Progres AMBITROL 100 User manual

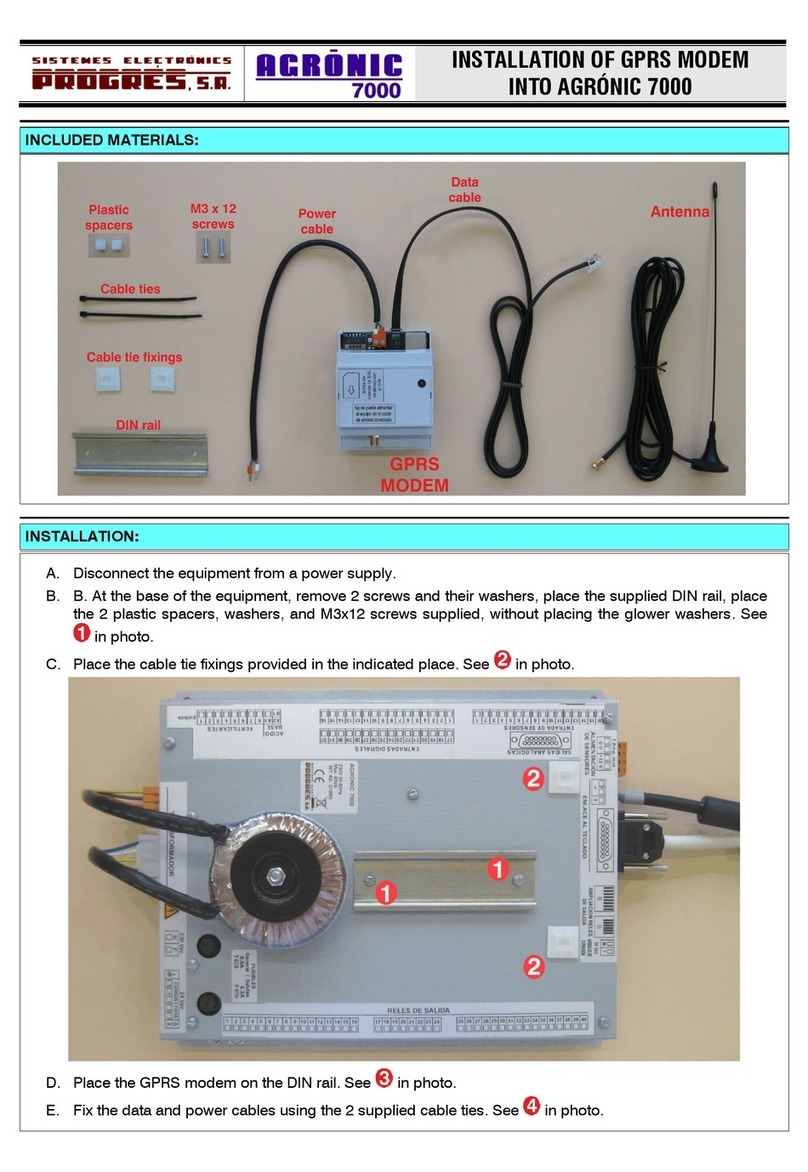

1

INSTRUCTION

MANUAL

MODELS 102 Y 103

INDEX

Sec. Theme Page

1. BASIC DESCRIPTION 1

2. INTRODUCTION 2

3. DIMENSIONS 4

4. INSTALLATION 5

4.1. Placing the equipment 5

4.2. Connection 5

4.3. Supply 5

4.4. Inputs 5

4.5. Outlets 6

5. CONFIGURATION 7

5.1. Inputs 7

5.2. Outlets 8

5.3. Programming 8

6. USE 10

6.1. Programmes 11

6.2.. Curves 12

6.3. Record 12

6.4. Anomalies 13

6.5. Various 13

6.6. Consult 14

7. DETAILED DESCRIPTION OF TYPES 15

8. AMBITROL 100H 23

9. AMBITROL 100HS 23

PRESENTATION

We wish to take this opportunity to thank you for

the confidence in us which you have shown in

expressing interest or adquiring the AMBITROL

102/103.

This confidence, for our part, stimulates our

efforts to meet and surpass the expectations of our

clients to justify the traditional quality of our products.

This manual will explain the specification of the

equipment as well as its installation and use.

However, if after reading this you still have any

doubts, contact us and we will happily answer them.

1. BASIC DESCRIPTION

Model 102/103 is a complete

electronic system for the automatic control of the

environmental parameters in climatic premises such as

farms, greenhouses, drying sheds, cold rooms, etc.

with 8 analogical inputs (for sensors) and 2 digital ones

(to condition working), plus 8 analogical outlets of relay

(all/nothing) expandable, and 3 or 8 analogical,

according to model, (outlets 0/10 V), with ten

programmes of control.

As it is configurable, we can control sensors of

temperature, relative humidity, harmful gases,

lightness, solar radiation, levels, etc.; and act on

numerous windows, fans, heaters, cooling systems,

humidifiers, irrigations, alarms, lighting, engines, etc.

Every one of the controls is configurable in its

inputs, outlets, type of working, conditioners, values of

reference, differentials, alarms, etc.

The references can be programmed by hand

(being possible to modify them personally whenever it

is necessary) or following some curves prefixed by the

user himself once and which are being modified

automatically as time goes by, according to what is

set.

The use of prefixed curves of behaving gives big

nimbleness to those controls in which the references

must be changed periodically.

All the records, anomalies, values and other

information useful for the control are registered in the

memory of the system, being possible to see them on

screen.

WARRANTY

AMBITROL 100 enjoys a WARRANY of two

years against any manufacturing fault.

OPTIONS

2

•Possibility of having 16 outlets of relay.

•Possibility of having 8 analogical outlets

(Model 103).

•Version without box, ready to fit in other

cabinets.

•Version that works with12 V DC (Battery).

•Model AMBITROL 101 (without analogical

outlets).

•Versión “100H” para la humidificación

secuencial.

•Versión “100HS” para la humidificación

secuencial y la regulación de ventanas por

tiempo de apertura.

•Models with software adapted to the

necessities of the clients.

OTHER EQUIPMENT

For those installations where more than 10

controls are necessary, and easy, and nonexpensive

to increase, if it is necessary, we suggest the

AMBITROL 500; which has got a central processing

unit to which can be connected a printer, and some

pheripheric processing units of inputs/outlets which

can be placed hundreds of metres away.

2. INTRODUCTION

Model 102/103 is a complete

environmental controller whose qualities and

peculiarities have to be known by the installer and the

user so that a maximum profit is reached, so we

recommend the careful reading of this Manual.

The manual is divided in four chapters:

a) Introduction (pages 1-4)

b) Installation (pages 5-6)

c) Configuration (pages 7-9)

d) Use (pages 10-22)

The INTRODUCTION is where you are now,

and we recommend its reading to both installers and

users.

The INSTALLATION is the chapter addressed to

the installator who has to connect the equipment to the

other elements that make up the system.

The CONFIGURATION is the chapter which

shows how to configure or adapt the equipment to the

particular necessities of every installation. This work

has to be done by an installator.

The USE is the chapter addressed to the user,

as it contains all the instructions about the

programation and the follow up.

The equipment has and illuminated alpha-

numeric screen with forty characters which shows the

questions that the controller does to the user, his

answers, the programmes and all the other stored

data, the current workings, etc.

SCREEN

It has also got a keyboard with fourteen keys

which are used to acced to the equipment.

There are keys which show numbers from 0 to 9

which will be pressed whenever it is necessary to enter

a number.

The same keys also show the initials of the days

of the week and they will be pressed whenever it is

necessary to enter in the controller one or several

days.

There are two keys with the words "Si"(yes) and

"No" which will be pressed in some cases to answer

yes or no to the questions on the screen.

There is a key with an arrow which is used to

move fast along the data on the screen.

The same key, with the sign "-" is used to enter

negative values.

The key "ENTER" is used to confirm the validity

of the datum typed previously or shown on the screen

placing the cursor below it. This key is bigger than the

others as it is used constantly.

The key "CON" is used to consult the current

state of the programmes which are being carried out

and that of the inputs and outlets.

The key "FUN" is used for entering the six basic

functionsof the controller, as it is shown as follows.

KEYBOARD

ENTRAR =ENTER

FUNCION =FUNCTION

CON =CONSULTATION

DOM =SUNDAY

LUN =MONDAY

MAR =TUESDAY

MIE =WEDNESDAY

JUE =THURSDAY

VIE =FRIDAY

SAP =SATURDAY

DIARIO =DAILY

SI =YES

NO =NO

FUNCTIONS

On pressing the key "FUN" we acced to the

section of FUNCTIONS of the equipment, showing the

following MENU:

3

F1: Programmes

F2: Curves

F3: Record

F4: Anomalies

F5: Configuration

F6: Miscellaneous

To choose a FUNCTION, press its

corresponding number and "ENTER". When pressing

the number you acced to directly to one of the three

above seen screens (the screen also changes with the

key "FUN").

DESCRIPTION OF THE FUNCTIONS

PROGRAMMES

With this function you access to the most

important data of every working programme.

CURVES

Here the values are given in order to form a

curve to be followed by the programme.

RECORD

Statistic of the last seven days for every one of

the programmes.

ANOMALIES

Record of the different anomalies that can take

place in the installation.

CONFIGURATION

Here the equipment is configurated to adapt it to

the necessities of the installation to be controlled. This

is normally done by the installator. It is important not to

access this function without an exact knowledge of

what you are going to modify.

VARIOUS

To leave the alarm in the stand by position or

not, set the clock or leave the equipment temporarily in

stop.

In some screens some letters with inverted

background will appear and they have got the following

meaning.

P= Programme: Programme number.

C= Curve: Activated curve (1) or deactivated (0)

E= Input: Value of the sensor/s of input.

S= Outlet: State of the outlet.

TYPES OF WORKING

We call types of working to the different ways of

working the equipment allows.

TYPE-01

Input of sensors, outlet by relay.

When the value of the sensor is lower than the

value of reference, the outlet is activated until it

overcomes it and reaches the value of the differential.

Examples: Heating, Humidification, etc.

TYPE-02

Input of sensors, outlet by relay.

When the value of the sensor is higher than the

value of reference, the outlet is activated until It

reaches the value of the differential.

Examples: Refrigeration, drying, etc.

TYPE-03

Timetable programme, outlet by relay.

When the day and time programme are

reached, the outlet is activated, finishing when there is

no more time of activation left. Up to 99 periodical

activations can even be programmed, at the same

time. The programme can also be started obeying any

other programme.

Example: Lighting, feeding, irrigation,

humidification by time, when the humidity of a certain

value decreases, etc.

TYPE-04

Input of sensors, analogical outlet (0-10 V).

Every programme is given a reference, a

proportional band and amaximum and minimum

percentage of outlet. When the value of the sensor is

lower than the reference, the outlet increases

proportionally from the minimum to the maximum,

obtaining this last one when the sensor reaches the

value of reference minus the programmed proportional

band. Example: Proportional heating.

TYPE –05

Input of sensors, analogical outlet (0-10 V)

The programme is given a reference, a

proportional band and a maximum and minimum

percentage of outlet. When the value of the sensor is

higher than the reference, the outlet increases

proportionally from the minimum to the maximum,

obtaining this last one when the sensor reaches the

value of reference plus the programmed proportional

band. Example: Forced ventilation.

TYPE-06

Input of sensors, outlet by two relays (open -

close).

Special type to work on windows with lathe so

that the natural ventilation can be made. When the

temperature is higher than the reference, some timings

are made, one of stop and another of opening. The

same happens to close, when the temperature is lower

than the reference minus the differential.

TYPE-07

4

Input of sensors, outlet by relay with modulation

of the working time proportional to the changes of the

sensors.

The programme is given a reference, a

proportional band and a maximum and minimum

percentage of outlet.

When the value of the sensor is lower than the

reference, the oulet increases proportionally from the

minimum to the maximum, obtaining this last one when

the sensor reaches the value of reference

minus the programmed proportional band.

The value of time, called "cycle of modulation",

corresponds to the 100% of the time of activation of

outlet. If the value of proportion decreases, the outlet

will be activated for as long as it corresponds from the

percentage of the cycle of modulation and the rest of

the proportion will not be activated. This will be

repeated once the time of the cycle of modulation is

finished.

Example: proportional heating.

TYPE-08

Input of sensors, outlet by relay with modulation

of the time of proportional activation to the changes of

the sensors. The programme is given a reference, a

proportional band and a maximum and minimum

percentage of outlet.

When the value of the sensor is higher than the

reference, the outlet increases proportionally from the

minimum to the maximum, obtaining this last one when

the sensor reaches the value of reference plus the

programmed proportional band.

The value of time, called "cycle of modulation",

corresponds to the 100% of the time of activation of

outlet. If the value of proportion decreases, the outlet

will be activated for as long as it corresponds from the

percentage of the cycle of modulation and the rest of

the proportion will not be activated. This will be

repeated once the time of the cycle of modulation is

finished.

Example: proportional ventilation.

TYPE-09

Input of sensors, outlet by two relays (open,

close).

Type to work on windows, hatches, motorized

valves etc. with sign / retromessage of position. This

sign and the value of the sensors work on the outlets

of opening and closing to maintain the suitable

position.

3. DIMENSIONS

5

4. INSTALLATION

4.1. PLACING THE EQUIPMENT

The equipment is provided in a hermetically

sealed box (IP 65) with a transparent front cover and

an opaque cover for the connection housing.

For the wall-mounting of the unit, there are two

holed pieces in the upper corners. There are also two

more holes in the inside of the connection housing.

Fix the unit with screws on a wall or similar, so

that the screen is in your field of vision.

Avoid proximity to:

-High voltage devices.

-Transformers.

-Motors or sources of vibration.

-Or any other source of interference which

coud affect the correct working of the unit.

-Also avoid temperatures in excess of 50ºC,

condensation, drips, vibrations, etc.

To maintain the isolation of the unit, it is

essential to keep the transparent and opaque panels

closed.

4.2. CONNECTION

To connect the unit, remove the lower cover to

reach the terminals.

For the cable entries, it is necessary to remove

the relevant dies (this should be done with the

connection cover in place and screwed to avoid

possible breakage).

It is advisable to install the stuffing box

(prensaestopas) in the open dies, which are included

with the unit.

It is advisable to connect the cables to the

terminals with terminal connection, which are also

included with the unit.

4.3. SUPPLY TO THE EQUIPMENT

The power supply should be at 220 V. AC. It is

recommendable to do this as directly as possible from

the general switch, avoiding that the same cable

supplies command lines, relays, switchers, etc.

Do not use the same line which supplies the unit

to supply the outlets of relays.

For unestable or fluctuating voltages, use grid

stabilizers.

It is important to connect the earth terminal, to

discharge the perturbations which there could be in the

supply.

If the equipment is placed on an electric

switchboard, the earth terminals of the equipment

should be joined in star, at the same point of the

switchboared and from this one to the earth terminal

bar with a section equal to the supply cables of the

switchboard.

The equipment is protected in the supply by a

varistor between the phase and the neutral which will

short circuit the fuse on detecting an overload on the

line, and the two supply lines are filtered towards the

earth terminal.

Do not increase the value of the fuse (0.4 A) as

this would suppose the destruction of components. On

the backside of the cover for the connection housing

there are some spare fuses stuck.

Group of three grid supply terminals to the

equipment (right side).

TERMINAL 1: Input of phase of 220 V ac,

protected by the fuse.

TERMINAL 2: Input of neutral of 220 V.

TERMINAL 3: Input of earth terminal

4.4. INPUTS

TERMINAL 1.-Digital input number 1.

TERMINAL 2.-Digital input number 2.

Those two inputs are optojoined to protect the

circuits; the input will be activated when we join them,

with a contact, to terminal number 6.

The contacts of the connection systems which

are connected here must be normally open and free of

tension.

TERMINALS 7 TO 14: Inputs of sensors from

number 1 to number 8.

The inputs of sensors are prepared in the

factory to adapt them to the different values of tension

or power that every sensor can have.

An input without modification has a level of 0 to

5 V. (If those limits are overcome, it can cause

breakage to the system).

TERMINAL 15: Analogical internal earth (it is not

used). TERMINAL 16: Supply of sensors. Earth at 0 V.

TERMINAL 17: Supply of sensors. 17 V positive

stabilizing.

TERMINAL 18: Supply of sensors.18 V negative

without stabilizing.

NOTES: Make sure that the cables from the

inputs of sensors and digitals are installed away from

the lines of tension of the installation.

Make sure that the cables are screened and the

casing is connected to the earth of the equipment.

4.5. OUTLETS

TERMINAL 3:Analogical outlet of 0 to 10 V, nº 3.

TERMINAL 4:Analogical outlet of 0 to 10 V, nº 2.

TERMINAL 5:Analogical outlet of 0 to 10 V, nº 1.

TERMINAL 6:General of analogical outlets.

Avoid to shortcircuit an analogical outlet with the

general of analogical outlets.

TERMINAL 16:Outlet supply sensors -Earth to

0v.

6

TERMINAL 17:Outlet supply sensors -17 V

positive stabilizing.

TERMINAL 18:Outlet supply sensors -18 V

negative without stabilizing.

TERMINAL 19:Outlet of relay nº8 -Normally

outlet of alarm.

TERMINAL 20: Relay outlet nº7.

TERMINAL 21: Relay outlet nº6.

TERMINAL 22: Relay outlet nº5.

TERMINAL 23: Relay outlet nº4.

TERMINAL 24: Relay outlet nº3.

TERMINAL 25: Relay outlet nº2.

TERMINAL 26: Relay outlet nº1.

TERMINAL 27: General of outlets. It is necessary

to supply (220 or 24 V) so that it can go out through

the relays.

The general is protected with the fuse of outlets

for a maximum power of 2.5 A.

Do not exceed a 1 A current load for each outlet

by relay.

Every contact of relay is protected by a varistor

which avoids the sparks or interferences which are

produced when we open the contact with inductive

charge.

BE CAREFUL WITH THE ANALOGICAL

OUTLETS OF THE AMBITROL!

In the AMBITROL equipments with analogical

outlets of 0 to 10 V, it is necessary to protect these

outlets with screened cable. What is more, this cable

must never be installed by the power lines.

The screen of the cable will be connected to the

earth terminal by one of its ends. If there is not an

earth terminal, it will be connected to the general of

analogical outlets.

These outlets are normally connected to

regulating equipment, so we have to take into account

that some of these equipment, on being disconnected

from the grid, can produce an overload in the outlets.

In these cases, we have to install a device which on

disconnecting the regulating equipment of the grid,

also disconnects the sign of 0-10 V. (this anomaly has

been detected in gas regulators).

It is also necessary to screen the analogical

inputs of the sensors and to place them away from the

power lines.

If the equipment is placed, because there is no

other possibility, next to contactors with inductive

charges, it may be necessary to install, in its contacts,

spark suppressors, so that these do not affect the

equipment.

CONNECTION SCHEMES: INPUTS AND SUPPLY

CONNECTION SCHEME: OUTLETS

5. CONFIGURATION

The first thing to be done when the equipment is

installed is to configurate it. This is to be done by the

installator.

7

To do so, press the "FUN" key and choose

option 5, which shows the MENU OF

CONFIGURATION.

F5: Configuration

F6: Various

CONFIGU.:Programmes=

1

Inputs=2 Outlets= 3

5.1. INPUTS

Normally the INPUTS are already configurated

and prepared in the circuit in the factory, so the

following data is already configurated in memory.

If you choose option 2 (INPUTS) of the menu of

CONFIGURATION, you will see the following screen:

Number of input= 0

ANALOGICAL INPUTS

The maximum number of analogical sensors to

be connected is 8.

Every sensor is given a number which

corresponds to the input to which it is connected. This

input has already been predetermined and

configurated in the factory.

One sensor can give value to several

programmes.

The number of measure unit is used to give a

name to the type of value which controls the sensor.

Num. of input= 1

Measure unit= 01

Here is a list of the measure units.

01-Temperature ºC 08-Radiation Wm2

02-Relat. humidity %HR

09-Units Uds

03-Lighting Klx 10-Pressure Psi

04-Relation %11-Flow m3h

05-Speed m/s

12-Flow l/h

06-Direction º13-Carbon dioxide

C02

07-Acidity pH 14-Ammonia NH3

Every sensor has a tare (calibration) in relation

to a pattern. It is important not to modify this value,

unless a calibration has been done.

The maximum value of the tare is +120 or 12.0.

Num. of input=8

Tare= 03.5%HR 76.3

To modify the value of the tare we have to

calculate the error of the reading of the sensor and add

or deduct it to the value of the tare.

Example: Tare = 03.5% HR 76.3

If the correct value, according to the pattern,

was 75.0% HR, compared with the value of the

reading (76.3) there is a difference of minus 01.3%,

which has to be deducted from the value of the tare

(3.5 -

1.3 = 2.2%) resulting as follows: Tare =02.2% Hr

75.0.

If the tare has to be negative, enter first the

value and then press the key "-".

To the right of the value of the tare it indicates

the value of the sensor; this will be useful in the

programmes which give us averages of two sensors,

being here where you can see sensor by sensor.

To escape, enter the sensor "0" or press "FUN"

or "CON".

DIGITAL INPUTS

The two digital inputs included in the

programme, can be used as external conditioners of

the programmes (for levels, etc) or as counters of

impulses (to register the consumption of water and

feed, etc).

To configurate them, when the screen demands

the number of input, answer with "9".

The next question will appear on the screen:

Counting 1 (Yes/No)=Yes

With "Yes" it will be input of counting, with "No" it

will be conditioning input.

Answering "Yes", the next question will be :

Counting 1 (Yes/No)=Yes

Impulse value 1= 01.0

The value of impulse corresponds to the

quantity equivalent to every impulse received from a

counter of water, weight, etc. The maximum value is

12.0. For the input nº 2 it will ask the same.

8

5.2. OUTLETS

CONFIGU.:Programmes=

1

Inputs=2 Outlets= 3

If the option 3 (INPUTS) is chosen from the

menu of CONFIGURATION we will be able to

configurate the analogical outlets with the following

screen.

It is not necessary to configurate the outlets by

relay.

Num. of outlet=0

(analogical 0-10v)

The maximum number of analogical outlets is 3

(optionally 4) in Model 102 and 8 in Model 103.

The analogical value goes from 0 to 10 V. and it

corresponds to the 0 to 100% that will be shown on the

screen as value of outlet.

This outlet is normally connected to controllers

of speed, lightness, powered valves, hatches

controllers, etc.

It is possible that, for example, a speed

controller needs to work from 2 to 10 volts, for the

engine to start well at low speed; then, in the minimum

tension it will be given a value of 02.0 volts (in this

case the 0% corresponds to 0 volts and the 1% to 2

volts).

Num. of outlet= 3

Minimum tension 00.0V

We can also fix beforehand the level of

maximum tension.

Num. of outlet= 3

Maximum tension 10.0V

The equipment which receives the tension may

need the inverted sign (from 10 to 0V.) in this case,

enter in minimum tension 10.0V and in maximum

tension 00.0V.

To escape, enter the outlet "0" or press "FUN" or

"CON".

5.3. PROGRAMMES

CONFIGU.:Programmes=1

Inputs=2 Outlets= 3

Choosing option 1 (Programmes) from the menu

of CONFIGURATION you can configurate

programmes, but it is necessary to configurate the

inputs and outlets before, as they are related to the

programme.

First, we can see the following screen asking for

the number of PROGRAMME we want to access, give

the number and "ENTER". The equipment has

capacity for 10 programmes.

Num. of programme= 00

(to configurate)

Once the number has been entered, we can see

the following screen.

P05

Type of working=1

In the question "type of working of the

programme" we have to take into account what it is

going to control, because the number of type is what

conditions totally the questions and answers of the

programme.

(At the end of this Manual there is a detailed

description of every TYPE).

If the value 00 is entered, it erases all the data

of this programme.

Once the type is entered, it will ask for the text

and a number; these will be used to identify the type of

control and where the programme is working.

P05

Text=00 Number=0

The list of texts is as follows.

01-TERM (Thermostat)

09-ALAR (Alarm)

02-CALE (Heating)

10-TIEM (Time)

03-VENT (Ventilation)

11-AGUA (Water)

04-HUMI (Humidification)

12-ALIM (Feed)

05-VTNA (Window)

13-CONT (Control)

06-REFR (Refrigeration)

14-ILUM (Lighting)

07-NAVE (Premise)

15-SALA (Room)

08-ZONA (Area)

16--A

The number is used to identify different

programmes which have the same function, for

example several thermostats which will be given

different numbers to differenciate them.

A programme normally needs to read from some

sounds (inputs) placed in the installation to compare

that value with the programmed one and in this way

act on the corresponding outlet.

Every programme can read one or two sounds,

if there are two it takes the average .

P05 TERM-1

Num. of inputs= 00

9

In the question of "inputs", if the number of

sensor is not entered, the programme will not go on to

the next question.

One sound can be read by several programmes.

In the programmes where a sign of

retromessage is used, it will ask for the number of

input of this retromessage.

All the programmes have an outlet, which can

be of relay or analogical. Depending on the type of

programme, the controller will know which type it is.

To the question "number of outlet" we can also

answer with 0; in this way the programme does not act

externally, but it can condition other programmes.

P05 TERM-1

Num. of outlet=00

The last outlet of relay (nº 8) is normally used as

outlet of alarm. (Explanation in section ALARM).

Several programmes can act on the same outlet

of relay, but the priority is for the activation.

The programmes type 6 and 9 (windows) need

two outlets to work, one that opens and another that

closes. This question will be answered with the

number of outlet that has to open, and the equipment

will automatically assign the following number to

close. For this reason, it is necessary to assign a

number of outlet that is followed by another one which

has not been assigned.

Any programme can be "conditioned" by another

one and it has a priority effect in the outlet.

P05 TERM-1

Conditioning pro.=00

It can also be conditioned by one of the two

existing digital inputs (to connect securities external to

the equipment) if they are not used to count.

For the input "1" enter the code 81 and for the

input "2" the code 82, in the blank for the conditioning

programme.

Next it will ask how it will be affected, and we

have to answer with one of the following codes:

P05 TERM-1

Affects on code= 00

AFFECTS ON

CODE TYPES 4-5-7-8-9TYPE 6

TYPES1-

2

00 Outlet at 0% Stop Stop

01 Outlet at100% Close Start

02 Outlet at minimum Open

03

Outlet at maximum

04 Outlet at 25 %

05 Outlet at 50 %

06 Outlet at 75 %

07 Limits at 25 %

08 Limits at 50 %

09 Deducts the % of the programme,

minus % of the conditioning.

10 Adds the % of the programme, plus %

of the conditioning.

11 Outlet at 0 %, plus the 10 % of the

outlet of conditioning.

12 Outlet at 5 %, plus the 10 % of the

outlet of conditioning.

13 Outlet at 5 %, plus the 20 % of the

outlet of conditioning.

Then it asks again for a new number of

programme; to escape enter "00" or "FUN" or "CON".

The TIMING PROGRAMMES (type 3) have a

variant in the questions of CONFIGURATION of

programmes, in these programmes it asks for the time

format we want to programme them in.

P04 WATER-1

(h:m):0 (m.s):1 =00

A "0" is for hours and minutes and a "1" for

minutes and seconds. If there is an electric cut while

the programme is working, it does not discount the

time the cut lasted (starting the timing in the point

where it was interrupted, but it will do so if we add 10

to the values of this question, entering a 10 or a 11

respectively (losing the time of temporization

corresponding to the cut.

10

6. USE

6.1. PROGRAMMES

To acced to every one of the programmes of

values (not of Configuration) press the key "FUN" and

choose option 1, then it will ask the number of

programme.

F1: Programmes

F2: Curves

Num. of programme= 00

(for values)

Once we have entered the number, it shows the

following screen, in which for two seconds, it informs

about the type of working of the programme.

P03 HEAT-1 C0

Type of working= 1

Once the timing is finished, in the second line,

the message of type of working is normally replaced by

the value of the reference.

P03 HEAT-1 C0

Reference= 22.0 ºC

The cursor is placed in the value of the curve

"C". If the value is zero "C0", the datum of the

reference will be entered manually.

If you want that the value of reference changes

automatically as time goes by, we will have to activate

the curve that every programme has, giving the value

"1".

If you do not want to modify the number of

curve, press the key "ENTER" and then it will ask the

value of reference.

P02 VENT-1 C1pos=018

Reference= 22.6 ºC

Once the curve is activated, it will ask the

position (pos) in the curve, which goes from 0 to 250

days.

The position increases automatically every day

at 0 hours and can be modified at any moment.

The value of reference is updated automatically

every hour.

With the cursor placed in "pos", we can modify

the value or press directly "ENTER", placing the cursor

at the right side of the lower line.From this point,

pressing the key with the arrow we can modify again

"pos". When the curve is activated, the value of

reference can not be modified directly.

Once the value of reference has been entered, it

asks for the "differential" of working; This is done in the

types of outlet by relay (types 1-2-6, except type 3,7,8

and 9).

P02 VENT-1 C1pos=018

Differential= 00.5 ºC

This value is added or deducted, according to

the type of working, to the reference to calculate the

stop of the working.

In the types with analogical outlet (types 4-5), of

proportional action (types 7-8) and proportional

window (type 9), we are asked for the "proportional

band", which is also added or deducted to the

reference so that the value of outlet reaches the

maximum of its value.

For these types, it will later ask for the maximum

and minimum value of outlet. This is useful to maintain

tops in the value of outlet even though the value of the

sensor is moved from the referenced values.

If the curve is active, we will not be able to

change directly the maximum and minimum values.

Every programme, except the types 3-6 (timing,

window), will be asked some values of high and low

alarm.

P03 HEAT-1 C0

High alarm(+)= 03.0

P03 HEAT-1 C0

Low alarm(-)= 02.5

These values are added (high) and deducted

(low) to the reference and, if the value of the sensor is

superior to the added value or is inferior to the

deducted value and it stays like that for at least 30

seconds, the relay of alarm (outlet 8) will be activated

until this condition disappears.

The programme, date and time when this

happened will also be registered in the section of

ANOMALIES.

If the values of alarm are entered in negative,

the alarm will be activated as long as the value of the

sensor is between the two values of alarm.

At the end of every programme, it asks if we

want to act on the outlet manually.

P03 HEAT-1 C0

Manual (Yes/No)= No

If we answer with the key "SI" (YES) and

"ENTER", different screens will appear depending on

the type of working:

FOR TYPE 1 AND 2 (outlet by relay)

P03 HEAT-1 C0

Start:1 Stop:0 = 0

11

A "1" starts the outlet and a "0" deactivates it,

this happens indefinitely in all the types, as long as we

do not answer "NO" to the question of Manual

(Yes/No).

FOR TYPE 3 (timing relay)

P03 WATER C0

Start:1 Stop:0 = 0

FOR TYPES 4-5 (analogical) AND 7-8-9 (proportional)

We enter the value that we want in the outlet.

P03 HEAT-1 C0

Outlet= 089%

FOR TYPE 6 (windows)

P03 VTNA-1 C0

Stop:0 Op.:1 Cl.:2=0

0:Stop 1:Open 2:Close

6.1.1. TIMING PROGRAMMES (TYPE 3)

In the timing programmes, type 3, we will be ask

some different questions about the values of the

programme:

P03 HEAT-1 C0

Start=08:00

P03 HEAT-1 C0

Days=SMTWTFS

P03 HEAT-1 C1pos=015

T. working= 00:00

P03 C0

N. workings= 00

The "start" is the time when the programme will

start working in relation to the question of "days".

To programme the days, press the keys that

have the days on them, pressing once to programme it

and once to erase it. To enter or erase all the days

press the key "daily".

A variant in the "start" of the programme is that

instead of start working by timing it can do so by

command of another programme, to do so in the value

of the time of start, we will enter the code 90 or 91 and,

in the minutes, the number of programme that will start

this one.

The difference between code 90 and 91 is that

the first one will stop if the programme which started it

goes from start to stop and the second one will not

stop until it has finished all the programme.

The programmes with analogical outlet or of

proportional action are started when the outlet is over

60% and stop when it decreases below 40%

Then it asks if it will work with curve. If we

answer yes, it also asks for the position.

The next question is "Time of working", which is

the time that the outlet will be working.

The "Number of workings" is the number of

times that it will repeat the working.

The "Frequency" is the time between the starts

of different workings.

Both the "Time of working" and the "Frequency"

can work in hours and minutes or in minutes and

seconds. (This selection will be done in Configuration).

If the programme is started manually, the outlet

will start during the programmed time and the cycles,

cancelling automatically the MANUAL state in order to

be activated automatically.

If there is an electric cut during the time of start,

when the power is back the programme will already be

started.

If the programme is started and it has not

finished the previous working completely, the number

of workings will be added.

To cancel the time left when the programme is

working, start the MANUAL at Stop and then take out

the Manual answering "NO".

6.1.2. WINDOWS (TYPE 6)

Another variant in the questions is, for the type 6

that works on windows:

P01 VTNA-1 C0

Reference= 24.0 ºC

P01 VTNA-1 C0

Differential= 05.0 ºC

P01 VTNA-1 C0

Timing open = 05 s

P01 VTNA-1 C0

Pause open = 128 s

P01 VTNA-1 C0

Timing close= 08 s

P01 VTNA-1 C0

Pause close= 128 s

P01 VTNA-1 C0

12

Manual (Yes/No)= No

The reference is the value at which it will start to

open when the value of the sensor is superior to this

one.

It will close when the value of the sensor is

inferior to the value of the reference minus the

differential.

When it is at open or close, some timings take

place so that the climatic changes, produced on

moving the windows, are taken correctly by the

sensors.

First the pauses of open or close take place and

then the timings of open and close and they will be

repeated when the value of the sensor has to open or

close.

The timings can be programmed up to 99

seconds and the pauses up to 999.

6.2. CURVES

The curve of every programme is an important

feature that the programme has and that can be very

useful in applications such as the automatic increase

and/or decrease of temperature, the automatic

modification of the time of lighting, etc.

To enter in the curves of every one of the

programmes, press the key "FUN" and choose option

2, and it will ask for the number of programme.

F1: Programmes

F2: Curves

Num of programme= 00

(for curves)

Every programme has a curve, except the types

4-5-7-8-9, in which there is a seond curve that contains

the maximum and minimum values of outlet. For this

reason, it asks, in these types, to which of the two

curves we want to access.

P02 VENT-1C0

Once the number of curve is entered, it will ask

for the position and the reference of the first point out

of the four that each curve contains. At the right of the

number of curve it shows us the point which is asking.

P02 VENT-1C1 Point1

Pos=000 Ref= 00.0 ºC

Every point has a value of situation in the time,

in days, and some values of reference according to the

type of working.

The curves can be compared with patterns

which are used by the programmes in order to do a

variable and automatic control.

Here we can see a simple example.

P02 HEAT-1C1 Point1

Pos=003 Ref= 29.8 ºC

Pos=008 Ref= 27.5 ºC

Pos=020 Ref= 25.0 ºC

Pos=045 Ref= 20.0 ºC

This curve would control the temperature as the

animal grows, for example.

Every point corresponds to days of growth and

the reference of temperature will change in the values

that correspond within these points.

We have to say that if point 1 does not

correspond to 0 days, the value of reference that the

programme will take will be fix, until reaching the

position of point 1; in the example the first three days

of reference will be 29.8 ºC.

The same happens from the fourth point; in the

example after 45 days the value will stay at 20.0ºC.

6.3. RECORD

The record is an statistical record of the last

seven days, for everyone of the programmes.

To acced to the record of every programme,

press the key "FUN" and choose option 3, and it will

ask for the number of programme.

F3: Record

F4: Anomalies

Num. of programme= 00

(for record)

Once the number is entered, it will show today's

record. To see the previous six days, press the key

with arrow.

To see another programme, press the key

"ENTER". To escape press the keys "FUN" or "CON".

In the upper line of the record it shows at the

left, the text of the programme, in the center, the day

and month and at the right the hours and minutes in

which the programme has been working if the outlet is

by relay (type 6 no). If it is analogical (types 4-5) or

proportional (types 7-8-9) outle, it shows the average

of the day of the percentage of the value of the outlet.

At the lower line, at the left, it shows the highest

value of reading of the sensor, at the center the

average of all the readings of the day, and at the right

the lowest one.

TERM-121/08 (04:48)

20.2 19.6 18.4 ºC

For the reading of the accumulated values in

every one of the inputs/counters (if they are

configurated as such) enter in the function of Record.

13

When it asks for the number of programme,

enter "11" for the input 1 and "12" for the input 2.

The first value shown corresponds to the

accumulated from today. To see the six previous days,

press the key with the arrow.

The data are not updated while you are seeing

the record of counting.

23/04

Counter 1= 00001

6.4. ANOMALIES

The anomalies is a record of the incidences that

have taken place and have affected the correct

working of what it is controlled.

To enter in anomalies, press the key "FUN" and

choose option 4, then it will show the first anomaly, if

there is any.

F3: Record

F4: Anomalies

The maximum number of anomalies registered

is 15, if there are more than 15 it will cancel the oldest

one.

At the right upper line of every anomaly it shows

the text "E.y/n" (Erase? yes or no). If you press "YES"

it erases it and goes to the next one, not to erase this

one press "NO". On reaching the last anomaly it goes

back to Functions.

Here is a list of the different anomalies:

-Electric supply failure: If there is an electric

supply failure which is longer than a minute and

shorter than 24 hours, it will be registered as follows.

Electric cut. E. Y/n

15/04 from 21:34 to 23:17

-Without battery: If there is a disconnection of

the equipment superior to four days the memory of the

record and of anomalies may be erased. The

configuration, the programmes and the curves are not

erased.

Without battery E.y/n

27/03

-Alarm in programme: Any programme to which

we have given values in high or low alarm and the

value of the sensor is superior to these ones, for at

least thirty seconds, the outlet of alarm will be

activated and the anomaly will be registered.

Alarm in P03 E. Y/n

27/03 15:06

6.5. VARIOUS

To acced to VARIOUS, press key "FUN" and

choose option 6 and it will show a MENU OF

VARIOUS.

F5: Configuration

F4: Various

VARIOUS: Alarm=1

Clock=2 Stop=3

6.5.1. ALARM

Choosing option "1", we can inhibit the outlet of

the alarm, both when it is working or not, to use it and

in this way, use the outlet as a normal one.

Alarm (Yes/No)= Yes

If we answer with "Yes" it will ask if we want that

the outlet of alarm is normally closed. If we answer

"Yes", the start will be closed until there is an alarm or

an electric cut.

Alarm (Yes/No)= Yes

Normal. Closed= No

6.5.2. CLOCK

Choosing option "2" we can set the time in the

internal clock.

Thur.15:26 14/06/00

-Set time-

6.5.3. STOP

With the option "3" we can set the equipment at

STOP, which means that all the outlets are

disactivated.

In STOP (Yes/No)= No

6.6. CONSULT

The option of CONSULT is used to examine, in

a simple way, the state of the inputs and outlets of

every programme.

To enter this section, press the key "CON".

From nowonwards the key with arrow or with CON

move the programmes on the screen.

To have direct access to the consult of a

programme, enter its number. The programme 10 is

the key "0".

14

The first screen that is displayed when we press

the key "CON", informs about the time and date. It also

indicates the quantity of anomalies that have taken

place or if the equipment is at STOP.

Mon. 15:23 17/07/00

A102 Anomalies=05

Mon. 15:23 17/07/00

A102 *STOP*

The other screens of consult show us the data

of every one of the programmes.

In the upper line it indicates the number of the

programme that is being consulted, then the text and

at the right the value of the input of the sensors.

At the lower line it shows the value of the outlet,

both in Manual and in Alarm.

The values of the inputs and outlets are updated

on the screen every second.

P05 TERM-1 E 18.9 ºC

S Start(man.) ALARM

The value of the input changes in the timing

programmes (type 3) as no value of sensor is

indicated, but we indicate the value of time that is left

to finish the working. If it is in hours and minutes, the

format is 00:00 if it is in minutes and seconds 00.00.

And, at the right of the lower line it shows in brackets

the number of cycles that are left to finish.

P08 TMP-0 E 01:33

S Pause (02)

The value or state of the outlet can vary

according to the type of working, here are some

examples:

S Start

S Stop

S 000 %

S 100 %

S Open

SClose

S Pause

S Paus. O

S Paus. C

An asterisk (*) will appear between the "S" and

the value of outlets, in the programmes that in that

moment are being conditioned by another programme

or by a digital input, to indicate so.

An arrow up or down can also appear here, in

the programmes with analogical outlet or of

proportional action, indicating that the value of outlet

has reached the maximum or minimum programmed

value.

15

7. DETAILED DESCRIPTION OF THE TYPES

TYPE 1

Input of sensors, outlet by relay.

When the value of the sensor is lower than the

value of reference, the outlet is activated until it

overcomes it and reaches the value of the differential.

Examples: Heating, Humidification, Minimum

Alarm etc.

CONSULT

P06 HUMI-4 E 78.5%HR

S Stop

PROGRAMME

P06 HUMI-4 C0

Reference= 75.0%HR

Differential= 03.0%HR

High alarm(+)= 00.0

Low alarm(-)= 00.0

Manual (Yes/no)= No

CURVE 1

P06 HUMI-4 C1Pto1

Pos=000 Ref=00.0%HR

Pos=000 Ref=00.0%HR

Pos=000 Ref=00.0%HR

Pos=000 Ref=00.0%HR

Pos=000 Ref=00.0%HR

CONFIGURATION

P06 HUMI-4

Type of working= 1

Text= 04 Number= 4

Num. of inputs= 5 0

Num. of outlet= 06

Conditioning Pro.= 00

Affects in code= 00

RECORD

HUMI-421/06 (01:05)

78.9 77.5 74.3 ºC

VALUE OF SENSOR

High alarm

20.0

DIFFERENTIAL

15.0

REFERENCE

10.0

5.0

Low alarm

START

STOP

16

TYPE 2

Input of sensors, outlet by relay.

When the value of the sensor is higher than the

value of reference, the outlet is activated until it

reaches the value of the differential.

Examples: Refrigeration, drying, Maximum

alarm, etc. CONSULT

P05 TERM-1 E 18.9 ºC

S Start

PROGRAMME

P05 TERM-1 C0

Reference= 20.0%ºC

Differential= 01.5%ºC

High alarm(+)= 04.0

Low alarm(-)= 06.0

Manual (Yes/no)= No

CURVE 1

P05 TERM-1 C1Pto1

Pos=000 Ref=24.0%ºC

Pos=012 Ref=22.0%ºC

Pos=020 Ref=21.3%ºC

Pos=032 Ref=19.5%ºC

CONFIGURATION

P05 TERM-1

Type of working= 2

Text= 01 Number= 1

Num. of inputs= 1 0

Num. of outlet= 07

Conditioning Pro.= 00

Affects in code= 00

RECORD

TERM-1 21/06 (03:32)

20.2 19.6 18.4 ºC

High alarm

VALUE OF SENSOR

20.0

REFERENCE

DIFFERENTIAL

15.0

10.0

Low alarm

5.0

START

STOP

TYPE 3

Timing programme, outlet by relay.

When the day and time programmed are

reached, the outlet is activated, finishing when there is

no more time of activation left. Up to 99 periodical

activations can be programmed, at the same time.

The programme can also be started obeying to

any other programme.

Example: Lighting, feeding, irrigation,

humidification by time, when the humidity of a certain

value decreases.

CONSULT

P04 WATER-1 E 00:12

S Start

PROGRAMME

P04 WATER-1 C0

Start= 08:00

Days= SMTWTFS

T.working= 00:15

N. workings= 02

Frequency= 06:00

Manual (Yes/No)= No

CURVE1

P04 WATER-1 C1Pto1

Pos=000 Ref=00:11

Pos=025 Ref=00:14

Pos=045 Ref=00:19

Pos=130 Ref=00:28

CONFIGURATION

P04 WATER-1

Type of working= 3

Text= 01 Number= 1

Num. of outlet= 03

(h:m):0 (m.s):1 00

Conditioning Pro= 00

RECORD

WATER-1 27/06 (00:30)

17

TYPE 4

Input of sensors, analogical outlet (0-10 V). The

programme is given a reference, a proportional band

and a maximum and minimum percentage of outlet.

When the value of the sensor is lower than the

reference, the outlet increases proportionally from the

minimum to the maximum, obtaining this last one when

the sensor reaches the value of reference minus the

programmed proportional band.

Example: Proportional heating.

CONSULT

P03 HEAT-1 E 21.5 ºC

S 025%

PROGRAMME

P03 HEAT-1 C0

Reference= 22.0 ºC

Pro. Band= 02.0 ºC

Min= 00% Max= 090%

High alarm(+)= 00.0

Low alarm(-)= 03.8

Manual (Yes/no)= No

CURVE1

P03 HEAT-1 C1Pto1

Pos=000 Ref=34.0 ºC

Pos=017 Ref=26.5 ºC

Pos=035 Ref=23.5 ºC

Pos=045 Ref=22.0 ºC

CURVE2

P03 HEAT-1 C1Pto1

Min=00% Max=090%

Min=00% Max=085%

Min=00% Max=075%

Min=00% Max=070%

CONFIGURATION

P03 HEAT-1

Type of working= 4

Text= 02 Number= 1

Num. of inputs= 30

Num. of outlet= 03

Conditioning Pro.= 00

Affects in code= 00

RECORD

HEAT-1 24/06 (047%)

22.1 21.2 19.7 ºC

High alarm

15.0

VALUE OF

SENSOR

12.5

REFERENCE

10.0

PROPORTIONAL BAND

7.5

Low alarm

5.0

100 %

MAXIMUM

MINIMUM

000 %

18

TYPE 5

Input of sensors, analogical outlet (0-10 V). The

programme is given a reference, a proportional band

and a maximum and minimum percentage of outlet.

When the value of the sensor is higher than the

reference, the outlet increases proportionally from the

minimum to the maximum, obtaining this last

one when the sensor reaches the value of reference

plus the programmed proportional band.

Example: Forced ventilation.

CONSULT

P02 VENT-1 E 24.8 ºC

S 100%

PROGRAMME

P02 VENT-1 C2pos=012

Reference= 22.5 ºC

Pro. Band= 02.0 ºC

Min= 10% Max= 100%

High alarm(+)= 04.0

Low alarm(-)= 00.0

Manual (Yes/no)= No

CURVE1

P02 VENT-1 C1Pto1

Pos=000 Ref=285 ºC

Pos=017 Ref=265 ºC

Pos=035 Ref=235 ºC

Pos=045 Ref=220 ºC

CURVE2

P02 VENT-1 C1Pto1

Min=05% Max=080%

Min=12% Max=090%

Min=18% Max=100%

Min=25% Max=100%

CONFIGURATION

P02 VENT-1

Type of working= 5

Text= 02 Number= 1

Num. of inputs= 14

Num. of outlet= 02

Conditioning Pro.= 00

Affects in code= 00

RECORD

VENT-1 21/06 (083%)

24.9 23.4 22.4 ºC

In the inputs of the powermeter of

retromessage of window, the maximum and minimum

values can be configured, within a margin from 0 to 5

volts. To do so, enter in Function-5-Configurate-2-

Inputs, and it will ask for the number of input, then

enter the number to which the powermeter is

connected to. At unit of measure answer with 4.

Next it will ask for the minimum value of tension

that the powermeter gives when the window is closed;

if for example, it is 1.2 volts enter 12; do the same with

the maximum value.

High alarm

15.0

VALUE OF

SENSOR PROPORTIONAL BAND

12.5

REFERENCE

10.0

7.5

Low alarm

5.0

100%

MAXIMU

M

MINIMU

M

000%

The type of working 5, normally used for

forced ventilation, adds the feature of modulating the

analogical outlet of 0-10 volts when the temperature

drops 1ºC below the programmed reference, applying

a regulation equal to the proportional band. The cycle

of modulation is of 300 seconds.

19

TYPE 6

Input of sensors, outlet by two relays (open -

close).

Special type to work on windows with lathe so

that the natural ventilation can be made.

When the temperature is higher than the

reference, some timings are made, one of stop and

another of opening.

The same happens to close, when the

temperature is lower than the reference minus the

differential.

CONSULT

P01 VTNA-0 E 24.8 ºC

S Open

PROGRAMME

P01 VTNA-0 C0

Reference= 24.0 ºC

Differential= 02.0 ºC

Tim. Open= 05 s

Pause Open = 128 s

Tim. Close= 100 s

Pause Close= 100s

Manual (Yes/no)= No

CURVE1

P01 VTNA-0 C1Pto1

Pos=000 Ref=24.8 ºC

Pos=045 Ref=21.3 ºC

Pos=000 Ref=000 ºC

Pos=000 Ref=000 ºC

CONFIGURATION

P01 VTNA-0

Type of working= 6

Text= 05 Number= 0

Num. of inputs= 87

Num. of outlet= 04(5)

Conditioning Pro.= 00

Affects in code= 00

RECORD

VTNA-0 21/06

24.9 23.4 21.7 ºC

High alarm

20.0

REFERENCE

15.0

DIFFERENTIAL

10.0

Low

alarm

5.0

OPEN

STOP

CLOSE

20

TYPE 7

Input of sensors, outlet by relay with modulation

of the working time proportional to the changes of the

sensors.

The programme is given a reference, a

proportional band and a maximum and minimum

percentage of outlet.

When the value of the sensor is lower than the

reference, the outlet increases proportionally from the

minimum to the maximum, obtaining this last one when

the sensor reaches the value of reference minus the

programmed proportional band.

The value of time, called "cycle of modulation",

corresponds to the 100% of the time of activation of

outlet. If the value of proportion decreases, the outlet

will be activated for as long as it corresponds from the

percentage of the cycle of modulation and the rest of

the proportion will not be activated. This will be

repeated once the time of the cycle of modulation is

finished.

Example: proportional heating.

CONSULT

P03 HEAT-1 E 21.5 ºC

S 025 %

PROGRAMME

P03 HEAT-1 C0

Reference= 22.0 ºC

Pro. Band= 02.0 ºC

Min= 00% Max= 090%

High alarm(+)= 00.0

Low alarm(-)= 03.8

Manual (Yes/no)= No

CURVE1

P03 HEAT-1 C1Pto1

Pos=000 Ref=34.0 ºC

Pos=017 Ref=26.5 ºC

Pos=035 Ref=23.5 ºC

Pos=045 Ref=22.0 ºC

CURVE2

P03 HEAT-1 C2Pto1

Min=00% Max=090%

Min=00% Max=085%

Min=00% Max=075%

Min=00% Max=070%

CONFIGURATION

P03 HEAT-1

Type of working= 7

Text= 02 Number= 1

Num. of inputs= 3 0

Num. of outlet= 03

Modulation cycle= 000

Conditioning Pro.= 00

Affects in code= 00

RECORD

HEAT-1 21/06 (047%)

22.1 21.2 19.7 ºC

High alarm

20.0

REFERENCE

15.0

Value of sensor

10.0

PROPORTIONAL BAND

Low Alarm

5.0

Maximum

100%

Minimum

0%

Staterelay

of outlet

This manual suits for next models

2

Table of contents

Other Progres Controllers manuals

Popular Controllers manuals by other brands

Taconova

Taconova FWCK Installation and operating instructions for manual and remote control options

Show Tec

Show Tec SC-2412 user manual

Preferred Utilities

Preferred Utilities Quanta-Flame 5004-890 quick start guide

Raven

Raven Hawkeye installation manual

HTC

HTC Vive Tracker Developer Guidelines

Srne

Srne ML Series user manual

Rotex

Rotex Controller Series Product documentation

Precision Digital Corporation

Precision Digital Corporation ProtEX-MAX PD8-6210 instruction manual

Westinghouse

Westinghouse IWB-PC02 user manual

Elsema

Elsema Eclipse MCS Setup manual

Remote Control

Remote Control RCEL005X instructions

Sungrow

Sungrow PVS-24MH user manual