Protectowire SRP4x4 User manual

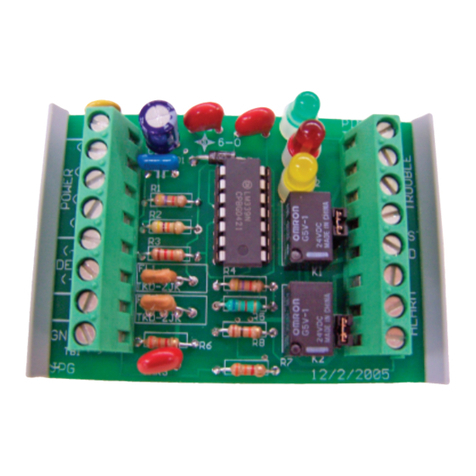

STANDARD RELEASE PANEL

OPERATING & MAINTENANCE MANUAL

SRP4x4

An ISO 9001:2008 Registered Company

APPROVED

IMPORTANT SERVICE NOTICE

When requesting service assistance, or to order parts for this

control panel, you are required to provide the Model Number,

Drawing Number and Serial Number. This product information

is recorded on the Panel Identification Label located inside the

control panel. Please have this information available before call-

ing your Authorized Protectowire Distributor or the Factory.

1

Table of Contents

General Information & Panel Specification

Company Information / Publishing Date ............................................................................................ 2

Notice & Warnings............................................................................................................................... 3

System Description & Features............................................................................................................ 4

Systems Specifications..................................................................................................................... 5 - 6

Enclosure Information

Enclosure Dimensions...................................................................................................................... 7 - 9

Panel Mounting................................................................................................................................... 10

Battery Cabinet Mounting................................................................................................................... 11

Wiring

Wire Routing Detail (Power Limited vs Non-Power Limited).......................................................... 12

Wire Size Estimator............................................................................................................................ 13

Field Wiring (Initiating Device Circuits)........................................................................................... 14

Field Wiring (NAC & Solenoid Release Circuits)............................................................................ 15

Options

Alarm Point Location Meter (PDM-1000-4)...................................................................................... 16

Auxiliary Relay Module (RB-4)......................................................................................................... 17

Class A Alarm Notification Module (AM-91-2)................................................................................. 18

Installation / Troubleshooting

Installation Test & Maintenance.......................................................................................................... 19

Troubleshooting............................................................................................................................ 20 - 24

Programming

Wire Diagram Program Chart...................................................................................................... 25 - 39

Battery Calculations

Battery Size Selection Chart............................................................................................................... 40

Panel Instructions (tearout)................................................................................................................. 41

Appendix A

Listed Solenoids, Notification Appliance Devices, Listed Smoke Detectors.............................. 42 - 44

2

The Protectowire Co., Inc.

60 Washington Street, Pembroke, MA

U.S.A. 02359-1833

Telephone: 1-781-826-3878

Fax: 1-781-826-2045

WWW.PROTECTOWIRE.COM

Model SRP-4x4 Standard Release Panel

Operating & Maintenance Manual

Man-2002 Rev. C

Publish Date 08-04-2016

3

Notice

TESTING AND MAINTENANCE OF SYSTEM CONTROLS SHALL BE PERFORMED BY COMPETENT

PERSONNEL HAVING JURISDICTION OVER THIS PROTECTIVE SIGNALING SYSTEM.

TESTING ZONES WITH SOLENOID RELEASE CIRCUITS AND EQUIPMENT SHUTDOWN CONTACTS

MAY BE ACCOMPLISHED BY USE OF A JUMPER WIRE ACROSS EACH DETECTION / INITIATING CIR-

CUIT FIELD WIRING TERMINALS ONLY AFTER THE OUTPUT DISCONNECT SWITCH, LOCATED IN

THE LOWER LEFT CORNER OF MAIN BOARD, HAS BEEN PLACED IN THE LEFT POSITION. SLIDING

THIS SWITCH IN THE LEFT POSITION ALLOWS OUTPUT SIGNALS FOR OP2, OP3, AND OP4 TO BE

BYPASSED.

NOTE: IT IS ALWAYS GOOD PRACTICE TO DISCONNECT ALL PRE-ACTION SYSTEMS PRIOR TO

TESTING.

WARNING!

FATAL ELECTRICAL SHOCK AND EQUIPMENT

DAMAGE MAY RESULT FROM FAILURE TO REMOVE

ALL POWER PRIOR TO SERVICING SYSTEM.

CAUTION

The Protectowire Co., Inc. designs and manufactures fire protection systems to meet both UL and FM

Global criteria for electrical transients introduced on both the power supply side of the system and into the

panel from field wiring for initiating device circuits, notification appliance circuits, and other external field

routed wiring.

Fire protection systems located in areas subject to lightning strikes, or subject to other severe transients,

and electromagnetic interference, should be protected similar to computers and other electronic systems

with supplemental surge and filter protection both on the power supply side and on field wiring for initiat-

ing device circuits, notification appliance circuits and other field routed wiring.

Please refer to surge/filter manufacturers, (eg., DITEK 800-753-2345, www.ditekcorp.com) to specify

devices for your particular conditions. The National Lightning Safety Institute (www. LightningSafety.com)

also provides valuable information regarding the problems and solutions of providing lightning protection

including assuring true earth ground conditions.

Lightning strikes, other severe power surges, and significant EMI/RFI interference, by their nature, are

beyond normal design criteria and are outside the warrantee for manufacturing defects.

4

MODEL SRP-4x4

STANDARD RELEASE PANEL

System Description & Setup

The Model SRP-4x4 is a Fire Alarm Control/Releasing Panel which is FM approved, UL Inc. Listed. It is designed

primarily for use as a releasing panel for Pre-action and Deluge, water based extinguishing systems. This unit is in

compliance with NFPA-13, NFPA-72, and UL864 and can be used as a stand alone Fire Control Panel.

The Fire Control Panel is programmable by way of three (3) eight (8) position DIP switches. Select a system pro-

gramming scheme that meets your requirements as depicted on pages 25 thru 39. Special attention must be taken

in positioning dip switches for proper panel operation.

System Features

Four (4) Supervised Class A (style D) or Class B (style A or B) Initiating device circuits which may be configured

for the following functions.

1. Standard Initiating Device Circuits Compatible with the following:

a. Up to 10,000 Feet (3,048m) of Protectowire type PHSC linear heat detector.

b. Up to 5 (0.045mA) Hochiki smoke detectors.

c. Any combination of Normally Open contact initiating devices.

Examples: Conventional Manual Pull Stations, Waterflow Switches, Conventional Spot heat

detectors.

2. Supervisory Initiating Device Circuits Compatible with the following:

a. Any combination of Normally Open contact initiating devices.

Examples: Low air pressure switches, Valve Tamper Switches.

Four (4) Supervised Class B (Style Y) Output Zones: Each Output can be set up for any of the

following:

1) Notification Appliance Circuit (Output #1 thru #4)

2) Release circuit (Outputs #2, 3, and/or 4)

3) Supervisory Bell circuit (Outputs #3 & 4 only)

4) Trouble Bell circuit (Output #4 only)

- Releasing Zones can be set up for either single or cross zone operation

- All circuits are inherently Power-Limited per NFPA 70 (nec) see 760

- Initiating circuits can be wired as Class A or B

- Output circuits # 2, 3, and 4 have disable feature

- Signal Silence Button (common alarm and/or trouble conditions)

- System Reset Button

- Built-in Trouble/Supervisory Buzzer

- Auxiliary Contacts for Alarm/Trouble/Supervisory

- On Board 24V Auxiliary Power (100mA MAX) Resettable

- Ground Fault Detection (2.2K ohms to Ground)

- Battery Trouble circuit (low battery, battery overcharge, battery disconnect)

- 24 or 90 hour Battery Standby operation available Options:

1) AM-91-2 Module: converts Class B Notification Appliance circuit to Class A

2) PDM-1000-4 Protectowire Digital Alarm Point Location Meter.

3) RB-4 Auxiliary Alarm Relays

5

SPECIFICATIONS

Housing

Type: 16 gauge steel.

Door: Piano Hinged, lockable.

Dimensions: 20 1/2” x 14 1/4” x 4 3/4”

Finish: Red enamel with red, black and white logo/label.

Knockouts: Minimum of one 1/2” and two 3/4” knockouts on each side, top and bottom.

Visual Indicators

(Visible LED’s with door closed)

AC-ON: (1) Green

System Silence, System Trouble, Ground Fault Detection, Battery Trouble, and Output

Disconnect Supervisory: (5) Yellow

Common Alarm: (1) Red

Supervisory Zone Alarm: (1) Yellow

Input and Output Zone Trouble: (9) Yellow

Input and Output Zone Alarm: (8) Red

Control Buttons

Signal Silence: Momentary - Silences alarm signaling circuits, trouble buzzer and outputs

programmed as supervisory bell or trouble bell.

System Reset: Momentary - Resets all alarm circuits if condition has been corrected.

Removes power from initiating circuits.

Initiating Device Circuits (4 TOTAL)

4 NFPA Style D (Class A) or Style B (Class B)

Power-limited

IDC loop current (IDC): 0.3 mA.

IDC alarm trip current: 6.0 mA minimum.

IDC alarm current (short circuit): 44 mA max.

Normal loop voltage: 23 VDC

Linear heat detector resistance: 2000 ohms max.

Maximum Impedance to insure Alarm: 2.4K ohms.

End of Line Resistor: ELR-8.2K (Required in Class B configuration only)

Two Wire Detector capacity (per zone): 5 - 0.045 mA type Hochiki smoke detectors

Low/Disconnected Battery

Battery and system trouble indication when voltage falls out of range between 21 -29 Volts, or

has been disconnected

Fused battery and reverse polarity protection is provided.

Conditioning Resistor: 2.2 K ohm (Remove and replace with batteries)

6

SPECIFICATIONS (continued)

Output Circuit (4 TOTAL)

(ALARM INDICATING, RELEASING, SUPERVISORY AND TROUBLE BELL)

4 Supervised Notification Appliance Circuits (NAC) Class B, reverses polarity on alarm

(Optional Class A Module: AM-91-2). Maximum line loss not to exceed 1.0 Volts or 1 Ohm fully loaded.

Power-limited, each circuit has self-resetting type fuse (PTC).

Output #1; Dedicated for Notification Only; rated 24V FWR regulated, 1 amp continuous.

Outputs #2, 3 & 4 rated 24VDC regulated, 1 amp each, 2.1 amps combined for Solenoid activation.

Per UL listings circuits are rated .25 amps each, .75 amps combined for Notification Devices

Standby terminal voltage approximately -2.7VDC.

End of Line Resistor ELR-8.2K ohms.

Compatible Solenoids: FM Solenoid Groups A, B, D, E, F, G, I, J & K

For UL see Appendix A for compatible Solenoids.

Supervisory Circuit (1 TOTAL)

Supervisory monitors the following:

High/Low Air

Tamper/Valve positioning and etal

One latching Class B Supervised Initiating Device Circuit.

Power-limited.

End of Line Resistor ELR-8.2K ohms.

Circuit loop resistance 100 ohms.

Increase in circuit resistance causes supervisory trouble and system trouble.

Maximum resistance for supervisory signal 2200 ohms to insure alarm.

Minimum current 4.5 mA to insure alarm (10 mA short circuit maximum).

Normal supervisory standby loop current 2 mA.

Normal standby loop voltage 19.5VDC.

Input Power

120VAC - 1.37 Amp max. (50-60 Hz) or 240VAC - .85 Amp max. (50-60 Hz)

Green AC-ON LED goes off with AC power loss, causes system trouble and buzzer to sound.

System on battery backup.

System Trouble is also generated if voltage drops below 102V under alarm load, system is

transferred to battery backup.

Power Requirements

Standby - 160 mA @ 24VDC, 7.0 AMP Batteries for 24 hour standby

- 160mA @ 24VDC, 18.0 AMP Batteries for 90 hour standby (FM Requirement)

Alarm - 3.5 AMP MAX. @ 24VDC All Zones.

Battery Charger Specifications: 27 VDC @ 1.2mA trickle; 1 Amp fast charge.

33 AH Battery maximum, sealed rechargeable type.

Outputs

System Remote Signaling Relay contacts rated 3A, 30VDC (resistive) for Alarm, Supervisory & Trouble.

Auxiliary Power - 24VDC regulated. Rated 100mA max. Power-limited. (Resettable)

7

FRONT VIEW BACK VIEW

20.12 20.12

13.06

1.75

12.00

14.12

Ø0.62

1.06

Ø0.28

Ø0.28

14.12

9.87

1.06

0.60

IMPORTANT: The stated dimensions are for the enclosure back box only and do not

account for the overall dimensions of the enclosure with the door installed. To account

for the enclosure door and hinges add an additional 0.4” to the back box width, and

0.08” to the depth.

Caution: Do not drill through the top of the enclosure for conduit entry. Metal filings

will damage system components and voids factory warranty. Use knockouts provided

and seal all conduit openings to prevent water ingress.

ENCLOSURE DIMENSIONS

8

ENCLOSURE DIMENSIONS

IMPORTANT: The stated dimensions are for the enclosure back box only and do not account for the overall dimen-

sions of the enclosure with the door installed. To account for the enclosure door and hinges add an additional 0.4” to the

back box width & height, and 0.08” to the depth.

Caution: Do not drill through the top of the enclosure for conduit entry. Metal filings will damage system com-

ponents and voids factory warranty. Use knockouts provided and seal all conduit openings to prevent water

ingress.

TOP/BOTTOM VIEW

KNOCKOUTS

LEFT/RIGHT SIDE VIEW

3.5

1.5

1.5

20.12

1.5

1.5

1.1

4.5

3.0

1.5

3.0

4.5

1.0

0.88

1.1

0.88

7.5

0.88

1.1

4.62

9

ENCLOSURE DIMENSIONS

0.6

4

14.40

20.40

DOOR FRONT/SIDE VIEW

10

‘

0.28

‘‘

0

‘

.28

.62

.28

9.81

0.60 1.0

ALARM

SILENCE

BATT TRO

TROUBLE

SYSTEM

OUTPUT

4

GND FLT

AC ON

OUTPUT

OUTPUT

2

3

TROUBLE

GENERAL

1

SUPVRY.

ZONE

ALARM TROUBLE

4

ZONE

ZONE

ZONE

ALARM

2

3

TROUBLE

1

PANEL

FIRE

CONTROL

COM ALARM

OUT. DISC.

SUPVISRY

PANEL MOUNTING

- Panel shall be located in a clean, dry,

vibration free environment. Panel shall not be

subjected to extreme temperatures or humidity.

- Panel shall be wall mounted only, with the

top of enclosure at a height of 6 feet. Secure

the panel using the mounting holes provided.

- The panel must be easily accessible for main-

tenance with no physical obstructions blocking

it’s access or visual operation.

- The panels hinged door requires an additional

16 inches of free space. This additional space

allows the front door to be fully swung open.

- Do not drill through the top of the enclosure

for conduit entry. Metal filings will damage

system components and voids factory warranty.

Use knockouts provided and seal all conduit

openings to prevent water ingress.

- Once panel has been mounted connect all

required conduit, field wiring, detection

circuits, audible devices and/or solenoid valves.

Lastly connect input and battery back-up

power.

- Follow the Installation, Testing and

Maintenace procedure for complete testing

and operations of installed system.

11

BATTERY CABINET MOUNTING

- The Battery Cabinet should be mounted directly below

the SRP-4x4 Panel. The Battery wiring is classified as Non-

Power-Limited. Therefore the wiring must be segregated

from Power-Limited wiring with a minimum of two cable

entry openings and a 1/4” spacing between the two

conductors.

- Batteries are connected to the Fire Control Panel by using

16 AWG wire to the supplied PWSC splicing connector

(501740) and passed thru closed nipple rigid metal conduit.

- Battery wire leads should be color coded with respect to

supplied battery wiring of the panel.

Caution: Always observe polarity when connecting up

batteries. Improper connection will cause the battery

fuse to blow. See Page 41 for proper Battery Calculation

Sizing.

Caution: Batteries contain sulfuric acid which can cause

severe burns to the skin and eyes. If contact is made

with sulfuric acid, immediately flush skin or eyes with

water for 15 minutes and seek immediate medical

attention.

PWSC SPLICING CONNECTOR

PWSC SPLICING CONNECTOR

SRP-4X4 FIRE CONTROL PANEL

SRP-4X4 FIRE CONTROL PANEL

(501740)

(501740)

BLACK

BLACK

RED

RED

BLACK 16 AWG WIRE

BLACK 16 AWG WIRE

12 VOLT BATTERY

12 VOLT BATTERY

12 VOLT BATTERY

12 VOLT BATTERY

RED 16 AWG WIRE

RED 16 AWG WIRE

BLACK 16 AWG WIRE

BLACK 16 AWG WIRE

CLOSED NIPPLE CONDUIT CONNECTOR

CLOSED NIPPLE CONDUIT CONNECTOR

(BATTERY CABINET E-.5)

(BATTERY CABINET E-.5)

+

+

+

+

-

-

-

-

CIRCUIT

BREAKER

WARNING

HIGH VOLTAGE

110-120V

ALARM

ALARM

OUTPUT CIRCUITS

OUTPUT CIRCUITS

BATT TRO

BATT TRO

OUTPUT

OUTPUT

4

4

GND FLT

GND FLT

AC ON

AC ON

OUTPUT

OUTPUT

OUTPUT

OUTPUT

2

2

3

3

TROUBLE

TROUBLE

GENERAL

GENERAL

1

1

ZONE

ZONE

4

4

ZONE

ZONE

ZONE

ZONE

ZONE

ZONE

ALARM

ALARM

2

2

3

3

TROUBLE

TROUBLE

1

1

PANEL

FIRE

CONTROL

1

1

SUPVRY.

SUPVRY.

3

3

INPUT ZONES

INPUT ZONES

2

2

4

4

TROUBLE

TROUBLE

SILENCE

SILENCE

SYSTEM

SYSTEM

TROUBLE

TROUBLE

ALARM

ALARM

SUPVRY

SUPVRY

COM ALARM

COM ALARM

OUT. DISC.

OUT. DISC.

SUPVISRY

SUPVISRY

CAUTION

DE-ENERGIZE

UNIT PRIOR

TO

SERVICING

REMOVE

REMOVE

DISPLAY

DISPLAY

PLATE

PLATE

FOR

FOR

PROGRAMMING

PROGRAMMING

ACCESS

ACCESS

-+ OP1 OP2

+ - OP3

+-

OP4

+-

+24V -COM NO NC

TROUBLE ALARM

NOCOM NC

SUPERVISORY

COM NO NC SRP-4x4

PUSH TO READ ALARM POINT

GN L

ZONE 1 2 3 4

+- -

ZONE 2

+

ZONE 3

-+

ZONE 4

+-

SUPERV.

+-

RTN +

L OUT

PT 1 PT 2 PT 3 PT 4

GND

BATTERY

-

+

DISC.

TRANSFORMER AC INPUT

+

AL PT LOCATOR

METER

ZONE 1

SYSTEM

SILENCE

SYSTEM

RESET

7.00 20.00

20.25

18.00

9.50

.28

2 PL

12.25

1.00

1.50

.50

.14 R

.87

DETAIL "A"

SEE DETAIL "A"

12.00

BATTERY CABINET DIMENSIONS

- Battery Cabinet can be purchased in two colors, red (E-.5) or beige (E-.5B)

12

SRP-4x4 Fire Alarm Control Panel

Typical Panel Wire Routing Detail

NOTE: ALL NON-POWER-LIMITED

WIRING MUST BE SEGREGATED

FROM POWER-LIMITED WIRING WITH

A MINIMUM OF TWO CABLE ENTRY

OPENINGS AND 1/4"SPACING

BETWEEN THE TWO CONDUCTOR

TYPES

DRY CONTACTS FROM COMMON

TROUBLE, COMMON ALARM &

SUPERVISORY RELAY CONNECTIONS

ARE ONLY CONSIDERED

POWER-LIMITED WHEN CONNECTED TO

A POWER LIMITED SOURCE

ALARM

ALARM

OUTPUT CIRCUITS

OUTPUT CIRCUITS

BATT TRO

BATT TRO

OUTPUT

OUTPUT

4

4

GND FLT

GND FLT

AC ON

AC ON

OUTPUT

OUTPUT

OUTPUT

OUTPUT

2

2

3

3

TROUBLE

TROUBLE

GENERAL

GENERAL

1

1

ZONE

ZONE

4

4

ZONE

ZONE

ZONE

ZONE

ZONE

ZONE

ALARM

ALARM

2

2

3

3

TROUBLE

TROUBLE

1

1

PANEL

FIRE

CONTROL

1

1

SUPVRY.

SUPVRY.

3

3

INPUT ZONES

INPUT ZONES

2

2

4

4

POWER-LIMITED CIRCUITS

POWER-LIMITED CIRCUITS

NON-POWER-LIMITED CIRCUITS

BATTERIES: NON-POWER-LIMITED CIRCUITS

TROUBLE

TROUBLE

SILENCE

SILENCE

SYSTEM

SYSTEM

TROUBLE

TROUBLE

ALARM

ALARM

SUPVRY

SUPVRY

COM ALARM

COM ALARM

110-120V

110-120V

HIGH VOLTAGE

HIGH VOLTAGE

WARNING:

WARNING:

CIRCUIT

CIRCUIT

BREAKER

BREAKER

POWER-LIMITED CIRCUITS

OUT. DISC.

OUT. DISC.

SUPVISRY

SUPVISRY

-+ OP1 OP2

+ - OP3

+-

OP4

+-

+24V -COM NO NC

TROUBLE ALARM

NOCOM NC

SUPERVISORY

COM NO NC SRP-4x4

PUSH TO READ ALARM POINT

GN L

ZONE 1 2 3 4

+- -

ZONE 2

+

ZONE 3

-+

ZONE 4

+-

SUPERV.

+-

RTN +

L OUT

PT 1 PT 2 PT 3 PT 4

GND

BATTERY

-

+

DISC.

TRANSFORMER AC INPUT

+

AL PT LOCATOR

METER

ZONE 1

SYSTEM

SILENCE

SYSTEM

RESET

CAUTION

DE-ENERGIZE

UNIT PRIOR

TO

SERVICING

REMOVE

REMOVE

DISPLAY

DISPLAY

PLATE

PLATE

FOR

FOR

PROGRAMMING

PROGRAMMING

ACCESS

ACCESS

When bringing field wires to and from the control panel you must maintain segregation between Power Limited

and Non-Power Limited wiring. Use the illustration below as a guideline for routing wire within the system enclo-

sure. Also reference the field wiring sections of this manual to determine which field connections are Power

Limited and which are Non-Power Limited

13

GAUGE (AWG) OHMS PER 1,000 FT.

SINGLE CONDUCTOR

10 1.018

12 1.619

14 2.575

16 4.094

18 6.510

TOTAL

DEVICED

LOAD

(AMPS)

FEET OF 2 CONDUCTOR WIRE

18 AWG 16 AWG 14 AWG 12 AWG 10 AWG

0.060 2560 4070 6470 10290 16370

0.125 1225 1950 3165 4940 7855

0.250 610 975 1550 2470 3925

0.375 405 650 1035 1645 2615

0.500 305 485 765 1235 1960

0.625 245 390 620 985 1570

0.750 200 325 515 820 1305

1.000 150 240 385 615 980

1.250 120 195 310 490 785

1.500 100 160 255 410 650

1.750 85 135 220 350 560

2.000 75 120 190 305 490

DEVICE MFGR MODEL AMPS

HORNS

AMESCO

H24W 0.035

HW-24 0.035

WHEELOCK MIZ 0.043

FEDERAL 450 0.25

MOTOR

BELLS

AMESCO

MBA-6-24 0.012

MBA-8-24 0.025

WHEELOCK MB 0.030

STROBE

AMESCO

SLW24W 0.120

SAD24 0.250

WHEELOCK

AHWP 0.100

ASWP 0.113

FEDERAL LP3 SERIES 0.22

HORN/

STROBE

AMESCO

SHW24W 0.088

SHP24 0.250

WHEELOCK NS4 0.361

STROBE/

BUZZER FEDERAL

AV1ST 0.39

AV1 0.98

FOR COMPLETE LIST OF NOTIFICATION APPLIANCE

DEVICES AND THEIR CORRESPONDING CURRENT

DRAW SEE APPENDIX A

TABLE 3 - ALARM INDICATING CIRCUIT

WIRE SIZE FOR 24VDC POLARIZING DEVICES

ALARM NOTIFICATION APPLIANCE CIRCUIT WIRE SIZE ESTIMATOR

To insure that all notification appliance circuits will be supplied with adequate power to operate, it is necessary to use

the correct size cable for the distance and current requirements of each circuit. Follow the steps below to calculate the

correct wire size for your application. The calculations are based on a maximum line loss (voltage drop) of 1.0 volts.

1. Calculate the required alarm device current.

(Number of Devices) X (Device Current) = Total Alarm Device Current (AMPS)

2. Determine the wire run distance in feet from the panel to the last alarm device.

3. Find the load current (AMPS) on Table 3 that best matches the required alarm device current. If the device current is

in between two values, use the higher value.

4. Find the wire run distance to the right of the device current value chosen in step 3 which is greater than your

requirement.

5. The gauge at the top of the distance column is what will be required to insure a maximum line loss of less than 1

volt, or 1 ohm max. fully loaded.

EXAMPLE: If the total alarm device load is .680 AMPS; select .750 AMPS. If the measured distance is

400 feet; select 515 feet which is in the 14 AWG column.

TABLE 2 - COPPER WIRE RESISTANCE

NOTE: The maximum alarm indicating circuit resistance is

calculated for a line loss of 1 volt divided by the maximum

alarm device current.

AWG = AMERICAN WIRE GAUGE

TABLE 1 - COMPATIBLE 24VDC

POLARIZING SIGNALING DEVICES

14

FIELD WIRING

SUPERVISED INITIATING DEVICE CIRCUITS

CLASS A (NFPA STYLE D) / CLASS B (NFPA STYLE B)

Use the following compatible devices approved by The Protectowire Co., Inc.

- UP TO 10,000 FEET OF PROTECTOWIRE (May be placed after last detector)

- UP TO (5) 0.045mA TWO-WIRE HOCHIKI SMOKE DETECTORS

NOTES: Maximum feed cable resistance = 100 OHMS to last smoke detector. Feed cable may consist of any

combination of PROTECTOWIRE or copper wire.

Hochiki Smoke detectors PRO SERIES #SLR-24 (Photoelectric), #SIJ-24 (Ionization)

Detector Identifier - HD-3 Base Identifier - HB-3. Also, #SLR-24H Photo/Heat Smoke Detector Identifier –

HB-3. Per UL 864 9th edition stipulation has been added that two wire smoke detectors of different models

are not to be mixed or matched on a system.

Note: Power-limited field wiring must be isolated from non-power-limited field wiring.

Use 14 - 18 AWG wire UL Listed for Application.

CIRCUITS (1)

SW. SUPERVISORY

(-) OUT

(+) OUT

CLASS B

234

L RTN +

L OUT

PT 1 PT 2 PT 3 PT 4

GND

AL PT LOCATOR

METER

SMOKE

DET.

HEAT

SPOT

ZONE 1

FEED CABLE

100 OHMS MAX.

PROTECTOWIRE

FEED CABLE

TYPICAL CLASS A DETECTION

(NFPA STYLES D)

ZB-4-QC-MP

ZONE BOX

PROTECTOWIRE

LINE HEAT

DETECTOR

UP TO 500 FT.

(+) OUT

(-) OUT

(+) RET.

(-) RET.

ZB-4-QC-MP

ZONE BOX

ZONE 2 ZONE 3 ZONE 4

ISOLATED FROM NON

NOTE: POWER LIMITED

FIELD WIRING MUST BE

POWER LIMITED FIELD WIRING.

READ ALARM POINT

TYPICAL CLASS B DETECTION

FEED CABLE

PROTECTOWIRE

2 43

WITH ELR

(ZB-4-QC-MP)

ZONE BOX

(10,000 FT. TOTAL)

9,500 FT.

UP TO ADD'L

DETECTOR

LINE HEAT

PROTECTOWIRE

ZB-4-QC-MP

ZONE BOX

(-) OUT

ZONE 2

PT 2

AL PT LOCATOR

METER

L RTN +

PT 1

ZONE 1

(+) OUT

L OUT

(-) OUT

(+) OUT

(-) OUT

ZONE 4

PT 3

(-) OUT

ZONE 3

(+) OUT

(+) OUT

PT 4

RESISTANCE TO

100 OHMS MAX.

FEED CABLE

MAXIMUM

DETECTOR

UP TO 500 FT.

LINE HEAT

PROTECTOWIRE

ZONE BOX

ZB-4-QC-MP

ZONE BOX

ZB-4-QC-MP

1/2W

8.2K

(NFPA STYLES B)

ELR

8.2K 1/2W

SUPERVISORY 1

GND

READ ALARM POINT

DET.

SMOKE

DET.

DET.

SMOKE

LAST DETECTOR

RESISTANCE TO

LAST DETECTOR

*UPPER RIGHT CORNER

OF BOARD

*UPPER RIGHT CORNER

OF BOARD

SWITCH

SWITCH

SUPERVISORY

MAXIMUM AMOUNT OF

FEED CABLE / PROTECTOWIRE

CANNOT EXCEED 100 OHMS

WHEN UTILIZING SMOKE

NOTE: UP TO 10,000 FT OF PROTECTOWIRE

PER ZONE, WHEN NO SMOKE DETECTORS

ARE UTILIZED

DETECTORS

Note:

The panel is supplied with ELR-8.2K Ohm Resistors on all Initiating

circuits. When wiring detection zone in a Class B configuration, these

resistors must be removed and placed at the end of each detection

circuit and mounted in a Protectowire Zone Box (ZB-4-QC-MP).

See above illustration.

ZONE BOX

ZONE BOX

ZB-4-QC-MP

ZB-4-QC-MP

ZONE DESIGNATION

ZONE DESIGNATION

:_________

:_________

ELR VALUE: ______________

ELR VALUE: ______________

DATE:____________________

DATE:____________________

INSTALLER:_______________

INSTALLER:_______________

15

FIELD WIRING

SUPERVISED ALARM NOTIFICATION, SOLENOID RELEASE CIRCUITS

& NON-SUPERVISED AUXILIARY 24V USAGE

NOTE: OUTPUT CIRCUIT #1 USED FOR NOTIFICATION PURPOSES ONLY WHILE

OUTPUT CIRCUITS #2 thru #4 MAY BE USED FOR EITHER NOTIFICATION AND/OR RELEASING

-

-

+

+

Output circuits OP1 thru OP4 are all power-limited circuits and must be segregated from non-power-limited

circuits with a minimum spacing of two cable entry openings and 1/4” spacing between the two conductor types.

See wire routing detail for layout.

To provide proper supervision of solenoid coils, the ELD must be installed in the same junction box as the

solenoid.

Auxiliary 24 V output is power-limited, with a maximum current draw of 100mA. It is an un-supervised circuit,

therefore it can only be used for three purposes per UL 864 requirements.

NOTES:

1) As a bell, register or similar indicating device included as part of the control-unit assembly.

2) As an alarm bell installed in the same room as the control unit provided the bell circuit conductors are to be

installed in conduit or have equivalent protection.

3) Or as a supplemental signal annunciator, signal-sounding appliance, motor stop, or similar appliance,

provided that neither a short circuit, a break, or a ground fault will not prevent normal operation other than

the omission of the supplementary feature.

Use 10-14 AWG wire, UL listed for application.

16

PDM-1000-4

PROTECTOWIRE ALARM POINT LOCATION METER

DESCRIPTION:

The PDM-1000-4 PROTECTOWIRE Digital Alarm Point Location Meter is designed to help locate a heat actuated

point on a PROTECTOWIRE line heat detector circuit. This meter identifies the distance in feet or meters (preset

at the factory) along the detector from the start of the run to the actuated point.

Note: The PDM-1000-4 is calibrated at the factory and only requires adjustment to compensate for field cable

resistance at the time of installation.

OPERATION:

When an alarm signal is received at the main control panel, depress the meter switch (see illustration below) of the

zone in alarm. The meter will then display the distance to the actuated portion of the PROTECTOWIRE line heat

detector circuit.

CALIBRATION:

The copper feed wire between the control panel and the zone (junction) box at the start of the PROTECTOWIRE

run has an inherent resistance. This resistance although small compared to that of the PROTECTOWIRE, will

introduce an error in the digital meter reading. The longer the feed wire, the greater the error. Adjust the meter per

the following procedure to compensate for field wiring resistance.

1. Disconnect all alarm and/or releasing devices connected to the control panel

and apply power to the system before proceeding.

2. Connect a jumper wire across the detection circuit at the beginning of the

PROTECTOWIRE run (at the zone box). Caution: This will trip the detec-

tion circuit into an alarm condition.

3. At the control panel press the meter read switch for the appropriate zone in

alarm. The meter will display the feed cable error.

4. To cancel out (zero) this value, adjust the corresponding PT# potentiometer

on the main panel for the zone in alarm by using a small screwdriver to turn

the potentiometer until the meter reads zero (see below).

Note: the positive (+) and negative (-) indicator will fluctuate when zeroed.

5. Repeat this procedure for all other zones containing PROTECTOWIRE

line heat detector.

Note:

The PROTECTOWIRE digital meter is designed for reading lengths of PROTECTOWIRE line heat detector cable

installed at an ambient temperature of 70º F. Since the inner conductors of PROTECTOWIRE consists of two

steel wires, the inherent cable resistance is subject to change proportionally to temperature. For each 10º F change

in temperature a 1% change in total measure cable length can be expected. Using #14 AWG or larger copper feed

wire in detection circuits that have PROTECTOWIRE will minimize meter reading error.

PUSH TO READ ALARM POINT

ZONE 1 2 3 4

METER RELAY

METER RELAY

METER RELAY

METER RELAY

ZONE

+- -

ONE

+

ONE

-+

ZON

+-

SUPERV.

+-

-

L RTN + L OUT

PT 1 PT 2 PT 3 PT 4

GND

AL PT LOCATOR

METER

FIELD ADJUSTMENT

FOR PWM-D ON MAIN PANEL

(UPPER RIGHT CORNER OF BOARD)

ZONE ALARM

METER SWITCHES

17

RB-4

AUXILIARY RELAY MODULE

Description - Auxiliary signaling relays are often needed to provide an interface to other systems for annunciation

and/or electrical shutdown. The RB-4 Relay Module provides 4 individually zone activated sets of Form “C”

contacts in one module.

Operation - The RB-4 relays are normally de-energized. Each relay ( 1 – 4) is activated by an alarm of its corre-

sponding input circuit (1 – 4). Indicators L1 through L4 (Red) illuminate when the corresponding relay is activated.

RB-4

Form “C” Contacts

RED

FRONT VIEW

RED

RB-4

SRP-4x4

SRP-4x4

WIRING HARNESS H1

STANDOFFS 6 PLACES

WIRING HARNESS H1

WIRING HARNESS H1

SIDE VIEW

JP3

JP3

Mounting Diagram

Electrical

DC Contact Rating - 1 AMP @ 24VDC (Resistive)

Contact Configuration (4) - SPDT

Coil Rating each (4) - 0.013 AMPS @ 24VDC

Terminal Wire Capacity - 18-14 AWG Solid/Braid

Indicator - Red LED

18

CLASS “A” ALARM NOTIFICATION

APPLIANCE CIRCUIT ADAPTER

Description: The AM-91-2 Alarm Notification Appliance Circuit Adapter Module converts the two Class B system

Alarm Notification Appliance Circuits from the Main Board to Class A type circuits. This provides four wire alarm

notification appliance circuits in lieu of the standard 2 wire circuits.

Operation: The two wire Class B circuits are wired into the module input terminals (TB1). The AM-91-2 then

conditions and converts the circuits to four wire Class A alarm notification appliance circuits. This Alarm notifica-

tion appliance output circuit is fully supervised with the reverse polarity current flow. A short or open in the field

wiring is detected by the system controls. Once an alarm is initiated the circuit immediately reverses polarity and the

24V FWR power is supplied to the alarm notification appliance devices. If a single break occurs in the circuit all

devices will still be supplied power in an alarm state due to the nature of a Class A wiring configuration.

Voltage 24V regulated Full wave rectified (FWR) with battery

standby 1 AMPS per circuit 2.1 AMPS maximum combined.

Current

Maximum 2 conductor copper feed cable resistance

may not exceed 1 OHM (see below)

#10 AWG Maximum of 500’ (feet) Reference DS-9066

#12 AWG Maximum of 300’ (feet) Reference DS-9066

#14 AWG Maximum of 200’ (feet) Reference DS-9066

LAST 1ST

1STLAST

OUTPUTS OP2

OP1

TB2 (SRP-4x4)

SUPERVISED

CLASS B

SIGNALING

CIRCUIT #2

SUPERVISED

CLASS B

SIGNALING

CIRCUIT #1 (+)

(-)

(-) RETURN

(-) OUT

(+) OUT

(+) RETURN

(+) RETURN

(+) OUT

(-) OUT

(-) RETURN

SUPERVISED

CLASS A

SIGNAL

CIRCUIT #1

(+)

(-)

SUPERVISED

CLASS A

SIGNAL

CIRCUIT #2

AM-91-2 Class A Alarm Notification Appliance

Circuit Adapter Module

Note: Polarity of Notification

Appliance Circuits shown in

Alarm Condition

AM-91-2

Table of contents

Other Protectowire Control Unit manuals