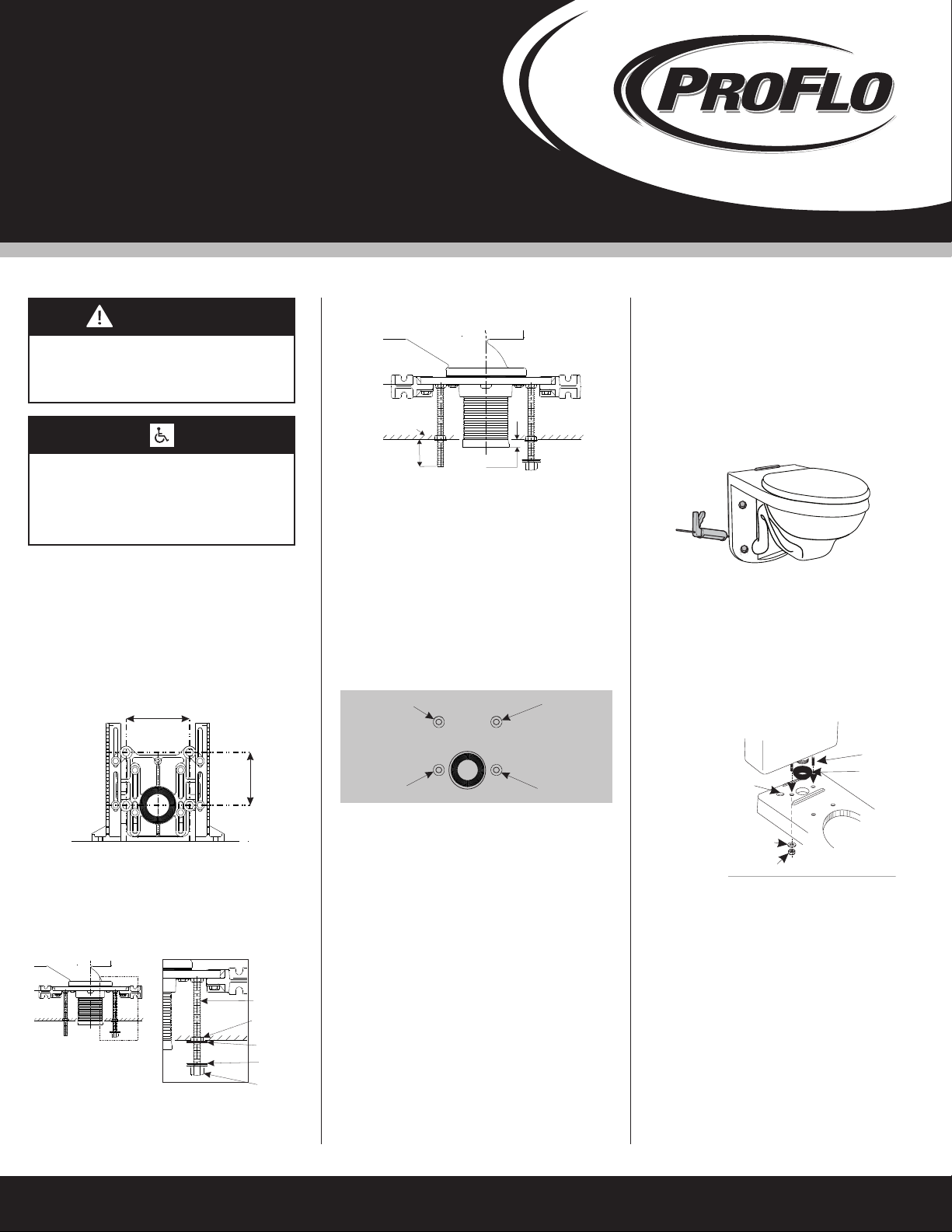

Install the fiber washer and cap nut onto the mounting

stud #2, hand tighten until the nut and washer are

touching the china. Hand snug firmly the cap nut against

the china, this is all that is necessary for mounting the

cap nut and washer to stud #2.

.

Caulk sealant into the gap between the toilet and the

finished wall.

Using two people, install the bowl onto the fixture mounting

studs.

Place the fiber washer supplied with the carrier/support on

mounting studs #1, #3 and #4. (Do not place a fiber

washer or cap nut on mounting stud #2 at this time.)

Place the cap nut supplied with the carrier/support on

mounting studs #1, #3 and #4. While holding the bowl

level and using an adjustable wrench, tighten the three

cap nuts until they are snug.

CAUTION: PRODUCT IS FRAGILE

Do not over tighten nuts more than a snug fit.

With the tapered side of the large rubber gasket facing

away from the tank, slip the rubber gasket over the

thread of the flushvalve on the bottom of the tank.

Connect the flexible water supply tube (Not Included)

onto the fill valve of the tank.

Set the tank onto the bowl,

with the tapered side of the

large rubber gasket towards

the bowl. While lowering the

tank onto the bowl, route

the flexible supply tube

through the opening provided.

9Fit the tapered side of the large rubber gasket into the

inlet opening of the bowl. The tank should sit level and

parallel to the finished wall.

Place the small rubber gaskets onto the tank mounting

bolts that were supplied with your tank. Slide both bolts

into the mounting holes from inside the tank.

Secure the tank by placing the metal washer and nut

onto the bottom of the tank bolts and tighten by hand

both nuts while holding the tank level.

With the tank level and sitting parallel to the wall, begin

to tight the nuts alternating between the two nuts to

keep the tank even. Tighten the nuts until the tank is

snug against the sanitary tank bar on the bowl.

CAUTION: PRODUCT IS FRAGILE

Do not over tighten nuts more than a snug fit.

Connect the flexible water supply line from the tank to

the shutoff valve. Tighten all coupling nuts securely.

Turn on water at the supply valve and allow the tank to fill.

Check all fittings for leakage and tighten any fittings that

are leaking.

10

Water

Supply

Opening

When performance matters.

WARNING: Do not use plumbers putty, pipe dope or any other sealant on the

water supply connections to this tank.

is void if any type of sealant is used on the water supply connection.WARRANTY

Note: If you wrench tighten the cap nut on mounting

stud #2 you will break the china since there is no

back nut on this stud.

.

WARNING

N

O

B

L

E

A

C

H

D

R

O

P

-

I

N

S

N

O

B

L

E

A

C

H

D

R

O

P

-

I

N

S

DO NOT USE IN-TANK TOILET BOWL CLEANERS

CONTAINING BLEACH OR CHLORINE

Result in Damage to tank components and may cause flooding

and property damage.

1.

2. Void Tynan Plumbing Fixtures Limited Warranty

Use of such products will:

ADVERTENCIA

EL PRODUCTO ES FRÁGIL.

Manéjese con cuidado para evitar

su ruptura y posibles daños.

Para la instalación en donde se considera

el cumplimiento con la ADA, la altura del

asiento debe ser de 17’’ y 19’’ (432mm

483mm) desde el piso terminado.

A

B

C

D

Recommended Tools & Materials

(A) Regular Screwdriver

(B) Adjustable Wrench

(C) Marker

(D) Tape Measure

(E) Level

(F) Silicone Sealant

(G) Putty Knife

(H) Flexible Supply Tube (Not Included)

(I) Closet Carrier/Support (Not Included)

CAUTION: PRODUCT IS FRAGILE

Handle with care to avoid breakage and possible injury!

When performance matters.

When performance matters.

Note: Views in this illustrations are for general representation

and may not necessarily define the exact contours of the product.

7730/7730HE

REV 10/2013

-1-

If you are installing the toilet on an existing support system,

make sure the system is in compliance with local code

requirements and the support system is weight rated for

the application requirements.

12

EG

F

If replacing an existing toilet be certain to shut off

water supply before removing old toilet.

SINK INSTALLATION:

34

Wall Hung Back Outlet Toilet with Tank Installation

For typical installation of the wall hung back outlet fixture, a

4-bolt Carrier/Support system, (not supplied with this unit)

must be used for attaching the water closet to the carrier/support

system and waste drain. Refer to the Installation Instructions

that were supplied with the Closet Carrier/Support System for

installation of the unit.

H

Place back up nuts supplied with the carrier/support on mounting

stud #1, #3 and #4. No back-up nut is used on mounting

stud #2! Adjust the two lower back-up nuts so the front face of

the nuts are 1/16”away from the finished wall. Using a level,

adjust the back-up nut on mounting stud #1 to a vertical plane

with mounting stud #3. Place back-up washer on the three

installed back-up nuts.

Note; If the wall is irregular, the three back-up nuts and

washers must be positioned to allow a minimum of 1/16”

gap between the fixture and the wall.

7-1/2”

(190mm)

9”(228mm)

I

Vista frontal Corte de los accesorios de montaje

For installations where consideration is given for

ADA compliance, the seat height must be 17”to

19”(432 to 483) from the finished floor.

Pernos de montaje N.º 1

vista de la pared terminada

Pernos de montaje N.º 2

Pernos de montaje N.º 3 Pernos de montaje N.º 4

Drenaje residual

pernos de

montaje

tuerca de

respaldo

tuerca de

respaldo

arandela de

fibra

tapa de la

tuerca

cabezal de

desague

5/16”

(8mm)

Mounting studs should extend 2-1/8”(54mm) beyond the

finished wall.

The waste horn should extend 5/16”(8mm) beyond the

finished wall.

pared terminada

vista superior

del transportador

A

B

C

D

Recommended Tools & Materials

(A) Regular Screwdriver

(B) Adjustable Wrench

(C) Marker

(D) Tape Measure

(E) Level

(F) Silicone Sealant

(G) Putty Knife

(H) Flexible Supply Tube (Not Included)

(I) Closet Carrier/Support (Not Included)

CAUTION: PRODUCT IS FRAGILE

Handle with care to avoid breakage and possible injury!

When performance matters.

When performance matters.

Note: Views in this illustrations are for general representation

and may not necessarily define the exact contours of the product.

7730/7730HE

REV 10/2013

-1-

If you are installing the toilet on an existing support system,

make sure the system is in compliance with local code

requirements and the support system is weight rated for

the application requirements.

12

EG

F

If replacing an existing toilet be certain to shut off

water supply before removing old toilet.

SINK INSTALLATION:

34

Wall Hung Back Outlet Toilet with Tank Installation

For typical installation of the wall hung back outlet fixture, a

4-bolt Carrier/Support system, (not supplied with this unit)

must be used for attaching the water closet to the carrier/support

system and waste drain. Refer to the Installation Instructions

that were supplied with the Closet Carrier/Support System for

installation of the unit.

H

Place back up nuts supplied with the carrier/support on mounting

stud #1, #3 and #4. No back-up nut is used on mounting

stud #2! Adjust the two lower back-up nuts so the front face of

the nuts are 1/16”away from the finished wall. Using a level,

adjust the back-up nut on mounting stud #1 to a vertical plane

with mounting stud #3. Place back-up washer on the three

installed back-up nuts.

Note; If the wall is irregular, the three back-up nuts and

washers must be positioned to allow a minimum of 1/16”

gap between the fixture and the wall.

7-1/2”

(190mm)

9”(228mm)

I

Vista frontal Corte de los accesorios de montaje

For installations where consideration is given for

ADA compliance, the seat height must be 17”to

19”(432 to 483) from the finished floor.

Pernos de montaje N.º 1

vista de la pared terminada

Pernos de montaje N.º 2

Pernos de montaje N.º 3 Pernos de montaje N.º 4

Drenaje residual

pernos de

montaje

2-1/8”

(54mm)

tuerca de

respaldo

tuerca de

respaldo

arandela de

fibra

tapa de la

tuerca

cabezal de

desague

5/16”

(8mm)

Mounting studs should extend 2-1/8”(54mm) beyond the

finished wall.

The waste horn should extend 5/16”(8mm) beyond the

finished wall.

pared terminada

vista superior

del transportador

empaque

de hule

pernos del

tanque

arandelas del

tanque

tuercas del tanque

-2-

Note: The back-up nuts, also referred to as the

bearing nuts, must be set to take the full loading

from the fixture while allowing a 1/6”clearance

between the fixture and the finished wall.

Follow the carrier manufacturer’s recommendation

settings for the outlet connection.

When setting fixture onto the carrier, it is not

recommended to use a wax ring, felt or neoprene

are recommended.

When setting the fixture to the carrier, the waste

gasket must be compressed sufficiently to assure

a positive gas and watertight seal.

56

78

Install the fiber washer and cap nut onto the mounting

stud #2, hand tighten until the nut and washer are

touching the china. Hand snug firmly the cap nut against

the china, this is all that is necessary for mounting the

cap nut and washer to stud #2.

.

Caulk sealant into the gap between the toilet and the

finished wall.

Using two people, install the bowl onto the fixture mounting

studs.

Place the fiber washer supplied with the carrier/support on

mounting studs #1, #3 and #4. (Do not place a fiber

washer or cap nut on mounting stud #2 at this time.)

Place the cap nut supplied with the carrier/support on

mounting studs #1, #3 and #4. While holding the bowl

level and using an adjustable wrench, tighten the three

cap nuts until they are snug.

CAUTION: PRODUCT IS FRAGILE

Do not over tighten nuts more than a snug fit.

With the tapered side of the large rubber gasket facing

away from the tank, slip the rubber gasket over the

thread of the flushvalve on the bottom of the tank.

Connect the flexible water supply tube (Not Included)

onto the fill valve of the tank.

9Fit the tapered side of the large rubber gasket into the

inlet opening of the bowl. The tank should sit level and

parallel to the finished wall.

Place the small rubber gaskets onto the tank mounting

bolts that were supplied with your tank. Slide both bolts

into the mounting holes from inside the tank.

Secure the tank by placing the metal washer and nut

onto the bottom of the tank bolts and tighten by hand

both nuts while holding the tank level.

With the tank level and sitting parallel to the wall, begin

to tight the nuts alternating between the two nuts to

keep the tank even. Tighten the nuts until the tank is

snug against the sanitary tank bar on the bowl.

CAUTION: PRODUCT IS FRAGILE

Do not over tighten nuts more than a snug fit.

Connect the flexible water supply line from the tank to

the shutoff valve. Tighten all coupling nuts securely.

Turn on water at the supply valve and allow the tank to fill.

Check all fittings for leakage and tighten any fittings that

are leaking.

10

apertura del

suministro de agua

When performance matters.

WARNING: Do not use plumbers putty, pipe dope or any other sealant on the

water supply connections to this tank.

is void if any type of sealant is used on the water supply connection.WARRANTY

Note: If you wrench tighten the cap nut on mounting

stud #2 you will break the china since there is no

back nut on this stud.

.

WARNING

N

O

B

L

E

A

C

H

D

R

O

P

-

I

N

S

N

O

B

L

E

A

C

H

D

R

O

P

-

I

N

S

DO NOT USE IN-TANK TOILET BOWL CLEANERS

CONTAINING BLEACH OR CHLORINE

Result in Damage to tank components and may cause flooding

and property damage.

1.

2. Void Tynan Plumbing Fixtures Limited Warranty

Use of such products will:

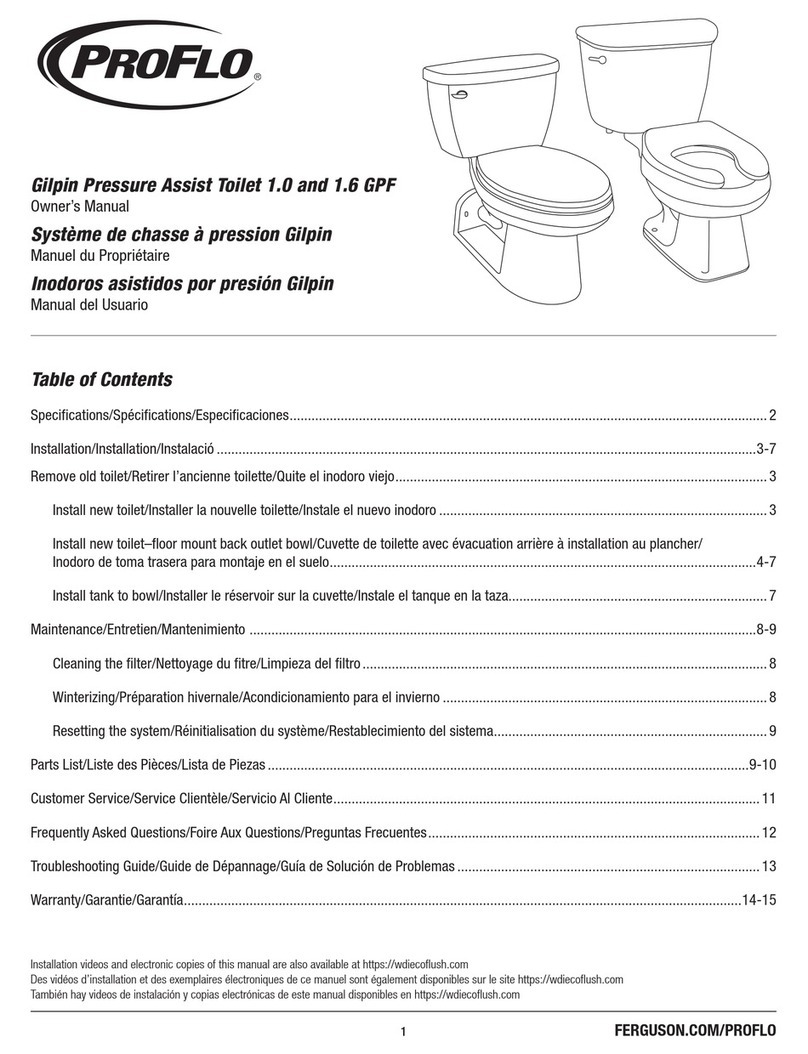

Instrucciones de instalación

Tanque con descarga

por gravedad

PF1705 / 1710 /

PF1705HE / PF1710HE

Distributed Exclusively by Ferguson and Wolseley Canada

© 2014 Ferguson Enterprises, Inc. 18218 04/14

A

B

C

D

Recommended Tools & Materials

(A) Regular Screwdriver

(B) Adjustable Wrench

(C) Marker

(D) Tape Measure

(E) Level

(F) Silicone Sealant

(G) Putty Knife

(H) Flexible Supply Tube (Not Included)

(I) Closet Carrier/Support (Not Included)

CAUTION: PRODUCT IS FRAGILE

Handle with care to avoid breakage and possible injury!

When performance matters.

When performance matters.

Note: Views in this illustrations are for general representation

and may not necessarily define the exact contours of the product.

7730/7730HE

REV 10/2013

-1-

If you are installing the toilet on an existing support system,

make sure the system is in compliance with local code

requirements and the support system is weight rated for

the application requirements.

12

EG

F

If replacing an existing toilet be certain to shut off

water supply before removing old toilet.

SINK INSTALLATION:

34

Wall Hung Back Outlet Toilet with Tank Installation

For typical installation of the wall hung back outlet fixture, a

4-bolt Carrier/Support system, (not supplied with this unit)

must be used for attaching the water closet to the carrier/support

system and waste drain. Refer to the Installation Instructions

that were supplied with the Closet Carrier/Support System for

installation of the unit.

H

Place back up nuts supplied with the carrier/support on mounting

stud #1, #3 and #4. No back-up nut is used on mounting

stud #2! Adjust the two lower back-up nuts so the front face of

the nuts are 1/16”away from the finished wall. Using a level,

adjust the back-up nut on mounting stud #1 to a vertical plane

with mounting stud #3. Place back-up washer on the three

installed back-up nuts.

Note; If the wall is irregular, the three back-up nuts and

washers must be positioned to allow a minimum of 1/16”

gap between the fixture and the wall.

7-1/2”

(190mm)

9”(228mm)

I

Vista frontal Corte de los accesorios de montaje

For installations where consideration is given for

ADA compliance, the seat height must be 17”to

19”(432 to 483) from the finished floor.

Pernos de montaje N.º 1

vista de la pared terminada

Pernos de montaje N.º 2

Pernos de montaje N.º 3 Pernos de montaje N.º 4

Drenaje residual

pernos de

montaje

2-1/8”

(54mm)

tuerca de

respaldo

tuerca de

respaldo

arandela de

fibra

tapa de la

tuerca

cabezal de

desague

5/16”

(8mm)

Mounting studs should extend 2-1/8”(54mm) beyond the

finished wall.

The waste horn should extend 5/16”(8mm) beyond the

finished wall.

pared terminada

vista superior

del transportador