Basic precautions should always be followed, including the following safety

instructions when using this equipment. Read all instructions before using

this equipment.

1. Before exercising and to avoid injuring your muscles, it is highly

recommended that you perform warm-up exercises for each muscle group.

Please refer to Warm Up section of the Owner’s Manual.

2. Please make sure all components are not damaged and are working order

before using. This equipment should be placed on a stable, flat surface.

Using a mat or similar material on the ground is recommended.

3. Please wear proper clothes and shoes when using this equipment. Do not

wear loose clothing that may get caught by any part of the equipment.

4. Only perform maintenance or adjustments that are instructed in this manual.

Should any problems arise, discontinue use and consult with customer

service at Paradigm.

5. Be careful when stepping on or stepping off the pedals. Always hold onto

the handlebars first and make sure the pedal at your side is at its lowest

position, then step on. With your other leg, stride over the main frame and

come to rest onto the other pedal. To ensure the pedals run smoothly, push

or pull on the handlebars first, then follow with leg motion. To dismount,

reduce pedaling speed gradually before you stop. When stepping off the

machine, make sure one pedal is at its lowest position and step out of there

before stepping out of the pedal at the highest position.

6. Keep dry - do not operate in wet or moist condition.

7. Do not use the equipment outdoors.

8. This equipment is for household use only.

9. Only one person should be on the equipment at a time.

10.Keep children and pets away from the product at all times.

11.This machine is designed for adults only.

12.This product requires a minimum of 6 feet of space for safe operation.

13.If you feel any chest pains, nausea, dizziness, or short of breath, you should

stop exercising immediately and consult with your physician before

continuing.

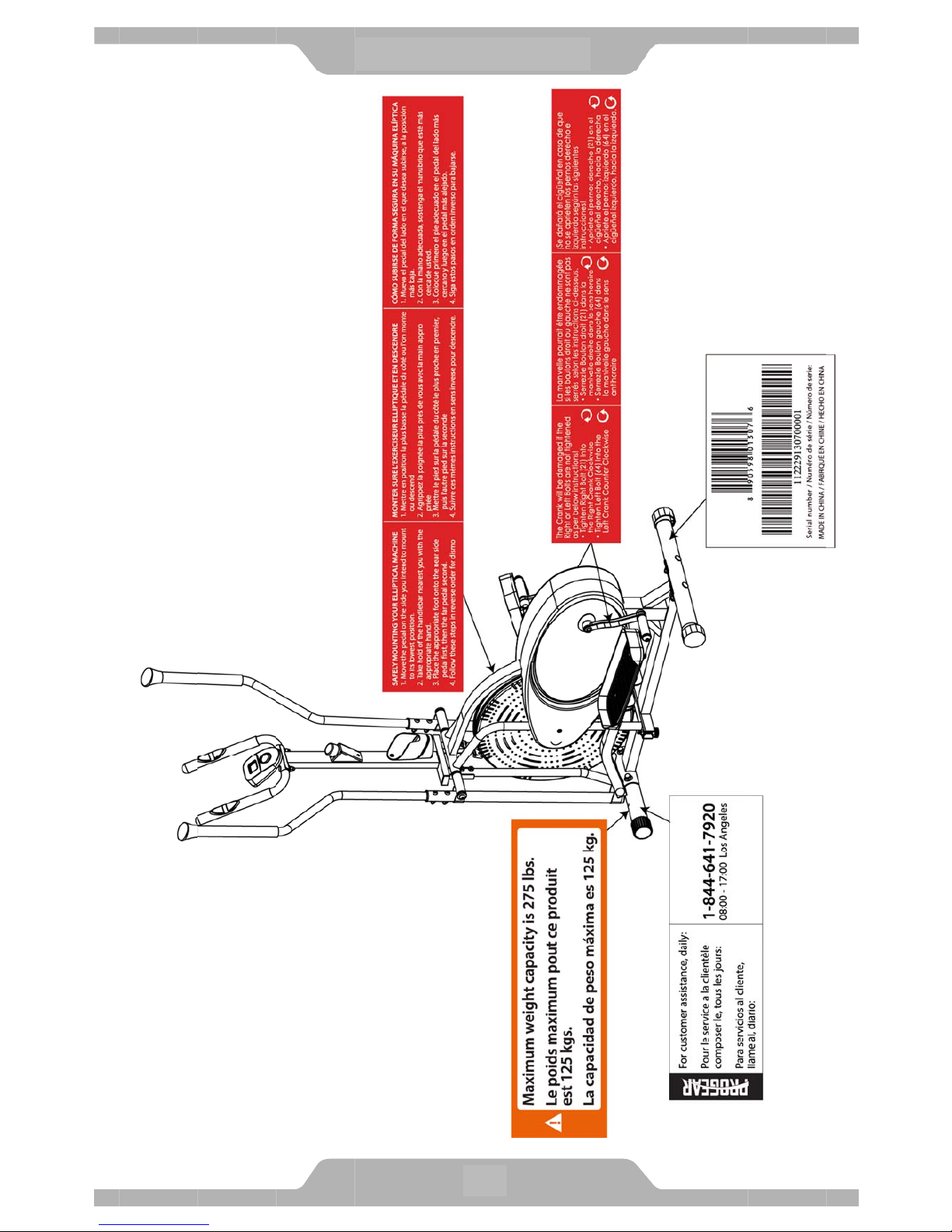

14.The maximum weight capacity for this product is 275 lbs/125 kgs.

WARNING:Before beginning any exercise program consult your

physician. This is especially important for the people who are over 35 years

old or who have pre-existing health problems.

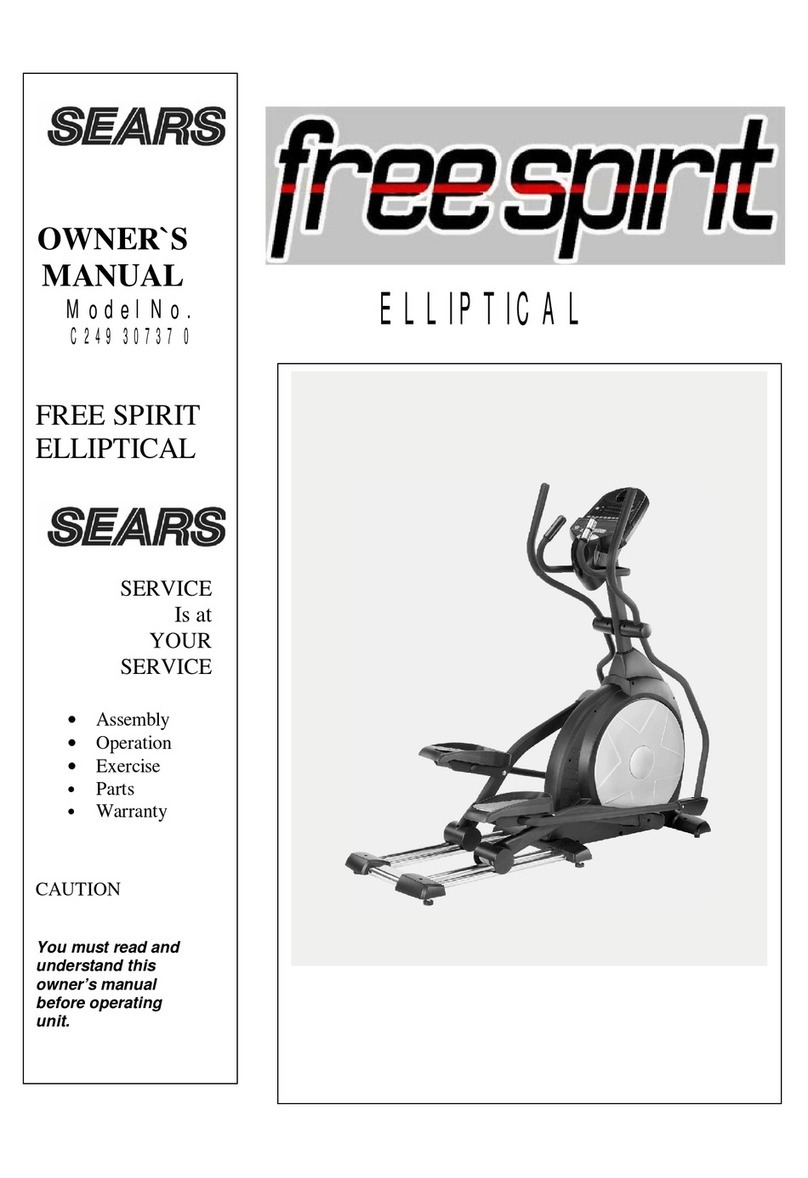

CAUTION:Read all instructions carefully before operating this

product. Retain this Owner’s Manual for future reference.

4

IMPORTANTSAFETYINSTRUCTIONS