Progres AGRONIC 52 User manual

1

INSTRUCTION

MANUAL

24 V ac

INDEX

Sec.

Theme

Page

1.

INTRODUCTION

1

2.

SCREEN DATA

2

3.

CHARACTERISTICS OF THE UNIT

2

4.

DIMENSIONS

3

5.

INPUTS AND OUTLETS

3

5.1.

Inputs

3

5.2.

Outlets

4

6.

OPERATING THEORY

4

7.

CONFIGURATION OF THE INSTALLER

5

8.

CONSULTATION

6

9.

PROGRAMMING

6

10.

CONFIGURATION OF THE USER

6

11.

CALIBRATION

7

12.

BREAKDOWNS

7

13.

SYNOPTIC OF FUNCTIONS

8

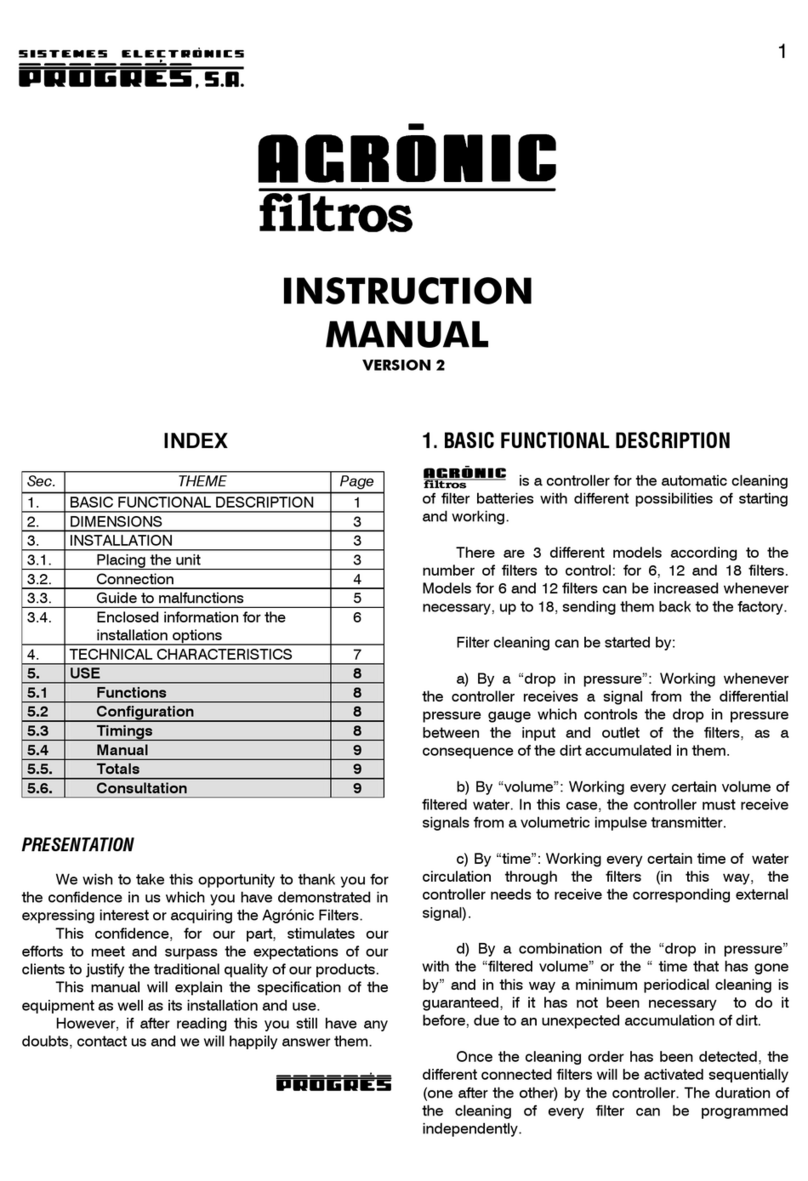

PRESENTATION

We wish to take this opportunity to thank you for the

confidence in us which you have demonstrated in express-

ing interest or acquiring Agrónic 52.

This confidence, for our part, stimulates our efforts to

meet and surpass the expectations of our clients to justify

the traditional quality of our products.

This Manual will allow you to see the capacity of the

unit as well as its installation and use.

However, if after reading this you still have any

doubts, contact us and we will happily answer them.

1. INTRODUCTION

Agrónic 52 is a unit which continuously mixes two

waters in order to obtain a programmed conductivity, by

using one or two motorised valves.

There are 3 formulas or programmes which are start-

ed by external orders received by the corresponding inputs.

The programming can be done either by the expected

level of conductivity or by the opening percentage ex-

pected for every motorised valve.

Up to 2 motorised valves can be connected. Every

motorised valve has an outlet to open and another one to

close.

There is also an outlet for alarm.

Feeding of the unit at 24 Vac. Optionally, at 12 Vdc.

There are 3 inputs for the start of the programmes

and 1 input to detect breakdowns.

There is also 1 input for the conductivity sensor, with

a transmitter which is integrated in the unit circuitry.

The calibration of sensors is done with the keyboard.

It is easy to use and programme by means of three

keys and a LC screen with 14 millimetre-high digits.

There is a CE alarm, being possible to configure the

high value, the low one and the delay in the detection of an

irregularity.

Configurable delay for the detection of start inputs

and breakdowns.

It is possible to stop or not the programme which is

being working when there is an alarm.

The motorised valves can also be activated manually.

Configuration of the motorised valve which will con-

trol the water with more conductivity, as well as configura-

tion of the one which will control the water we want to

save.

It is possible to programme a minimum opening of the

motorised valves.

The unit is located in a poly-carbonate closed box.

Agrónic 52 follows the CE guidelines.

2

2. SCREEN DATA

Information is displayed on the screen in the following

way: the first two digits indicate the code in which we are.

The following block of digits gives information about the

motorised valve M1, while the last block of digits makes

reference to the motorised valve M2 or to the electric

conductivity.

Use the “C” key to go from one code to the next one.

If you keep pressing this key, the code will change rapidly.

Use the “+” and “-“ keys to modify the values which

are displayed on the screen. These keys will increase or de-

crease the active value which is displayed in that moment.

If you keep pressing the key, it increases or decreases rap-

idly.

3. CHARACTERISTICS OF THE UNIT

Feeding

Power source

24 V. ac

Energy consumption

Average consume: 8,5 VA

Input fuse

2,5 A, type F, 250 V (fast)

Outlet

Inputs

Number

5

Number

4

Type

Relay, Triac. optolinked

Type

Optolinked

Environment

Weight (approximate)

Memory backup

Temperature

0º C a 45º C

1 Kg.

Parameters, pro-

grammes

It can not be

erased

Humidity

< 85 %

Height

2000 m.

Pollution

Grade II

DECLARATION OF CONFORMITY

It follows the 89/336/CEE Guidelines for the Electromagnetic compatibility and the 73/23/CEE

Guidelines of Low Tension for the Fulfilment of the Product Security. The fulfilment of the follow-

ing specifications was demonstrated as indicated in the Official Diary of the European Communi-

ties.

Symbols which can be displayed on the product

Double insulation

3

4. DIMENSIONS

All measures in mm.

5. INPUTS AND OUTLETS

5.1. INPUTS.

The unit has four digital inputs (D1,D2,D3,D4). Three

of them work as switches (D1,D2 and D3), starting or

stopping the corresponding programme, while the fourth

one is a breakdown input (D4).

The activation of inputs is done through their connec-

tion to the common.

A time for the detection delay can be configured for

every input, but deactivation is immediate.

The conductivity reference or the opening percentage

of the available motorised valves can be configured for

every input or programmes 1, 2 and 3. It is not possible to

activate more than one input at the same time.

Input 4, breakdown, is only taken into account if a

programme is working. If it activates, it always stops the

programme, without taking into account the established

configuration.

The unit also has an input for conductivity sensor.

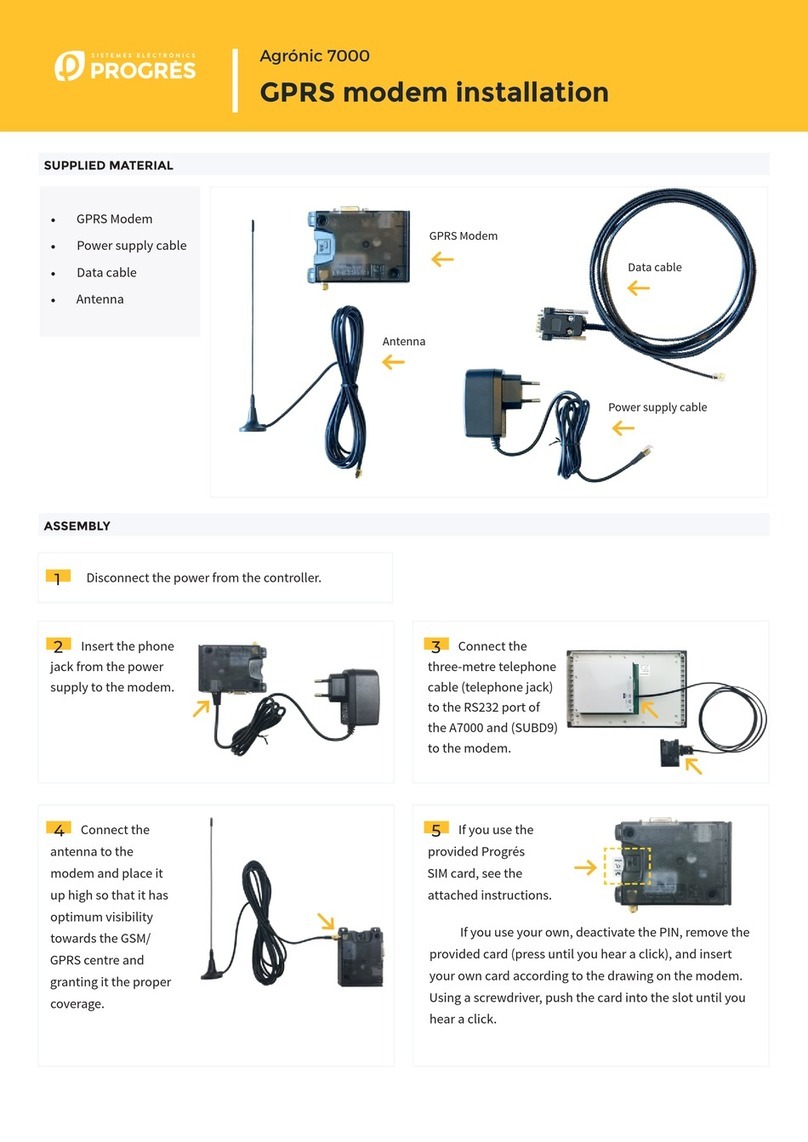

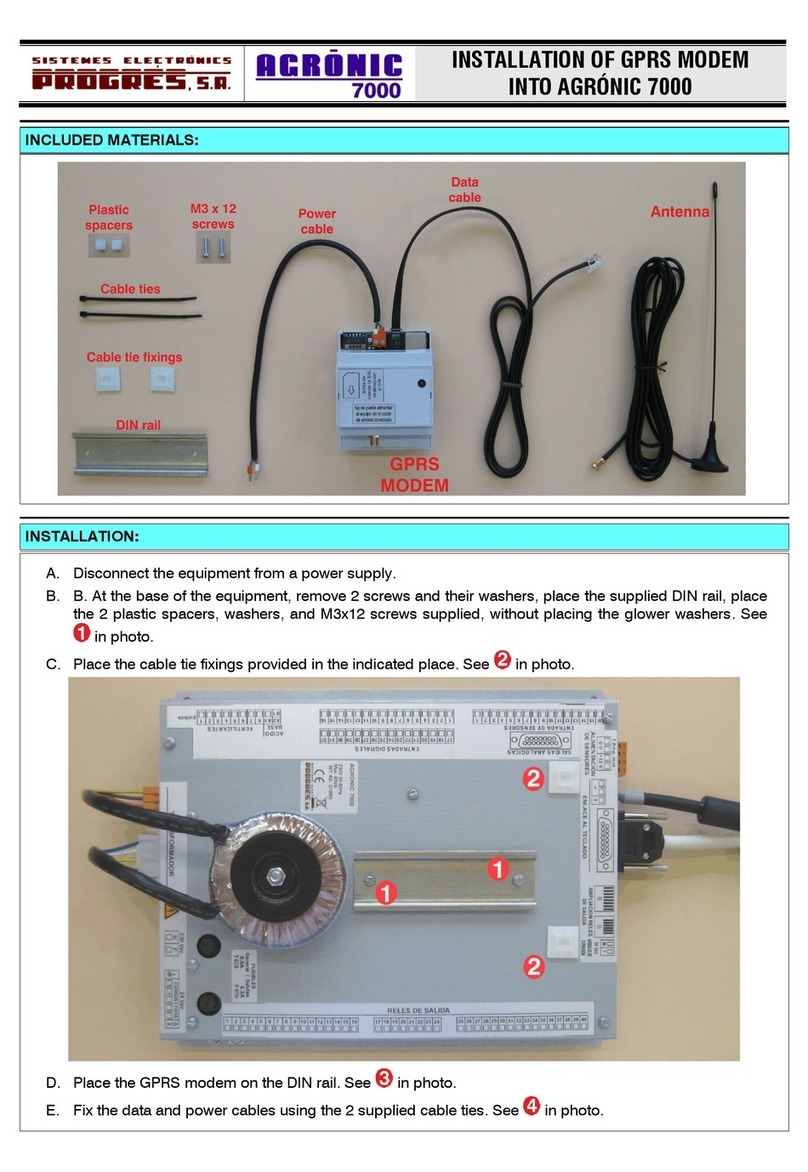

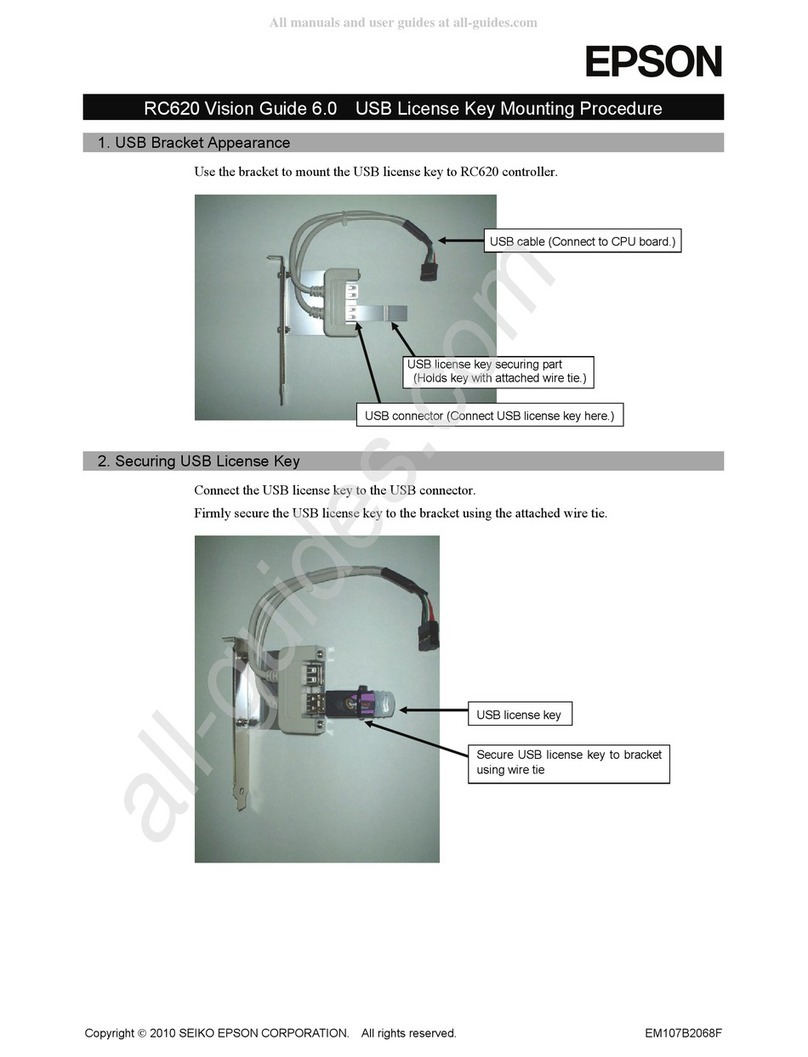

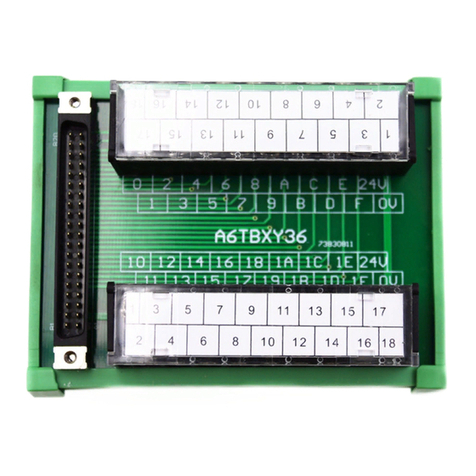

SECTION OF THE UNIT SUPERIOR BOARD

VERY IMPORTANT: The grid must be connected to the

box terminal of the unit.

4

5.2. OUTLETS.

The unit has 5 digital outlets.

Outlets are protected by a 2.5 A fuse F Type (fast). Re-

place it with a similar one if it fuses.

SECTION OF THE UNIT INFERIOR BOARD

- S1, S2: Digital outlets for the opening and closing of

the motorised valve M1. S1 is connected to the closing

terminal of the motorised valve and S2 to the opening one.

If no motorised valve is connected to these outlets, but

there is an electrovalve, connect it to S2.

- S3, S4: Digital outlets for the opening and closing of

the motorised valve M2. S3 is connected to the closing

terminal of the motorised valve and S4 to the opening one.

If no motorised valve is connected to these outlets, but

there is an electrovalve, connect it to S4.

- S5: Digital outlet used for the breakdown warning.

DIGITAL OUTLET CONNECTION

6. OPERATING THEORY

The unit can be programmed in two different ways:

- By opening: In this case, the programmer only opens

the existing motorised valves up to the point indicated in

the programme and it does not carry out any type of regu-

lation. However, it checks whether the conductivity level is

within the established alarm limits.

- By conductivity reference: When the reading of the

electric conductivity (CE) is higher or lower than the speci-

fied permissiveness margin, the programmer corrects the

deviation making minimum movements of the motorised

valve chosen for the regulation. If only one motorised valve

is available, it will be the chosen one. In order to know

whether the programmer has to open or close the motor-

ised valve it takes into account the CE level (high or low CE)

which the water controlled by the motorised has in refer-

ence to the other water.

If two motorised valves are available, the programmer

starts the regulation by opening as much as possible one of

the motorised valves (the one which corresponds to the

cheapest water) and it regulates with the other one. If the

opening of this motorised valve reaches its minimum, it is

not possible to obtain the reference indicated in the pro-

gramme. Otherwise, if the motorised valve reaches its max-

imum opening, the programmer tries to reach the indicated

reference, closing the motorised valve which corresponds

to the cheapest water.

While a programme is working, it is not possible that

the two motorised valves reach their minimum opening,

but it is possible that both are completely open.

5

7. CONFIGURATION OF THE INSTALLER

This configuration must be done by the installer of the

unit. To access it, press the “+” and “-“ keys at the same

time while being at code C0. Press the “C” key to go to the

following code. Press the “+” and “-“ keys to change the

values. Press the “C” key until the C0 code is displayed to go

back to CONSULTATION.

Do not change the parameters related to the motor-

ised valves if a programme is working or the motorised

valves are moving. It may cause a malfunction in the unit.

In the programming by openings, only codes 10 to 13

are significant.

- Code 00: Programming mode. By opening percentage

(set at YES pressing the “+” key) or by conductivity ref-

erence (set at NO pressing the “-“ key).

- Code 01, 02, 03 and 04: Timings. Indicate, in seconds,

the time that must go by from the detection of the acti-

vation of an input until the programmer takes it into ac-

count. The value must go from 0 to 99.

- Code 05: Alarm outlet: Set at YES (press the “+” key)

so that outlet S5 activates when there is a breakdown.

Set at NO (press the “-“ key) so that outlet S5 does not

activate.

- Code 06: Initial regulation delay. Indicate the time in

seconds that the programmer has to wait before start-

ing the regulation when a programme starts. During this

time, the applied opening percentage will be memo-

rised in the last irrigation. This allows the stabilisation of

the mixing. The value must go from 0 to 250.

- Codes 07: Self-adjustment delay. Indicate, in seconds,

the time that has to go by between an adjustment at-

tempt and the next one. The self-adjustment time is the

time that has to go by since a change has taken place at

the opening of one of the motorised valves until the fol-

lowing change takes place. The minimum time is 4 sec-

onds and the maximum 99.

- Code 08: Permissiveness margin. Indicate how much

the reading of the CE can differ from the given refer-

ence without a regulation taking place. Diminish the

value to obtain more precision. Increase the value to

diminish the movement of the motorised valve/s. The

minimum value is 0 the maximum 0,5.

- Code 09: Higher conductivity water. Press the “+” key

if A1 (water controlled by the motorised valve M1) is

the water with the highest conductivity. Press the “-“

key if A2 (water controlled by the motorised valve M2)

is the one with the highest conductivity.

- Code 10: Available motorised valves. The available mo-

torised valves are changed with the “+” and “-“ keys. In-

dicate A1 if there is only one motorised valve and it is

connected to the outlets S1 and S2. Indicate A2 if there

is only one motorised valve and it is connected to the

outlets S3 and S4. Indicate A1 and A2 if there are two

motorised valves.

- Code 11: Opening time of the motorised valves. Indi-

cate the necessary time in seconds to completely open

the motorised valves M1 and/or M2 being completely

closed. The maximum time is 199 seconds.

- Code 12: Minimum movement percentage of the mo-

torised valves. Indicate the minimum opening of the

motorised valve M1 and/or M2. The values go from 0.1

to 5.0.

- Code 13: Minimum opening of motorised valve M1

and/or M2 while the mixing is taking place. If it is not

possible to get the expected number (due to the mini-

mum movement of the motorised valve) we will ap-

proach at it as much as possible, by defect or excess.

The control values go from 0 to 99.

- Code 14: Water to be saved. Indicate which water you

want to spend the least. Press the “+” key to indicate

A2 (water regulated by motorised valve M2) or press

the “-“ key to indicate A1 (water regulated by motorised

valve M1).

6

8. CONSULTATION

The first two codes of the programmer correspond to

consultations of the unit state (C0 and C1).

- Code C0: It shows which programme is activated (a

hyphen if none is activated) and the conductivity read-

ing in mS which reaches the unit through the sensor. If

a breakdown takes place, the programmer shows this

code and the alarm origin (programme number) in-

termittently, and the reason for it (high or low con-

ductivity, breakdown input). For further information

read the section BREAKDOWNS.

C

0.

1

1.

8

(.) It indicates man-

ual activation of

motorised valves.

Nº of activated

programme (- if

none is activated)

Reading of the

conductivity

sensor.

- Code C1: it shows the opening percentage of every

motorised valve. The previous code, C0, is acceded by

pressing the “+” or “-“ keys.

C

1

2

1

3

3

% of opening of the

motorised valve M1

% of opening of

the motorised

valve M2

9. PROGRAMMING

The codes that go from C2 to C4 are used to define

every programme, having to specify either the desired level

of conductivity or the opening percentage of the motorised

valve.

When programming openings, every code is divided

into two sections. The first one corresponds to values of the

motorised valve M1, while the second one corresponds to

values of the motorised valve M2. The opening of a motor-

ised valve can not be varied if it is moving.

Press the “C” key to change section or code and

the “+” and “-“ keys to increase or decrease the value of

the section which is active, that is to say the one which has

a blinking point on its left.

When programming the conductivity level, codes

C2, C3 and C4 are used to indicate the desired reference

value for conductivity (value from 0 to 9.9).

C

2

1.

7

Conductivity refer-

ence

If the programming is done by opening of the motor-

ised valves, the value will go from 0 to 99. Only the opening

of the motorised valves which have been configured will be

required.

C

2

.3

0

3

3

Section to be

modified

% of opening of the

motorised valve M1

% of opening of the

motorised valve M2

10. CONFIGURATION OF THE USER

In this section we can find the parameters which allow

you to adjust the working of the unit, as well as the sensor

calibration and the manual activation of the motorised

valves. To access this section, press the “C” and “+” keys at

the same time when the programmer is at code C0 of con-

sultation.

If no input is activated, the programmer goes to sen-

sor calibration; otherwise, it goes directly to the first con-

figuration code (code 03).

Press the “C” key to go from one code to another. Use

the “+” and “-“ keys to change values. Press the “C” key,

until code C0 appears, to go back to consultation.

Codes U0 and U1, which correspond to calibration, are

explained in the CALIBRATION section.

- Code U2: Manual activation of the motorised valves.

The first section corresponds to the activation of the

motorised valve M1 and the second one to the activa-

tion of the motorised valve M2. If one of the motor-

ised valves is not available, the corresponding section

does not appear. When the opening percentage of any

of the motorised valves is varied, the indicated

movement will be carried out. Set value 0 at the mo-

torised valves to finish the manual opening. While it is

at manual a flashing dot appears just at the end of the

option code. It is not possible to activate any pro-

gramme while in manual mode. It is possible to vary

the opening of a motorised valve if this one is in

movement.

- Code U3: High and low CE alarms respectively. If the

programming is done by reference of conductivity, en-

ter, in the first section, the difference that there has to

be above the indicated reference in order to activate

the alarm, as a level of conductivity which is too high

7

has been reached. If the programming is by openings,

indicate the maximum conductivity value which is al-

lowed. Values go from 0.0 to 9.9. In the second section,

enter the difference there must be below the expected

reference so that the alarm activates because it has

reached a level of conductivity which is too low. If the

programming is by openings, indicate the minimum

conductivity value which is allowed. Values go from 0 to

9.9.

- Code U4: Delay in alarm detection. Indicate the num-

ber of seconds during which conductivity must be at an

alarm level before its activation. The value must be be-

tween 0 and 999.

- Code U5: Indicate whether the active programme must

be deactivated when a breakdown takes place (press

the “+” key for YES to be displayed on the screen) or it

must continue its working (press the “-” key for NO to

be displayed on the screen). In the last case, the en-

trance of another programme will not be allowed. This

value does not affect input nº 4, which will always stop

the active programme.

- Code U6: Alarm working and at stop. In the first sec-

tion, indicate the number of seconds the alarm must be

working in the cycle of alarm signal. The value must be

between 1 and 99 (0 means “do not start”). In the sec-

ond section, indicate the number of seconds the alarm

must be at stop in the cycle of alarm signal. These val-

ues must be between 0 and 99 and it only has sense if

outlet S5 has been programmed as alarm outlet (0

means alarm always working, if there is time in the pre-

vious section).

11. CALIBRATION

In the configuration of the user, codes U0 and U1 are

used to calibrate sensors. In order to carry out the calibra-

tion, take the sensor out of the pipe and leave in a place

where it has no contact with water. Next, go to code U0. On

entering in everyone of the codes, the code and value

which is expected from the sensor appears for a few sec-

onds. After these seconds, the screen blinks and displays

the reading which is being obtained from the sensor. If the

reading is stable enough and similar to the desired one, the

screen stops blinking after ten seconds, indicating that the

sensor has been calibrated. Pressing the “+” and “-” keys at

the same time the unit is forced to accept the value which

is being displayed on the screen at that moment. Once this

point has been reached in the code U0, deep or fill the sen-

sor with pattern liquid of 5.0 mS and press the “C” key to

change to code U1.

If the calibration of sensor is not to be done, press the

“C” key during the initial seconds or press the “C” key until

the code changes, when the screen is blinking.

In order to have a good calibration, the sensor and

the liquid have to be as close as possible to 25ºC degrees.

Then, the liquid value and the automatic compensation

that the sensor have will be correct. If the irrigation water is

cooler than 25ºC the sensor it should be taken out for sev-

eral minutes because the sensor has and inertia to the

temperature changes.

If a suitable calibration is not done in the first code,

the second one does not appear. So, to do a valid calibra-

tion of the sensor, it is necessary to do the two codes cor-

rectly.

12. BREAKDOWNS

When the unit detects a breakdown, because a non

desired level of conductivity has been reached or because

input 4 has been activated, the screen displays the consul-

tation code C0 and the information about the reason of the

breakdown in a blinking way. This message will disappear

on pressing the “C” key. If it has been indicated that the

programme has to stop, the action will take place and the

activation of another programme will not be allowed. If ,

apart from that, it has been indicated that outlet S5 works

as alarm outlet, it will activate according to what is indicat-

ed in the configuration of the user.

Option code

Origin of the alarm (CE, E4)

C

0

A

1

C

E

_

Indicator of the

alarm and nº of

programme

Type of alarm (low, a hy-

phen below, high, a hy-

phen above)

8

13. SYNOPTIC OF FUNCTIONS

Table of contents

Other Progres Controllers manuals

Popular Controllers manuals by other brands

Siemens

Siemens Desigo RXC20.1 manual

TERMOFOL

TERMOFOL Mark II TF-H2 operating manual

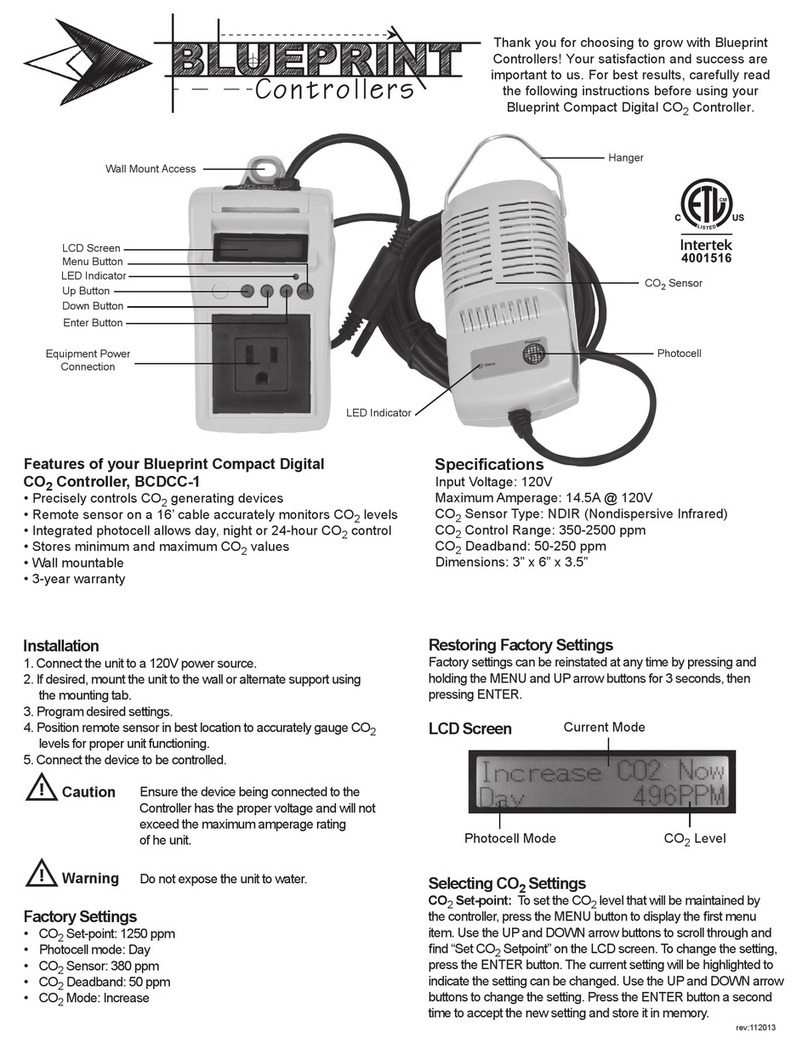

Blueprint Controllers

Blueprint Controllers BCDCC-1 manual

Pentair

Pentair Biffi F02 Installation and maintenance instructions

Danfoss

Danfoss VLT AQUA Drive FC 202 installation manual

Mitsubishi

Mitsubishi Melsec A series user manual