Rev: 01.07.22 Page 10 CCD-0001459

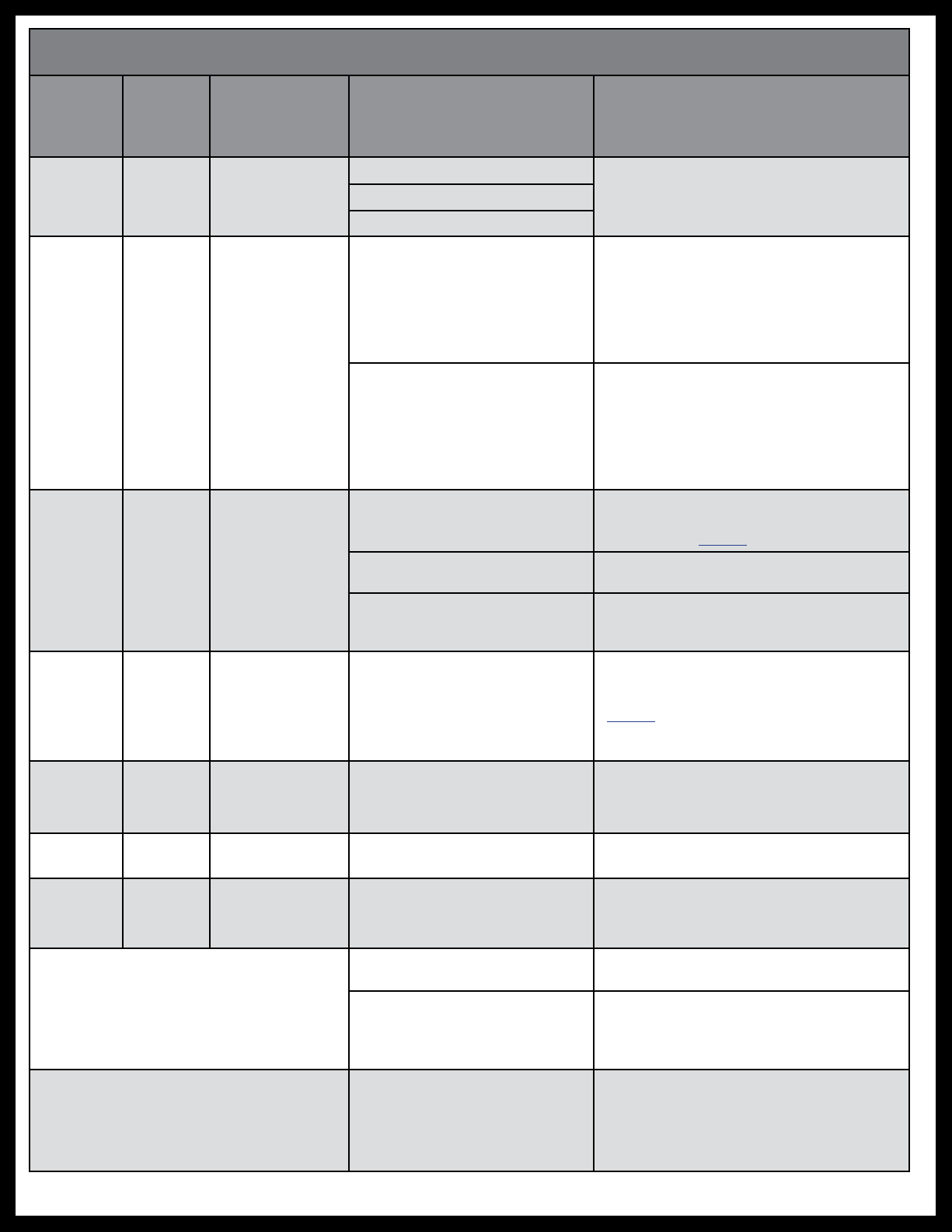

Fault Code Table - Programmable Controller 700155/700157

Fault

Code

(# of RED

flashes)

Fault

Type Description Why? What Should Be Done?

1 Major Stops not

programmed

Stops have not been set

Stops must be programmed by an

authorized service facility.

Stops were cleared

Stops were improperly set

2 Minor System fault

Obstruction present

Run slide-out room in opposite direction of

drag. If slide-out room continues to move

in opposite direction, remove obstruction

or have damaged component replaced. If

slide-out room stops moving in opposite

direction, observe fault code and refer to

this chart.

Excessive system drag

Run slide-out room in opposite direction of

drag. If slide-out room continues to move

in opposite direction, remove obstruction

or have damaged component replaced. If

slide-out room stops moving in opposite

direction, observe fault code and refer to

this chart.

4 Major Motor fault

Bad or loose connection(s)

Check all connections at controller and

motor. See Wiring Diagram for Controller

1510000199 / 366697, 700155, 700157.

Defective harness Check harness for broken wires. Replace as

needed.

Open or shorted motor

Apply a 12V DC power source to the motor.

If motor does not operate, replace the

motor.

6 Minor Excessive

battery voltage

Supply voltage to controller is

17V DC or greater

Use a multimeter to check 2-pin power

connector at controller. See Wiring

Diagram for Controller 1510000199 /

366697, 700155, 700157. If the voltage is

17V DC or higher, contact OEM for power

and ground supplies.

7 Major Stops Not

Programmed

• Stops have not been set

• Stops were cleared

• Stops were improperly set

Stops need to be programmed according

to the programing instructions in this

document.

8 Minor Fuse, Motor 1 Motor fuse concern Contact Lippert Representative

9 Major Battery Drop

Out

Battery dropped below 8.5V

while extending or retracting

slide

Charge battery, start vehicle, generator, or

make sure unit is pugged into shore power.

Park brake LED flashing (700157 only)

Parking brake not set if

applicable Set parking brake if applicable

Ground signal lost at

park brake connector

on controller

Check for continuity to ground on wire

plugged into park brake connector at

controller. See Wiring Diagram.

Low voltage LED flashing Incoming voltage to controller

is below 12V DC

Use a multimeter to check 2-pin power

connector at controller. See Wiring

Diagram. If the voltage is below 12V DC,

contact OEM for recommendation.