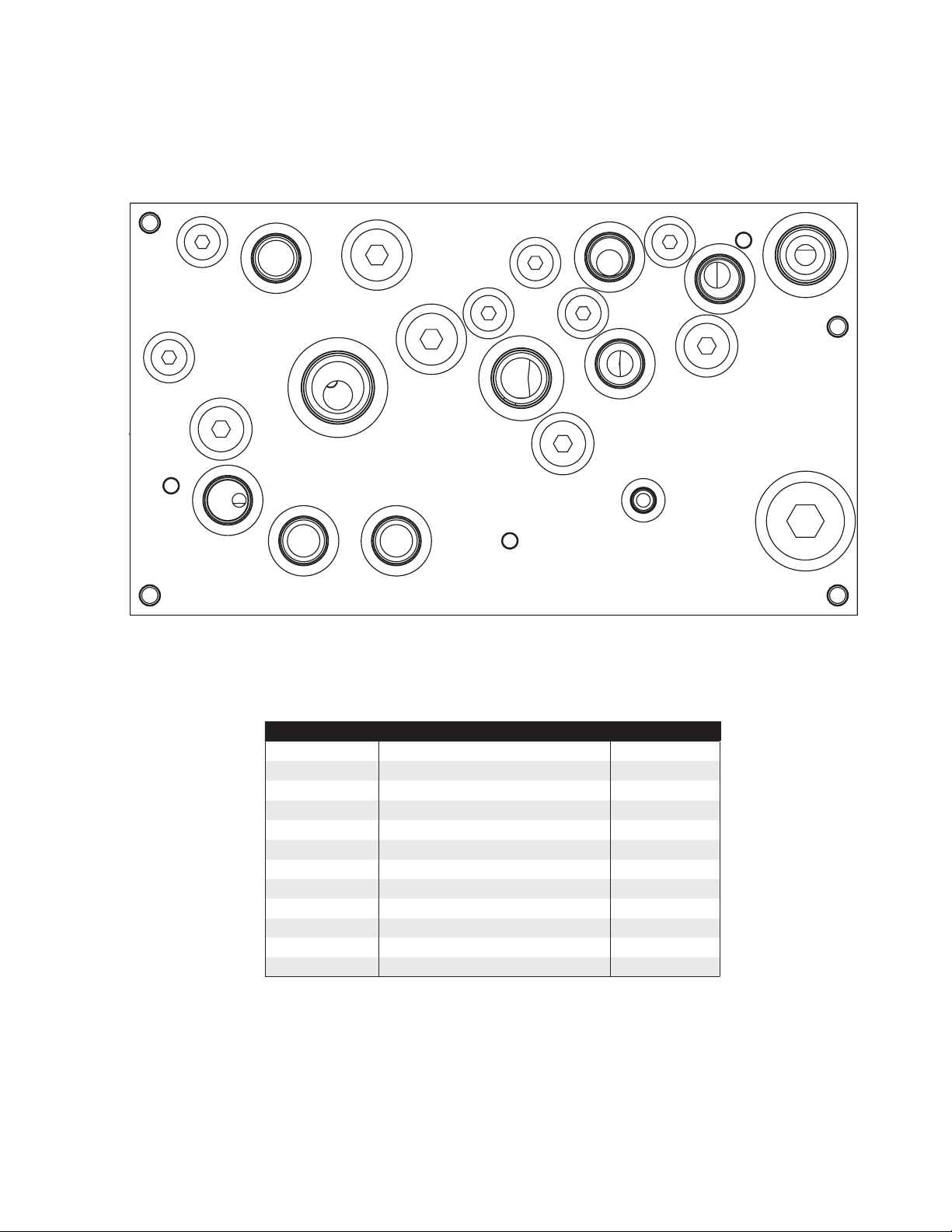

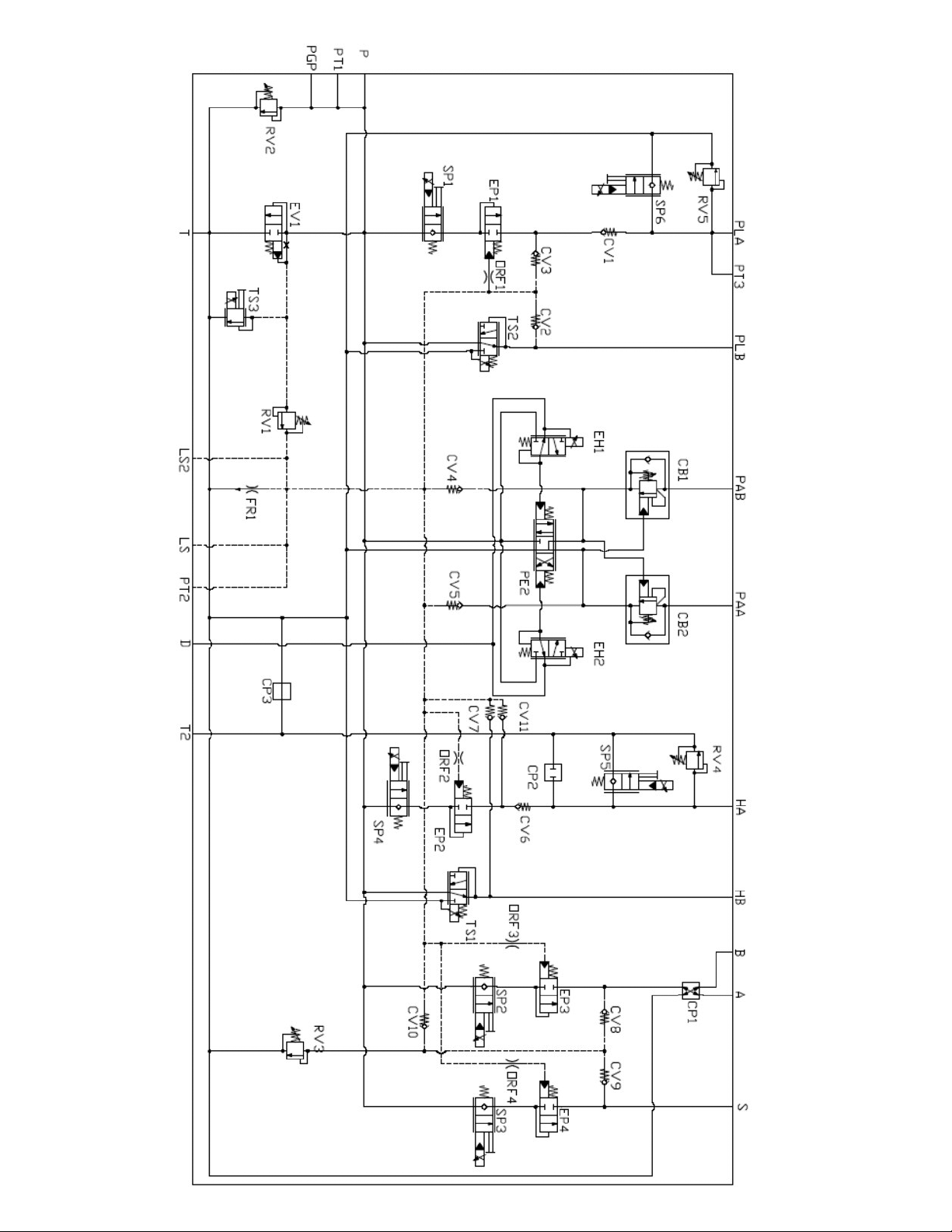

Pump Gage Port (PGP) – Indicates the inlet pressure from the pump. This pressure will be approximately 200 to 300

PSI higher than the Load Sense pressure.

Load Sense (LS2) – Indicates the pressure of the load. If more than one function is operating, the higher load pressure

will be observed. There will only be a pressure from the LS port if a function is operating. Remember, the Pump Gauge

will display a pressure approximately 200 PSI higher than the LS Gauge while a function is operating.

EV1 (Plugged when used with a piston pump) – unloading pressure compensating cartridge. EV1 is a normally closed

-two position - two way -pilot cartridge. It can provide a low pressure path for pump ow to escape to tank. This is its

primary function when the pump is bypassing (no functions operating). The bypass pressure of the pump in this state

will vary from about 20-60 PSI depending upon the pump ow. This pressure will show at PGP. The path to tank is

opened by pump pressure being applied to the left side pilot of EV1 which forces the valve open. The right side pilot

line of EV1 is drained to tank through the TS3 when not engaged (Electrically Actuated Main Relief Valve) to allow the

EV1 valve to open fully.

TS3 – Electrically Actuated Main Relief Valve. TS3 is a normally open two position - two way solenoid operated relief

valve. When its solenoid is not energized it provides a drain path for the pilot pressure on the right side of EV1. This

allows for pilot pressure on the left side of EV1 to push it open and expose a low pressure path for the pump ow to

escape to tank.

TS3 - will energize whenever any function of the Advantage Plus is operating. This closes the pilot drain on the right

side of EV1 and that in-turn causes EV1 to begin shutting off the pump ow escape to tank. Pump ow is now forced to

move toward the actuators as required. If TS3 was energized by itself or manually overridden without any other system

valves functioning, the pressure at PGP would be approximately 200 PSI to 300 PSI. The L.S. port would not show

pressure.

In addition, the TS3 valve is used as the main relief. It is an electrically adjustable relief that can be adjusted up to a

maximum setting of 3000 PSI.

RV1 (Plugged when used with a piston pump) – Boost Pressure Relief Valve. RV1’s purpose is to raise the

differential or boost pressure between PGP and LS by a margin of approximately 200 to 300 PSI. It comes into

play when TS1 is energized. At that point the pilot pressure on the right side of EV1 can only drain through RV1.

RV1’s internal bias spring is set for 200 PSI. That means the pressure of EV1’s pilots (both sides) must build to at

least 200 PSI before the right side pilot can drain through RV1 and allow EV1 to begin to open. This boost pressure

is required to allow ow to get through other cartridge valves in the system to operate functions.

When RV1 has a load-sense pressure applied to its right side, which is communicated from the array of LS check

valves (CV2, CV3, CV4, CV5, CV7, CV11, etc) this will add to the pressure required for EV1 to drain its right side

pilot and open. For example, if the load-sense pressure for a spreader motor is 1000 PSI, this will be added to the

(200 PSI) spring bias pressure of RV1. Now EV1 cannot begin to open its path to tank until the pump pressure has

achieved something slightly higher than 1200 PSI. PGP would display 1200 PSI and L.S. port would display 1000

PSI. In this way the system will always attempt to sustain a differential or boost pressure of approximately 200 PSI.

FR1– Load sense drain orice. FR1 provides a controlled drain for the load-sense pilot line. Its function is to

ensure that the pressure cannot be trapped in this pilot and result in EV1 not being able to fully open at low

pressure when required.

Post Compensators (EP1, EP2, EP3, and EP4) – The post compensators ensure that all functions will operate

simultaneously during low pump ow situations (when the circuit requires more oil than the pump can provide).

The pilots of the post compensators are directly tied to the LS pressure network. Each compensator will modulate

ow by restricting or allowing ow to pass to achieve a constant differential. This differential across all of the

compensators allows all of the functions to work with each other to prevent any one function from coming to a

complete stop.

RV2 – Clipper Relief – The purpose of this valve is to provide redundant pressure protection and clip any pressure

spikes that occur due to load shocks. Therefore, when a shock load occurs within the system, this relief will clip

any pressure beyond its set point.

10

EXPLANATION OF UNLOADING CIRCUIT

HYDRAULIC