1

EC DECLARATION OF CONFORMITY

Conforming to EEC Directive 98/37/EC

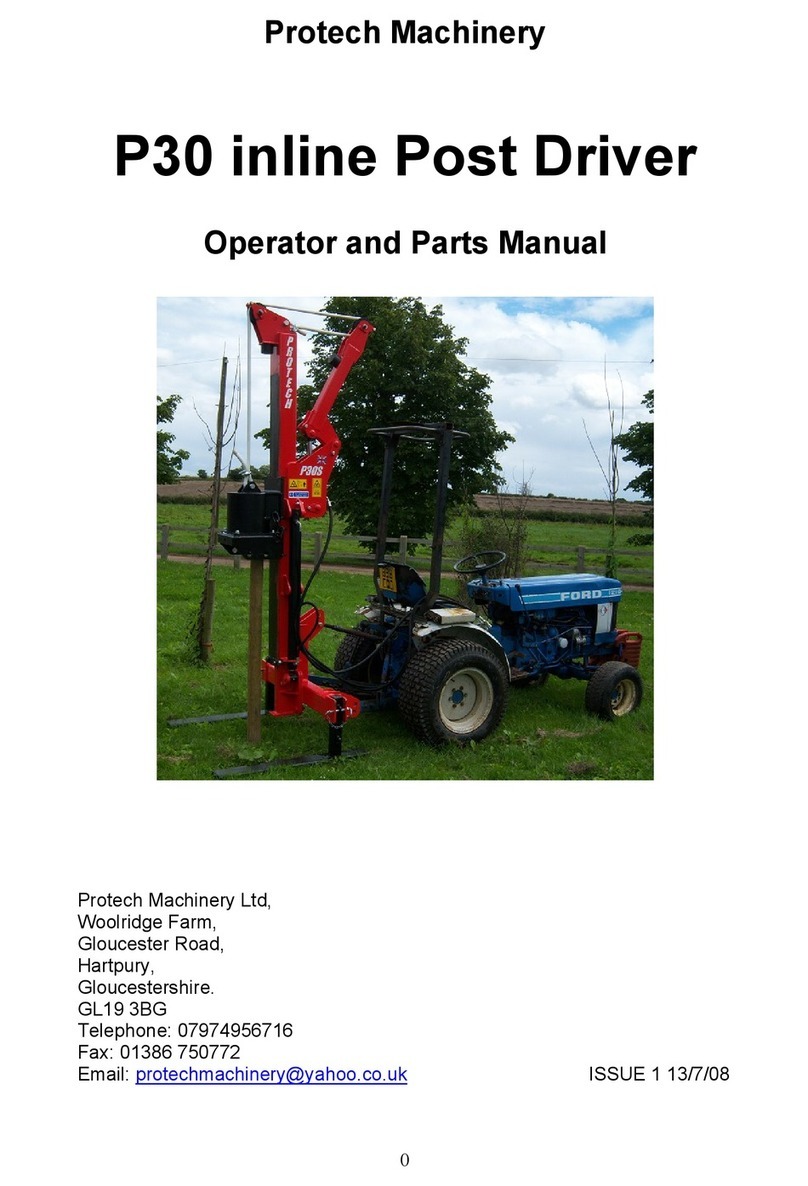

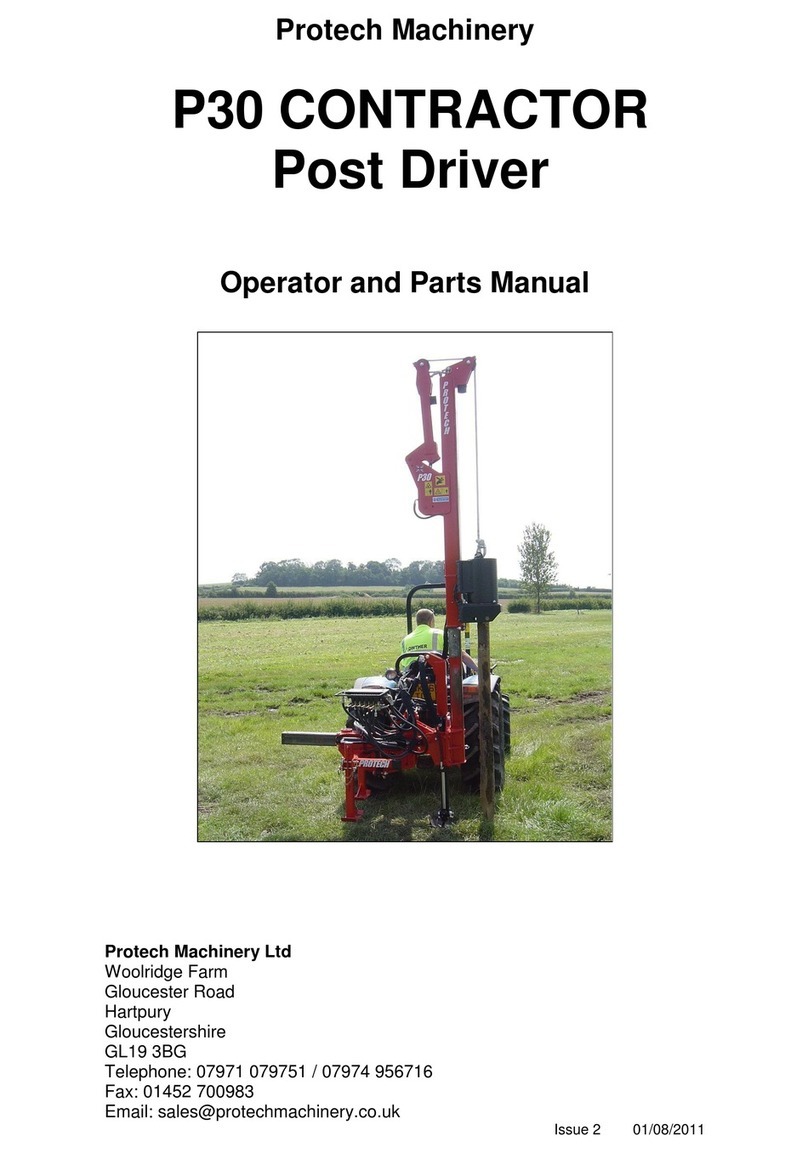

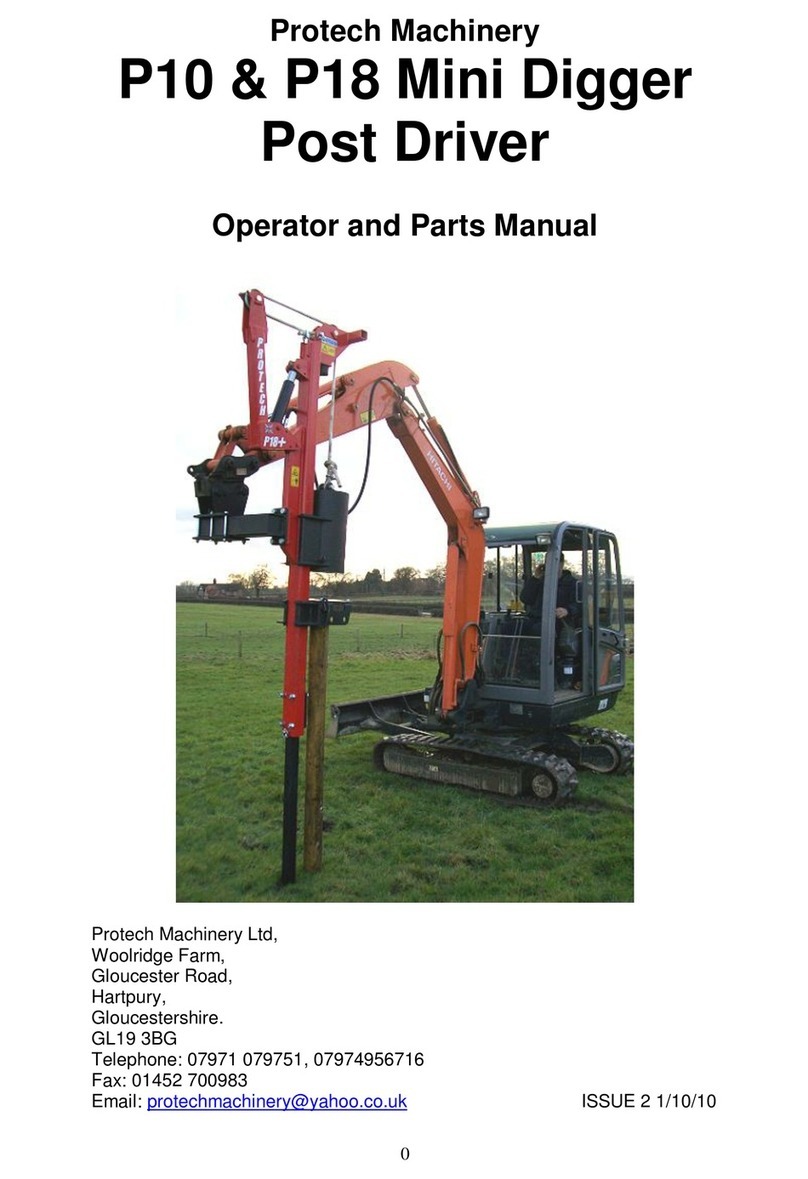

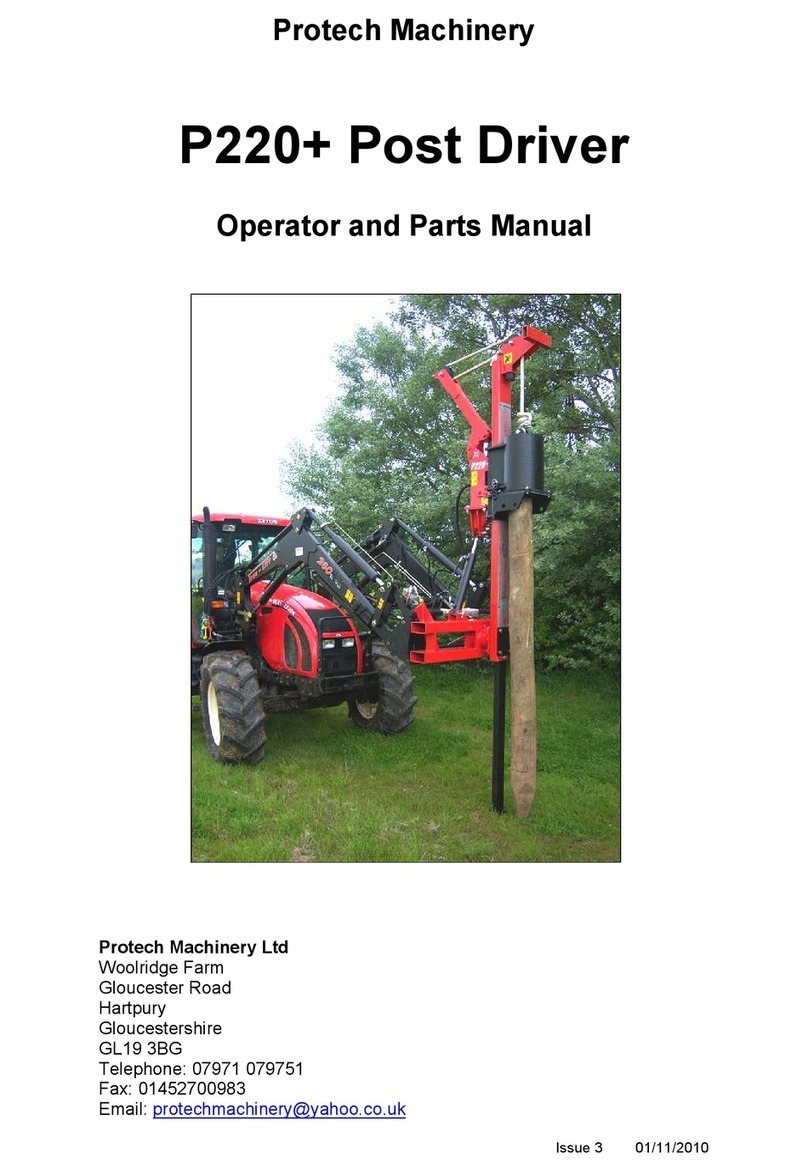

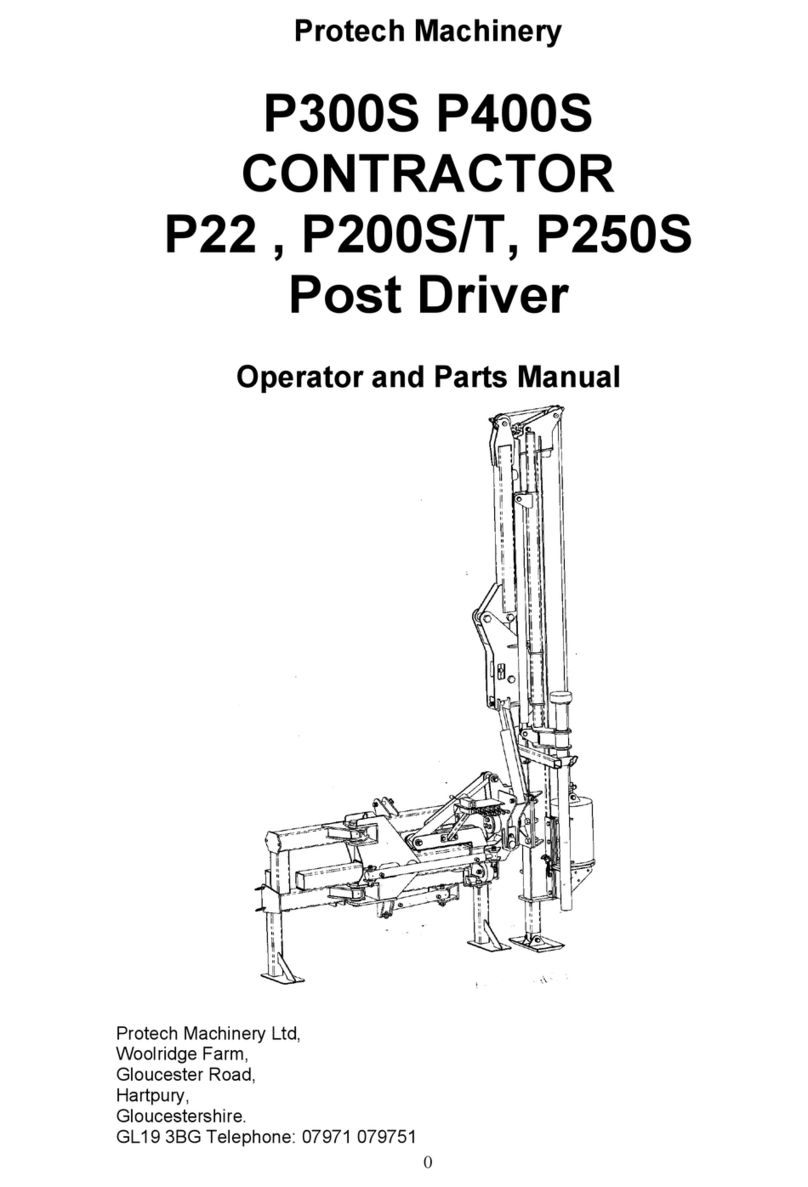

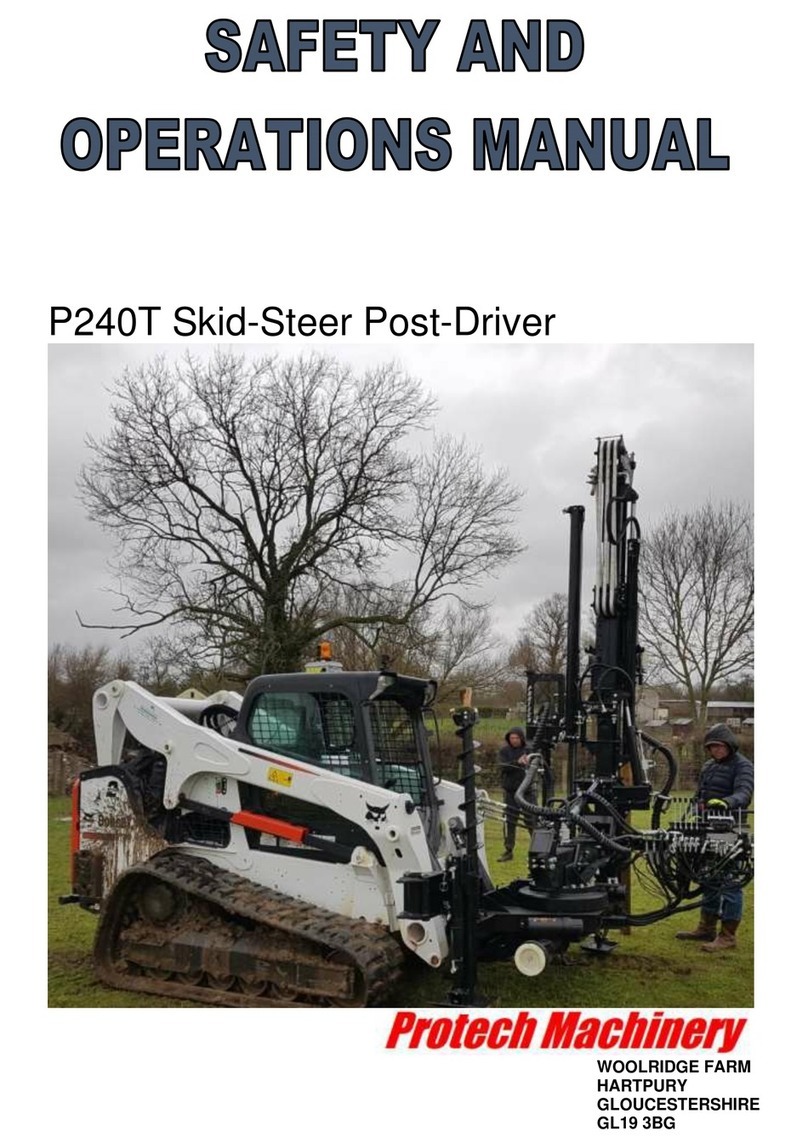

We Protech Machinery Ltd

Of Woolridge Farm,

Gloucester Road,

Hartpury,

Gloucestershire.

GL19 3BG

Hereby declare that the product: POSTDRIVER

Product Code P230S

Serial Number series

Manufactured by the above Company complies with the required provisions of

the Directive 98/37/EC

To effect the correct application of the safety requirements stated in the EEC

Directives, the following standards and/or technical specification have been

used:

THE SUPPLY OF MACHINERY (SAFETY) REGULATIONS 2008.

S.I. No.299 of 2007. Safety, Health and Welfare at work.

Health and Safety at Work Act, 1974 (UK).

EN 1SO 14121-1: 2007 `Safety of machinery. Principles for risk

assessment`.

EN ISO 13857 – Safety of machinery: Safety distances to prevent

hazard zones being reached by upper and lower limbs.

Signed……………………………………………………………………………..

On behalf of Protech Machinery

Status……………………………………………………………………………….

Date…………………………………………………………………………………