ROBBO MINI User manual

ROBBO

3D PRINTER MINI

User Manual

2

Table of Contents

1. Introduction 4

2. Purpose 4

3. Specifications 4

4. Contents of Delivery Kit 5

5. Structure and Workin Principle 5

5.1. Physical Form 5

5.1.1. Mountin base 6

5.1.2. Print bed 6

5.1.3. Z-axis slidin cradle 7

5.2. Printin Technolo y 7

5.3. Suitable Workin Materials 8

6. Safety Instructions 9

7. Software 9

7.1. Description of Repetier-Host 9

7.2. Software Installation 12

7.2.1. For Windows 12

7.2.2. For Linux 16

7.3. Software Setup 17

8. Preparation for Work 21

9. Maintenance 22

9.1. Lubrication 22

9.2. Replacement of Filament 22

9.3. Notched Belt Tension 23

9.3.1. Pullin -up the Х-axis belt 24

9.3.2. Pullin -up the Y-axis belt 24

9.4. First Launch 25

9.5. Test Printin 26

9.6. Troubleshootin 26

Z-Position accuracy 26

3

1. Introduction

Congratulations on purchasing the ROBBO 3D PRINTER MINI (further on, also referred as 3D

printer”).

This Manual will help you to get acquainted with the 3D printer and to print your first item.

Disclaimer: Failure to follow this Manual instructions may lead to personal injury, damage to

the 3D printer, or disfigured product.

2. Purpose

ROBBO 3D PRINTER MINI is designed for home usage and mastering the 3D printing. The 3D

printer uses fused-deposition layering technology to create a physical object after a digital 3D

model. Despite its relatively small size, the 3D printer enables you to create a variety of

artworks, plastic mechanisms, utensils etc. Models for 3D printing can be found on dedicated

websites, such as https://www.thingiverse.com.

3. Specifications

Power supply voltage ~12 V

Power consumption 100 W

Working area dimensions (X, Y, Z) 170×100×100 mm

Z-axis layer resolution 0.1–0.3 mm

Accuracy along the X- and Y-axis 0.01 mm

Travelling speed along the X- and Y-axis 3,000 mm/min

Travelling speed along the Z-axis 100 mm/min

Working instrument type One extruder

Working instrument specifications

Nozzle diameter 0.4 mm

Max temperature 250°C

Filament diameter (thickness) 1.75 mm

Material Type PLA

3D-model file format STL

Computer connection via USB

SD card use no

Print bed without heating

Dimensions (Length×Width×Height) 370×280×350 mm

Weight 3.5 kg

Environment conditions

Temperature: 15–25 °С

Humidity: up to 70%

Operating: indoors only

Air ventilation Natural ventilation is required

4

4. Contents of Deli ery Kit

The ROBBO 3D PRINTER MINI delivery kit includes:

● Assembled and configured 3D printer

● USB stick with software and setup

● Filament filter

● Power supply unit

● USB cable

5. Structure and Working Principle

5.1. Physical Form

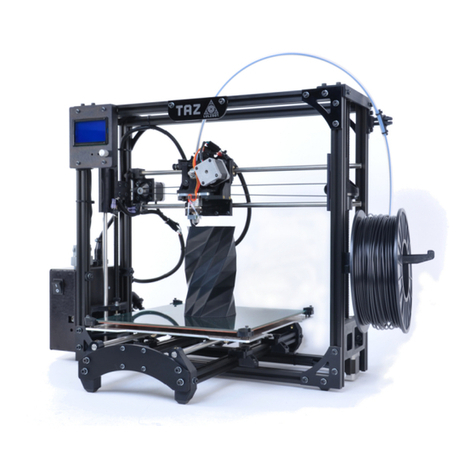

3D printer consists of the following main units:

● Mounting base (shown in red colour)

● Z-axis sliding cradle (shown in yellow)

● Print bed (shown in blue)

● Guiding rods holder (shown in green)

5

5.1.1. Mounting base

The mounting base of the 3D printer houses two stepped motors (Y and Z) and electronics

compartment.

5.1.2. Print bed

Moving print bed consists of X-axis stepped motor, guiding rods, and printing surface.

6

5.1.3. Z-axis sliding cradle

Z-axis sliding cradle includes extruder’s motor, extruder, and airstream cooler (with the hood).

5.2. Printing technology

ROBBO 3D PRINTER MINI uses Fused Depositing Method (FDM). 3D objects are created by

depositing the fused layers of melted plastic on the print bed.

The main unit of the 3D printer is extruder. It heats up the plastic filament and extrudes

the melted filament onto the print bed.

Extruder’s motor feeds the filament into the extruder’s pipe (made of PTFE), through

which the filament gets into the chamber of the heater to be heated up to the melting temperature

and poured through the nozzle under pressure. The temperature in the chamber is kept high by

the heater and controlled by a thermal resistor (changing its resistance with the change of the

temperature).

7

5.3. Suitable working materials

The choice of the working materials for ROBBO 3D PRINTER MINI is based on four criteria:

● Operating temperature of the extruder (will the plastic melt?)

● Surface adhesion (will the plastic hold to the surface?)

● Extruder’s geometry (will the plastic be driven-up?)

● Nozzle size (will the plastic go through it?)

Maximal temperature achievable in the extruder is 250°С. For the best surface adhesion of

melted plastic we recommend using a special adhesive tape (3M Bluetape 2090). It perfectly

matches PLA-based plastics and plastics with low shrinkage ratio. ABS plastic would adhere

such surface as well, but it has drastic temperature shrinkage resulting in distortion of the model.

The extruder of our 3D printer has a short distance between the drive-up cog-wheel and the

PTFE pipe supplying the plastic into the heating zone. This enables printing with pliant plastics.

When melted, plastics (e.g. PLA) can be mixed with various fillers, i.e., powder of a solid

material. Particles of such powder can exceed the nozzle diameter as of its size. In this case, the

particle will jam the nozzle and hinder the plastic passing through. In our 3D printer, the nozzle

diameter is 0.4 mm, which enables printing with the majority of composite plastics.

Suitable materials are PLA, FLEX, SBS, composite plastics (Bronzefill, woodfill, carbonfill).

8

6. Safety Instructions

● Use the 3D printer in well-ventilated rooms with ambient temperature of 15–25°C and

humidity up to 70%.

● Do not use the 3D printer in dust-laden and/or humid environment.

● Do not use the 3D printer outdoors.

● Mount the 3D printer on an even stable surface far from flammable substances, open fire,

water sources.

● Do not hinder the moving parts during printing.

● Do not touch the heater when the 3D printer is working.

● Do not let foreign objects in moving parts and fans.

7. Software

ROBBO 3D PRINTER MINI runs the free and open source firmware Marlin.

(https://github.com/MarlinFirmware/Marlin)

Free application Repetier-Host is used as operating software (https://www.repetier.com)

Free application Slic3r is used to prepare the 3D model for printing (http://slic3r.org/)

7.1. Description of Repetier-Host

On launching Repetier-Host application, the main window of the application opens. There are

three toolbars with buttons plus the main working area.

The toolbars are described below.

9

Left-side toolbar

Toolbar on top (Upper toolbar)

10

Right-side toolbar

The right-side toolbar contains five tabs with buttons.

●1 — Object Placement

●2 — Slicer

●3 — Pre iew

This tab shows the parameters of the ready model (printing time, number of layers, approximate

length of the filament needed).

11

●4 — Manual Control

●5 — SD Card

It enables saving the ready model on an SD card for printing afterwards.

7.2. Software Installation

The accompanying USB stick contains the distributions of the required software. The

software is free, and you can also download the latest versions from the developers’ website.

The software is installed by two stages. First to install is Repetier-Host, and the next is

Slic3r.

7.2.1. For Windows

The installation steps are shown in the pictures.

1. Run Setup.exe:

2. Choose the language that you prefer:

12

3. Click [Next]:

4. Tick the checkbox to accept the license agreement and click [Next]:

13

5. Choose a folder for software installation:

6. Choose the program components to install (make your choice as shown in the picture):

14

7. Create the shortcut to launch the program:

8. Create such shortcut on the desktop too:

15

9. Click [Install]!

After that, copy Slic3r folder into the folder where Repetier-Host has been installed:

Congratulations, the software is installed! Go to Section 7.3 of this Manual.

7.2.2. For Linux

To install Repetier-Host, unpack the archive in your home directory. To do so, you have

to unpack it in the Home folder of your system. Then the Slic3r folder should be copied

from USB stick to the Repetier-Host folder (which you have just unpacked). From the

Repetier-Host folder, run the scripts Configure-First and InstallDependencies.

16

7.3. Software Setup

3D printer has two categories of settings: Repetier-Host settings and Slic3r settings.

Repetier-Host settings are to be typed manually in the Printer Settings window.

For that, click the [Printer Settings] button:

Copy the values from the picture below (the [Connection] tab):

WARNING: while choosing COM port, the 3D printer should be connected.

Select COM port from the Port” list, then click [Refresh ports] and try again.

3D printer will match the COM port that disappears on disconnecting USB.

17

Copy the values from the picture (the [Printer] tab):

Copy the values from the picture (the [Extruder] tab):

18

Copy the values from the picture (the [Printer Shape] tab):

Congratulations, you have configured Repetier-Host.

Now we have to go to Slic3r settings.

19

Slic3r settings are loaded automatically. To load them, go to the [Slicer] tab and click the

[Confuguration] button:

In the window that opens, select [File], then click [Load Config Bundle], and choose the file that

contains the settings (ROBBO_3D-PRINTER_MINI_Slic3r_config_bundle) on USB stick.

20

Table of contents