Prusa Original Prusa i3 MK2 User manual

Pleasealwaysrefertothehttp://www.prusa3d.com/drivers/

foranupdatedversionofthis3Dprintinghandbook(PDFdownload).

QUICK GUIDE TO THE FIRST PRINT

1.Placetheprinteronaflatandstablesurface(page11)

2.Readthesafetyinstructionscarefully(page7)

3.Downloadandinstallthedrivers(page27)

4.Preparetheprintsurface(page11),runselftest(page13)andcalibratethe

printer(page14)

5.InsertSDintotheprinterandprintyourfirstmodel(page20,page29)

Handbookversion1.03fromJune19th,2016.©PrusaResearchs.r.o.

2

About the author

JosefPrusa(bornFeb23

rd

,1990)becameinterestedinthe3Dprintingphenomenonbefore

joiningthePrague’sUniversityofEconomicsin2009atfirstitwasahobby,anew

technologyopentochangesandimprovements.Thehobbysoonbecameapassionand

JosefgrewintooneoftheleadingdevelopersofAdrienBowyer’sinternational,opensource,

RepRapproject.Today,youcanseethePrusadesignindifferentversionsallaroundthe

world,itisoneofthemostpopularprintersandthankstoit,knowledgeaboutthe3Dprinting

technologysignificantlyincreasedamongpublic.

Jo’sworkonselfreplicatingprinters(youcanprinttheotherprinterpartswithyourprinter)

arestillongoingandcurrentlythereisPrusai3thethirditerationoftheoriginal3Dprinter.It

isconstantlyupdatedwiththelatestinnovationsandyou'vejustpurchaseditslatestversion.

Inadditiontoprinterhardwareupgrades,themaingoalistomakethetechnologymore

accessibleandunderstandableforallusers.

JosefPrusaalsoorganizesworkshopsforthepublic,participatesinprofessional

conferencesdedicatedtothepopularizationof3Dprinting.Forexample,helecturedatthe

TEDxconferenceinPragueandVienna,atWorldMakerFaireinNewYork,MakerFairein

RomeorattheOpenHardwareSummithostedbyMIT.JosefalsoteachesArduinoat

CharlesUniversityandwasalsoalecturerattheAcademyofArtsinPrague.

Inhisownwords,heimagines3Dprinterswillbeavailableineveryhomeinanottoodistant

future.Ifanythingisneeded,youcansimplyprintit.Inthisfield,youjustpushthe

boundarieseveryday...We'regladyou'repartofitwithus!

3

Table of contents

Abouttheauthor 3

Tableofcontents 4

2Productdetails 6

3Introduction 6

3.1Glossary 6

3.2Disclaimer 7

3.3Safetyinstructions 7

3.4Licenses 7

4OriginalPrusai3MK2printer 8

5OriginalPrusai3MK2printerkit 9

6Firststeps 10

6.1Printerunpackingandproperhandling 10

6.2Printerassembly 11

6.3Setupbeforeprinting 11

6.3.1PEIprintsurfacepreparation 11

6.3.2Increasingtheadhesion 12

6.3.3PluggingtheACpower 13

6.3.4Selftest 13

6.3.5PreparingtheZCalibration 14

6.3.5.1CheckingtheYAxis(kitonly) 14

6.3.5.2Probealignment(kitonly) 14

6.3.5.3CheckingtheZaxis 16

6.3.6Loadingthefilamentintotheextruder 17

6.3.7ZCalibration 18

6.3.7.1FinetuningtheZadjustment 19

6.3.7.2Securingoftheprobe(kitonly) 19

7Printing 20

7.1PrinterControl 21

7.1.1LCDscreen 21

7.1.2Printstatistics 21

7.1.2Silentvs.Hipowermode 22

7.1.3Factoryreset 22

7.1.4LCDlayout 22

7.1.5Printspeedversusprintquality 24

7.1.6USBcableandPronterface 24

7.2Printeraddons 26

7.2.1Differentnozzles 26

7.2.1.1Hardenedsteelnozzle 27

7.2.1.20.25mmnozzle 27

8Printerdrivers 27

9Printingyourownmodels 27

9.1Whereyoucangetthe3Dmodels? 27

9.2Inwhatprogramyoucancreateyourownmodels? 28

4

9.3Slic3r 28

9.4Bundled3Dmodels 29

9.5PrintincolorwithColorPrint 30

9.6Printingofnonstandardmodels 32

9.6.1Printingwithsupportmaterial 32

9.6.2Largeobjectprinting 33

10Materials 34

10.1ABS 34

10.2PLA 34

10.3PET 34

10.4HIPS 34

10.5PP 34

10.6Nylon(TaulmanBridge) 34

10.7Flex 35

11FAQPrintermaintenanceandprintissues 36

11.1Printsurfacepreparation 36

11.2Clogged/jammedextruder 36

11.3Nozzlecleaning 37

11.4Replacing/changingthenozzle 37

11.5Axisfluency 38

11.5Printingproblems 39

11.5.1LayersbreakandsplitwhenprintingfromABSmaterial 39

11.5.2Modelscontaineithertoomuchornotenoughofthefilament 39

11.6Problemswithfinishedmodels 39

11.6.1Modelbreaksand/oriseasilydamaged 39

12FAQcommonissueswhenassemblingtheprinterkit 40

12.1Nozzle/printsurfacegapisgreaterinthemiddlethanatthecorners 40

12.2Printerstopsprintingsoonafterstart 41

12.3Printercan’treadSDcard 41

12.4LooseXand/orYaxisbelts 42

12.5Detachedcablestotheheatbed 43

12.6Looseheatbedzipties 43

Importantnotice,tip,hintorinformationthathelpsyouprintwithease.

Readcarefully!Thispartoftexthasuppermostimportanceeitherforusersafetyof

foraproperprinterservice.

Thissymbolindicatestextrelatedtoprinterkitonly.

5

2 Product details

Title:OriginalPrusai3MK2/OriginalPrusai3MK2(kit),Filament:1.75mm

Manufacturer:PrusaResearchs.r.o.,621/8aPrvnihopluku,Prague,18600,CzechRepublic

Contacts:phone+420222263718,email:[email protected]

EEEgroup:3(ITand/ortelecommunicationequipment),Deviceuse:indooronly

Powersupply:90135VAC,2A/180264VAC,1A(5060Hz)

Workingtemperaturerange:18°C(PLA)38°C,indooruseonly

Workinghumidity:85%orless

Kitweight(brutto/netto):9.8kg/6.3kg,assembledprinterweight(brutto/netto):12kg/

6.3kg.Serialnumberislocatedontheprintercontrolunitandalsoonthepackaging.

3 Introduction

Thankyouforpurchasingouroriginal3DprinterOriginalPrusai3MK2fromJosefPrusa

eitherasanassembledprinteroraprinterkitasyourpurchasesupportsuswithitsfurther

development.Readthehandbookcarefully,please,allchapterscontainvaluableinfoforthe

correctserviceoftheprinter.

Pleasecheckthehttp://prusa3d.com/driverspageforupdatedversionofthis3D

printinghanbook(PDFdownload).

Incaseofanyprinterrelatedproblemdonothesitatetocontactusat[email protected]

.We

aregladtoreceiveallyourvaluablecommentsandtips.Westronglysuggestyoutovisitour

officialforumatforum.prusa3d.com,whereyoucanfindsolutionstocommonissues,tips,

adviceandhintsinadditiontoactualinformationabouttheOriginalPrusai3printer’s

development.

3.1 Glossary

Bed,Heatbed,PrintbedCommonlyusedtermforprintingpadaheatedareaof3D

printerwhere3Dobjectsareprinted.

ExtruderPrintingheadorextruderisapartofaprinterconsistingofanozzle,hobbed

pulley,idlerandanozzlefan.

FilamentTermforplasticprovidedonspooliscalled“filament”,it’susedthroughoutthis

handbookaswellasintheLCDmenuontheprinter.

Heater,Hotendothernameforaprintingnozzle.

1.753Dprintersusetwodifferentdiameters(thickness)ofafilament(thickness):2.85mm

(commonlycalledas3mm)and1.75mm.1.75mmversionismoreusedworldwidethough

thereisnodifferenceinprintingquality.

6

3.2 Disclaimer

FailuretoreadtheManualmayleadtopersonalinjury,inferiorresultsordamagetothe3D

printer.Alwaysensurethatanyonewhooperatesthe3Dprinterknowsandunderstandsthe

contentsoftheManual.Wecannotcontroltheconditionsinwhichyouassemblethe

OriginalPrusai3.Forthisandotherreasonswedonotassumeresponsibilityandexpressly

disclaimliabilityforloss,injuries,damage,orexpensearisingoutoforinanywayconnected

withtheassembly,handling,storage,useordisposaloftheproduct.Theinformationinthis

Manualisprovidedwithoutanywarranty,expressorimplied,regardingitscorrectness.

3.3 Safety instructions

Pleasebeverycautiousduringanyinteractionwiththeprinter.Thisprinterisan

electricaldevicewithmovingpartsandhottemperatureareas.

1.Deviceisforindooruseonly.Donotexposetheprintertorainorsnow.Alwayskeepthe

printerinadryenvironmentataminimumdistanceof30cmfromotherobjects.

2.Alwaysplacetheprinteronastableplace,whereitcannotfallortipover.

3.Theprintersupplyishouseholdpoweroutlet230VAC,50Hzor110VAC/60Hz;Never

connecttheprintertoadifferentpowersupply,itmaycausemalfunctionordamagetothe

printer.

4.Placethepowercordsoyoucan’tstumbleonit,orsteponitorotherwiseexposetoany

damage.Makesurethatthepowercordisnotmechanicallyorotherwisedamaged.Stop

usingdamagedcableimmediatelyandreplaceit.

5.Whenyoudisconnectthepowercordfromthesocket,pulltheplugratherthanthecordto

reducetheriskofdamagetoplugorACoutlet.

6.Neverdisassembletheprinterpowersupply,itdoesnotcontainanypartsthatcouldbe

repairedbyanunskilledworker.Allrepairsmustbeprovidedbyaqualifiedtechnician.

7.Donottouchthenozzleorheatbedwhentheprinterisprintingoriswarmingup.Note

thatthetemperatureofthenozzleis210300°C(410572°F);heatbedtemperaturecan

reachover100°C(212°F).Temperaturesabove40°C(104°F)cancauseharmtohuman

body.

8.Donotreachinsidetheprinterwhileitisstillinoperation.Aninjurymaybecausedbyits

movingparts.

9.Preventchildrenfromunsupervisedaccesstotheprinterevenwhentheprinterisnot

printing.

10.Donotleavetheprinterunattendedwhileit'sstillon!

11.Plasticisbeingmeltedduringprintingwhichproducesodors.Setuptheprintersome

placewellventilated.

3.4 Licenses

OriginalPrusai3MK2printerisapartoftheRepRapproject,thefirstopensource3Dprinter

projectfreetouseunderaGNUGPLv3license(www.gnu.org/licenses/gpl3.0.en.html).If

youimproveoralteranypartofaprinterandyouarewillingtosell,thenyouhavetopublish

thesourcecodesunderthesamelicense.All3Dprintedelementsoftheprinterthatcanbe

improveduponcanbefoundathttp://www.prusa3d.com/prusai3printableparts/.

7

4 Original Prusa i3 MK2 printer

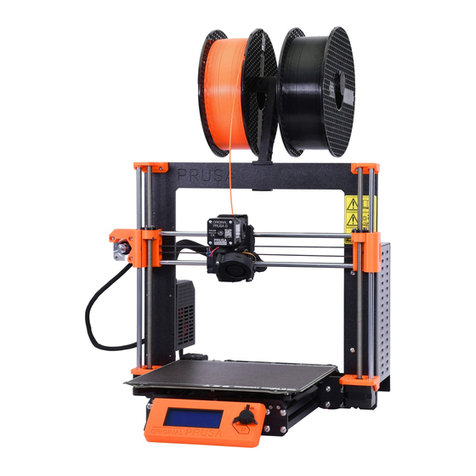

Unliketheprinterkit,it’scompletelyassembledandalmostreadytoprint.Afterpluggingin

andrunningthenecessarycalibrationyou,canprinta3Dobjectinthematterofminutes

afterunpackingtheprinter.Keepinmindyoucanuseoursupportemailwhenyou

purchasedtheassembledprinter.Donothesitatetowriteusifyouneedanyadviceorhelp.

Wewillgladlyhelpwithanyspecificprints.

3Dprintersusetwodifferentdiametersofafilament(youcanfindmoreinchapter

Materials

):2.85mmand1.75mm.1.75mmversionisusedmoreworldwide,though

thereisnodifferenceinprintingquality.Filamentisprovidedonaspoolwhereyou

canfindthebasicinformationfilamentmaker,material(ABS,PLA,etc.)andfilament

diameter.2.85mmfilamentiscommonlycalledas3mm.

Thisprintersupportsonlya1.75mmfilament.Pleasecheckthefilamentdiametertobe

1.75mmbeforeinsertingintotheextruder.Donottrytoinsertwiderfilamentitcoulddamage

theextruder.

Pict.1OriginalPrusai3MK2

printer

description

8

5 Original Prusa i3 MK2 printer kit

OriginalPrusai3MK2kitispicturedinpict.2.Detailedinformationandassembly

descriptioncanbefoundinchapter6.2Printerassembly.Weofferthesupportfor

userswhopurchasedtheprinterkitthroughourofficialforum.Ifyouneedhelpdo

nothesitatetovisitourforumatforum.prusa3d.com.Youcanfindtheanswersfor

yourproblemthere.Ifnot,pleasejustpostyourquestiondirectlythere.

Pict.2OriginalPrusai3MK2

printer

kitunboxed

9

6 First steps

6.1 Printer unpacking and proper handling

Holdingtheupperframe,taketheprinterandpullitoutfromthebox.Becarefulwhen

handlingtheprinternottodamagetheelectronicsandthustheproperprinterfunctionality.

Anytimeyoumovetheprinter,alwaysholdtheupperframewithhotbeduprightpointing

awayfromyouaspicturedinpict.3.

Pict.3

Proper

handlingofa

printer

10

6.2 Printer assembly

WithOriginalPrusai3MK2printerkitwesuggesttofollowtheguidelinesand

assemblethekitaccordingtothetheonlinemanualatmanual.prusa3d.com.(Online

manualisavailableinseverallanguagesonthewebsite).Theconstructionofthe

printershouldnottakemorethanoneworkingday.Afterasuccessfulcompletion

continuetothechapter6.3Setupbeforeprinting.

6.3 Setup before printing

● Placetheprintertoahorizontallystableposition,bestplaceisaworkbenchwhere

thereisnoriskofdraft.

● Attachthefilamentholderstotheupperframe.

● AttachFilamenttotheholders.Makesurethefilamentspooldoesn’tjamandcan

movefreely.

Filamentisacommontermfortheplasticrodmaterialprovidedonaspoolfrom

which3Dobjectsareprinted.

6.3.1 PEI print surface preparation

Toachievethebestadhesiononthenewsurface,itisimportanttokeepthesurfaceclean.

Cleaningofthesurfaceisveryeasy.ThebestoptionisIsopropylalcoholavailablein

drugstoreswhichisthebestforABS,PLAandothers,expectforPETGwheretheadhesion

maybetoostrong.Secondoptionistouseagentlesprayofawindowcleaner(Windexor

similar)onapapertowelandwipethesurface.Thebedcanbecleanedevenwhilehot,just

becarefulnottotouchthesurfaceorthenozzle.Alternatively,youcancleanthebedwith

warmwaterandafewdropsofadishsoaponapapertowel.Denaturedalcoholisyet

anotheroption.

Thesurfacedoesnothavetobecleanedbeforeeveryprint!Itisjustimportanttonot

touchtheprintbedwithyourhandsordirtytools.Cleanyourtoolswiththesame

solutionasyouwouldthebedandyouwillbeabletostartyournextprintrightaway.

Youcanleavesmallmarksontheprintsurfacewithyournozzleortools,theywilltypically

beshinierthantherest.Itdoesnotaffectthefunctionalityoradhesion.However,ifyouwant

tohavesamesurfacelookonthewholeprintbedyoucanresurfaceit.Theeasiestwayisto

takeahardsideofdrykitchenspongeandwipetheaffectedareawithcircularmotiongently

fewtimes.

11

6.3.2 Increasing the adhesion

Insomespecialoccasions,likeatallobjectwithaverysmallcontactareawiththeprint

surface,youmightneedtoincreasetheadhesion.FortunatelyPEIisaverychemically

resistantpolymerandyoucantemporaryapplyotheradhesionsolutionswithoutdamaging

it.

ThisalsoappliestomaterialswhichwouldnotsticktoPEIotherwise,likeNylonetc.

Beforeapplyinganythingtothebed,considerusingBrimoptioninSlic3rwhichincreases

thesurfaceareaofthefirstlayer.

ForPLAandNylonblendsasimplegluestickdoesthetrick.Gluecanbelatereasily

removedbywindowcleanerordishsoapwater.

ForABSprints,ABSjuicecanbeusedandlatercleanedwithpureacetone.Beverygentle

whenapplyingthejuiceanddosowhilethebediscold.Printswillattachverystrongly.

Preparedjuicecanbealsopurchasedinoureshop.Unfortunately,UPSservice

doesnotallowtodeliveranyacetonebasedproductsduetoshippingconstraints.In

thatcaseyougetonlythebottleandABSfromoureshopandyouhavetosource

theacetonelocally.

Pic.4

ABSJuicecanbeusedto

increasetheadhesion

12

6.3.3 Plugging the AC power

● PlugintheACpowercord,checktomakesurethepropersettingforACvoltageis

selected(110V/220V)andturnontheswitch.

6.3.4 Selftest

Thepurposeoftheselftestroutineistocheckmostcommonerrorswhenassemblingand

connectingelectronicsandtohelpindicateanypossibleerrorsafterassembly.Youcanrun

theSelftestfromSettingsmenuonLCDpanel.Thisshouldnotbenecessaryonthe

assembledprintersasthosearepretested.

Initiatingthisroutineperformsaseriesoftests.Theprogressandresultsofeachstepare

displayedontheLCD.Incaseoferrorsfound,theselftestisinterruptedandthereasonfor

errorisshowntoguideusersintroubleshooting.

Testconsistsof

Heatbedandhotendproperwiring

XYZmotorsproperwiringandfunctionality

XYZendstopmechanicalsettingsandproperwiring.

Errormessagesandresolution:

Heater/ThermistorNotconnected:

Checkproperwiringofhotendpowercablesandthermistorcables.Ensurethatboth

areproperlyconnectedtotheRamboelectronics,andthattheyarenotswapped.

Bed/HeaterWiringerror:

Checkthatheatbedandhotendpowercablesarenotswappedorthermistorcables

frombothhotendandheatbedarenotswappedintheRamboelectronics.

EndstopsWiringerror{XYZ

}:

Checkthepropercablingofendstops.Routineindicatesaxisonwhichendstop

reportedmalfunctionorisnotproperlyresponding.Checktheproperconnectionin

theRamboelectronics.

Motor{XYZ

}Endstop{XYZ

}:

Checkthatmotorandendstoponindicatedaxisareproperlyconnectedtothe

Ramboelectronicsandnotswappedwithmotororendstopofdifferentaxis.Axis

causingtheproblemsisindicatedontheLCDpanel.

EndstopnothitMotor{XZY

}:

Checkmechanicalsettingsthatendstopcanbereachedwhenaxisisinmaximal

position.

13

6.3.5 Preparing the Z Calibration

TheOriginalPrusai3MK2comeswithafullmeshbedlevelingfeature,howeverforthisto

workweneedtofirstcalibratethedistancebetweentipofthenozzleandP.I.N.D.A(Prusa

INDuctionAutoleveling)probe.

Theprocessisfairlystraightforward,solet’sgettoit.

6.3.5.1 Checking the Y‐Axis (kit only)

Forautocalibrationtoworkproperly,itisextremelyimportantfortheYaxistobe

perpendiculartotheXaxis.Thiscanbeeasilycheckedbylookingattheprinter

fromthetopandvisuallyaligningtheXaxisrodswithlinesontheheatbed.You

canseeitonthenextpicture.IftheYaxisismisaligned,youcaneasilyadjustthe

positionoftheYaxisinsidetheframebylooseningtheM10nutsontheYaxisandsecuring

thematthenewlyadjustedposition.

Pic.5Xaxisrodsmustbevisuallyalignedwithlinesontheheatbed.

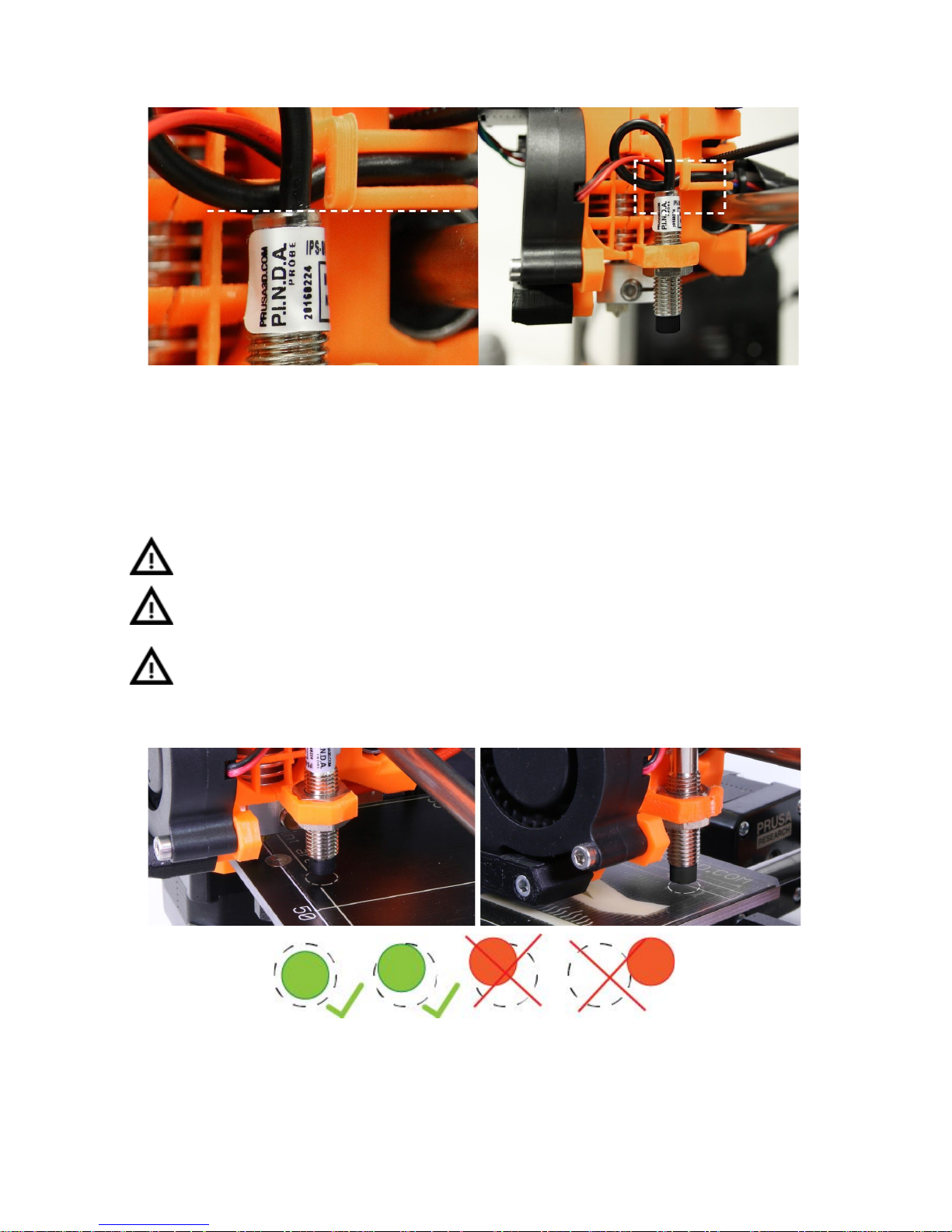

6.3.5.2 Probe alignment (kit only)

Thefirststepistomechanicallysetthepositionoftheprobe.Thetopoftheprobe

shouldbealignedwiththebottomofaprintedpartasyoucanseeinthepicture

number6.Thepositioncanbeeasilychangedevenonanassembledprinterby

looseningthebottomnutfewturns,movingthewholeprobeandadjustingthetop

nutaccordingly.

Securethebottomnutafterwardsoritcangetlooseduringprintinglater!

Alsotheprobeshouldbeperpendiculartotheprintbed.

14

Pic.6Thetopoftheprobeshouldbealignedwiththebottomofaprintedpart

WhenyouruntheCalibrateZfeaturefromtheSettingsmenuontheLCDpanel,theprinter

willrunthecalibrationroutine.Closelywatchhowtheprobeapproachesthe9calibration

points.1standthelastpointsaremarkedwithwhitedashedcirclesforeasyrecognition.The

probemustbeinsidethosecirclestosuccessfullycalibrate.

Thenozzlemustnottouchtheprintsurfaceduringthiscold

calibration.IfitbendstheprintsurfaceORtheprobeisnot

insidethecircles,itiswrongandyouhavetoreadjustthe

P.I.N.D.Aprobe!Onlythenyoushouldcontinuewiththecalibration

process.Ifyou’rehavingtrouble,feelfreetoaskusforhelp.Ifthe

problemisnottakencareofduringthecoldcalibration,thenozzle

willpermanentlydamagetheprintsurfacewhenhot.

Pic.7Theprobemustbeinsidethecirclestosuccessfullycalibrate

.

Iftheprobeismisaligned,youcaneasilyadjustthepositionoftheYaxisinsidetheframeby

looseningtheM10nutsontheYaxisandsecuringthematthenewlyadjustedposition.

15

6.3.5.3 Checking the Z‐axis

ItisextremelyimportantforbothXENDpartstobeatthesameheight.Thiscanbe

achievedbyraisingtheZaxisuntilithitsthetopfromtheLCDmenu.GotoSettings>

Moveaxis>MoveZandrotatetheknobuntiltheaxisreachesthetop.Don’tworry,the

motorsdonothaveenoughpowertodamageanything,butitwillmaketheZaxisniceand

straight.

Pic.8ItisextremelyimportantforbothXENDpartstobeatthesameheight

Ifthereisanymisalignment,itwillcausetheprintertotouchtheprintsurfacewiththenozzle

typicallyonthe3calibrationpointsontherightside.

16

6.3.6 Loading the filament into the extruder

● PresstheLCDknobtoenterthemainmenuontheLCD.Rotatethebuttontochoose

PreheatoptionandconfirmbypressingtheLCDknob.Nextyouchoosethematerial

youwillprintfrom.ChooseamaterialthenconfirmwithLCDknob.Thenozzleand

heatbedwillheattotherequestedtemperature.

● Youneedtopreheatthenozzlebeforeinsertingthefilament(andthebedtooifyou

liketoprintrightaway).Thetemperaturedependsonthematerialused.Detailed

informationaboutnozzleandbedtemperaturesaredescribedatchapter10

Materials.

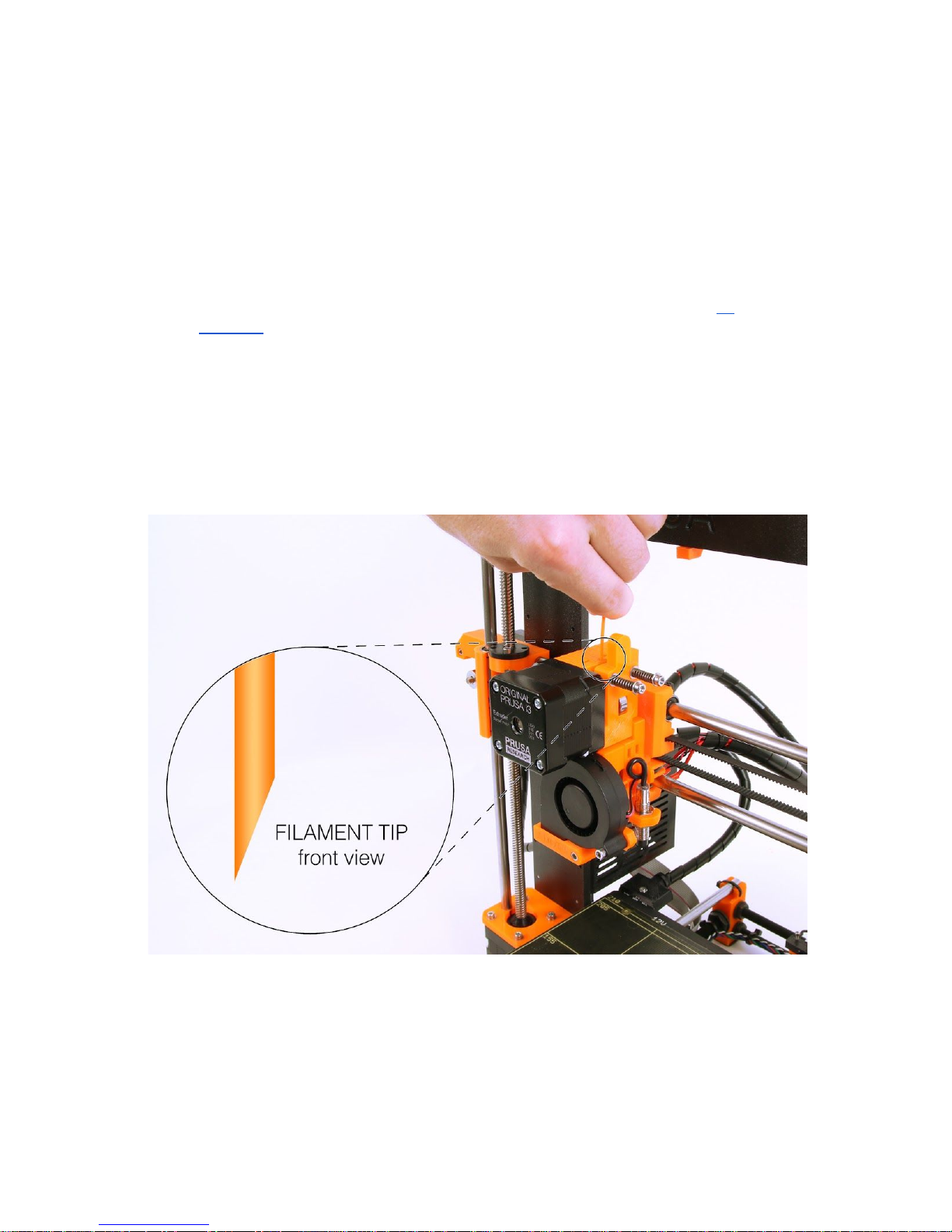

●PresstheLCDknobontheLCDpaneltoenterthemainmenu.Insertthefilamentto

theextruder,choosetheLoadfilamentoptioninthemenuandpressthebuttonto

confirm.Filamentisthenloadedtotheextruderbytheextruderstepper

automatically.Youshouldcutthetopofthefilamentasshowninthepicturebelow

(pict.9detail).

Pict.9

Loading

the

filament

totheextruder

● Checkifthefilamentisflowingfromthenozzle.

● Ifyouchangethefilamentforanewonedonotforgettocompletelyremovetheold

filamentbeforetheprinting.

17

6.3.7 Z Calibration

NOTE:ThecalibrationprocesshasbeenmadeeasierandisnowcalledV2Calibration.If

the

V2Calibration.gcode

isnotpresentonyourSDcardyoucaneasilyobtainitfromour

supportoronour

http://www.prusa3d.com/drivers/

page.

Checkifyourprintsurfaceisclean!Youcanfindinstructionshowtocleanitin

thechapter6.3.1PEIprintsurfacepreparation.Don'tforgettocomplete6.3.5

PreparingtheZCalibrationchapteroryoucanpermanentlydamagetheprint

surface!

Nowwewillfinallycalibratethedistancebetweentipofthenozzleandtheprobe.Preheat

thenozzleforPLA.OntheLCDmenu,gotoPrintfromSDandrunV2calibration.gcode

filefromthebundledSDcard.

Theprinterwillprobethebedandstartprintingzigzagpatternontheprintsurface.The

nozzlewillbeattheheightbasedontheP.I.N.D.Aprobesetting,itmustnotbyanymeans

touchtheprintsurface.

Pict.10Howtotunethenozzleheightliveduringthetestprint

Observethelinewhichisbeingextrudedontheprintsurface.GototheLCDmenuand

choosetheLiveadjustZoption.Anewmenuwillshowupwhereyoucantunethenozzle

heightliveduringthetestprint.Thepointistolowerthenozzleuntiltheextrudedplastic

sticksnicelytothebedandyoucanseeitisbeingslightlysquished.

18

6.3.7.1 Finetuning the Z adjustment

Afterfinishingthecalibrationgcode,itisagoodideatoprintasimpleobject.ThePrusa

gcodefromthesuppliedSDcardisagreatexample.TheLiveadjustZfunctionworks

duringeveryprint,soyoucanfinetuneatanypoint.Youcanseetheproperlytunedfirst

layerontheimagesbelow.

Pict.11Theproperlytunedfirstlayer

Nowyouaredone!

6.3.7.2 Securing of the probe (kit only)

Aftercoupleofprintsideallysecurethebottomnutontheprobewithadropof

Loctite243(BlueThreadlocker)topreventlooseningovertime.

Pict.12securethebottomnutontheprobewithadropofLoctite243

19

7 Printing

● Makesurethatthenozzleandthebedareheatedtothedesiredtemperature.Ifyou

forgettopreheattheprintingnozzleandthebedbeforeprinting,theprinterwill

automaticallycheckthetemperaturesofthenozzleandthebed;printingwillstart

whendesiredtemperatureisreacheditcantakeseveralminutes.However,we

recommendpreheatingtheprinterbeforehandasdescribedinthechapter6.3.6

Loadingthefilamentintotheextruder.

Donotletthepreheatedprinteridle.Whenaprinterispreheatedandnonprinting

materialinanextruderdegradesovertimeitmaycausethenozzletojamup.

● Watchthefirstfewprintedlayerstobesurefilamenthasattachedtothebed

properly(5to10minutes).

● PresstheLCDknobandchoosethePrintfromSDoptionfrommenu,pressto

confirmandpickthedesiredmodelmodel_name.gcode.Printerwillstartprintingthe

object.

Thefilename(.gcode)mustnotcontainanyspecialcharactersotherwisethe

printerisnotabletodisplaythefileontheLCD.IfyouremovetheSDwhileprinting,

printerwillpauseautomatically.WhenyoureinserttheSD,presstheLCDknoband

choose“Continue”option.Confirmandprintingwillresume.

● Whenprintingisfinishedletthenozzleandheatbedcooldownbeforeremovingthe

printedobject.Alwayshandletheprintedobjectswhentemperatureofthebedand

nozzledroptotheroomtemperature,whenthebedishotobjectsareveryhardto

remove.Pullthebedtowardsyouandremovetheobjectgently.

● Ifyouexperienceanytroublesremovingtheobject(especiallythesmallones)you

canuseaflattoollikeaspatulaorStanleyblade.

Pict.13

Removing

the

model

fromPEIprintsurfacewithspatula

20

This manual suits for next models

1

Table of contents

Other Prusa 3D Printer manuals