Pronomic 90P User manual

Parts for Stationary

lifter

(90P/125P130P/175P/

225P)

Original instructions

It is important that you read and understand the manual before assembly.

Do you have any questions? –Please contact the distributor or the manufacturer.

Pronomic AB

Visiting address:

Domherrevägen 15

192 55 Sollentuna

Sweden

Postal address:

Box 5504

192 05 Sollentuna

Sweden

Phone: +46 8-544 706 60

Fax: +46 8-544 706 70

E-mail: info@pronomic.se

www.pronomic.se

R150415

Contents

1Description of the parts......................................................................................................1

1.1 Warranty...................................................................................................................................... 1

1.2 Components ................................................................................................................................ 1

2Assembly............................................................................................................................ 3

2.1 Disassembly and scrapping ......................................................................................................... 4

3Using the Stationary lifter ..................................................................................................5

3.1 Remote control............................................................................................................................ 5

3.2 Power pack .................................................................................................................................. 5

4Safety and Limitations........................................................................................................5

4.1 Limitations ................................................................................................................................... 5

4.2 Storage and transport ................................................................................................................. 6

4.3 Loading and unloading ................................................................................................................ 6

5Maintenance ......................................................................................................................7

5.1 Every day ..................................................................................................................................... 7

5.1.1 General ............................................................................................................................................. 7

5.2 Every year, or when needed........................................................................................................ 7

5.2.1 Cleaning ............................................................................................................................................ 7

5.2.2 Electrical connections....................................................................................................................... 7

5.2.3 Wear of machine parts..................................................................................................................... 7

5.2.4 Nuts and bolts................................................................................................................................... 7

5.2.5 Lift column........................................................................................................................................ 7

5.3 Trouble shooting.......................................................................................................................... 9

6Technical specifications......................................................................................................9

7Load diagram ................................................................................................................... 10

7.1 90P Setup................................................................................................................................... 10

7.2 125P Setup................................................................................................................................. 11

7.3 130P Setup................................................................................................................................. 12

7.4 175P Setup................................................................................................................................. 13

7.5 225P Setup................................................................................................................................. 14

DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY .............................. 15

INSTALLATION..........................................................................................................................16

________________________________________________________________________________

1 –Stationary lifter (90/125/130/175/225P)

1Description of the stationary lifter

The parts for the stationary lifter includes the lift column, cross-member with motor, power pack

converting 230V or 115V AC to 24V DC and a remote control.

The stationary lifter can be equipped with different types of load carriers, such as load platform,

prong, fork, squeeze tool, turn unit or customized solutions. The goods are placed on the load

carrier, and by pressing the buttons on the remote control the load carrier is adjusted to the

desired height.

The stationary lifter is only to be used indoors in well-lit environments on level surfaces.

Additional technical documentation can be ordered from Pronomic.

1.1 Warranty

The warranty is valid for one (1) year from the date of delivery for defects in material and

manufacturing. For the warranty to be valid maintenance must have been carried out in

accordance with this manual. The warranty does not cover normal maintenance, settings,

adjustments or associated labour costs. Damage due to misuse or incorrect use of the equipment

will void the warranty.

1.2 Components

The stationary lifter consists of a number of modules. The locations of these are shown in the

image on the next page. Please contact Pronomic for information regarding part numbers.

Column

Remote control

Cross-member

Load carrier

Power pack

The appearance of the components may differ from the image.

________________________________________________________________________________

2 –Stationary lifter (90/125/130/175/225P)

1

2

4

3

5

________________________________________________________________________________

3 –Stationary lifter (90/125/130/175/225P)

2Assembly

Protective footwear should be used when assembling the stationary lifter, to prevent injuries if

parts are dropped.

It is important that the modules are installed according to this specifications.

Confirm the design of the structure that the stationary lifter is mounted to. Consider the load

diagrams starting on page 10.

1. In position A in the picture above. Mount the cross-member to the structure using 8 M8

bolts grade 8.8. At least 30mm of thread is needed inside of the cross-member. Do not

tighten to hard, use 15 Nm.

2. In position B in the picture above. Screw bars should be positioned with the lowest screw at

least 245mm from the bottom end of the column. For 90/125/130P the distance should be

at least 145mm from bottom end of the column. The screw bars should be fastened with 4

M8 nyloc nuts against the structure (2 nuts for 90/125/130P). Do not tighten to hard, use 15

Nm.

3. Position the power pack in such a way that the main switch can be reached. Make sure the

power cable does not enter the path of the load carrier. Make sure the power pack is well

protected against external damage.

4. Attach the load carrier with the supplied screws and washers in the slide of the column.

________________________________________________________________________________

4 –Stationary lifter (90/125/130/175/225P)

5. Connect the power cable from cross-member to power pack. Connect the remote control if

needed.

6. Connect the power pack to main power

7. Perform a static load test, with 1.25 x the maximum load.

(Move the load carrier to the middle of the column and apply the load.)

8. The stationary lifter is now read for use.

2.1 Disassembly and scrapping

To disassemble the stationary lifter, follow the instructions in section Assembly, but in reverse

order.

When the stationary lifter is due for scrapping the machine should be handed in to a recycling

centre or Pronomic to ensure reuse and safe handling of all parts.

________________________________________________________________________________

5 –Stationary lifter (90/125/130/175/225P)

3Using the Stationary lifter

If the load is left on the stationary lifter for some time it may be necessary to lower the load

before it can be raised.

3.1 Remote control

The load carrier is raised and lowered by pressing the buttons on the remote control. The remote

control has either two or four buttons and is used as shown below.

The remote control should be placed to allow the user to easily press the buttons.

3.2 Power pack

Modifying the power pack is dangerous. It should not be exposed to splashed or running water.

Turn of the power pack when not in use.

4Safety and Limitations

Use the protective equipment (e.g. protective footwear) required to handle the goods.

The stated maximum load may not be exceeded.

The stationary lifter must not be used for lifting people.

Note the crush hazard between the load carrier and fixed objects or floor when raising and

lowering the load carrier. Do not keep hands or other body parts under the load.

4.1 Limitations

The column and slide is not designed to withstand horizontal force such as impacts with loads

exceeding the loads presented in the load diagram in this manual. Make sure the equipment is

protected especially from impacts far out on the load carrier.

Up/down

Slowly up/down

Up/down

________________________________________________________________________________

6 –Stationary lifter (90/125/130/175/225P)

4.2 Storage and transport

During storage and transport the remote control and motor cable should be disconnected.

The parts should be secured during transport to avoid the risk of damage.

4.3 Loading and unloading

The user is responsible for ensuring that the stationary lifter is loaded correctly.

The centre of gravity of the goods should always be centred on the load carrier and as close to the

column as possible, for maximum stability.

The load carrier should be positioned at the correct height before loading/unloading. To allow a

good working position the load should be pushed or pulled off and on the load carrier.

________________________________________________________________________________

7 –Stationary lifter (90/125/130/175/225P)

5Maintenance

In order for the stationary lifter to function properly it is important that maintenance is carried out

in accordance with what is described below. The stated service intervals are applicable during

normal use. Normal use is set to 150 lift actions per day(24h) or 1 lift action every third minute

during 8h.

Further use requires more frequent service intervals. This does not apply to chapter 5.1 but

effects the interval under chapter 5.2. For example: Using the stationary lifter for 300 lift actions

per day will shorten the interval from every year to every six month.

Only spare parts supplied or approved by Pronomic may be used.

After disassembly/assembly of the column or load carrier a load test should be performed, see

section Assembly.

5.1 Every day

5.1.1 General

Keep the lifter clean and avoid dirt or fluids from reaching past brushes to lift screw and slide.

5.2 Every year, or when needed

5.2.1 Cleaning

Clean the lifter using detergent suitable for painted surfaces, aluminium and stainless steel. Follow

the instructions on the detergent. Wipe the lifter dry after cleaning. Do not use hose or high-

pressure jet as this may damage the electronics and the paint.

5.2.2 Electrical connections

Check all connections and repair any damage or wear. If needed, replace with new parts.

5.2.3 Wear of machine parts

Check the parts of the machine in order to identify any cracking or wear.

5.2.4 Nuts and bolts

Make sure all nuts and bolts are tightened.

5.2.5 Lift column

Lift the column from the cross-member.

Clean the brush stripes and wipe the column clean.

Remove the four corner screws at the top of the column. (Not the three in the middle)

Pull out, wipe and lubricate the lift screw with new ball bearing grease.

________________________________________________________________________________

8 –Stationary lifter (90/125/130/175/225P)

Put the lift screw back and tighten the screws.

Check the coupling, by making sure the sleeve and the hub located inside the column and inside

the cross-member are intact and in working order.

Put the lift column back and perform load test, see section Assembly.

________________________________________________________________________________

9 –Stationary lifter (90/125/130/175/225P)

5.3 Trouble shooting

The stationary lifter is designed for safe and efficient operation, provided that routine

maintenance is carried out in accordance with the instructions given. If problems arise, some

guidance is provided below. If the problem persists after action has been taken –Please contact

service technician or Pronomic.

If the load carrier does not move at all, or very slowly:

•Verify that the maximum load is not exceeded.

•Check the AC/DC converter.

If the lift trolley sounds strange:

•Make sure the stationary lifter is correctly assembled, see section Assembly.

•See section Maintenance.

6Technical specifications

Model

90P

125P

130P

175P

225P

Max-load

90kg

125kg

130kg

175kg

225kg

Voltage

24 V DC

Main voltage

230 V AC 50 Hz or 115 V AC 60 Hz

Noise

The noise level does not exceed 70 dB(A)

Vibration

Vibrations do not exceed 2.5 m/s2

Test factor for static testing

1.25

________________________________________________________________________________

10 –Stationary lifter (90/125/130/175/225P)

7Load diagram

7.1 90P Setup

________________________________________________________________________________

11 –Stationary lifter (90/125/130/175/225P)

7.2 125P Setup

________________________________________________________________________________

12 –Stationary lifter (90/125/130/175/225P)

7.3 130P Setup

________________________________________________________________________________

13 –Stationary lifter (90/125/130/175/225P)

7.4 175P Setup

________________________________________________________________________________

14 –Stationary lifter (90/125/130/175/225P)

7.5 225P Setup

________________________________________________________________________________

15 –Stationary lifter (90/125/130/175/225P)

DECLARATION OF INCORPORATION OF PARTLY COMPLETED MACHINERY

Manufacturer

Pronomic AB

Box 5504

192 05 Sollentuna

Sweden

Model

Parts for stationary lifter 90P 125P 130P 175P 225P

Serial number

Static load test

Applied EC directives:

2006/42/EC

Machinery Directive

2004/108/EC

EMC Directive

Applied standards:

EN ISO 12100-1:2010

Safety of machinery –General principles for design. Risk assessment and risk

reduction

SS-EN 349+A1:2008

Safety of machinery - Minimum gaps to avoid crushing of parts of the human body

We hereby declare that the above-referenced partly completed machine, installed and maintained after

instructions provided in this manual, is in conformity with stated directives and standards.

The partly completed machinery must not be put into service until the final machinery into which it is to

be incorporated has been declared in conformity with the provisions of this Directive.

Sollentuna, 2015-01-20

…………………………………………………………

Joakim Stannow, PRONOMIC AB

______________________________________________________________________________

The partly completed machine has been modified and/or equipped with attachments as follows:

……………………………………………………………………………………………………………………………………………………………………….…….

……………………………………………………………………………………………………………………………………………………………………….…….

After modification a supplementary risk analysis has been performed and the partly completed machine is

certified to be in conformity with the directives and standards above.

…………………………………………………………………………………………

Place, date

…………………………………………………………………………………………

Name

…………………………………………………………………………

Company

________________________________________________________________________________

16 –Stationary lifter (90/125/130/175/225P)

INSTALLATION

PRONOMIC AB is not responsible for installation of the partly completed machine.

The partly completed machine has been installed according to the instructions in this manual and

the safety and limitations has been considered.

………………………………………

Place, date

…………………………………………………………….. ……………………………………………

Name Company

________________________________________________________________________________

17 –Stationary lifter (90/125/130/175/225P)

This manual suits for next models

4

Table of contents

Other Pronomic Lifting System manuals

Popular Lifting System manuals by other brands

REID LIFTING

REID LIFTING PORTA-DAVIT 500 Series Assembly & operation

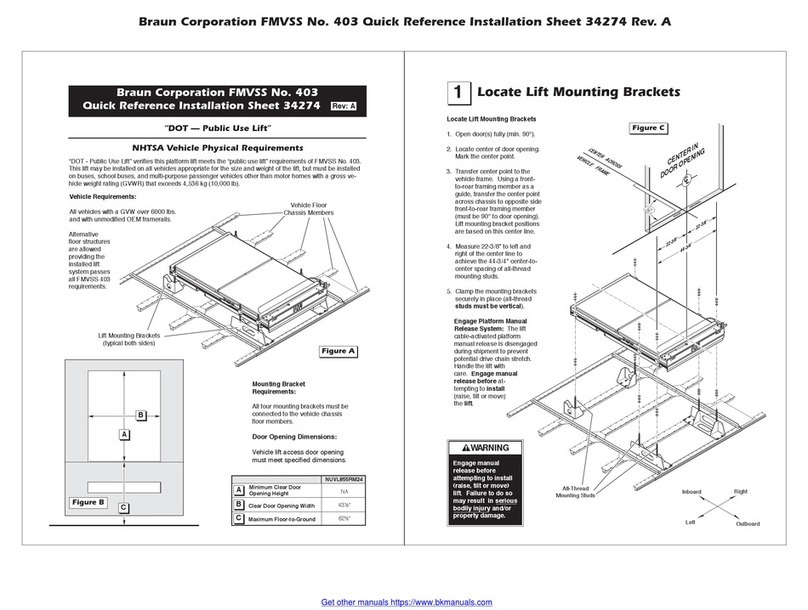

Braun

Braun FMVSS 403 quick reference

Black Widow

Black Widow BW-1500AO-V2 installation manual

SCANCLIMBER

SCANCLIMBER SC500K instruction manual

APlusLift

APlusLift MT1500 Installation manual & operation instructions

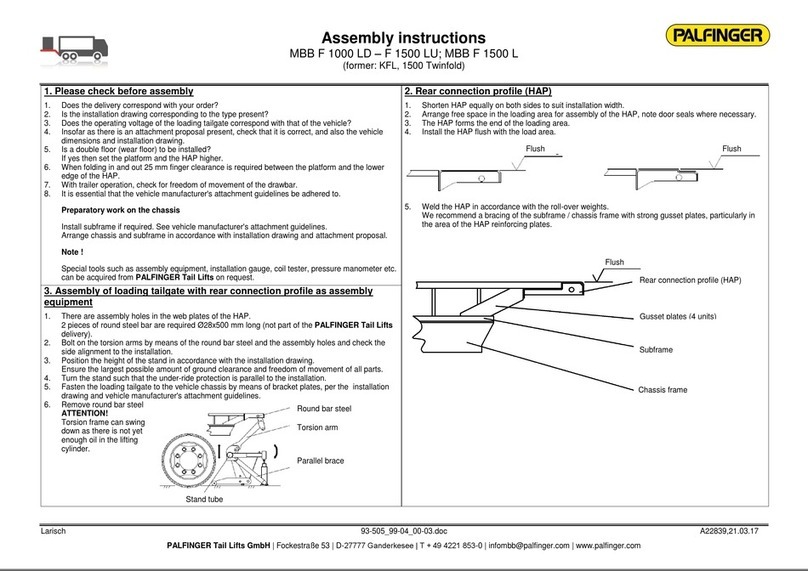

Palfinger

Palfinger MBB F 1000 LD Assembly instructions