PRONAILS VISION PRO 800 User manual

- 1 -

USER MANUAL

VISION PRO 800

THE FUTURE

OF PROFESSIONAL

NAIL STYLING

CONTENTS

1 Important information before initial operation.................2

1.1 Symbols used ..............................................................................2

1.2 General safety instructions .....................................................2

1.3 Scope of delivery .......................................................................3

1.4 Packaging .....................................................................................3

1.5 Recycling ......................................................................................3

2 Intended use ................................................................................3

2.1 Ambient conditions ...................................................................3

2.2 Storage and transport ..............................................................3

3 Vision Pro 800 ........................................................................... 4

3.1 Front view ................................................................................... 4

3.2 Rear view ..................................................................................... 4

4 Handpiece .................................................................................... 4

5 Customer and user protection ..............................................5

6 Commissioning ...........................................................................5

6.1 Preparing the unit ......................................................................5

6.2 Attaching the suction hose support ...................................6

6.3 Connecting the handpiece to the unit ................................6

6.4 Inserting rotating instruments .............................................6

6.5 Connecting the foot switch ....................................................7

6.6 Connecting the power supply ...............................................8

6.7 Inserting the pad holder ..........................................................8

7 Operation - Instrument ............................................................8

7.1 Control panel ...............................................................................9

7.2 Memory Function .......................................................................9

7.3 Speed Control with the Foot Switch .................................10

7.4 Key lock touch display ...........................................................10

7.5 Replacing the dust bag ..........................................................10

7.6 Replacing the vacuum filter .................................................10

8 Operation - Handpiece ............................................................ 11

8.1 Changing the bits ..................................................................... 11

8.2 Disconnecting the handpiece from the motor unit .......... 12

8.3 Attaching the handpiece to the motor unit .................... 12

9 Cleaning, preparation and care ...........................................14

9.1 Cleaning and Disinfection - handpiece ...........................14

9.2 Cleaning and disinfection - device ....................................14

10 Maintenance ...............................................................................14

11 Accessories and spare parts ................................................ 15

12 Technical data ........................................................................... 15

13 Warranty ..................................................................................... 15

14 Disposal ....................................................................................... 15

15 Possible error messages ........................................................ 16

Annex 1 ................................................................................................... 17

Annex 2 .................................................................................................. 19

- 2 -

1 IMPORTANT INFORMATION BEFORE INITIAL OPERATION

The information for use is an integral part of the manicure and pedicure device and must be kept close by. If you pass the

manicure and pedicure device on to a third party, also pass on the information for use, as it contains important instructions

for starting up and operating the device.

In order to get to know the many advantages of the device and to ensure the safety of the device, it is absolutely necessary to

read this user information and the safety instructions contained therein carefully before using the device.

After unpacking, please check that the unit is complete according to the scope of delivery and that it has not been damaged

during transport. If there are any doubts, please contact your ProNails Distributor immediately.

1.1 SYMBOLS USED

Caution, Attention Important information.

This symbol indicates a danger to people or to the appliance.

Caution Mains voltage! Danger of electric shock.

References to additional information in the usage information.

Disposal note

1.2 GENERAL SAFETY INSTRUCTIONS

• Operate the device only if it is in perfect condition and only in the sense of its intended use.

• The user must apply and comply with all applicable directives and laws, as well as applicable national regulations, in

particular the applicable occupational health and safety regulations and accident prevention measures.

• Before using the device for the first time, check that the type of current and mains voltage of the power source match the

specifications on the type plate.

• Only connect the device to a suitable socket. The device may only be operated with the mains adapter supplied.

• If malfunctions occur, switch o the device immediately and disconnect it from the mains. In this case, contact your

ProNails Distributor.

• If the speed setting (touch display) or display elements show any damage or no longer function properly, the device must

no longer be used. Switch o the device immediately, disconnect the mains plug and contact your ProNails Distributor.

• If liquids or other foreign matter get into the interior of the device, the device must be switched o immediately and

disconnected from the power supply. Contact your ProNails Distributor before continuing to use the appliance.

• Unauthorised opening of the device or tampering with the handpiece is not permitted. Unauthorised opening of the device

or the handpiece will render the warranty invalid.

• The warranty also becomes invalid if the consumables specified in the information for use are not used, if the customer or

other unauthorised persons tamper with the device, if the device is used for purposes other than those for which it was

intended, if damage is caused by gross negligence or improper use.

• In the event of abnormal functioning of the VP800 appliance or the handpiece, discontinue use immediately and contact

your ProNails Distributor.

• All handpieces, micromotors and instruments are designed and constructed for their specific applications. Improper use

may result in damage to human tissues, premature wear, and destruction of the instruments and endangerment of the

customer, the user or third parties.

• Never operate the device without a dust bag or motor protection.

• Never operate the device without a bit If you are not working with the device always insert the dummy pin.

• Only use bits with a maximum head diameter of 13mm and a maximum head length of 25mm

• Only use bits with a pin length of 31.75mm and a pin diameter of 2.35mm

1.3 SCOPE OF DELIVERY

The scope of delivery includes:

1 Piece Device

1 Piece Handpiece with dummy pin

1 Piece Mains adapter

1 Piece Motor Filter

5 Pieces Dust bags

1 Piece Antenna holder for suction tube

1 Piece Cotton Pad holder

Optional scope of delivery:

Progressive Foot Pedal - for stepless speed control

- 3 -

1.4 PACKING

The packaging protects the appliance from damage during transport. The packaging is made of valuable materials that can

be recycled.

We recommend that you keep the packaging box and the padding inserts for return shipment in case of maintenance

or repair.

1.5 RECYCLING

If you want to dispose of the packaging, make sure that it is disposed of according to type. For this purpose, use the local

possibilities for collecting paper, cardboard and light packaging. Old appliances do not belong in household waste and must

be disposed of as electronic waste.

2 INTENDED USE

The Vision Pro 800 is intended for cosmetic applications in manicure and pedicure salon services.

The handpiece of the device can accommodate rotating instruments such as burs and abrasives. It is used in the following

areas and applications for dry technology:

• Grinding and milling of gel or acrylic nail enhancements

• Cleaning and polishing nails

• Removal of calluses

Use of the device in other areas and applications is at your own risk and can be potentially dangerous. Improper use can lead

to damage to persons and property.

• The manufacturer cannot be held responsible for damage caused by improper use or incorrect operation.

• In the event of improper use, opening or modification of the appliance, any claim under the warranty will be

invalidated.

2.1 AMBIENT CONDITIONS

Operation

Temperature range +10 to +35 °C

Relative humidity, non-condensing; no tropical protection 30 to 85 %

Air pressure 860 to 1060 mbar

Transport

Temperature range -10 to +50 °C

Relative humidity, non-condensing, no tropical protection 10 to 85 %

Air pressure 500 to 1060 mbar

Storage

Temperature range -10 to +50 °C

Relative humidity, non-condensing, no tropical protection 10 to 85 %

Air pressure 500 to 1060 mbar

Subject to technical changes.

• In the event of ambient conditions outside the permissible functional limits, the application must be interrupted

immediately and the device switched o.

2.2 STORAGE AND TRANSPORT

For proper storage of the product, please observe the storage conditions.

The device is to be stored or transported in the outer packaging (original carton).

- 4 -

3 VISION PRO 800

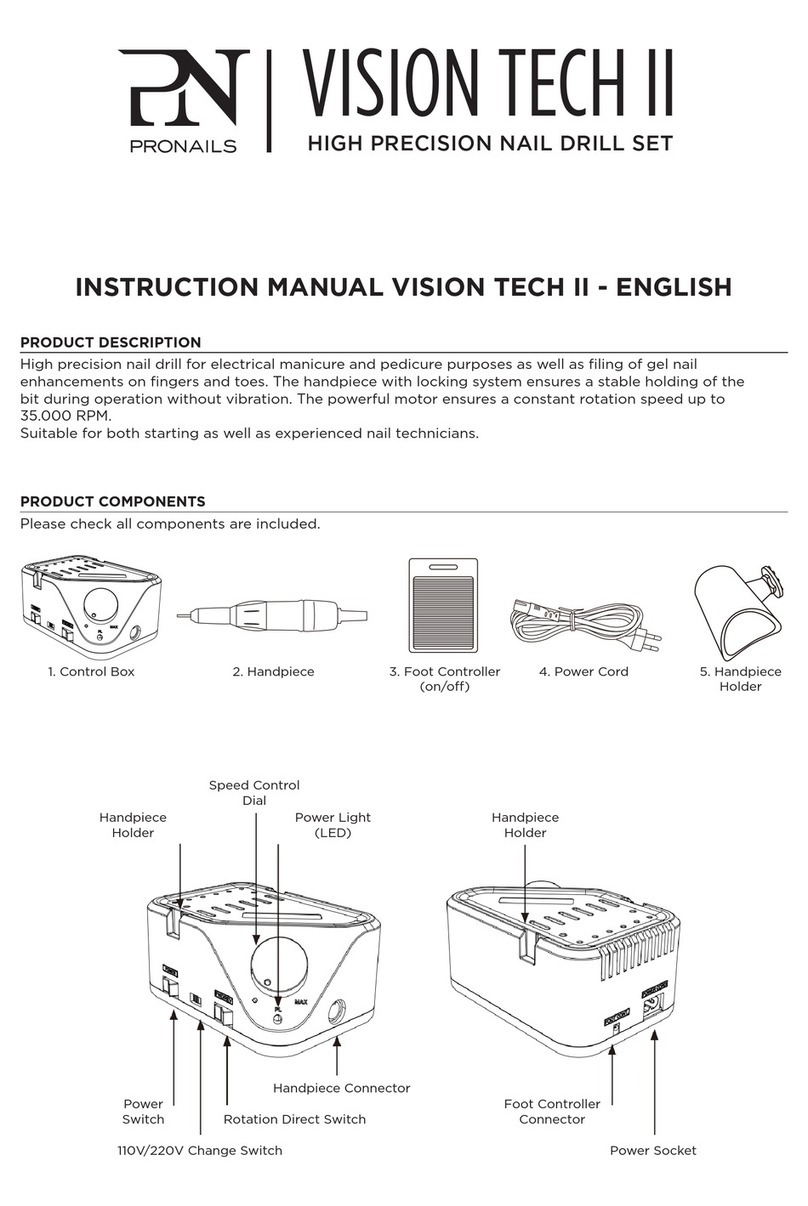

3.1 FRONT VIEW 3.2 REAR VIEW

4 HANDPIECE

Figure 3 – Handpiece Main components

01 Inner sleeve with clamping system

02 Outer Sleeve

03 Micro Motor

04 Suction hose

• Only rotary instruments with a cylindrical shaft diameter of 2.35mm may be used. Further information can be found

in DIN EN ISO 1797-1. In addition, observe the manufacturer’s instructions on the maximum speed, cleaning,

disinfection and sterilisation of the rotary instruments. See annex 1 for an overview of the ProNails approved bits with

rotation speed and direction.

Figure 1 – Front view

01 Device

02 Connection suction hose

03 Suction chamber cover

04 Cotton pad holder

05 Handpiece with suction hose

06 Handpiece holder

07 Bit holding positions

08 Support for suction hose

09 Touch display with controls

Figure 2 – Rear view

01 Main switch On/O

02 Connection - external mains adapter

03 Connection - Foot pedal

- 5 -

Figure 4 – Approved bit dimensions

Safety instructions for operating the handpiece

• Check the handpiece for vibration, noise and overheating before each use. If any irregularities occur, stop use immediately

and contact your ProNails Distributor.

• The user is responsible for regular maintenance and inspection of the handpiece.

• Improper use will lead to poor work results and risk of injury.

• Follow the manufacturer’s instructions for the handpiece.

• Do not use the handpiece while you want to change the direction of rotation. Wait until the direction of rotation has

changed before continuing to work.

• Instruments made of tool steel are susceptible to corrosion! Therefore, please use only cleaning and disinfecting agents

with corrosion protection for cleaning and disinfecting. Dry the instruments immediately after cleaning and disinfection.

• Do not subject the handpiece to mechanical shocks. Do not drop the handpiece, this can lead to a malfunction.

• Suction of liquids or air with a high liquid content (e.g. water mist) is not permitted and may damage the instrument.

• Do not operate the handpiece without a bit, as this may cause the handpiece to malfunction

5 CUSTOMER AND USER PROTECTION

For the protection of customers, users and third parties, the following points must be observed:

• Operate the device only if it is in perfect condition and only in the sense of its intended use.

• For your own safety, wear suitable personal protective equipment during use in accordance with applicable health and

safety regulations.

• Only operate the device when the motor filter and dust bag are inserted.

• Check the suction hose and the seal of the suction chamber for possible damage at regular intervals in order to detect a

possible reduction in suction power at an early stage and to avoid a possible increased dust load.

• During treatment, make sure that no loose objects (cloths, cotton wool, clothing, hair, jewellery, etc.) get into the treatment

field and can get caught in the rotating instruments.

• Clean the device after each use and before changing clients.

• Before or after a longer break in use, the device must also be cleaned and maintained.

• Have the prescribed service and maintenance work carried out regularly to ensure sustainable use and value retention.

6 START-UP

6.1 PREPARING THE DEVICE

Please first check the suitability of the premises at the place of use, especially with regard to power supply, evenness of the

installation surface, cleanliness of the room and climatic conditions - only when the premises are suitable, unpack the device.

Safety instructions for commissioning the device

• When using the device for the first time, please check the outer packaging of the device for possible external damage. If

transport damage is detected, contact your local ProNAils Distributor and clarify the further procedure.

• Make sure that the device is operated on a suitable stable level surface and cannot tip over or fall down.

• Make sure that the ventilation slots on the housing are not covered and remain unobstructed.

• The device must be positioned in such a way that, in the event of a malfunction, it can be easily disconnected from the

mains supply by pulling out the mains plug.

• Heat sources such as direct sunlight and radiators in the immediate vicinity of the device can have a negative eect on

cooling. For this reason, the device should not be set up near sources of heat.

• The device is not intended for operation in potentially explosive atmospheres or in wet rooms.

- 6 -

6.2 ATTACHMENT OF THE SUCTION HOSE SUPPORT

To attach the suction hose support, proceed as follows:

Step 1 Step 2

Insert the suction hose support on the upper side Turn the suction hose support clockwise as far as it will go

of the housing in the hole provided for it. into the thread of the handpiece holder below it.

Do not apply force.

Figure 5 - Attachment of the suction hose support

6.3 CONNECTING THE HANDPIECE TO THE DEVICE

To connect the handpiece, proceed as follows:

(1) Remove the safety notice from the suction chamber.

(2) Before connecting the handpiece, first push the dust bag included in the scope of delivery onto the pipe socket as far as

it will go.

(3) Carefully slide the pushed-on dust bag with the suction chamber cover into the suction chamber of the appliance and

connect the gliding pins with the contact sockets on the suc-tion chamber of the appliance.

• Please make sure that you insert the handpiece connector straight into the contact sockets when plugging it in and

do not tilt it.

6.4 INSERTING ROTARY INSTRUMENTS

To insert the rotary instruments, proceed as follows:

1. Make sure the micromotor is switched o before inserting the rotary instrument.

2. To be able to remove the dummy pin, turn the handpiece in the “OPEN” direction -

until the straight marking on the outer sleeve coincides with the triangular marking as

follows.

3. Remove the dummy pin from the chuck.

4. Now insert your selected working bit as deep as possible into the chuck until the end

stop can be felt.

5. To lock the bit firmly in place again, by turning the handpiece towards the “LOCK”

position - until the two straight markings coincide.

OPEN

LOCK

- 7 -

6. Check the tight fit of the instrument so that it cannot come loose during treatment.

7. The handpiece with the newly inserted bit is now ready for use.

Figure 6 - Locking & unlocking of bits

• Never change or insert rotating instruments until the micromotor has come to a complete stop.

• Do NOT lock the bit half-way! Always make sure the horizontal locking lines are fully aligned.

If the handpiece is operated while the bit is not fully locked then the bit will not turn and the

handpiece will overheat.

To check the concentricity of the rotating instruments, we recommend using a cutter

check gauge (see accessories).

6.5 CONNECTING THE PROGRESSIVE FOOT PEDAL

1. Make sure your device is turned o at the back of the

unit (green switch must be on “0”).

2. Insert the plug of the foot control into the

socket on the rear panel of the device before

operating the device. The socket of the foot

control is marked with the following symbol.

Make sure that the two arrows marked on

the connection plug are facing upward.

3. Now turn on your VP800 at the back of the device by

pressing the green switch to position “I”.

4. On the touch screen set both the maximum rotation

speed at as well as the suction power that you wish to

work at.

5. You can now work with the foot pedal without having

to touch the screen further. The harder you press on the

foot pedal, the higher the rotation speed will be until

you reach the maximum rotation speed which you have

set. You can decrease the rotation speed by lowering

the pressure on the foot pedal and stop it completely

by removing your foot from the foot swich.

• Please note that you may only connect or disconnect the handpiece to the suction chamber or the foot control to

the device when the main switch on the back of the device is in the OFF position.

OPEN

LOCK

WRONG

Figure 7 - Connection of foot pedal

- 8 -

6.6 CONNECTING THE MAINS ADAPTER

• In Europe, a mains voltage of 230V, 50Hz is used. Before switching on the appliance, please make sure that the

information on the type plate of the mains adapter corresponds to this value.

To connect the mains adapter, proceed as follows:

(1) Connect the supplied mains adapter to the mains socket on the back of the device (see figure 2).

The socket of the mains adapter is marked with the following symbol.

(2) Plug the mains adapter into a suitable socket.

• Only use the mains adapter included in the scope of delivery. Do not use the mains adapter if it is visibly damaged.

6.7 INSERTING THE COTTON PAD HOLDER

To insert the cotton pad holder, proceed as follows:

1. Insert the equipped pad holder from the rear into the slot on the side of the enclosure.

2. Position the hole of the pad holder over the fastening element on the bottom of the housing and lower the pad holder onto

the bottom of the housing.

3. So that the pad holder is fixed underneath the fastening element, now push it forward as far as it will go.

Figure 8 - Installing the cotton pad holder

7 OPERATION - DEVICE

Safety instructions for operation and handling of the device

• Check the mains adapter for damage at regular intervals. Under no circumstances should the device be operated with

a damaged mains adapter due to crushing, kinking, chafing or other influences. If you notice any damage to the mains

adapter, stop your work immediately, turn o the main switch of the device and disconnect the mains adapter from

the socket. First arrange for a replacement mains adapter before continuing your work or contact your local ProNails

Distributor.

• Check the dust bag level every 10 hours of operation. Replace a full dust bag immediately. After a set of 5 dust bags has

been used up, the motor filter must also be replaced.

• If the ambient conditions are outside the permissible operating limits, interrupt the manicure or pedicure service

immediately and switch o the appliance.

• Sucient ventilation of the appliance is necessary to prevent too much heat from developing inside the appliance. For this

reason, the appliance should not be placed near sources of heat such as radiators.

• Make sure that no moisture or liquids get inside the device.

• Never pull the mains plug out of the socket with wet hands and do not pull on the mains cable to remove the mains plug

from the socket!

• For safety reasons, the appliance must not be left switched on when it is unattended. The main switch must always be

switched o in this case.

• Before each use of the device, the user must satisfy himself of its functional safety and proper condition.

• Keep the device out of the reach of children and unauthorised persons!

• According to the workplace ordinance, the electrical system of commercially used rooms must be checked regularly.

Annual safety inspection of the device according to VDE 0701 and VDE 0702 (repeat inspection).

• Make sure that the handpiece is switched o before placing it in the handpiece holder.

• Moisture in the device may cause dangerous leakage currents to be discharged, which may result in a malfunction of

the device and an electric shock! Therefore, do not work in rooms with high humidity and protect the device from any

kind of moisture.

24V DC

- 9 -

7.1 CONTROL PANEL

Figure 9 - Touch display

Nr. Symbol Function

01 Setting the rotation speed of the Micromotor Increase & decrease the speed of the micromotor by wiping

along the scale

02 Change rotation direction Changing the direction of rotation (right/left)

03 Adjustment of the Suction power Increase & decrease the suction power by wiping along the scale

04 Digital display of the suction power Display of the suction power in percent

05 Suction Switching the suction on and o

06 Warning dust bag Lights up when the dust bag is full

07 Memory function Selection of memory function M1, M2, M3

08 Warning notice Maintenance Lights up as soon as the operating hours for regular maintenance

have been reached

09 Rotation Switching the micromotor on and o

10 Digital display of the speed of the micromotor Display of the speed in steps of 1000 Rpm

• Do not use the handpiece if you want to change the direction of rotation. Wait until the direction of rotation has

changed before you continue working.

7.2 MEMORY FUNCTION

With the memory function, dierent speeds of the micromotor can be stored with the corresponding suction power. The

following settings are predefined at the factory. You can adjust these settings individually for yourself afterwards.

M1 M2 M3

Speed 6.000 RPM 15.000 RPM 10.000 RPM

Extraction capacity 99 % 99 % 99 %

Direction of rotation right right right

Changing the memory function

To change the values in the memory function, proceed as follows:

(1) Switch on the device.

(2) Set the desired combination of rotation speed, rotation direction and suction power.

(3)Press the desired memory location M1, M2 or M3 for three seconds. Your set combination is now stored at the selected

memory location.

- 10 -

7.3 SPEED REGULATION WITH THE FOOT CONTROL

A second way to control the speed of the micromotor is to use the foot control. The software automatically detects whether

a foot control is connected to the device or not. With the progressive foot control, you can increase or decrease the desired

speed steplessly.

7.4 KEY LOCK TOUCH DISPLAY

If you want to clean the touch display, you can lock it for 30 seconds. To activate the key lock, press the ON/OFF key of the

micromotor [09] for three seconds - then the touch display is locked for 30 seconds during which a 30 seconds count-down

will be displayed on the screen.

7.5 REPLACING THE DUST BAG

• Never operate the appliance without a dust bag. This can lead to increased exposure to dust that is harmful to health

and can permanently damage the appliance.

After 10 hours of operation, the user is informed when the dust bag needs to be replaced by the following

illuminated symbol:

Please now check the filling level of the dust bag and replace the dust bag if necessary.

Pressing the on/o button of the extractor for 3 seconds resets the hour counter to zero.

To change the dust bag, proceed as follows:

(1) Switch o the device before changing the dust bag.

(2) Carefully pull the suction chamber cover out of the suction chamber towards you by the handle element. Make sure that

the filled dust bag does not slip o.

(3)Hold the dust bag downwards and pull it carefully from the pipe socket so that no dust particles escape.

(4)Dispose of the dust bag properly.

(5)Check the opened suction chamber for possible dirt and remove it if necessary.

(6)Now slide a new dust bag onto the pipe socket as far as it will go.

(7) Then insert the pushed-on dust bag into the suction chamber of the device and connect the suction chamber cover via the

contact pins with the contact sockets on the suction chamber of the appliance.

(8)Switch the appliance on again - the appliance is now ready for use again.

• Always keep the extraction chamber clean.

• Check the level of the dust bag once a week.

• The dust bag must not be emptied or reused

• Make sure to use only original dust filters from the manufacturer. You can order new dust bags from your contract

partner under item number 33041.11..

7.6 REPLACING THE VACUUM FILTER

To ensure high suction power of the appliance and occupational safety with regard to dust exposure at the workplace, the

motor filter must be changed after consumption of a dust bag set (5 pieces of dust bags).

To change the engine filter, proceed as follows:

(1) Switch o the device before changing the motor filter.

(2) Carefully pull the suction chamber cover by the handle element towards you out of the suction chamber. Make sure that

the filled dust bag does not slip o the hose nozzle.

(3)Check the opened suction chamber for possible dirt and remove it if necessary.

(4)Remove the motor filter located on the back of the suction chamber.

(5)Dispose of the motor filter properly.

(6)Insert the new motor filter into the suction chamber.

(7) Then close the suction chamber again with the suction chamber cover. Make sure the dustbag is properly connected.

(8)The device is now ready for use again

• When closing the extraction chamber, make sure that the contact pins of the hose connector match the contact

bushes on the extraction chamber of the device and are not damaged by possible jamming.

- 11 -

8 OPERATION - HANDPIECE

8.1 CHANGING THE BITS

• Never change or insert rotating instruments until the micromotor has come to a complete stop.

To change the bits, proceed as follows:

1. Switch o the micromotor before inserting the bit.

2. To be able to remove the bit, turn the handpiece in the “OPEN” direction - until the

following markings coincide

3. Remove the bit from the chuck.

4. Now insert the new bit as deeply as possible into the chuck until the end stop can be

felt.

5. To lock the bit firmly in place again, turn the handpiece in the “LOCK” direction until

the following markings are aligned. Never loch half-way and always make sure you turn

into the fully locked position as shown.

6. Check that the instrument is firmly in place so that it cannot come loose during treatment.

7. The handpiece with the newly inserted bit is now ready for use.

Figure 10 - Changing bits

• To check the concentricity of the rotating instruments,

we recommend using a cutter check gauge (see accessories).

Safety instructions for the use of rotary instruments

• Do not touch rotating instruments, there is a risk of injury!

• Only use bits up to a maximum diameter of 6 mm.

• Only use bits with a stainless steel shank.

• Disinfectants and cleaning agents with corrosion protection must be used

for instruments that are not protected against corrosion.

• Avoid contact with H2O2 (hydrogen peroxide). Carbide instruments are attacked and damaged.

• Rotating instruments made of hard metal and non-rust-proof instruments can become corroded which is damaging to the

handpiece.

• Clamp bits as deeply as possible .

• Avoid jamming or levering when inserting bits, as this may increase the risk of breakage. Bring the instruments up to speed

before applying them to the skin or nail.

• Excessive contact pressure can cause damage to the skin or nail areas due to overheating.

• Adhering to the speed recommendations of the manufacturer for the respective instruments leads to the best working

results. Exceeding the maximum permissible speed of the instruments (burs and grinders) can damage or destroy the

instruments and/or the handpiece.

OPEN

LOCK

OPEN

LOCK

WRONG

- 12 -

• For the maximum permissible speed, please refer to annex 1

• For safety reasons, do not use oily, worn or defective instruments that do not run smoothly, as otherwise a firm fit in the

collet chuck of the handpiece cannot be guaranteed.

• Only insert dry instruments into the handpiece.

• Only rotary instruments with a cylindrical shaft diameter of 2.35mm may be used.

Further information can be found in DIN EN ISO 1797-1.

• The rotary instruments should be stored dry at room temperature, protected from the eects of sunlight, heat and

moisture.

• Rotating instruments should be stored in suitable stands, trays or other containers.

8.2 DISCONNECTING THE HANDPIECE FROM THE MOTOR UNIT

To disconnect the handpiece from the motor unit, proceed as follows:

(1) Turn the outer sleeve to the open position before removal and

remove any bit or dummy pin from the handpiece. The straight line

should be alligend with the triangle as shown.

(2) Remove the outer sleeve of the handpiece by pulling it straight -

do not twist or bend it.

(3)Now remove the inner sleeve from the motor unit by pulling it

straight o.

(4)The handpiece is now disconnected from the motor unit and can

be cleaned and/or disinfected.

Figure 11 - Disassembly of the handpiece

8.3 ATTACHING THE HANDPIECE TO THE MOTOR UNIT

To attach the handpiece to the motor unit, proceed as follows:

(1) Push the inner sleeve onto the motor unit and press both components together until you feel and hear the inner sleeve

click into place on the motor unit. Make sure to align the narrow opening at the narrow lip and the wider opening at the

wider lip as shown on the pictures.

Figure 12 - Reassembly of inner sleeve to the motor unit

3

2

1

OPEN

OPEN

- 13 -

Figure 13 - Alignment of the outer sleeve to the inner sleeve

(2) Now push the outer sleeve over the inner sleeve onto the motor unit, observing the inner alignment. If the handpiece was

in the OPEN (= unlocked) position before removing the outer sleeve, then it must be reassembles in the open/unlocked

position. This means that the vertical mark on the outer sleeve should also be alligend with the triangular marking on the

handpiece. Turn the outer sleeve to the correct alignment position until it can be pushed over the inner sleeve without

exerting force. The outer sleeve can only be pushed over the inner sleeve in one position without exerting force. Engage

the outer sleeve in the motor unit with slight pressure.

WRONG CORRECT

✔

Figure 14 - Reassembly of outer sleeve to the handpiece

OPEN

- 14 -

9 CLEANING, PREPARATION AND CARE

9.1 CLEANING AND DISINFECTION - HANDPIECE

• Do not use any solvent-based or aggressive cleaning agents. Observe the prescribed cleaning intervals!

• NEVER clean the handpiece in boiling water, with chemicals, wire brushes or ultrasound. NEVER place the handpiece

in disinfectant or ultrasonic baths. NEVER place or immerse the handpiece in liquid, otherwise the handpiece could be

damaged.

• Do not lubricate or oil the motor.

Process for the handpiece

1. Preparation

• Remove the bit from the handpiece.

• Disconnect the handpiece from the motor unit

• Collect all components to be reprocessed in an area exclusively for contaminated instruments

• Remove all particles and debris from the handpiece and, if necessary, disinfect the handpiece on all external surfaces with a

cloth soaked in disinfectant. We recommend water-based disinfectants.

• Do not use a wire brush!

2. Cleaning

• Clean the handpiece with ProNails Clinilotion and a disposable cloth or tissue.

• Do not use a wire brush!

3. Disinfection

• Manual disinfection is carried out with Clinilotion and a disposable tissue.

• Never place the handpiece in the ultrasonic unit.

• Do not use disinfectants that are strongly alkaline or contain chlorine. The pH value of these agents must be between 2.5

and 9. Pay attention to the exposure times specified by the manufacturer.

4. Sterilisation

• If necessary, the outer and inner sleeve of the handpiece can be sterilised in an autoclave up to a temperature of 135°C

maximum. Please observe the instructions for use of the autoclave.

• Take into account the applicable national hygiene regulations for the reprocessing of handpieces.

5. Storage

• Store the handpiece protected from dust, sunlight, moisture and temperature fluctuations.

9.2 CLEANING AND DISINFECTION - DEVICE

Clean the housing (incl. hose) with a cloth moistened with ProNails Clinilotion.

If you want to clean the touch display, you can lock it for 30 seconds. To activate the key lock, press the ON/OFF key of the

micromotor [09] for three seconds - then the touch display is locked for 30 seconds during which a 30 seconds count-down

will be displayed on the screen.

• Always switch o and unplug the appliance before cleaning - otherwise there is a risk of electric shock!

• Do not use alcoholic, solvent-based or aggressive cleaning agents.

10 MAINTENANCE

Have the prescribed service and maintenance work carried out regularly to ensure sustainable use and value retention.

Equipment and handpiece maintenance

Every 500 operating hours

After the required number of operating hours has been reached, the following symbol lights up in the touch

display as a maintenance notice.

To have maintenance carried out correctly by an authorised ProNails specialised technician.

• Maintenance and repair may only be carried out by authorised specialist personnel. Modifications and repairs by

unauthorised personnel will void any warranty and liability of the manufacturer.

• Safety checks must be carried out at least every 12 months: Visual inspection of the device and accessories,

functional test of the device.

• As the manufacturer, we can only consider ourselves responsible for the safety-related properties of the device

if maintenance and repairs are carried out by the manufacturer or a repair company expressly authorised by the

manufacturer to do so, the prescribed service intervals are observed and the device is used in accordance with the

instructions for use.

- 15 -

• A further prerequisite is that components which aect the safety of the device are only replaced with original parts.

• Use the original packaging to return the device for repair or maintenance purposes. For correct packaging instructions see

annex 2.

11 ACCESSORIES AND SPARE PARTS

ProNails authorised bits Find on our website www.pronails.com

Set of 5 dust bags with motor filter 90105

Progressive Foot Pedal 90104

Burr test gauge Contact your local distributor

ProNails Clinilotion Find on our website www.pronails.com

12 TECHNICAL DATA

Mechanical data

Dimension (HxWxD) 205 mm x 160 mm x 220 mm

Weight, including handpiece 2,5 kg

Electrical data

Rated voltage 110-230 V AC / 50/60 Hz

Power consumption 100 W

Protection class Class II

Operating data

Operating mode Continuous operation

Acoustic emission 49 dB (A)

Speed micromotors 5.000 – 30.000 Rpm

13 WARRANTY

The warranty is 1 year or a maximum of 500 operating hours, excluding consumables and wearing parts such as filter bags,

motor filters, sealing rings, ball bearings, etc.

The warranty is extended by a further 500 operating hours, but does not exceed the original 12 months in total, if the

recommended device maintenance has been carried out in good time. The manufacturer reserves the right to determine and

analyse the cause of any problems

The warranty expires

• if the liquids and consumables specified in the information for use are not used,

• if the customer or other unauthorised persons tamper with the device or handpiece,

• if the device is used for purposes other than intended,

• if damage is caused by gross negligence or improper use.

14 DISPOSAL

Please observe the following instructions for disposing of the device, as infectious materials such as tissue residues and

grinding dust residues may be present on the housing, attachment and accessory parts and filters.

• Appliances marked with this symbol must not be disposed of with household waste! You are legally obliged to

dispose of old appliances separately from household waste (European Directive 2012/19/EU). You can obtain further

information on the disposal of your appliance free of charge from your contract partner from whom you purchased

the appliance.

15 POSSIBLE ERROR MESSAGES

• In case of other problems or malfunctions, please contact your contract partner or the manufacturer. Have repairs

carried out by authorised specialists only.

Malfunction

Bit does not rotate

Weak suction power

Device does not work,

No display on the

Front panel

Possible cause

• Is the device switched on?

• The handpiece is not fully/properly

locked.

• Defect on cable or motor.

• The dust bag is full.

• Is the device switched on?

• Is the mains cable not plugged in

correctly?

• Socket has no mains voltage.

Measures

• Check that the main switch is turned on.

• Reopen the handpiece and then reclose.

Make sure to turn the outer sleeve to the

end position to align the marking of the

sleeve with the closed marking line on the

micromotor part (rose) of the handpiece.

• Contact your ProNails distributor

• Change dust bag.

• Check that the mains switch is turned on.

• Check that the mains plug is correctly

plugged in.

• Check the function of the socket.

Professionails NV/SA, Ruiterijschool 11, B-2930 Brasschaat, Belgium - Tel +32 (0)3 669 61 67 - Fax +32 (0)3 669 93 27 - WWW.PRONAILS.COM

USE ONLY THE FOLLOWING APPROVED BITS

AT THE CORRECT ROTATION SPEED

ELECTRIC FILING

MANICURE BITS

10.000 RPM 15.000 RPM

Tungsten Trimmer Bit - MIN 6.000 - MAX 15.000 RPM - ref. 29487

R

10.000 RPM 15.000 RPM

Diamond Grinder Bit - MIN 6.000 - MAX 30.000 RPM - ref. 29486

L+R

10.000 RPM 15.000 RPM

Diamond Ball Bit - MIN 6.000 - MAX 30.000 RPM - ref. 29485

L+R

High Precision Drill Purple - ref. 28308

L+R

Ceramic Round Barrel Bit Medium Extra Long - ref. 24337

L+R

Ceramic Flame Bit Medium – ref. 29271

L+R

6.000 RPM

Finisher Bit - MIN 6.000 - MAX 30.000 RPM - ref. 29484

L+R

10.000 RPM 15.000 RPM

NATURAL NAIL PREPARATION

CLEANING UNDER NAIL

White Quartz Sanders Fine ref.28653

Rubber Tip for Sanders - ref. 27117

Diamond Nail Prepper Cone - ref. 28564

6.000 RPM

MIN 6.000 - MAX 30.000 RPM

Sander Fine 6.000 RPM Single Use

6.000 RPM

MIN 6.000 - MAX 30.000 RPM

L+R

L+R

HIGH PRECISION DRILLS

MIN 6.000 - MAX 15.000 RPM

CERAMIC BITS

MIN 6.000 - MAX 15.000 RPM

BABY MANICURE BITS

HARD BUILDERS & 3IN1 MASTER & ONE

6.000 RPM

Cuticle clean Bit - MIN 3.000 - MAX 6.000 RPM - ref. 29259

L+R

High Precision Drill Blue - ref. 28306

R

FLEXI BUILDERS

REMOVE GEL

DEPENDING ON THE BUILDER GEL YOU HAVE TO REMOVE

Flexi Builder

(Clear - Pink -

Frosted Pink)

White Quartz Sanders

Medium ref. 28655 - Rough ref. 28657

10.000 RPM 2.0000 RPM

VP800 MANUAL - ANNEX 1

- 18 -

USE ONLY THE FOLLOWING APPROVED BITS

AT THE CORRECT ROTATION SPEED

ELECTRIC FILING

PEDICURE BITS

10.000 RPM

Diamond Pedicure Callus bit - ref. 29722

R

15.000 RPM

Silicon Pedicure Polisher bit - ref. 29723

L+R

CLEANING BITS

Cleaning brush for bits - ref. 29724

CALLUS REMOVER

10.000 RPM

Ceramic Pedicure Callus bit - ref. 29721

L+R

BABY PEDICURE BITS

6.000 RPM

Cuticle clean Bit - MIN 3.000 - MAX 6.000 RPM - ref. 29259

L+R

10.000 RPM 15.000 RPM

Tungsten Trimmer Bit - MIN 6.000 - MAX 15.000 RPM - ref. 29487

R

10.000 RPM 15.000 RPM

Diamond Grinder Bit - MIN 6.000 - MAX 30.000 RPM - ref. 29486

L+R

10.000 RPM 15.000 RPM

Diamond Ball Bit - MIN 6.000 - MAX 30.000 RPM - ref. 29485

L+R

6.000 RPM

Finisher Bit - MIN 6.000 - MAX 30.000 RPM - ref. 29484

L+R

NEW

NEW

NEW

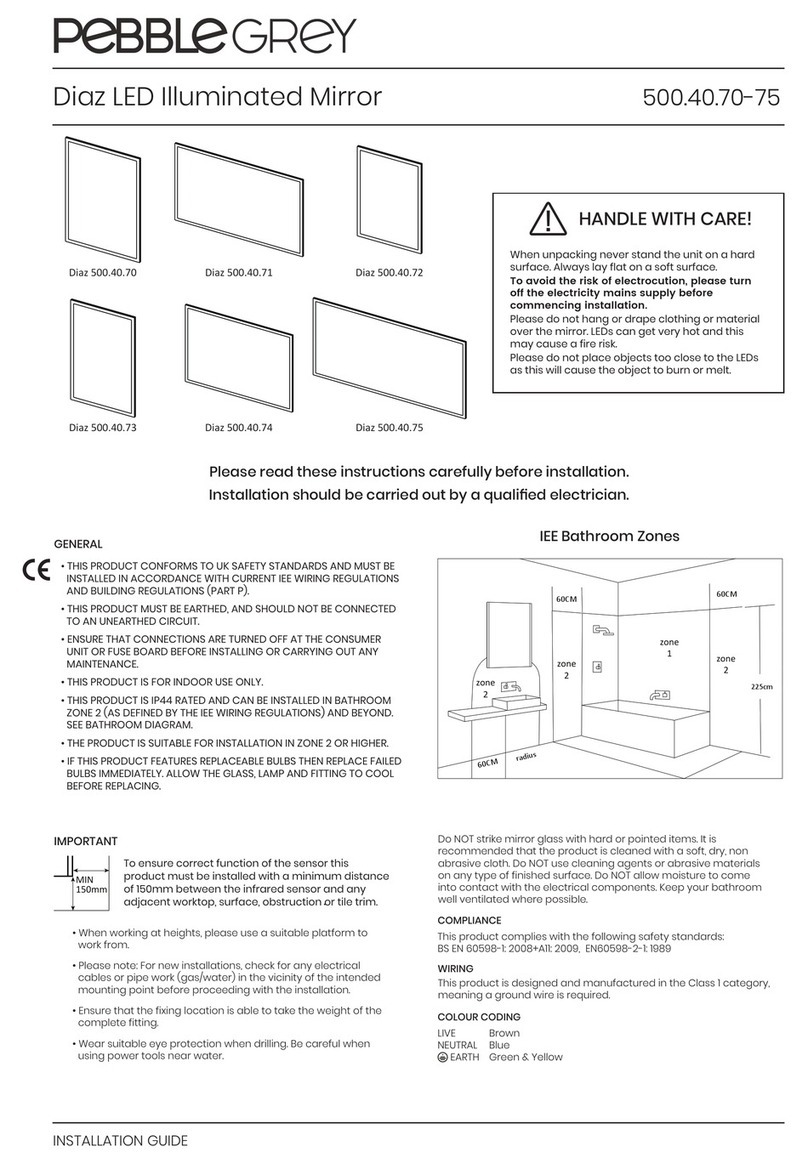

PACKAGING INTRUCTIONS

FOR MAINTENANCE OR REPAIR OF

VISION PRO 800

STEP 1

• Remove the dust bag and dispose of in waste

container

STEP 2

• Disconnect power supply and foot pedal and

remove all accessories such as cotton pads, bits,

suction tube and antenna.

• Wrap the device in plastic bag supplied with

delivery.

STEP 3

• Place the support base at the bottom of the box

with the corners folded downward and the plastic

surface on top as shown

STEP 4

• Place the device upright on top of the plastic

support foil with the bit holes facing upwards.

• Wrap the power supply and place next to the

device as shown.

STEP 5

• Protect the handpiece with the isolation foam and

wrap the connection part of the vacuum chamber

with bubble foil.

• Carefully place the handpiece in the box around

the device as shown

STEP 6

• Place the top protection frame with the plastic

foil facing the device and the folded edges facing

upwards.

• Place the power plug connection on top of the

frame as well as the wrapped antenna.

STEP 7

• Tape the box closed.

USE THE ORIGINAL BOX OF YOUR VP800 FOR RETURNS

1

3

5

7

2

4

6

Professionails NV/SA, Ruiterijschool 11, B-2930 Brasschaat, Belgium

Tel +32 (0)3 669 61 67 - Fax +32 (0)3 669 93 27 - WWW.PRONAILS.COM

VP800 MANUAL - ANNEX 2

Table of contents

Other PRONAILS Personal Care Product manuals