Prusa i3 Hephestos User manual

Pleasealwaysrefertothehttp://www.prusa3d.com/drivers/

forupdatedversionofthis3Dprintinghandbook(PDFdownload).

QUICK GUIDE TO THE FIRST PRINT

1.Placetheprinteronaflatandstablesurface(page10)

2.Readthesafetyinstructionscarefully(page5)

3.Downloadandinstallthedrivers(page22)

4.Preparetheglass(page10)andcalibratetheprinter(page12)

5.InsertSDintotheprinterandprintyourfirstmodel(page16)

Handbookversion1.01fromSeptember15

th

,2015.©PrusaResearchs.r.o.

2

Table of contents

1Productdetails

2Introduction

2.1Glossary

2.2Usedsymbols

2.3Safetyinstructions

2.4AssembledOriginalPrusai3Plusprinter

2.5OriginalPrusai3Plusprinterkit

2.6Licenses

3OriginalPrusai3Plusprinter

4OriginalPrusai3Plusprinterkit

5Firststeps

5.1Printerunpackingandproperhandling

5.2Printerassembly

5.3Setupbeforeprinting

5.3.1Glasspreparation

5.3.2ABSJuicepreparation

5.3.3PluggingtheACpower

5.3.4Calibration

5.3.5Loadingthefilamentintotheextruder

6Printing

6.1Printercontrols

6.1.1LCDscreen

6.1.2LCDlayout

6.1.3Printspeedversusprintquality

6.1.4USBcableandPronterface

7Printerdrivers

8Printingyourownmodels

8.1Whereyoucangetthe3Dmodels?

8.2Inwhatprogramyoucancreateyourownmodels?

8.3Slic3r

8.4Printingofnonstandardmodels

8.4.1Printingwithsupportmaterial

8.4.2Largeobjectprinting

9Materials

9.1ABS

9.2PLA

9.3PET

9.4HIPS

9.5PP

9.6Flex

10FAQPrintermaintenanceandprintissues

10.1Glasscleaning

10.2Clogged/jammedextruder

3

10.3Nozzlecleaning

10.4Axisfluency

10.5Calibrationissues

10.5.1Nozzletapstheglass

10.5.2DifferentspacingbetweennozzleandglassaftereveryZaxisreset

10.5.3Glassisunstableanddoesn’tholdfirmly

10.5.4DefaultXaxispositionisoutsidetheglass

10.5.5UnevenspacingofthenozzleontheXaxisoppositeends

10.6Printingproblems

10.6.1ABSmodelstearupfromtheglasswhenprinting

10.6.2LayersbreakandsplitwhenprintingfromABSmaterial

10.6.3Modelsmovetheglassduringtheprint

10.6.4Modelscontaineithertoomuchornotenoughofthefilament

10.7Problemswithfinishedmodels

10.7.1Modelbreaksand/oriseasilydestructed

11FAQcommonissueswhenassemblingtheprinterkit

11.1Nozzle/glassgapisgreaterinthemiddlethanatthecorners

11.2Printerstopsprintingsoonafterstart

11.3Printercan’treadSDcard

11.4LooseXand/orYaxisbelts

11.5Unattachedcablestotheheatbed

11.6Looseheatbedzipties

1 Product details

Title:OriginalPrusai3Plus/OriginalPrusai3Plus(kit)

Version:1.75mm

Manufacturer:PrusaResearchs.r.o.,PrvníhoPluku621/8a,Praha8,18600,Česká

republika

Contacts:phone+420222263718,email:[email protected]

EEEgroup:3(ITand/ortelecommunicationequipment)

Deviceuse:indooronly

Powersupply:90135VAC,2A/180264VAC,1A(5060Hz)

Workingtemperaturerange:18°C(PLA)38°C,indooruseonly

Workinghumidity:85%orless

Kitweight(brutto/netto):9.8kg/6.3kg

Assembledprinterweight(brutto/netto):12kg/6.3kg

Serialnumberislocatedontheprintercontrolunitandalsoonthepackaging.

4

2 Introduction

Thankyouforpurchasingouroriginal3DprinterPrusai3Plus1.75fromJosefPrusaeither

asaassembledprinteroraprinterkitasyourpurchasesupportsuswithitsfurther

development.Readthehandbookcarefully,please,allchapterscontainvaluableinfoforthe

correctserviceoftheprinter.

Pleasecheckthehttp://prusa3d.com/driverspageforupdatedversionofthis3D

printinghanbook(PDFdownload).

Incaseofanyprinterrelatedproblemdonothesitatetocontactusat[email protected]

.We

aregladtoreceiveallyourvaluablecommentsandtips.Westronglysuggestyoutovisitour

officialforumatforum.prusa3d.com,whereyoucanfindsolutionstocommonissues,tips,

adviceandhintsinadditiontoactualinformationabouttheOriginalPrusai3printer’s

development.

2.1 Glossary

Bed,Heatbed,PrintbedCommonlyusedtermforprintingpadaheatedareaof3D

printerwhere3Dobjectsareprinted.

ExtruderPrintingheadorextruderisapartofaprinterconsistingofanozzle,hobbed

pulley,idlerandanozzlefan.

FilamentTermforplasticprovidedonspooliscalled“filament”,it’susedthroughoutthis

handbookaswellasintheLCDmenuontheprinter.

Heater,Hotendothernameforaprintingnozzle.

1.753Dprintersusetwodifferentdiameters(thickness)ofafilament(thickness):2.85mm

(commonlycalledas3mm)and1.75mm.1.75mmversionismoreusedworldwidethough

thereisnodifferenceinprintingquality.

2.2 Used symbols

Importantnotice,tip,hintorinformationwhathelpsyouprintwithease.

Readcarefully!Thispartoftexthasuppermostimportanceeitherforusersafetyof

foraproperprinterservice.

Thissymbolindicatestextrelatedtoprinterkitonly.

2.3 Safety instructions

Pleasebeverycautiousduringanyinteractionwiththeprinter.Thisprinterisan

electricaldevicewithmovingpartsandhottemperatureareas.

1.Deviceisforindooruseonly.Donotexposetheprintertorainorsnow.Alwayskeepthe

printerinadryenvironmentataminimumdistanceof30cmfromotherobjects.

2.Alwaysplacetheprinteronastableplace,whereitcannotfallortipover.

5

3.Theprintersupplyishouseholdpoweroutlet230VAC,50Hzor110VAC/60Hz;Never

connecttheprintertoadifferentpowersupply,itmaycausemalfunctionordamagetothe

printer.

4.Placethepowercordsoyoucan’tstumbleonit,orsteponitorotherwiseexposetoany

damage.Makesurethatthepowercordisnotmechanicallyorotherwisedamaged.Stop

usingdamagedcableimmediatelyandreplaceit.

5.Whenyoudisconnectthepowercordfromthesocket,pulltheplugratherthanthecordto

reducetheriskofdamagetoplugorACoutlet.

6.Neverdisassembletheprinterpowersupply,itdoesnotcontainanypartsthatcouldbe

repairedbyunskilledworker.Allrepairsmustbeprovidedbyaqualifiedtechnician.

7.Donottouchthenozzleorheatbedwhentheprinterisprintingoriswarmingup.Note

thatthetemperatureofthenozzleis210260°C;heatbedtemperaturecanreachover100

°C.Temperaturesabove40°Ccancauseharmtohumanbody.

8.Preventchildrenfromunsupervisedaccesstotheprinterevenwhentheprinterisnot

printing.

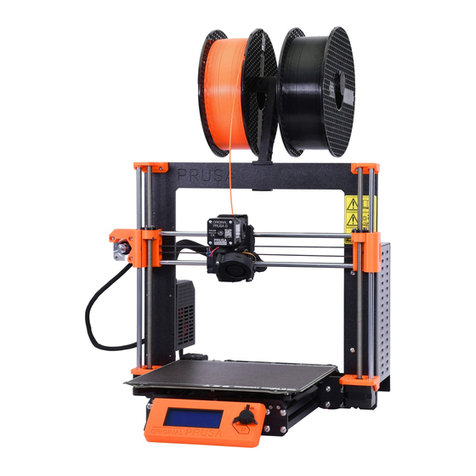

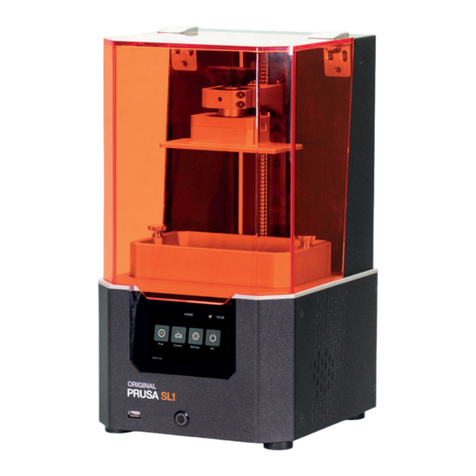

2.4 Assembled Original Prusa i3 Plus printer

YoucanfindapictureofanassembledOriginalPrusai3Plusprinterwithdescriptioninpict.

1nextpageofthishandbook.Unliketheprinterkitit’scompletelyassembledandalmost

readytoprint.Afterplugginginandnecessarycalibrationyoucanprintthe3Dobjectinthe

matterofminutesafterunpackingtheprinter.Keepinmindyoucanuseoursupportemail

whenyoupurchasedtheassembledprinter.Donothesitatetowriteusifyouneedany

adviceorhelp.Wewillgladlyhelpwithanyspecificprints.

3Dprintersusetwodifferentdiametersofafilament(youfindmoreinchapter

Materials

):2.85mmand1.75mm.1.75mmversionismoreusedworldwidethough

thereisnodifferenceinprintingquality.Filamentisprovidedonaspoolwhereyou

canfindthebasicinformationfilamentmaker,material(ABS,PLA,etc.)and

filamentdiameter.2.85mmfilamentiscommonlycalledas3mm.

Thisprintersupportsonlya1.75mmfilament.Pleasecheckthefilamentdiametertobe

1.75mmbeforeinsertingintotheextruder.Donottrytoinsertwiderfilamentitcoulddamage

theextruder.

2.5 Original Prusa i3 Plus printer kit

OriginalPrusai3Pluskitispicturedinpict.2.Detailedinformationandassembly

descriptioncanbefoundinchapterPrinterassembly.Weofferthesupportforusers

whopurchasedtheprinterkitthroughourofficialforum.Ifyouneedhelpdonot

hesitatetovisitourforumatforum.prusa3d.com.Youcanfindtheanswersforyour

problemthere.Ifnot,pleasejustaskyourquestionhere.

2.6 Licenses

OriginalPrusai3PlusprinterisapartoftheRepRapproject,thefirstopensource3Dprinter

projectfreetouseunderaGNUGPLv3license(www.gnu.org/licenses/gpl3.0.en.html).If

youimproveoralteranypartofaprinterandyouarewillingtosell,thenyouhavetopublish

thesourcecodesunderasamelicense.All3Dprintedelementsoftheprinterthatcanbe

improveduponcanbefoundathttp://www.prusa3d.com/prusai3printableparts/.

6

3 Original Prusa i3 Plus printer

Pict.1OriginalPrusai3Plus

printer

described

7

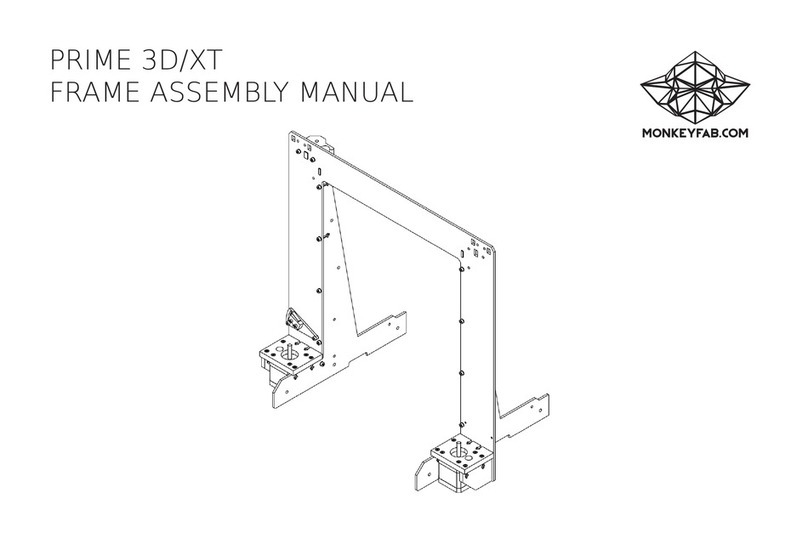

4 Original Prusa i3 Plus printer kit

Thecompletecontentsoftheprinterkitboxcanbeseenonthepicturebelow.

Pict.2OriginalPrusai3Plus

printer

kitunboxed

8

5 First steps

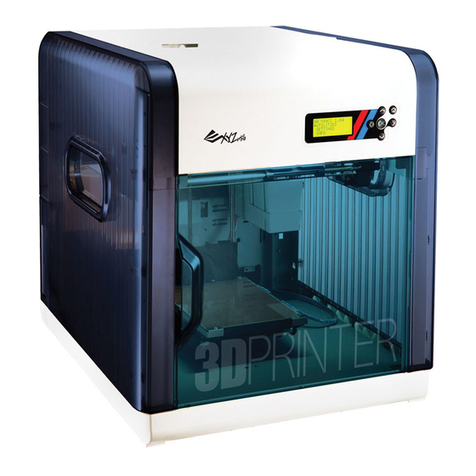

5.1 Printer unpacking and proper handling

Taketheprinterfortheupperframepullitoutfromthebox.Becarefulwhenhandlingwith

theprinternottodamagetheelectronicsandthustheproperprinterfunctionality.Anytime

youmovetheprinteralwaysholditfortheupperframewithhotbeduprightpointingaway

fromyouaspicturedinpict.3.

Pict.3

Proper

handlingofa

printer

9

5.2 Printer assembly

WithOriginalPrusai3Plusprinterkitwesuggesttofollowtheguidelinesand

assemblethekitaccordingtothetheonlinemanualatmanual.prusa3d.com.(Online

manualisavailableinseverallanguagesonthewebsite).Theconstructionofthe

printershouldnottakemorethanoneworkingday.Afterasuccessfulcompilation

continuetothechapterSetupbeforeprinting.

5.3 Setup before printing

● Placetheprintertothehorizontallystableposition,bestplaceisaworkbenchwhere

thereisnoriskofdraft.

● Attachthefilamentholderstotheupperframe.

● AttachFilamenttotheholders.Makesurethefilamentspooldoesn’tjamandcan

movefreely.

Filamentisacommontermfortheplasticrodmaterialprovidedonspool,from

which3Dobjectsareprinted.

5.3.1 Glass preparation

Theprintedobjectwillnotattachtotheheatbedproperlyifyoudonotpreparethebed

correctly.Differentmaterialsrequiredifferentglasspreparationyoucanfindmoreinthe

chapterMaterials.Commonstepsare:

● Glassalwayshastobepreparedcold,notpreheated.

● PutasmoothevenlayerofKores(orregulargluestickyoucansourcelocally)glue

providedwiththeprinter.Onethinlayerisenough.

● LetthegluedryandthenapplyonelayerofABSJuiceprovidedwiththeprinterin

plasticsprayer.

● Whentheglassisdryattachitfirmlytothebedwiththebinderclips.

Theglassprovidedwiththeprinter(bothassembledandkit)isalreadypreparedwith

theKoresglueandABSJuicesoyoucanuseitfortheprintwithoutanyfurther

preparation.

10

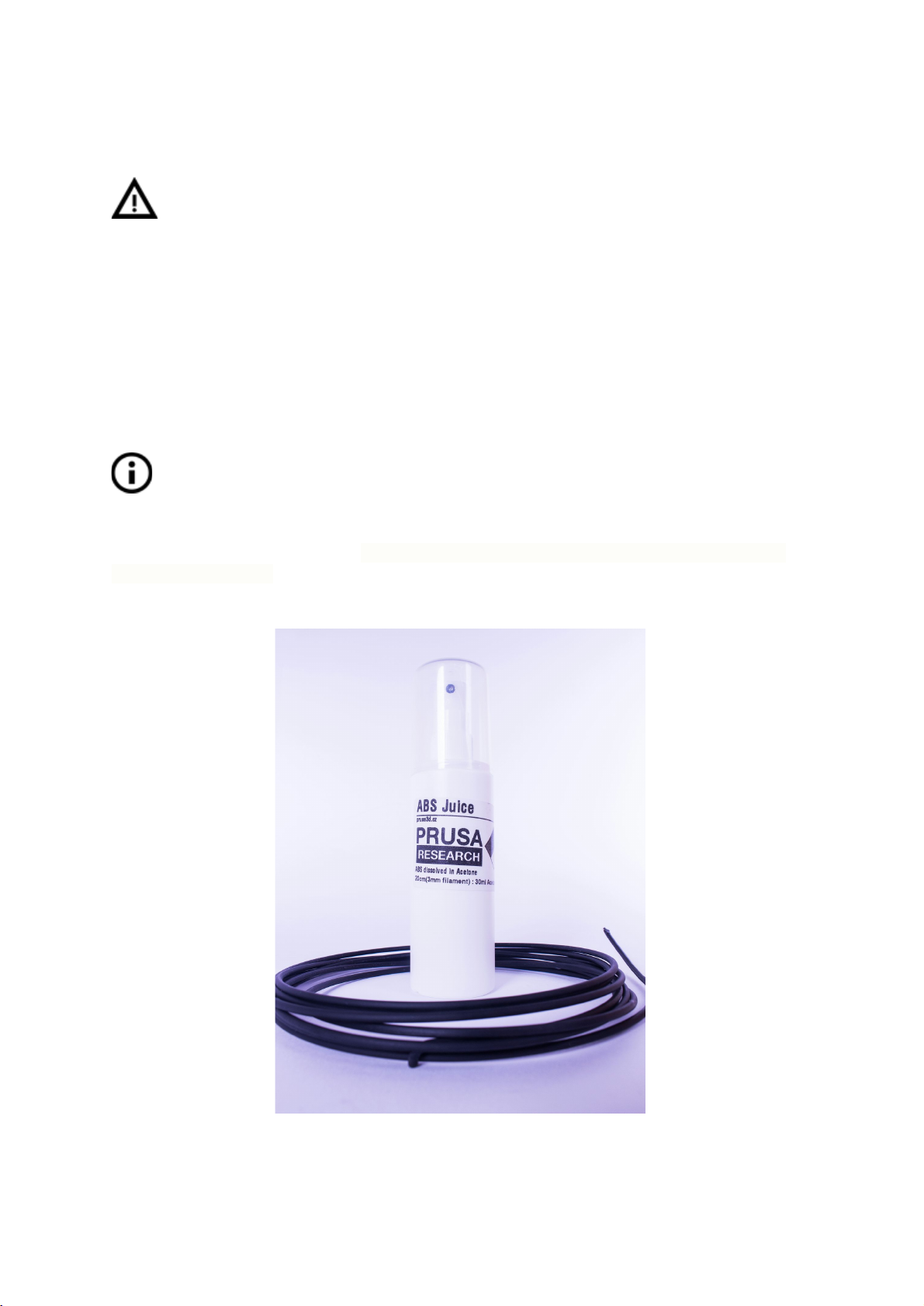

5.3.2 ABS Juice preparation

Acetoneisextremelyflammable,rapidlyevaporatingliquid.Handleitina

wellventilatedareaonly,protectyoureyesandskinfromsplashes.Neveroperate

withacetonenearopenflamesorotherheatsource;especiallyinareaswherea

sparkcanoccuracetonevaporsareeasilyignited.

WhenyourunoutoftheABSJuicesuppliedwiththeprinter,youcaneasilymakeyourown

mix.YouwillneedacontainerinwhichyoucanretainpureacetoneandanABSfilament.

ABSJuiceismadebydissolvingABSinpureacetone34cmfilament(thickness1.75mm)to

30mlofacetone.OriginalABSjuicecontaineris100ml,soyouneedafilamentlengthof

approximately114cm.Cutthefilamentintoshorterpiecestofitcomfortablyintothe

containerandthencoveritwith100mlofacetone.Closethecontainersecurelyandshake

forseveralminutes.Beforefirstuse,letthemixturestandforseveralhourstoABSfilament

completelydissolvedinacetone.

Preparedjuicecanbealsopurchasedinoureshop.Unfortunately,UPSservice

doesnotallowtodeliveranyacetonebasedproductsduetoshippingconstraints.In

thatcaseyougetonlythebottleandABSfromoureshopandyouhavetosource

theacetonelocally.Youcanalsousethealternativesolution,e.g.hairsprayalways

choosenonperfumedsprayandlookoutforextrahold

withingredientsincludingAcetate,

CopolymerandVinyl.

11

5.3.3 Plugging the AC power

● Checktheglassplacementandattachmenttotheheatbed.

● PlugintheACpowercord.

5.3.4 Calibration

Youneedtocalibratetheprinterbeforethefirstprint.Ifyoutransporttheprinteror

manipulatewithitexcessivelyyoushouldcheckandeventuallycalibrateitagain.Forthe

successfulcalibrationyouneedtohavetheprinterheatedbothnozzleandheatbed.

TemperaturecanbesetthroughLCDpanel.

● PresstheLCDknobtoenterthemainmenuonLCD.Rotatethebuttontochoose

PreheatoptionandconfirmbypressingtheLCDknob.Nextyouchoosethematerial

youwillprintfrom.ChooseamaterialthenconfirmwithLCDknob.Nozzleand

heatbedwillheattotherequestedtemperature.

Pict.4LCDpanelcontrols

12

● Youneedacommonbusinesscardforthecalibration.ChooseSettingsinmain

menuthenAutohomeoption.Thisstepsetsallaxesto[0,0,0]positions.

● Trytoputandmovethecalibrationpaper(businesscard)betweenthebedand

nozzle.Youhavetofeelaslightfrictionbetweenthepaperandthenozzle.

NozzlebeddistanceissetwithZadjusters.Thisstepisrepeatedinallfourcorners

oftheprintbed.

Calibrationpaperisattachedtothepackagewithwiththeheatbeadandtheglass.If

youdon’thavethecalibrationpaperyoucanuseanycommonbusinesscardpaper

(250g/m

2

).

Pict.5

Printer

calibrationusingthecalibrationpaper,smallorangewheelbottomright

cornerisaZadjuster(oneoffour).

13

● Figures6ato6cshowthefirstprintedlayer.Pict.6ashowstheresultwhennozzle

istoofarfromthebed,6biscorrectlycalibratedprinterand6cshowstheprintwhen

thenozzleistooclosetotheheatbed.

Pict.6a

Nozzle

istoofarfromtheglass.Filamentcouldn’tattach

properly

andtearsout.

Pict.6b

Calibrated

printer

showscontinuous

filament

layers.

Pict.6c

Nozzle

tooclosetotheglass.Layersaretoocompressed.

14

5.3.5 Loading the filament into the extruder

Ifyoufollowthemanualyoushouldhavethenozzleandthebedpreheated.

● Youneedtopreheatthenozzlebeforeinsertingthefilament(andthebedtooifyou

liketoprintrightaway).Thetemperaturedependsonthematerialused.Detailed

informationaboutnozzleandbedtemperaturesaredescribedatchapterMaterials.

●PresstheLCDknobontheLCDpaneltoenterthemainmenu.Insertthefilamentto

theextruder,choosetheLoadfilamentoptioninthemenuandpressthebuttonto

confirm.Filamentisthenloadedtotheextruderbytheextruderstepper

automatically.Youshouldcutthetopofthefilamentasshowninthepicturebelow

(pict.7detail).

Pict.7

Loading

the

filament

totheextruder

● Checkifthefilamentflowsfromthenozzle.

● Ifyouchangethefilamentforanewonedonotforgettocompletelyreleasetheold

filamentbeforetheprinting.

15

6 Printing

● Makesurethatthenozzleandthebedareheatedtothedesiredtemperature.Ifyou

forgettopreheattheprintingnozzleandthebedbeforeprintingtheprinterwill

automaticallycheckthetemperaturesofthenozzleandthebed;printingwillstart

whendesiredtemperatureisreacheditcantakeseveralminutes.However,we

recommendpreheatingtheprinterbeforehandasdescribedinthechapter

Calibration.

Donotletthepreheatedprinteridle.Whenaprinterispreheatedandnonprinting

materialinanextruderdegradesovertimeitmaycausethenozzletojamup.

● Watchthefirstfewprintedlayerstobesurefilamenthasattachedtothebedproperly

(5to10minutes).

● PresstheLCDknobandchoosethePrintfromSDoptionfrommenu,pressto

confirmandpickthedesiredmodelmodel_name.gcode.Printerwillstartprintingthe

object.

Thefilename(.gcode)mustnotcontainanyspecialcharactersotherwisethe

printerisnotabletodisplaythefileontheLCD.IfyouremovetheSDwhileprinting,

printerwillpauseautomatically.WhenyoureinserttheSD,presstheLCDknoband

choose“Continue”option.Confirmandprintingwillresume.

● Printerfirmwareallowsthefilamentchangeduringtheprinting.Thisoptionis

usefulwhenthefilamentisrunningoutandyoucanchangethespoolandcontinue

withprint.ChoosetheTuneandthenChangefilamentoptionduringtheprint.

Printerwillpausetheprintingprocess,unloadthefilamentandsignalsyouwiththe

soundtoinsertthenewfilament.Whenyouconfirmthefilamentwasloaded

correctlyprintingprocesswillcontinue.

● Otheroptionstousethefilamentchangeisamulticoloredprint.Theprocedureis

thesameasabovechoosetheTuneandthenChangefilamentoptionduringthe

print.Printerwillpausetheprintingprocess,unloadthefilamentandsignalsyouto

insertthenewfilament.

● Whenyouchangethefilament,LCDdisplaysthemessage“Changedcorrectly?”

withthreeoptions:

1. “Yes”Everythingwentokandprintingcancontinue.Checkifthenewcoloris

clearwithoutanyremainsofthepreviousfilamentifyes,choosethisoption

tocontinueprintingwithanewcolor.

2. “Filamentnotloaded”Ifthenewfilamentwasnotloadedproperly,choose

thisoptionandtheprinterwillstarttheautomaticfilamentloadagain.When

thefilamentisloadedproperly,youcanchoosethe“Yes”optionandthe

printingwillcontinuewithanewcolor.

3. “Colornotclear”Filamentwasloadedbutthecolorisstillspottedbya

previousfilament.Pressthebuttonwiththisoptionandtheprinterwillextrude

morefilamentfromthenozzle.Whenthecolorispurewithoutanyremainsof

16

thepreviousfilamentyoucanchoosethe“Yes”optionandtheprintingwill

continuewithanewcolor.

● Youcanrepeatthisprocedureasmanytimesasyouwanttheresultforinstance

canbeafivecoloredobject.

● Whenprintingisfinishedletthenozzleandheatbedcooldownbeforeremovingthe

printedobject.Alwayshandletheprintedobjectswhentemperatureofthebedand

nozzledroptotheroomtemperature,whenthebedishotobjectsareveryhardto

remove.Pullthebedtowardsyouandremovetheobjectgently.Youcanalso

removethebindingclips,removetheglasswithobjectoutoftheprinterandthen

separatetheobjectfromtheglass.

● Ifyouexperienceanytroublesremovingtheobject(especiallythesmallones)you

canuseaflattoollikeaspatulaorStanleyblade.

Pict.8

Removing

the

model

fromtheglasswithspatula

● Inrarecasespartoftheglasscangougewiththeobject.Withnormalglassitcould

happenmoreoften,withtemperedglassweusewithOriginalPrusai3,it’sextremely

rarecase.Ifthisishappenedtoyoujustusetheothersideoftheglassoryoucan

getthesubstituteglassfromoureshop.

Substituteglassisalsohandywhenyou’dliketoprintanotherobjectimmediately

afterfinishingthepreviousone.Justremovetheglassfromthebedandletthe

objectcooldownoutoftheprinter.Usethegloveswhenmanipulatingwiththe

glassitstemperaturecanreach100°C.

17

6.1 Printer controls

Therearetwowayscontrollingtheprinter.YoucanusetheLCDpanelintegratedwiththe

printeroryoucanconnectyourcomputerwithUSBcable.WesuggesttheLCDpanel

becauseofitsspeedandreliability,andmoreoveryoudonotrelyonacomputer.

6.1.1 LCD screen

● Mainscreenisaninformationscreendisplayingthemostimportantdetails.These

arethetemperatureofthenozzleandtheheatbed(1,2),printingtime(3)andthe

actualZaxisposition(5).

Pict.9LCDlayout

1. Nozzletemperature(actual/desiredtemperature)

2. Heatbedtemperature(actual/desiredtemperature)

3. Progressofprintingin%shownonlyduringtheprinting

4. Statusbar(Prusai3ready/Heating/model_name.gcode,etc.)

5. Zaxisposition

6. Printingspeed

7. Elapsedprintingtimeshownonlywhenprinting

18

6.1.2 LCD layout

Itemsnotmentionedbelowarenotusedforthecommonprintsetupyoushouldnot

changeanyoftheunmentioneditemsunlessyouareabsolutelysurewhatyouare

doing.

❏Infoscreen

❏Tune(duringtheprintingprocessonly)

❏Speed

❏Nozzle

❏Bed

❏Fanspeed

❏Flow

❏Changefilament

❏Pauseprint(duringtheprintingprocessonly)

❏Stopprint(duringtheprintingprocessonly)

❏Preheat

❏ABS255/100

❏PLA210/50

❏PET240/90

❏HIPS220/100

❏PP254/100

❏FLEX230/50

❏Cooldown

❏PrintfromSD

❏Loadfilament

❏Unloadfilament

❏Support

❏prusa3d.com

❏forum.prusa3d.com

❏howto.prusa3d.com

19

6.1.3 Print speed versus print quality

Printingasmallobjecttakesafewminutes,butprintinglargermodelsistimeconsuming

thereareprintstakingtensofhours.Theoverallprintingtimecanbechangedbydifferent

ways.FirstwaytoaltertheprintingspeedischanginglayerheightinSlic3rupperright

windowsshowsPrintsettingsoption.Defaultsettingis0.20mm(NORMAL),youcanspeed

uptheprinterbychoosingthe0.25mm(DRAFT)option.Raisingspeedwillresultthemodel

tobelessdetailedwithvisiblelayerborders.Ifyoupreferqualityoverspeed,choose0.10

mm(DETAIL)option.Printingtimewilldoublebutthemodelgetstheextradetail.Again,

higherprintingspeedresultsinlessdetailedmodel.

Speedcanbechangedalsowhileprinting.LCDshowstheFR100%itemit’sactualprint

speed(feedrate).ByturningtheLCDknobclockwiseyoucanincreasetheprintspeedupto

999%.However,wedonotadvisetoincreasethespeedover200%.Watchtheresultsof

increasedspeedontheprintedmodelandadjustthespeedeventually.

Whenincreasingthespeedalwayscheckthemodeliscooledproperlyespecially

whenprintingsmallobjectfromABSincreasedspeedcausesthedistortion

(sometimescalled“warping”)ofthemodel.Youcanpreventthisissuebyprinting

moresimilarobjectstogetherlayerprintingintervalislongenoughtopreventthis

issue.

Ifthemodelshowslowerqualitythandesiredyoucandecreasetheprintingspeedturnthe

LCDknobcounterclockwise.Maximumusableprintingspeedisaround20%ofnominal

speed.

6.1.4 USB cable and Pronterface

WestronglyrecommendtouseLCDpanelwhileprintingonPrusai31.75mm

Pronterfacedoesn’tsupportallfunctionsofanewfirmware(e.g.filamentchange

whileprinting).

KeepinmindthatwhenprintingfromthePronterfacethecomputermustbeconnectedto

theprinterduringthewholeprintingprocesscomputermustbepreventedfromsleep,

hibernationorshuttingdown.Disconnectingthecomputerduringtheprintendstheprinting

withouttheoptiontofinishtheobject.

● ConnecttheprintertothecomputerwiththeUSBcable.

20

Other manuals for i3 Hephestos

3

Table of contents

Other Prusa 3D Printer manuals