Protech Machinery P30 Product manual

Protech Machinery

P30 CONTRACTOR

Post Driver

Operator and Parts Manual

Protech Machinery Ltd

Woolridge Farm

Gloucester Road

Hartpury

Gloucestershire

GL19 3BG

Telephone: 07971 079751 / 07974 956716

Fax: 01452 700983

Email: [email protected] Issue 2 01/08/2011

1

Director

30th August, 2011

EC DECLARATION OF CONFORMITY

Conforming to EEC Directive 98/37/EC

We Protech Machinery Ltd

of Woolridge Farm

Gloucester Road

Hartpury

Gloucestershire

GL19 3BG

Hereby declare that the product: POSTDRIVER

Product Code P30 CONTRACTOR

Serial Number series

Manufactured by the above Company complies with the required provisions of

the Directive 98/37/EC

To effect the correct application of the safety requirements stated in the EEC

Directives, the following standards and/or technical specification have been

used:

BS EN 292-1: 1991 Safety of Machinery –Basic concepts, general principals

for design –Basic terminology, methodology.

BS EN 292–2: 1991 Safety of Machinery –Basic concepts, general principals

for design –Technical principals and specifications.

BS EN 294: 1992 Safety of Machinery –Safety distances to prevent danger

zones being reached by the upper limbs.

BS 5401: 1990 Guide to information content and presentation of operator’s

manuals provided for tractors and machinery for agriculture and forestry.

Signed……………………………………………………………………………..

On behalf of Protech Machinery

Status……………………………………………………………………………….

Date…………………………………………………………………………………

2

Contents

Page number

Introduction

3

Product Specification

4

Safety Rules

5

Label Identification

6

Delivery and installation

7

Safe use of the Post Diver

9

Safe use of the Tele Mast

11

2nd Stage Telescopic Mast

12

Transportation of the Post Driver

13

Storage of the Post Driver

13

Maintenance of the Post Driver

13

3

IMPORTANT NOTICE

Please read this manual before fitting or operating this machine.

Whenever any doubt exists please contact Protech Machinery for

assistance. If the machine is resold the Manual must be given to the

new owner.

Introduction

Dear Customer

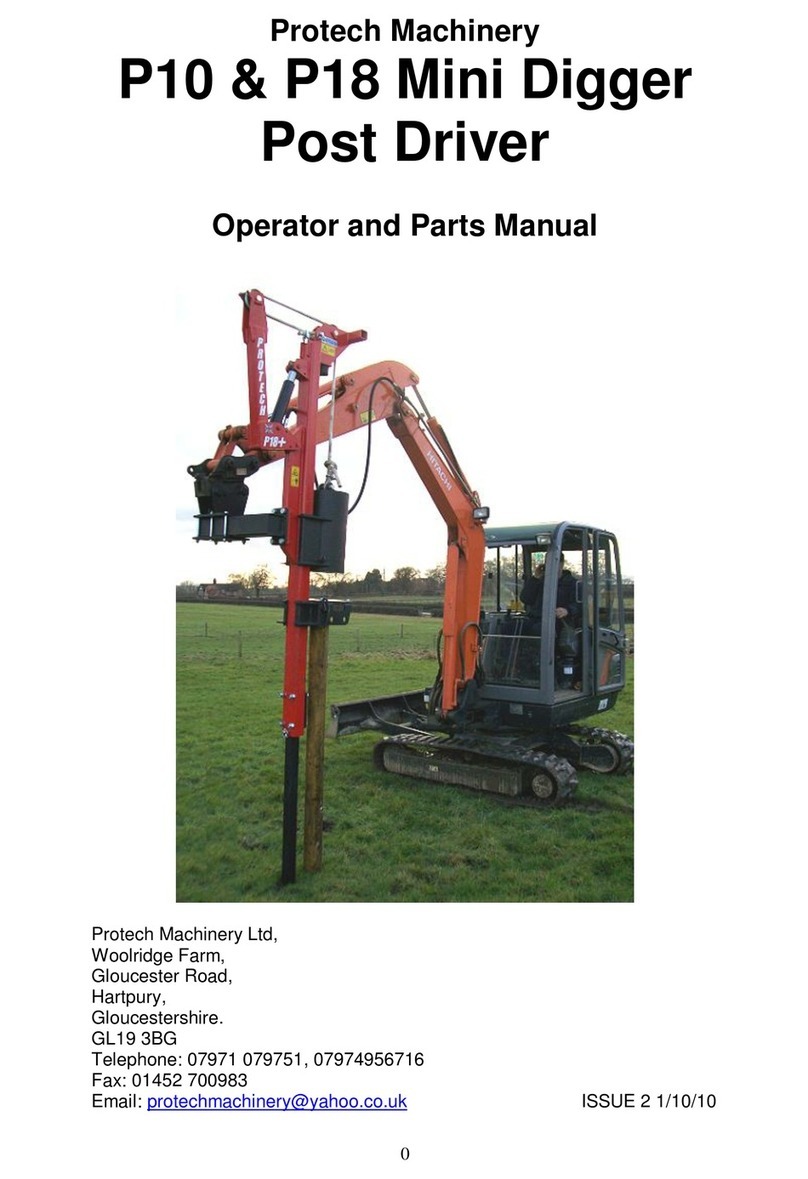

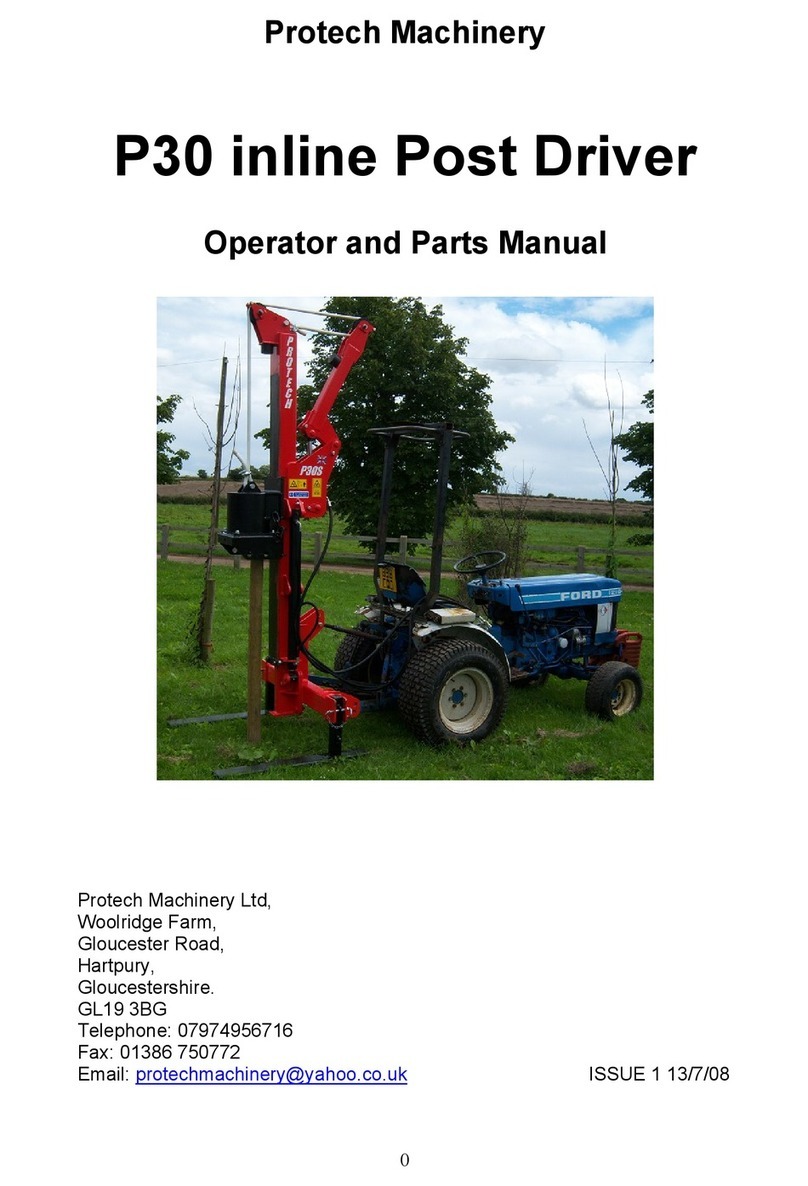

Thank you for purchasing a Protech P30 CONTRACTOR Post Driver.

Protech Machinery Ltd has produced this User Guide to assist and help you to

get the most from your post driver.

This manual is line with the relevant Health and Safety regulations to assist

you with operating this machinery without harm to yourself.

You should be aware that any person operating this machine with your

permission must be given adequate guidance and information to allow him or

her to use the machine safely.

Where as every effort has been made to ensure the Post Driver conforms to

Protech policy of quality, the machine cannot be expected to withstand abuse

caused by misuse and negligence by the operator.

4

Product Specification

Total Weight

600kg

Min Tractor Horsepower

From 35 HP

Max oil flow

50L/MIN

Oil pressure

150 bar

Linkage type

Cat 1

Rope Pulley

Lever Arm

Mast

side tilt ram

Pressure and

return control

hoses

Sideshift ram

Front & rear

leg lock pin

Front leg

Rear leg

Weight Rope

Mast

Driver Weight

Post Cap Plate

Mast stop

Hydraulic

mast leg ram

Mast leg

Lower link pins

5

Safety Rules

Whenever possible, warning Pictograms {Labels

without words} or warning labels are used on both

the machine near the point of danger, and in this

user manual near the relevant instructions

Before fitting the Post Driver to the Loader, it is the

operator’s responsibility to ensure the stability of

the Loader and Post Driver in all anticipated

conditions, and that the Loader is suitable for the

Post Driver.

Before using the Loader, check that it is in correct

working condition, with correct fluid levels and

correct tyre pressure.

Only the operator must control the Post Driver,

Spectators must be kept away from the machine at

all times.

The post cap plate must be used to hold posts at all

times. Under no circumstances should the post be

held manually while operating the Post Driver.

Before using the Post Driver, test the hydraulic

system for leaks. If a small leak is obvious, check

the location using a piece of cardboard. Small high

pressure leaks can penetrate the skin which need

medical attention.

During maintenance or adjustments:

Ensure that the weight is fully down, with the

rope relaxed.

Ensure that the hydraulic pressure is

released.

Ensure that the Loader engine is switched

off and the handbrake is secure on.

During Transport ensure:

That the weight is fully down

That the Post Driver is carried low to the

ground and with the mast crowded back for

stability and maximum clearance from

overhead obstructions.

Ensure that the transport lock is fitted to the

mast tilt ram.

Always drive at a safe speed and in

complete control of the vehicle.

When working on sliding ground, it is far safer to

drive up and down rather than across the slopes.

Always check for worn hydraulic components. Any

damaged rope must be replaced before failure

occurs –and must be a certified Protech

replacement.

No mast supporting components must be moved

until the mast is securely held in the vertical

position.

6

Label Identification

Where possible, warning labels are used both on the machine near the point

of danger and in this user Manual.

Standard Triangle to indicate

Alert/Warning

Warning read Product Manual

Warning danger area from tilting mast

Warning danger of feet being

crushed.

Warning eye protection must be warn

Warning ear protection must be warn

Warning Danger of falling weight

Warning Danger of overhead cables

Lubrication Point

Lifting point

7

Delivery and installation of the Post driver.

If the Post Driver has been delivered on a pallet then follow this assembly

procedure. To unload the pallet from the delivery lorry you will need a

minimum 1 ton lift capacity loader with pallet tines. Position the pallet onto

level and hard ground.

1. Using a loader with a 1 ton minimum lift capacity and with pallet tines,

attach a lifting sling (minimum 2 ton lifting sling) around the mast of the

post driver and onto both pallet tines of the loader as shown.

Raise the loader just so the lifting sling becomes taut.

2. Remove all banding which strapped the post driver to the wooden

pallet.

3. To connect the mast tilt ram, carefully raise the loader to tilt the mast.

Once the mast tilt ram holes are aligned then fit the mast tilt ram pin.

Never put your fingers through these holes to align the pin. If the

control panel is not attached then bolt the control panel with the

mounting bolts supplied.

Mast tilt ram pin

Mast tilt ram

Control Panel

Control bracket

Mounting bolts

8

4. Carefully raise the loader to lift the Post driver off the ground and

remove wooden pallet.

5. All legs must now be levelled. With the post driver still raised off the

ground connect the pressure and return control hoses to the tractor.

Be careful not to stretch these hydraulic hoses.

6. Operate the rear leg control lever which will raise and lower the mast

leg. Carefully lower the loader to rest the post driver onto the ground

and operate the rear leg so all legs are level and touching the ground.

This will make the machine level and stable. With the post driver on

the ground remove the lifting sling and disconnect the pressure and

return control hoses from the tractor.

7. Backshift option is available which travels at 90° to the sideshift and

parallel to the fenceline allowing forward & backward adjustment.

The post driver is now ready to be attached to the tractor.

9

Safe use of post driver

1.

Before the Post Driver is used,

ensure that every single person who

works with or works close to the post

driver reads and understands this

manual.

2.

Ensure that all Personnel working

near to the post driver must wear

protective clothing, i.e. Eye and Ear

defenders, strong safety boots and

gloves.

3.

There is a danger of injuring feet

under the foot, so no person must be

in this area when the Post Driver is

raised or lowered by the Loader.

4.

There is a danger from crushing

under the falling weight. No person

must be near the post when the

weight is falling. Never put a hand on

top of the post under any

circumstances.

5.

Be aware of overhead cables

6.

There is a danger of the mast tilting

and creating a trapping zone, no

person must be in this area.

7. Reverse the Tractor to the Post Driver and attach the lower link arms to

the link brackets on the Post Driver. Fit the supplied pins and securing

lynch pins.

8. Connect the Pressure and return control hoses to the tractor hydraulic

service.

9. Operate the mast side tilt control lever to work the hydraulic top link.

Extend the hydraulic top link to align with the top link mounting hole of

the tractor and fit top link pin and secure with lynch pin.

10

10.Adjust the Tractor link arm stabilisers to centralise the Post Driver and

reduce excessive lateral sway.

11.Raise the tractor links arms to raise the post driver of the ground and

remove the stabilising leg stand.

12.For the first use of the post driver, carefully operate all control levers to

clear any air that might be trapped in the hydraulic system.

13.Manually start a post in the desired location so it becomes self

supported. Make sure the tractor and post driver are at a safe distance

away from the manual process.

14.Make sure the Post Cap chain on the side of the Post cap is hooked

onto the driver weight and secured with the lynch pin. Then drive the

tractor and post driver into position with the weight and post cap raised

a short distance as to clear the top of the post. Never put your hand

on top of the post cap plate or underneath the driver weight.

15.Once in position and with the hydraulic rear leg in the fully closed

position fully lower the post driver on the tractors linkage until the front

legs are resting on the ground. For uneven ground the front leg lock

pin can be removed which allows the front legs to pivot and rest more

level. The Tele arm, Mast forward tilt and mast side tilt control levers

can be operated to align the machine with the post. Once at the

desired position, operate the rear leg control lever to lower the mast leg

onto the ground and stabilise the machine.

16.Carefully lower the post cap and driver weight onto the post and

release the post cap plate by unhooking both post cap chains.

17.With all persons at a safe distance from the post driver, operate the

weight control lever to raise weight and then lower, allowing the weight

to fall to hit the post

18.Raise and drop the weight until the driven position of the post has been

achieved.

19.Never drop the weight with the post cap resting on the mast stop. This

will cause damage to the machine.

20.Once at the driven position then connect the post cap back onto the

driver weight using the post cap chain and secure with lynch pins.

Carefully raise the driver weight and cap plate off the post using either

the weight control lever. Then drive the tractor and post driver away

from the post. Once clear of the post fully lower the weight. Do not

drive around with the driver weight raised up in the air.

NEVER PUT HANDS ON TOP OF THE POST

UNDER ANY CIRCUMSTANCES.

11

Safe Use of Telescopic Mast Option

1. The Telescopic Mast option enables up to 12 foot posts to be driven in the

ground.

2. Operate the Tele Mast lever to familiarise yourself with this function. This

will raise and lower the mast.

3. Depending on the post height, operate the Telescopic Mast ram to raise

the Mast clear of the post.

4. Carefully lower the post cap and driver weight onto the post and release

the post cap plate by unhooking both post cap chains.

5. With all persons at a safe distance from the post driver, raise the driver

weight then move the Tractor valve to exhaust the system, allowing the

weight to fall to hit the post.

6. Raise and drop the weight until the driven position of the post has been

achieved.

7. Never drop the weight with the post cap resting on the mast stop. This will

cause damage to the machine. Always lower the telescopic mast first to

give distance (minimum 300mm) between the post cap and mast stop.

8. Once at the driven position then connect the post cap back onto the driver

weight using both post cap chains and secure with lynch pins. Carefully

raise the driver weight and cap plate off the post using either the lever ram

or telescopic mast ram. Then drive the tractor and post driver away from

the post. Once clear of the post fully lower the telescopic mast and lever

ram. Do not drive around with the driver weight raised up in the air.

Telescopic Mast raised

up and down

NEVER

PUT HANDS ON TOP

OF THE POST

UNDER ANY

CIRCUMSTANCES

12

2nd stage Telescopic Mast

1. Fully raise the telescopic mast, then fit the mast lock pin through the

inner mast hole and secure with the lynch pin.

If there are multiple holes in the inner mast then always use the

uppermost hole.

2. Carefully lower the telescopic mast onto the pin just enough to carry

the weight of the mast. Do not power down onto the pin.

3. Turn off the tractor and operate the telescopic ram to relieve any

pressurised oil; then remove the telescopic ram pin. Restart the tractor

and retract the telescopic ram to align with the 2nd stage mounting

holes. Never ever use your finger to align the holes. Once the

holes are aligned re fit the telescopic ram pin.

Raise the telescopic mast and remove the mast lock pin. The post

driver is now ready for use. To adjust back to the 1st position apply the

same procedure. Never remove post driver from the tractor with the

mast in the 2nd stage position.

Inner mast

Mast lock pin

Telescopic ram

pin

2nd stage

telescopic mount

This position is only used for tall posts (12ft and over)

such as for deer fencing

13

Transportation of the Post Driver.

Always lower the weight and release any hydraulic pressure.

Always carry the Post Driver on the Tractor Linkage as low as possible but

without hitting the ground.

Storage and unhitching the Post Driver

Before unhitching from the tractor always fit the stabilising leg stand & front

leg locking pins and secure with lynch pins.

Where possible, store the Post Driver away from areas that have public

access

Store the Post Driver on level, stable ground.

Lower the weight and release any residual hydraulic pressure.

Store the hydraulic hose in a clean, secure place.

The Post Driver must be stored in a position to be easily reconnected to

the tractor.

Maintenance of the Post Driver

Daily

Check weight rope for any signs of wear. If in doubt, change the rope.

Check hydraulic hoses for any signs of wear. If in doubt change the hose.

Grease rope pulleys.

Apply grease to the face of the mast.

Weekly

Check the hydraulics for leaks.

Grease all arm pivots.

Check the rope pulleys turn freely.

Check all pivots for wear.

Other manuals for P30

1

Table of contents

Other Protech Machinery Construction Equipment manuals

Protech Machinery

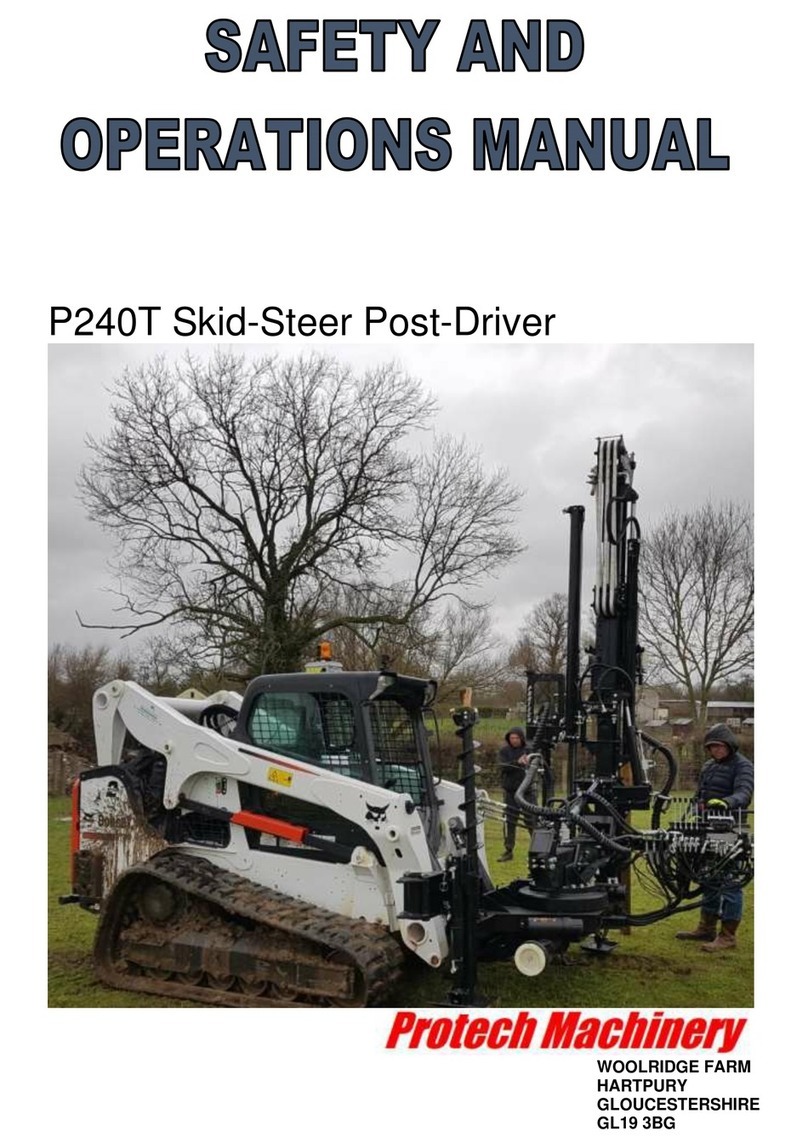

Protech Machinery P240T User manual

Protech Machinery

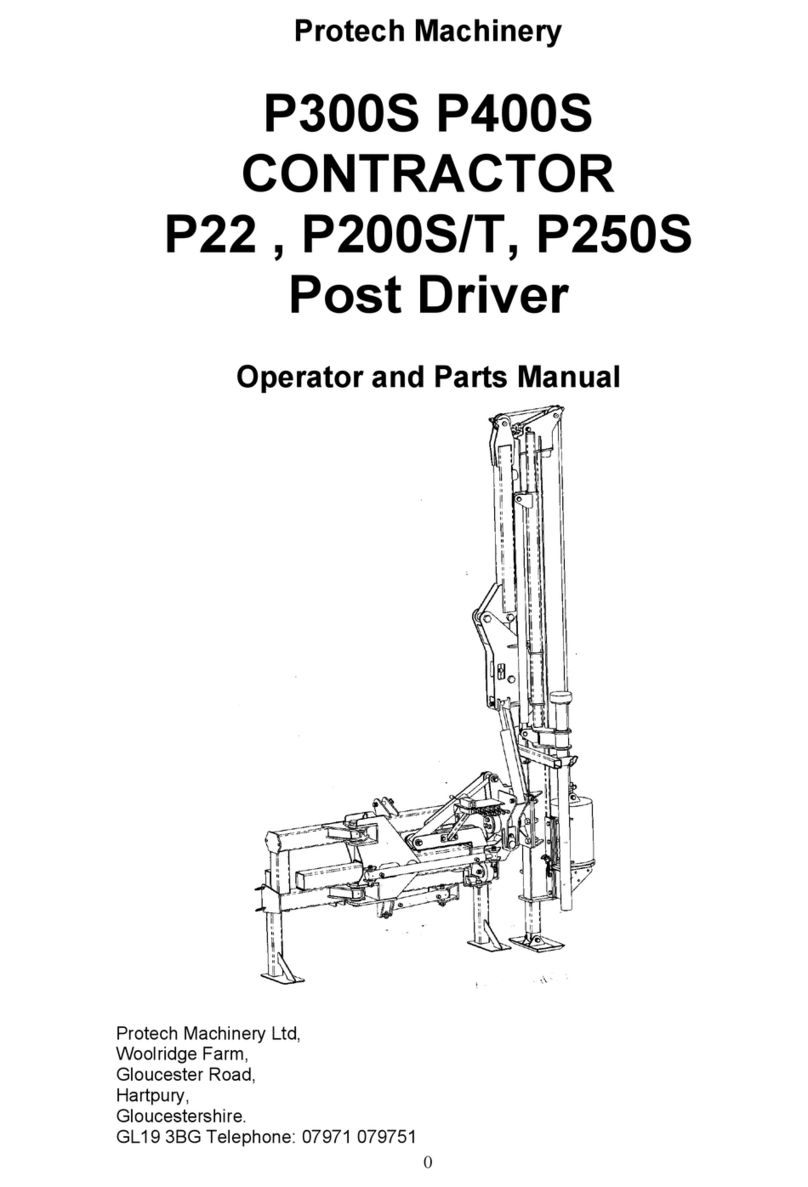

Protech Machinery P300S Product manual

Protech Machinery

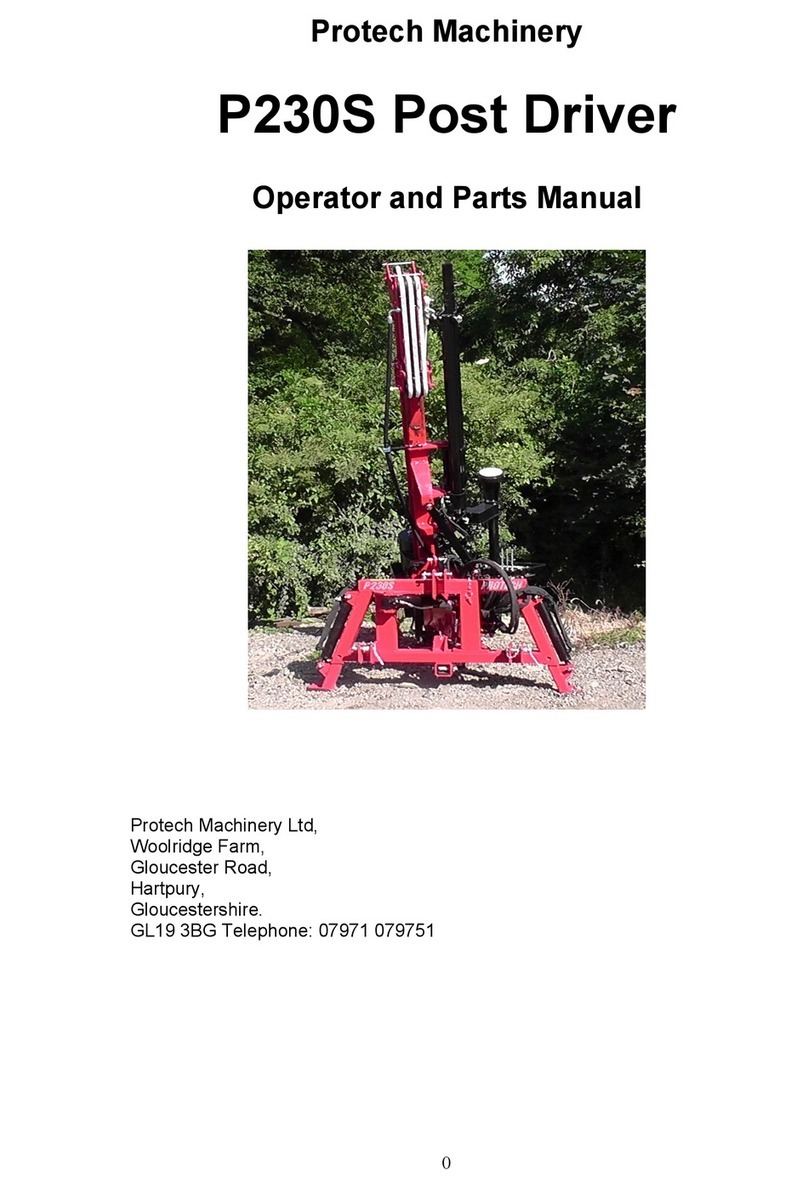

Protech Machinery P230S Post Driver Product manual

Protech Machinery

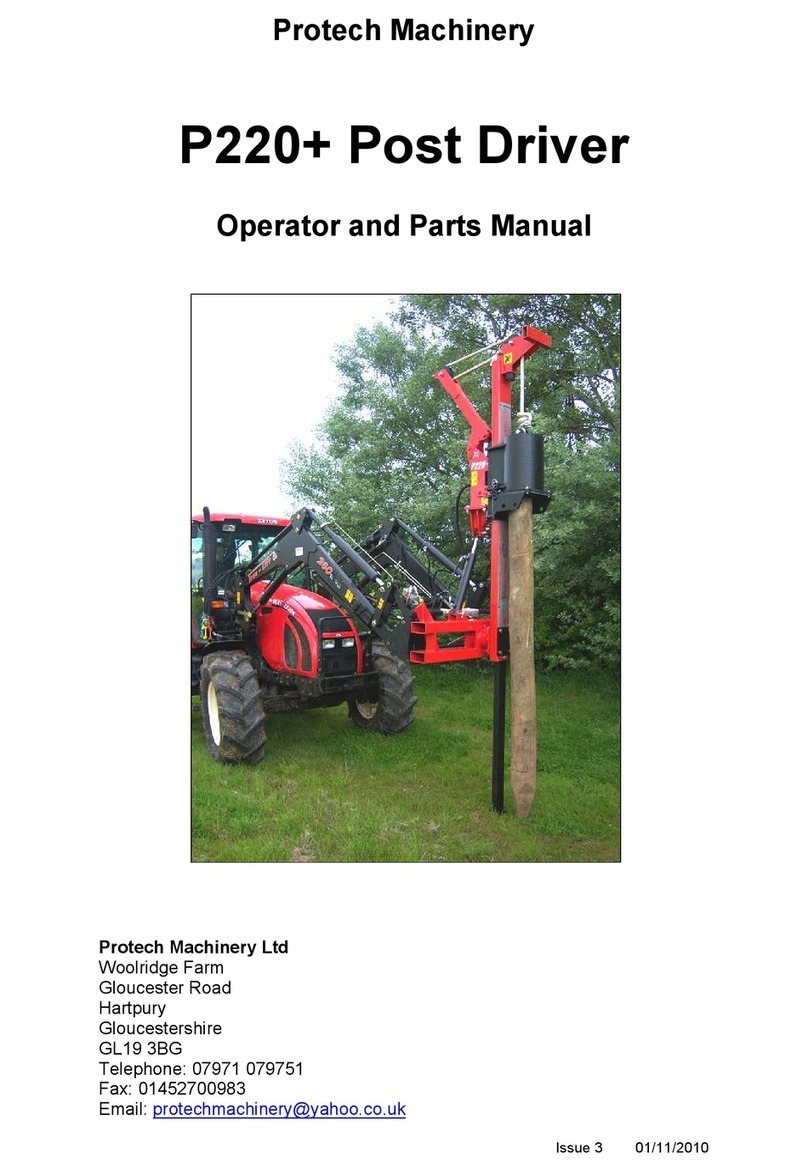

Protech Machinery P220+ Product manual

Protech Machinery

Protech Machinery P10 Product manual

Protech Machinery

Protech Machinery P30 Product manual