Proportion-Air ISQB1 Installation and operating instructions

1ISQB1 Installation Guide - 2/13/2015 | SSS

DESCRIPTION / IDENTIFICATION

The ISQB1 series control valve is an electronic

pressure regulator designed to precisely and

proportionally control the pressure of gaseous media

based on an electronic control signal.

The ISQB1 operates using two normally closed

solenoid valves, a pressure sensor, and a control

circuit. One valve is actuated to allow supply media

into the system. The second valve is actuated to allow

working media to vent through a threaded port to

atmosphere. The pressure sensor provides feedback

to the control circuit. The control circuit compares the

pressure sensor feedback to the user supplied

electronic command signal and actuates the

appropriate valve until the two signals match.

The ISQB1 series can be teamed with a variety of air

piloted pressure volume boosters for even greater

flow.

† Pressure ranges are customer specified. Output pressures other

than 100% are available.

ELECTRICAL

SUPPLY VOLTAGE 13.9 to 29 VDC (MAX)

SUPPLY CURRENT < 80 mA

COMMAND SIGNAL 4-20 mA Differential

COMMAND SIGNAL IMPEDANCE Current=100 Ω

MECHANICAL

PRESSURE RANGES Full Vacuum - 150 psig

(29.9 in. HG (Vac) - 10.3 Bar)

OUTPUT PRESSURE† 0-100% of range

FLOW RATE 0.80 SCFM @ 80 PSIG

(23 L/min @ 5.52 Bar)

Min CLOSED END VOLUME 1 in3

PORT SIZE 1/8” NPT

FILTRATION RECOMMENDED 20 Micron (included)

LINEARITY/HYSTERESIS <±0.15% F.S. BFSL

REPEATABILITY <±0.02% F.S.

ACCURACY <±0.2% F.S.

PHYSICAL

OPERATING TEMERPATURE 32-104°F (0-40°C) (T4)

WEIGHT 2.5 lbs. (1.1 Kg)

PROTECTION RATING NEMA 4

HOUSING Blue Anodized Aluminum

SPECIFICATIONS

HAZARDOUS AREA CLASSIFICATION

The ISQB is rated Intrinsically Safe and is

Factory Mutual approved for Class I, II &

III, Division 1, Groups C, D, E, F & G

Entity Parameters:

V Max = 29 VDC

I Max = 150 MA

Ci = 0.26uF

Li = 0

Field Wiring Drawing: ISQB-96026-2

NOTES: End user must determine fitness and

suitability of the ISQB1 control valve for their application.

The ISQB requires the use of Intrinsically Safe Barriers.

PROPORTION-AIR, INC.

8250 N. 600 West

McCordsville, IN 46055

877.331.1738

WETTED MATERIALS

PARAMTERS Port 1 (Pressure Port) Port 2 (Reference Port)

COVERS High Temperature Polyamide High Temperature Polyamide

SUBSTRATE Alumina Ceramic Alumina Ceramic

ADHESIVES Epoxy, RTV Epoxy, RTV

ELECTRONIC COMPONENTS Ceramic, Silicon Silicon, Glass, Gold, Solder

INSTALLATION & MAINTENANCE INSTRUCTIONS

2ISQB1 Installation Guide - 2/13/2015 | SSS

Electrical Connections:

1. All intrinsically safe installation must conform to

applicable Factory Mutual Code recommendations

and the National Electric Code, as well as any

applicable local codes or Fire Marshal directives. All

intrinsically safe installations must be performed by

personnel trained in the proper application of the

above.

2. Ensure all power is off before making any electrical

connections.

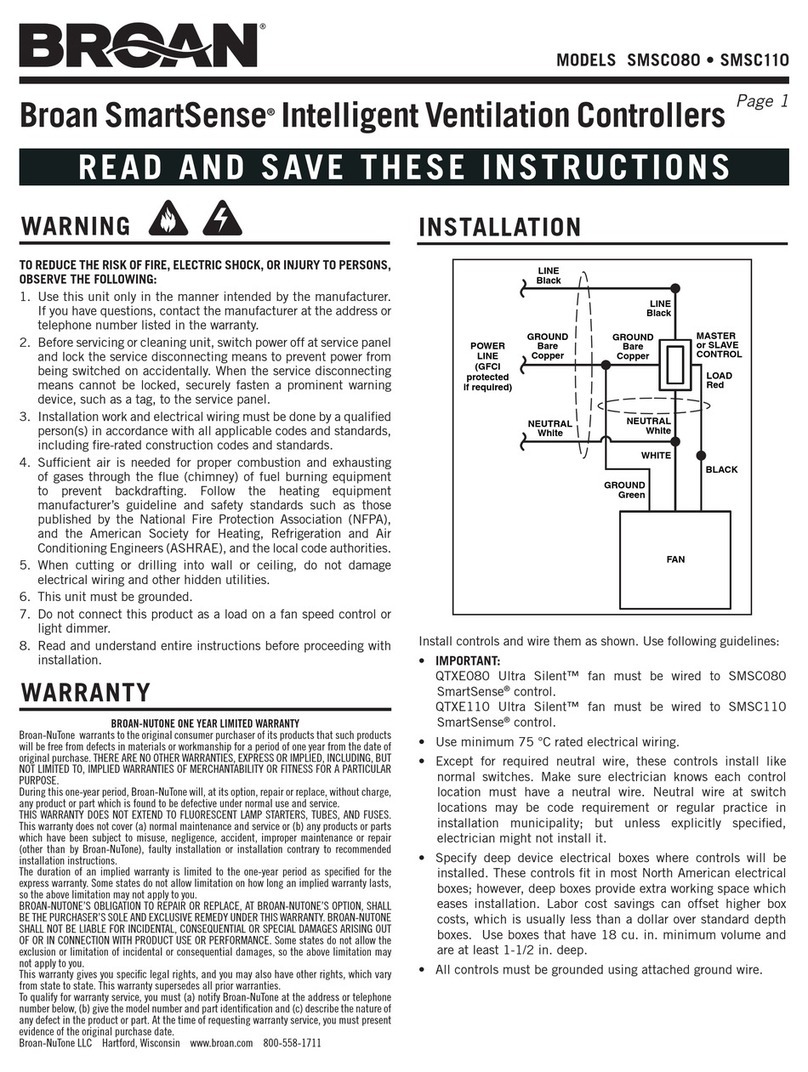

3. Figure 1 shows the location of the ISQB1 electrical

connector and figure 2 shows the connector. Table 2

identifies each connection

4. Must be wired in accordance with the supplied field

wiring drawing.

TABLE 2

ISQB1 PIN DESIGNATORS

PIN FUNCTION

1DC COMMON

2COMMAND (-)

3 NC

4COMMAND (+)

5NC

6POWER

Pneumatic Connections:

1. A typical 20 micron (minimum 40 micron) in-line filter

is recommended on the inlet of the ISQB1.

2. Connect supply pressure to the “IN” INLET PORT

(figure 1). See Table 1 for maximum supply

pressure.

3. Connect the “OUT” OUTLET PORT (figure 1) to the

device being controlled.

4. Media vents through exhaust port. If the media is

hazardous (classified), the threaded exhaust port

(figure 1) should be vented into a safe area.

5. Proceed with electrical connection.

TABLE 1

RATED PRESSURE FOR ISQB1 VALVES

For valves ordered with MAX.

calibrated pressure of Max. inlet pressure is

Vacuum up to 10 psig (0.69 bar) Consult factory

10.1 up to 30 psig (0.70 up to 2 bar) 35 psig (2.4 bar)

31 up to 100 psig (2.1 up to 7 bar) 110 psig (7.6 bar)

101 up to 150 psig (7 up to 12 bar) 150 psig (12 bar)

Figure 1

ZERO & SPAN

ACCESS CAP

THREADED

EXHAUST PORT

10-32 UNF

ELECTRICAL

CONNECTOR

QBT-01

BRACKET

ATMOSPHERIC

REFERENCE

INLET PORT OUTLET PORT

Figure 2

PIN 1

DC COMMON (-)

PIN 2

4-20 MA COMMAND (-)

PIN 6

DC POWER (+)

PIN 4

4-20 MA COMMAND (+)

NC

NC

Before you get started, please read these warnings:

Examine the product. Ensure that you received what you

ordered.

Read this guide first before you start and save it for later use.

All compressed air and power should be shut off before

installing, removing or performing maintenance on this product.

Installation and use of this product should be under the

supervision and control of properly qualified personnel in order

to avoid the risk of injury or death.

Media vents through exhaust port. If the media is hazardous

(classified), the exhaust port should be vented into a safe area.

3ISQB1 Installation Guide - 2/13/2015 | SSS

FIELD WIRING DRAWING ISQB-96026-2 (General Barrier)

4ISQB1 Installation Guide - 2/13/2015 | SSS

FIELD WIRING DRAWING ISQB-96026-2 (PEPPERL-FUCHS KFD2)

5ISQB1 Installation Guide - 2/13/2015 | SSS

FIELD WIRING DRAWING ISQB-96026-2 (PEPPERL-FUCHS Z728/KFD2)

6ISQB1 Installation Guide - 2/13/2015 | SSS

FIELD WIRING DRAWING ISQB-96026-2 (PHEONIX CONTACT MACX)

7ISQB1 Installation Guide - 2/13/2015 | SSS

FIELD WIRING DRAWING ISQB-96026-2 (PEPPERL-FUCHS KFD0)

8ISQB1 Installation Guide - 2/13/2015 | SSS

FIELD WIRING DRAWING ISQB-96026-2 (PEPPERL-FUCHS Z728)

9ISQB1 Installation Guide - 2/13/2015 | SSS

Example Part Number : ISQB1 T B N I X Z P 150 PS G BR

YOUR PART NUMBER : T I X

Section ——> 1 2 3 4 5 6 7 8 9 10 11 12 Options

1 Series

ISF1 Nonincindive ISF1*

ISQB1 Intrinsically Safe ISQB1

11 Pressure Unit

PS PSI Inches Hg IH

MB Millibars Inches H2OIW

BR Bar mm H2OMW

KP Kilopascal Kilograms/cm² KG

MP Megapascal Torr* TR

MH mm Hg

3 Manifold Material

B Brass (Standard)

A Aluminum

4 Thread Type

N NPT (Standard)

P BSPP

5 Input Signal Range

I 4 to 20 mADC

6 Monitor Signal Range

X No Monitor

7 Zero Offset

N 0% Pressure Starts Below Atmosphere

P 0% Pressure Starts Above Atmosphere

Z 0% Pressure Starts at Zero (Typical)

9 Full Scale Pressure Type

N 100% Pressure Ends Below Atmosphere

P 100% Pressure Ends Above Atmosphere

Z 100% Pressure Ends at Zero

10 Full Scale Pressure

Must be less than or equal to 150 psig

12 Pressure Unit of Measure

A Absolute Pressure

G Gage Pressure

8 Zero Offset Pressure

Typical is 0 (blank)*- If Greater than 30% of Full Scale

Pressure (#9 below) Please Consult Factory.

*Requires Afor Pressure Unit of Measure

*If Zfor Zero Offset (#7), please leave blank

2 Sensor Type

T -14.7 to 150 psig

13 Options

R1 Rotate Connector 180 Degrees

BR Install Foot Bracket

MOUNTING BRACKET

Type Bracket P#

Wrap-Around QBT-01

Please Note: The user has the additional

responsibility of supplying and or ensuring that the

connector/cable that is used with any Proportion-

Air ISQB or ISF1 series FM approved product,

meets all local and national codes for intrinsically

safe wiring.

10 ISQB1 Installation Guide - 2/13/2015 | SSS

5. Set the electrical command input to 20mADC. Adjust

the SPAN potentiometer until MAXIMUM desired

pressure is reached (clockwise to increase pressure).

6. Set the electrical command input to 10 percent of full

value (5.6mA).

7. Adjust the ZERO potentiometer until 10 percent of

maximum desired pressure is reached. (clockwise

increases pressure).

8. The ZERO and SPAN potentiometers interact slightly.

Repeat steps 5-10 until no error exists.

9. Verify unit shuts off by going to 4mADC command.

Check linearity by going to at least six pressures

throughout the full range.

NOTE: Only use this step if your device is totally

out of calibration. If it is slightly out of calibration,

omit this step and move on to paragraph 5. Using a

small screwdriver, turn both potentiometers 15 turns

clockwise. Then turn them 7 turns counter clockwise.

This will put the ISQB1 roughly at mid scale.

Re-calibration:

1. Wire the ISQB1 according to the section titled

“Electrical Connections.”

2. Connect a precision pressure gage or pressure

transducer to the OUTLET PORT of the ISQB1.

NOTE: There must be a closed volume of at least

1 in3 between the OUTLET PORT and the measuring

device for the ISQB1 to be stable.

3. Provide supply pressure to the INLET PORT of the

ISQB1. (See figure 1). Make sure supply pressure

does not exceed the rating for the valve. (see table 1)

All ISQB1 valves come calibrated from the factory by

trained personnel using precision calibration equipment.

The ISQB1 is a closed loop control valve using a

precision electronic pressure sensor. Typical drift is less

than 1% over the life of the product. If your ISQB1

appears to be out of calibration by more than 1%, it is not

likely to be ISQB1. Check the system for plumbing

leakage, wiring and electronic signal levels. Verify the

accuracy of your measuring equipment before re-

calibrating. If the ISQB1 valve needs re-calibration, use

the procedure described below:

RE-CALIBRATION PROCEDURE

4. Remove the zero and span plug on top of the ISQB1

to access the ZERO and SPAN adjustment

potentiometers (figure 1).

ISQB1 & BRACKET DIMENSIONS

11 ISQB1 Installation Guide - 2/13/2015 | SSS

Improper operaon could result in serious injury to persons or

loss of life!

1. PRODUCT COMPATIBILITY

Proporon-Air, Inc. products and accessories are for use in

industrial pneumac applicaons with compressed air

media. The compability of the equipment is the

responsibility of the end user. Product performance and

safety are the responsibility of the person who determined

the compability of the system. Also, this person is

responsible for connuously reviewing the suitability of the

products specied for the system, referencing the latest

catalog, installaon manual, Safety Precauons and all

materials related to the product.

2. EMERGENCY SHUTOFF

Proporon, Inc. products cannot be used as an emergency

shuto. A redundant safety system should be installed in

the system to prevent serious injury or loss of life.

3. EXPLOSIVE ATMOSPHERES

Products and equipment should not be used where

harmful, corrosive or explosive materials or gases are

present. Unless cered, Proporon-Air, Inc. products

cannot be used with ammable gases or in hazardous

environments.

4. AIR QUALITY

Clean, dry air is not required for Proporon-Air, Inc.

products. However, a 40 micron parculate lter is

recommended to prevent solid contaminaon from

entering the product.

5. TEMPERATURE

Products should be used with a media and ambient

environment inside of the specied temperature range of

32°F to 158°F. Consult factory for expanded temperature

ranges.

6. OPERATION

Only trained and cered personnel should operate

electronic and pneumac machinery and equipment.

Electronics and pneumacs are very dangerous when

handled incorrectly. All industry standard safety guidelines

should be observed.

7. SERVICE AND MAINTENANCE

Service and maintenance of machinery and equipment

should only be handled by trained and experienced

operators. Inspecon should only be performed aer

safety has been conrmed. Ensure all supply pressure has

been exhausted and residual energy (compressed gas,

springs, gravity, etc.) has been released in the enre

system prior to removing equipment for service or

maintenance.

Warning

Improper operaon could result in serious injury to persons or

damages to equipment!

1. PNEUMATIC CONNECTION

All pipes, pneumac hose and tubing should be free of all

contaminaon, debris and chips prior to installaon. Flush

pipes with compressed air to remove any loose parcles.

2. THREAD SEALANT

To prevent product contaminaon, thread tape is not

recommended. Instead, a non-migrang thread sealant is

recommended for installaon. Apply sealant a couple

threads from the end of the pipe thread to prevent

contaminaon.

3. ELECTRICAL CONNECTION

To prevent electronic damage, all electrical specicaons

should be reviewed and all electrical connecons should

be veried prior to operaon.

Cauon

Exempon from Liability

Warranty

1. Proporon-Air, Inc. is exempted from any damages

resulng from any operaons not contained within the

catalogs and/or instrucon manuals and operaons

outside the range of its product specicaons.

2. Proporon-Air, Inc. is exempted from any damage or loss

whatsoever caused by malfuncons of its products when

combined with other devices or soware.

3. Proporon-Air, Inc. and its employees shall be exempted

from any damage or loss resulng from earthquakes, re,

third person acons, accidents, intenonal or

unintenonal operator error, product misapplicaon or

irregular operang condions.

4. Proporon-Air, Inc. and its employees shall be exempted

from any damage or loss, either direct or indirect,

including consequenal damage or loss, claims,

proceedings, demands, costs, expenses, judgments,

awards, loss of prots or loss of chance and any other

liability whatsoever including legal expenses and costs,

which may be suered or incurred, whether in tort

(including negligence), contract, breach of statutory duty,

equity or otherwise.

Proporon-Air, Inc. products are warranted to the original

purchaser only against defects in material or workmanship for

one (1) year from the date of manufacture. The extent of

Proporon-Air’s liability under this warranty is limited to repair

or replacement of the defecve unit at Proporon-Air’s opon.

Proporon-Air shall have no liability under this warranty where

improper installaon or ltraon occurred.

Safety Precauons

Please read all of the following Safety Precauons before installing or operang any Proporon-Air, Inc. equipment or accessories.

To conrm safety, be sure to observe ‘ISO 4414: Pneumac Fluid Power - General rules relang to systems’ and other safety

pracces.

Table of contents

Other Proportion-Air Controllers manuals

Popular Controllers manuals by other brands

ARI

ARI ARI-PACO 2G Operating and installation instructions

Sulion

Sulion Driver VISIO IoT manual

Chemitech IT Perdana

Chemitech IT Perdana pH/ORP-3500 Series Operation manual

Crestron

Crestron 302 installation guide

Bollfilter

Bollfilter 2200 Operating and installation instructions

Rockwell Automation

Rockwell Automation Allen-Bradley MicroLogix 1400 user manual