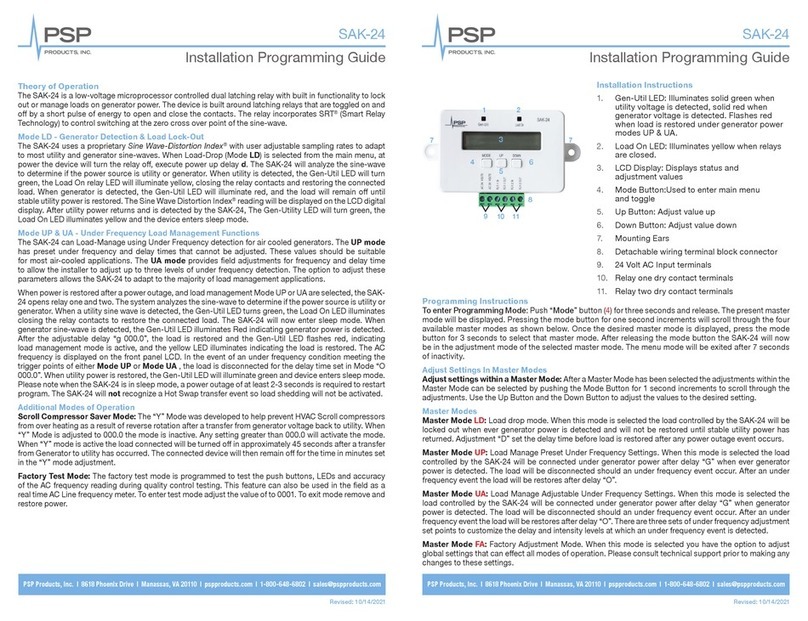

Left Arrow Key- The left arrow key is used to scroll thru screens

1 to 6. The screen sequence will be repeated after screen 6. Note:

The right arrow key does not scroll in reverse.

Load Shedding Control

Model LSC-04

Screen 1 Screen 2 Screen 3

Screen 4

Screen 5 Screen 6

Screens 1 to 5 are used to adjust the Amperage and time delays in the load shedding program. Note that screen 4 “Gen

Actual Cur” is not adjustable and is reading the amperage interpreted by the CT input. Also note that screen 6

displays the real time state of the output relays on the controller. Screen 7 indicated the NO or NC Mode of operation.

The LSC-04-S is a standalone load shedding controller designed to work with any single phase generator and a broad

range of connected load types controlled by DRY CONTACTS. The controller can be set for 2 different configurations

as follows. Normally open Mode is selected when I2 = 0 this mode is designed to work with loads that use a normally

open state for control purposes like normally closed relays. The Normally Closed Mode is selected when I2 = 24 V

DC. This mode is designed to work with normally closed control circuits like low voltage HVAC control wires and

normally open contactors.

Operation: The internal program starts to run on power up. At startup all relays will revert to their active state, NO

Configuration will close and NC Configuration will open. All relays will remain in their active state for the

duration of the Delay Shed period set by DR01. After DR01 times out the program will look at the value of Gen

Full Load DR02 to determine the maximum amps available. A comparator circuit will look at the assigned

amperage rating of DR03 Relay1 and the Gen Actual Cur reading, (this will always be determined by the higher of

the 2 CT inputs). When capacity is available Relay1 will revert to the NORMAL STATE and turn the load on.

After the load is restored the program will pause for the number of seconds set by input setting DR0A Stabilize

Time. After the delay period the program will compare the Gen Actual Cur reading, with Gen Full Load DR02

and the amps assigned to RELAY2 DR04, if the comparator program determined capacity is available RELAY2

will revert to its normal state turning on load 2. This sequence is repeated for RELAY3 DR05 and RELAY4 DRO6

.Any time the Gen Actual Cur reading exceeds 90% of Gen Full Load DR02 All relays will revert to their active

state removing all four of the loads from the circuit. The program will then repeat the process restoring one load at a

time until additional capacity is no longer available.

Programming Screens

Theory Of Operation

Screen 7