Prosense PQ Series User manual

2

PRS-UM-HT-EN-Rev1.0-19.12.2022

WARNING!

READ THIS INSTRUCTION FIRST!

This manual must be carefully read by all persons who have or will have the

responsibility for installing, using or servicing this product.

Like any equipment, this product will perform as designed only if installed,

used and serviced in accordance with the manufacturer’s instructions.

Otherwise, it could fail to perform as designed and persons who rely on this

product for their safety could suffer severe personal injury or death.

The warranties made by Prosense with respect to this product are voided if the

product is not installed, used and serviced in accordance with the instructions

in this user guide. Please protect yourself and other by following them.

3

PRS-UM-HT-EN-Rev1.0-19.12.2022

Contents

Introduction................................................................................................................................................4

Hand Terminal Menu..................................................................................................................................4

Menu structure.......................................................................................................................................5

Alarm Settings ........................................................................................................................................5

Configure ................................................................................................................................................7

Change date and time ........................................................................................................................7

Change Modbus address .................................................................................................................... 8

Change Analogue Output ...................................................................................................................8

Display Parameters................................................................................................................................. 9

Change Language................................................................................................................................9

Change Zero Suppression ................................................................................................................... 9

Change password ............................................................................................................................... 9

Bump Test.............................................................................................................................................10

Change Test Interval.........................................................................................................................10

Adjust Inhibit warning ......................................................................................................................11

Information Menu options ...................................................................................................................11

Display Event Logs ............................................................................................................................12

Display Concentration Trends ..........................................................................................................12

Display Measurements.....................................................................................................................12

Display Transmitter information ......................................................................................................13

Display Transmitter information ......................................................................................................13

Test Menu Options...............................................................................................................................13

Run Inhibit test .................................................................................................................................14

Run Display test................................................................................................................................14

Run Relay test...................................................................................................................................14

Run Analogue Output test................................................................................................................15

Run Bump Test .................................................................................................................................15

Calibration ................................................................................................................................................17

Set Reference Gas details.....................................................................................................................18

Set Calibration Cycle.............................................................................................................................18

Zero Calibration....................................................................................................................................19

Span Calibration ...................................................................................................................................19

Cancel Calibration.................................................................................................................................20

Warranty statement.................................................................................................................................21

Exclusions .........................................................................................................................................21

Warranty Limitation and Exclusion ..................................................................................................21

Limitation of Liability........................................................................................................................22

4

PRS-UM-HT-EN-Rev1.0-19.12.2022

Introduction

The Prosense hand terminal is designed to help maintenance and calibration operations on

Prosense PQ, PX, P, PC3 series detectors. The hand terminal uses MODBUS communication to

connect the detectors. Prosense PQ, PX, P, PC3 series detectors have onboard MODBUS

communication circuits. User should connect hand terminal MODBUS A and B ports to

detector MODBUS and B ports. Communication ports must match to each other for

communcation. Hand terminal operates with battery power and should be off to manage

battery life.

Hand Terminal Menu

Hand terminal has 3 buttons on display that will be used to perform operation which are

Enter, up (Increase) and down (decrease). To reach configuration menu press Enter. The

screen will request password information:

The password is 1234. User need to change the password as defined in “Change password”

step. You need to set values via using up and down keys. Once the value is set press Enter

again to confirm and move to the next digit. Confirmed digits will be made invisible by

detector program:

The screen will display menu options when correct password entered at last digit:

PASSWORD

0

PASSWORD

****

1. Alarm Settings

2. Calibrate

3. Configure

4. Information

5. Test

6. Exit

5

PRS-UM-HT-EN-Rev1.0-19.12.2022

Menu structure

PQ Series Detector menu includes all necessary steps to setup detector and display

information. Menu is available for only PQD and PQD-S models as they have display module.

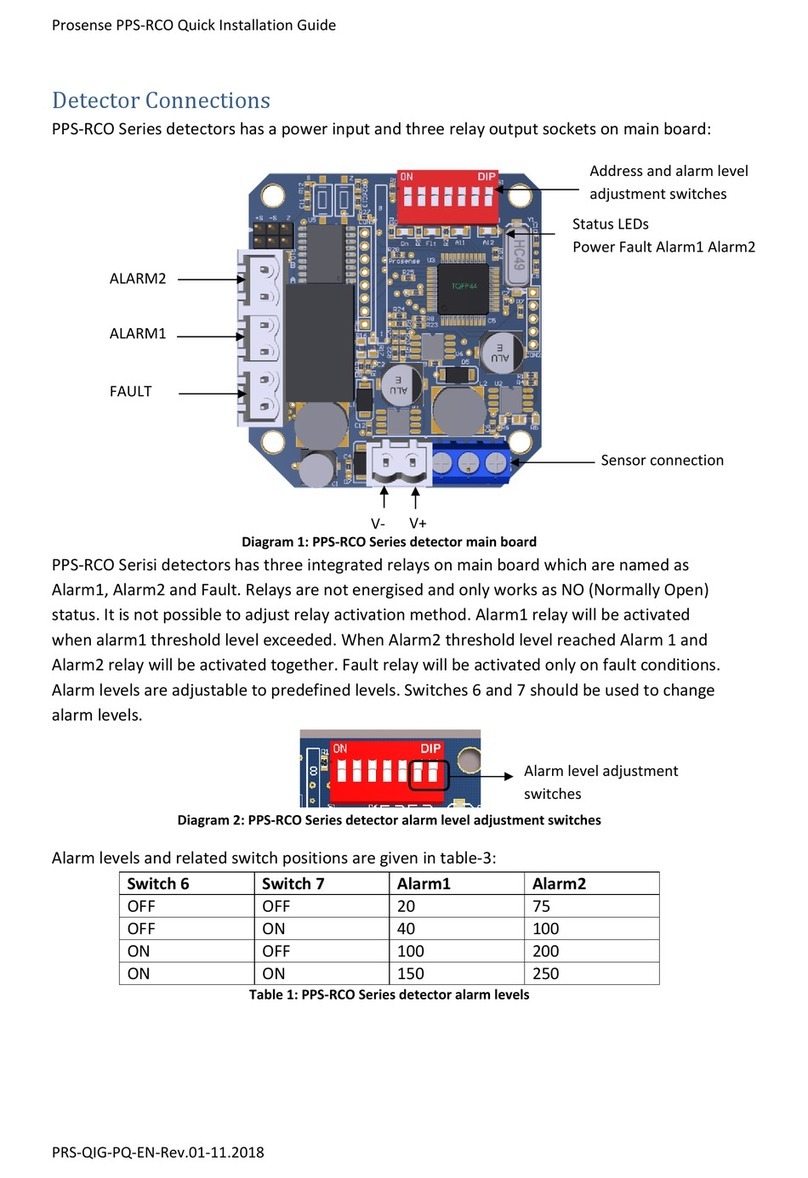

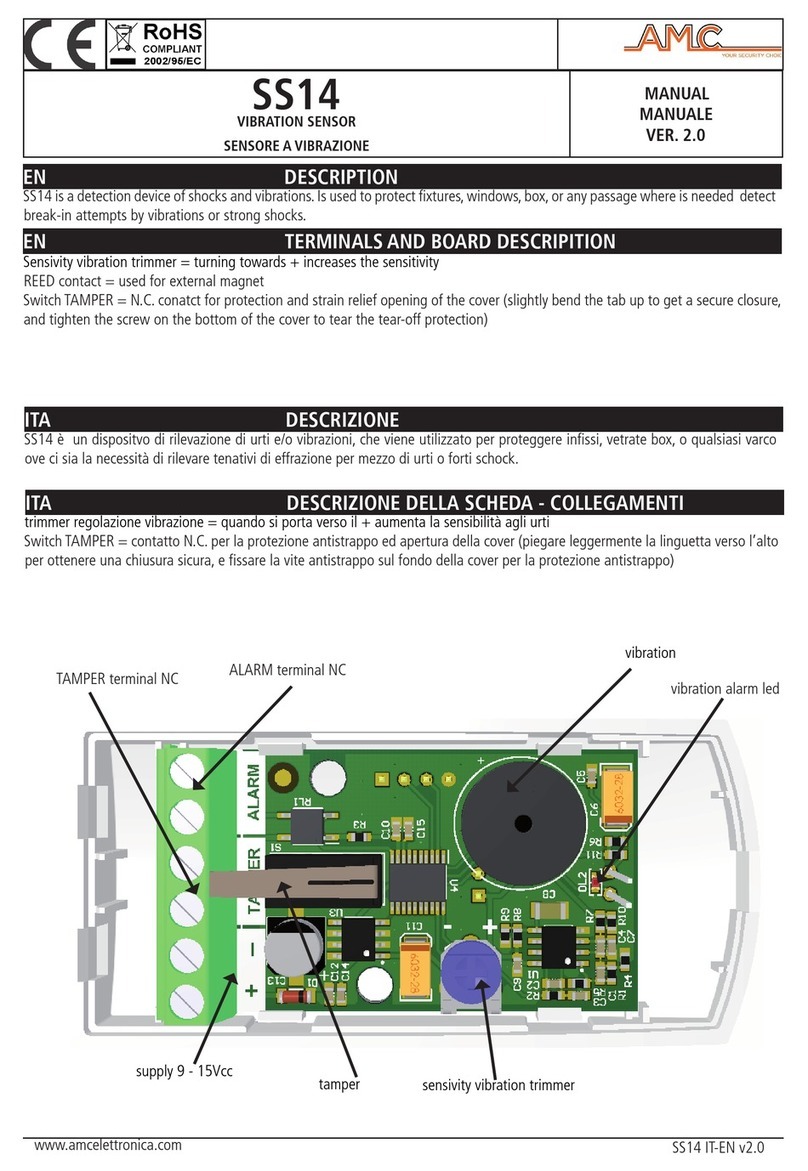

Diagram 16: Main menu structure

Alarm Settings

Alarm levels can be adjusted via using alarm menu steps. Alarm menu general structure is

given in diagram-12:

Diagram17: Alarm menu structure

Once you reach the main menu the first option is alarm settings. Press Enter to move the

alarm settings menu. A new menu listing alarm levels will be shown:

1. Alarm 1

2. Alarm 2

3. Alarm 3

4. Previous Menu

6

PRS-UM-HT-EN-Rev1.0-19.12.2022

Please select the alarm level you would like to adjust and press Enter key to see details. All

alarm details will be listed in new screen and parameters will be blinking one by one while you

set the values.

The first digit of the first alarm will start blinking to let you increase or decrease the digit via

using up and down keys. When you set the value, press again Enter key to move next digit.

The next digit will start blinking to allow you set desired value. When you complete, press

Enter key long enough. The display will show “Successful” message and return back to higher

level menu.

All alarm levels have same parameter that user can adjust if needed. Otherwise they will work

with their default settings. The meaning of parameters is as follows:

Level: The measurement level to raise the alarm

Auto-reset: Define how the alarm relays will work. If ‘YES’ selected the relay will be released

once the measurement level returned to normal. If ‘NO’ selected the relay will lock in their

position. According to IEC EN 60079-29-1 highes level alarm ”Alarm-2” is set to latch mode

without auto-reset.

Directions: Parameter to define in which way alarm will be activated whether increasing or

decreasing. For most toxic and flammable gases it will be raising, for oxygen it can be both

raising and falling.

Relay: It defines the alarm relay working conditions. Relays can be programmed as Energised

(NC) or Non-energized (NO) contact according to use cases and scenarios. When Energized is

selected, the relay will have energy during normal operation. When Non-energized is selected,

the relay is only energized when performing the switching function.

Off Delay: User can define delay to deactivate the alarms. Equipment keeps alarms and relay

contacts active fter measured gas level goes below the defined alarm level. This function must

be adjusted according to operating conditions and safety rules. For example, in some plants

ventilation fans kept activated after the measurement level falls below the alarm level. In such

cases the off delay feature can be used. The off-delay can only be defined in minutes.

Alarm 1 Settings

Level: 10%

Auto-reset: NO

Directions: Rising

Relay: De-energized

Off Delay:00 Min

7

PRS-UM-HT-EN-Rev1.0-19.12.2022

Configure

User can change the parameters of detector depending of the usage such as date, time,

password and detector address via configure menu. Select ‘Configure’ step on main menu to

perform changes. A new menu options will display with options:

The Configure menu structure is given in below diagram:

Diagram18: Configure menu structure

Change date and time

Date and Ttime fearue is only available on PQ Series. Other series would not use this option.

To change date and time select first menu item. Display will show date and time details:

1. Date and Time

2. Modbus Address

3. Analog Output

4. Display

5. Bump Test

6. Previous Menu

Date and Time

YY/MM/DD HH/MM/SS

18/03/27 15/38/27

8

PRS-UM-HT-EN-Rev1.0-19.12.2022

The first digit on screen will start blinking once entered the menu step. You can increase or

decrease the value via using up and down keys. Once desired value has been set press Enter

key to confirm and move to the next digit to set. Once all set press Enter key. The display will

show “Successful” message and return back to higher level menu.

Change Modbus address

To change detector address, select “Modbus Address” menu option. In RS485 communication

detectors are slave devices and control panel is the master device. Each detector must have

unique address to work together in same RS485 communication loop. Select “Modbus

Address” menu item via using up and down keys and press Enter key. Display will show default

detector address which is 1:

Address can be changed with up and down keys from 1 to 256. Once set to desired address

press Enter key long enough. The display will show “Successful” message and return back to

higher level menu.

Change Analogue Output

User can adjust analogue output levels depending of the status and function. To do this please

select “Analogue Output” menu item on configuration menu via using up and down keys and

select Enter key. Screen will display default values used for analogue output:

User can adjust these values to desired values depending of the application requirements

between 1 to 3.5 mA for Fault, Warm-up, Calibration, Inhibit and 20-22mA for Overrange.

Modbus Address

1

4-20mA Output

Fault : 2.0 mA

Warm Up : 3.0 mA

Calibration : 3.0 mA

Inhibit : 3.0 mA

Over Range : 22.0 mA

9

PRS-UM-HT-EN-Rev1.0-19.12.2022

Display Parameters

Detector display can be adjusted as per requirements. The display options are given in Display

menu item

Change Language

The detector display language can be changed to English or Turkish. To change Language first

select Configure option on main menu then select Display option and Language option. Once

you reach to Language screen you will able to switch display language:

Change Zero Suppression

User can adjust the way showing measurement level around zero level. If zero suppression

mode set to NO, detector will display measurement as detected. If zero suppression mode set

to YES, detector will show measurement levels as 0 (zero) up to 3% LEL. At 3% LEL it will

display measurements as detected.

To change zero suppression mode select Zero Suppression option on Display menu and pres

Enter key. Current zero suppression mode will be displayed. If needed change the value via

using up and down keys. Once adjusted press Enter key to record value.

Change password

User must change the defaut password for security reasons. The default password is 1234. To

change password select Password menu item via using up and down keys and press Enter key.

Display will ask new password:

1. Language

2. Zero Suppression

3. Password

4. Detector model

5. Previous Menu

Menu Language

English

Zero Suppression

NO

10

PRS-UM-HT-EN-Rev1.0-19.12.2022

Password must be 4 digits and should be set digit by digit via using up and down keys. When

completed, press Enter key long enough to confirm. The display will show “Successful”

message and return back to higher level menu. User should remember the password to

perform changes later on. If user forgets the password, detector should be returned back to

Prosense to reset password. No Field operation is available to reset password at customer

site.

Bump Test

Detectors should be tested to make sure they can perform their operations as defined. To do

this bump test should be performed in defined periods. Bump test parameters can be

adjusted via using Bump Test options in Configure menu. To start adjustments select Bump

Test step on Display menu. A new screen will display with available options:

Change Test Interval

To change bump test interval select Test Interval option on Bump Test Menu.

Once the bump test interval menu shown the time value will start blinking. User can change

the value via using up and down keys. Select Enter key to save the value when adjustment

done. The display will show “Successful” message and return back to previous menu.

New Password

0

1. Test Interval

2. Inhibit Warning

3. Previous Menu

Bump Test Interval

3 Month

11

PRS-UM-HT-EN-Rev1.0-19.12.2022

Adjust Inhibit warning

User can set or clear inhibit warning via using Inhibit warning option on Bump Test Menu. To

adjust warning please select Inhibit warning menu option. A new menu shown including

possible adjustment option:

If inhibit warning already set, the screen will display clear option:

Once decided select the option and press Enter key. The display will show “Successful”

message and return back to previous menu.

Information Menu options

Information menu provides more detailed information about measurements, events and

device itself. The Information menu structure is given in below diagram:

Diagram19: Information menu structure

1. Set

2. Previous Menu

1. Clear

2. Previous Menu

12

PRS-UM-HT-EN-Rev1.0-19.12.2022

Display Event Logs

Detector records all events starting from its power-on. To display recorded events, select

Event log option in Information menu. Detector will list the events:

The screen can display only one event. To see all events use up and down keys. All events

starting from first power-on has been saved in detector memory. It can store up to 250

events. Event log feature is only available on PQ series.

Display Concentration Trends

PQ detector can show gas concentration trends in screen as it is recording all the

measurement data in last 8 hours. Once this option selected a graphic screen will shown to

display gas measurements:

To return back to previous menu please press Enter key till the screen changes. This log

feature is only available on PQ series.

Display Measurements

To get more details about the measurements please select measurements option in

Information menu. Detector will display the voltage, current and temperature levels as in

below example:

Log[001]

08 AUG 18 11:08

ALARM AL1

100

------------------------

------------------------

-------------------------------------------------- T

Input Vol. :23.3V

Sensor Vol. :2506mV

Sensor ADC :504

Current Output :4mA

Line Res. :300 Ohm

Temperature :34C

13

PRS-UM-HT-EN-Rev1.0-19.12.2022

Display Transmitter information

To get details about transmitter and firmware level use transmitter information step in

Information menu. A screen will display details.

To return back to previous menu please press Enter key till the screen changes.

Display Transmitter information

To get details about transmitter and firmware level use transmitter information step in

Information menu. A screen will display details.

To return back to previous menu please press Enter key till the screen changes.

Test Menu Options

User can execute tests to check detectors functions. Test menu structure is given in below:

Diagram20: Test menu structure

Prosense Ltd. KS031

XMTR S/N:00021907

XMTR F/W:V.1.1.0

DSP F/W :V.1.1.1

Modbus Adr.:01

Test Due:18/12/2018

100%LEL METHANE

S/N:21A06583

Alarm 1:10

Alarm 2:15

Alarm 3:20

Cal. Due:18/09/2019

14

PRS-UM-HT-EN-Rev1.0-19.12.2022

To perform tests select Test menu item via up and down keys then press Enter key. The screen

will display test options:

To execute tests select desired test option and press Enter key. To return back to previous

menu please select Previous Menu option and press Enter key.

Run Inhibit test

User can initiate detector to work in inhibited mode. In this mode detector will provide the

signal level defined in configuration details for inhibited mode (default is 3mA) and the alarms

will be deactivated. When Inhibit option selected in Test menu below screen will display to set

inhibit detector:

If user finish the work or test it is necessary to clear inhibit mode to return detector to normal

operation. To do this user should re-enter to Inhibit menu in Test menu. The clear option will

be displayed at this time:

Run Display test

To execute display tests select Display option on Test menu and press Enter key. The detector

program will start display test via drawing different patterns. It might take one minute to

complete test. The display will return back to Test menu when test completed.

Run Relay test

It is possible to check relay functions via using menu options. Relays are only available if

optional relay module installed on to detector main board. To run relay test please select test

menu and select Relay option. Screen will display three options to test as there are three

relays on relay module. Select the menu option related to desired relay test and press Enter

key.

1. Inhibit

2. Display

3. Relay

4. Analog Output

5. Bump Test

6. Previous Menu

1. Set

2. Previous Menu

1. Clear

2. Previous Menu

15

PRS-UM-HT-EN-Rev1.0-19.12.2022

If fault relay test selected, detector will activate the relay and screen will display information:

If alarm relay selected, detector will activate related alarm relay and screen will display

information:

To return back to previous screen please press Enter key till the screen updated with previous

menu items.

Run Analogue Output test

To test analogue output level user can initiate the analogue output test in Test menu. Once

Analogue Output option selected press Enter Key. Screen will display the analogue output

level. User can increase or decrease the output signal level via using up and down keys.

To return back from Analogue Output test please press Enter key till the screen updated with

previous menu items.

Run Bump Test

Bump test can be run at any time when needed. The Bump test runs depending of the

parameters defined for bump test in configuration details. To initiate bump test please select

1. Fault Relay

2. Alarm 1 Relay

3. Alarm 2 Relay

4. Previous Menu

Fault Relay

is active

Alarm 1 Relay

is active

Analog Output

02.0 mA

16

PRS-UM-HT-EN-Rev1.0-19.12.2022

Bump test menu item in Test menu and press Enter key. Screen will display messages that

requesting user to apply test gas and press Enter

User should provide necessary gas and press Enter. The screen will return back to

measurement screen and show the measurement for 30 seconds.

While test executed detector will automatically went in to inhibited mode and Fault LED will

start blinking. After 30 seconds screen will alert user to remove the test gas from detector:

Detector will return to measurement screen for another 30 seconds with same message

Once the time counted down to zero the screen will display test results:

Apply test gas

> 15%LEL

Press enter

100 BUMP TEST

28

METHANE

2%LEL

Remove applied gas

100 BUMP TEST

23

METHANE

0%LEL

Start Concentration

0%LEL

Peak Concentration

24%LEL

End Concentration

0%LEL

17

PRS-UM-HT-EN-Rev1.0-19.12.2022

If test fails the screen will indicate the result

Once test completed screen will display back to Test menu items.

Calibration

It is recommended to periodically carry out calibration to ensure correct operation. Prosense

PQ series detector calibration includes two steps as zero and span calibration. It is possible to

perform each step independently. Prosense recommends to perform both calibration steps

for correct calibration. Detector should be powered and stabilized for at least 4 hours before

calibration. During the calibration phases the detector output is inhibited (default 3mA) to

avoid false alarms. Zero calibration of infrared sensors should be done with N2 and zero

calibration of other sensors should be done with zero air (O2 and N2 gas mixtures). It is

possible to use calibration gas from 25%LEL to 75%LEL gas concentrations via adjusting

reference gas details on detector menu for calibrating flammable gas detectors It is necessary

to use international tracable gases.

To calibrate the detector, use an appropriate span gas cylinder, constant flow regulator and

Prosense Gas Cap. The gas flow rate must be 0,5lt/min for correct calibration.

It is recommended to use a compressed air cylinder (20.9%Vol oxygen) to perform the zero

calibration if the area where the detector is located contains any residual amount of the

target gas. If no residual gas is present then the background air can be used to perform the

zero calibration.

To perform calibration select Calibration from menu:

Screen will show calibration options:

1. Alarm Settings

2. Calibrate

3. Configure

4. Information

5. Test

6. Exit

1. Set Zero

2. Set Span

3. Cancel Cal

4. Reference Gas

5. Cal. Interval

6. Previous Menu

Start Concentration

0%LEL

Peak Concentration

24%LEL

End Concentration

0%LEL

18

PRS-UM-HT-EN-Rev1.0-19.12.2022

It would be better to first set reference gas details and calibration cycle period as these values

cannot be altered once calibration started for zero or span. Zero or Span calibration can be

performed separately at any time. It is recommended to perform Zero calibration first and

perform Span calibration following zero calibration completion.

Set Reference Gas details

During calibration technician should use a certificated specific gas. The details of the gas

should be entered before starting the calibration. Otherwise detector program will use default

values entered at factory. If the calibration gas is different than default gas specifications the

calibration will fail or will be wrong. Select fourth item ‘Reference Gas’ on calibration menu to

set details of the gas you will use during calibration. The default value is % 30 LEL will be

displayed:

The first digit will start blinking on screen. You can change the value of each digit with up and

down keys. Once set, confirm value with Enter key and move to the next digit.

Set Calibration Cycle

Prosense recommends performing calibration with six months period. Hence this default

value is set to detector in factory. Detector will be faulted when calibration period expire. If

user wants to use different calibration period this should be set via using the option “Cal

Cycle” on calibration menu. Select “Cal Cycle” and press Enter. A new screen will display to

allow you set your calibration period:

The number will be blinking. Value can be adjusted using up and down keys. Once set press

Enter key to confirm and return back to calibration menu.

Reference Gas

030 %LEL

Calibration Cycle

6 Month

19

PRS-UM-HT-EN-Rev1.0-19.12.2022

Zero Calibration

Select Set Zero option on calibration menu and press Enter key to start zero calibration.

Program will request a confirmation to start zero calibration:

When entered zero calibration will start and calibration time will be counted down:

Zero gas should be applied to sensor during 60 seconds. For catalytic, pellistor and

electrochemical sensors use clean air gas, for infrared sensors use N2 gas. For more details

contact Prosense. Detector will automatically perform zero calibration while gas applied to

sensor during this period.

Span Calibration

To perform Span calibration Select Set Span option on calibration menu and press Enter key to

start span calibration. At same time prepare the span gas cylinder and regulator; mount the

calibration adaptor to the sensor head and apply gas to the detector. Program will request a

confirmation to start Span calibration:

CLEAN AIR

Apply zero gas

Press Enter

030 %LEL

METHANE

Apply gas

Press enter

CALIBRATION

ZERO: 45

METHANE

0%LEL

20

PRS-UM-HT-EN-Rev1.0-19.12.2022

After pressing Enter key screen will again show countdown for span period. The Span period

may vary depends on target gas:

Span gas should be applied to sensor during span period. Detector will automatically set span

level. When countdown completed it will return to monitoring screen via exiting from menu. If

you try to enter menu detector will ask password again.

When the countdown is complete, the detector exits the menu steps and returns measurment

screen but stays in calibration mode. In this case, the value is read on the screen as gas is

applied to the detector. However, the detector does not generate an alarm because the

detector is in calibration mode. After the calibration is completed, the detector continues to

operate in calibration mode until the amount of gas detected falls below the value defined for

alarm1 and the message “CALIBRATION” is displayed on the screen. When the amount of gas

detected after the calibration falls below the alarm1 level, the detector switches to the

normal operating mode from the calibration mode. The detector stays in calibration mode for

up to 5 minutes and returns to normal operating mode. If the gas level does not decrease for

5 minutes after the calibration, the detector starts to generate an alarm.

Cancel Calibration

Calibration can be cancelled anytime during calibration operation. If user thinks something

done wrong by mistake, should select “Cancel Cal” option on calibration menu. Detector will

ask confirmation to cancel:

Press Enter key to cancel calibration operation. Detector will erase the values recorded during

calibration steps and uses previously recorded calibration levels

CALIBRATION

SPAN: 45

METHANE

12 %LEL

Press Enter

to Cancel

Calibration

is canceled

Other manuals for PQ Series

2

This manual suits for next models

3

Table of contents

Other Prosense Security Sensor manuals

Popular Security Sensor manuals by other brands

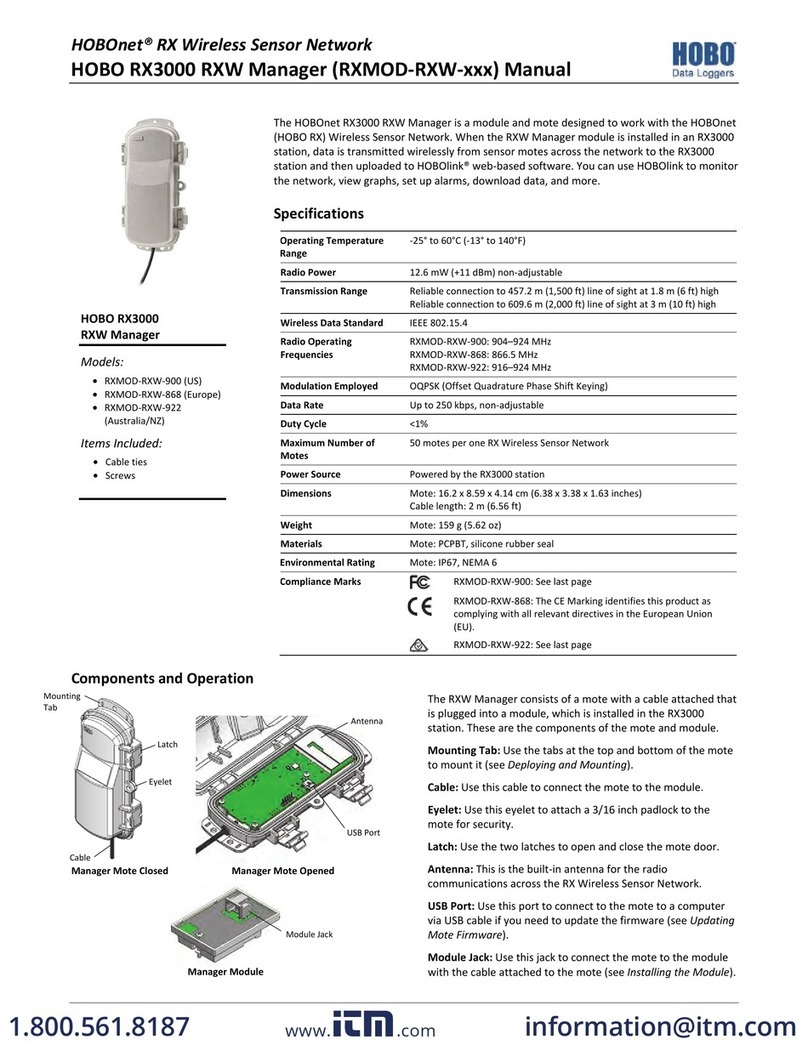

Hobo

Hobo HOBOnet RX manual

aci

aci A/CTA-5 Assembly, installation and operation instructions

Joyfay Delicate

Joyfay Delicate BX80 Operating instructions manual

Fracarro

Fracarro TEATRO' 35DT EVO quick start guide

Honeywell

Honeywell Ex-Or MLS2000DF Installation and commissioning instructions

Ecolink

Ecolink Firefighter CS-600 Installation manual & users guide