BIFFI PLA User manual

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4

June 2020

Biffi

PLA

Double-Acting Pneumatic Linear Actuator

Copyright © Bif. The information in this document is subject to change without notice. Updated data sheets can be obtained from our website www.bif.it or from your nearest Bif Center:

Bif Italia s.r.l. - Strada Bif 165, 29017 Fiorenzuola d'Arda (PC) – Italy PH: +39 0523 944 411 – bif_italia@bif.it

June 2020

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4

Revision Details

Revision Details

Revision Details

Rev. Date Description Prepared Checked Approved

4 June 2020 General update (Migration to new template)

3 May 2018 Updated Data-plate Ermanni Oreci Vigliano

2 April 2016 Updated applicable regulation (Section 1.1.1) Ermanni Oreci Vigliano

1October 2009 General update Ermanni Oreci Vigliano

0May 1999 Document release Lazzarini Aliani Ziveri

i

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4

Table of Contents

Table of Contents

June 2020

Table of Contents

Section 1: General Warnings

1.1 Generalities................................................................................................. 1

1.1.1 Applicable Regulation....................................................................... 1

1.1.2 Terms and Conditions....................................................................... 2

1.2 Identication Plate...................................................................................... 2

1.3 Introducing the Actuator ............................................................................ 3

1.4 Data Sheet .................................................................................................. 4

Section 2: Installation

2.1 Checks Upon Actuator Receipt .................................................................... 5

2.2 Actuator Handling ...................................................................................... 5

2.3 Storage ....................................................................................................... 6

2.4 Actuator Assembly on the Valve.................................................................. 7

2.4.1 Types of Assembly ............................................................................ 7

2.4.2 Assembly Procedure......................................................................... 7

2.5 Pneumatic Connections ............................................................................ 12

2.6 Electrical Connections (If Any)................................................................... 12

2.7 Commissioning......................................................................................... 13

Section 3: Operation and Use

3.1 Operation Description .............................................................................. 14

3.2 Residual Risks ............................................................................................ 15

3.3 Operations ................................................................................................. 15

3.3.1 Local Pneumatic Operation ............................................................ 15

3.3.2 Electric Remote Control to Open and to Close ................................ 16

3.3.3 Emergency Manual Operation by MSJ / MH ........................................ 16

3.3.4 Emergency Manual Operation by MHP ............................................... 17

3.4 Calibration of The Linear Stroke ................................................................. 17

3.5 Calibration of Micro-Switches (for Bif limit switch box*) ......................... 20

3.6 Calibration of the Operation Time ............................................................ 22

Section 4: Operational Tests and Inspections

Operational Tests and Inspections ...................................................................... 24

ii

Table of Contents

June 2020

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4

Table of Contents

Section 5: Maintenance

5.1 Periodic Maintenance................................................................................ 25

5.1.1 Check and Restore Oil Level in the Gas-Hydraulic Tanks................... 26

5.1.2 Gas Supply Dehydrating Filter Maintenance (if foreseen)................. 27

5.1.3 Lubrication of Actuator................................................................... 28

5.2 Extraordinary Maintenance....................................................................... 29

5.2.1 Replacement of Cylinder Seals ........................................................ 29

5.3 Dismantling and Demolition ..................................................................... 33

Section 6: Troubleshooting

6.1 Failure or Breakdown Research.................................................................. 34

Section 7: Layouts

7.1 Spare Parts Order...................................................................................... 35

7.2 Parts List for Maintenance and Replacing Procedure.................................. 36

Section 8: Date Report for Maintenance Operations

Date Report for Maintenance Operations ............................................................ 45

1

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4 June 2020

Section 1: General Warnings

General Warnings

Section 1: General Warnings

NOTICE

The manual is an integral part of the machine, it should be carefully read before carrying

out any operation and it should be kept for future references.

1.1 Generalities

Bif Italia s.r.l. actuators are conceived, manufactured and controlled according to the

Quality Control System in compliance with EN-ISO 9001 international regulation.

1.1.1 Applicable Regulation

EN ISO 12100:2010: Safety of machinery – General principles for design –

Risk assessment and risk reduction

2006/42/EC: Machine directive

2014/68/EU: Directive for pressure PED equipment

2014/35/EU: Directive for low voltage equipment

2014/30/EU: Directive for the electromagnetic compatibility

2014/34/EU: Directive and safety instructions for use in hazardous area

NOTICE

Bif Italia s.r.l. pays the highest attention to collecting and verifying the documentation

contained in this user manual. However Bif Italia s.r.l. is not liable for any mistakes

contained in this manual, for damage or accidents due to the use of the latter.

The information contained is of exclusive reserved ownership of Bif Italia s.r.l.

and may be modied without prior notice. All rights reserved.

2

June 2020

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4

Section 1: General Warnings

General Warnings

1.1.2 Terms and Conditions

Bif Italia s.r.l. guarantees that all the items produced are free of defects in workmanship

and manufacturing materials and meet relevant current specications, provided they

are installed, used and serviced according to the instructions contained in the present

manual. The warranty can last either one year from the date of installation by the initial

user of the product, or eighteen months from the date of shipment to the initial user,

depending on which event occurs rst. All detailed warranty conditions are specied in

the documentation forwarded together with the product. This warranty does not cover

special products or components not warranted by subcontractors, or materials that were

used or installed improperly or were modied or repaired by unauthorized staff. In the

event that a fault condition be caused by improper installation, maintenance or use, or by

irregular working conditions, the repairs will be charged according to applicable fees.

The warranty and Bif Italia s.r.l. liability shall lapse in the event that any modication

or tampering whatsoever be performed on the actuator.

1.2 Identication Plate

It is forbidden to modify the information and the marks without previous written

authorization by Bif Italia s.r.l.

The plate fastened on the actuator contains the following information (Figure 1).

Figure 1 Data Plate

3

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4 June 2020

Section 1: General Warnings

General Warnings

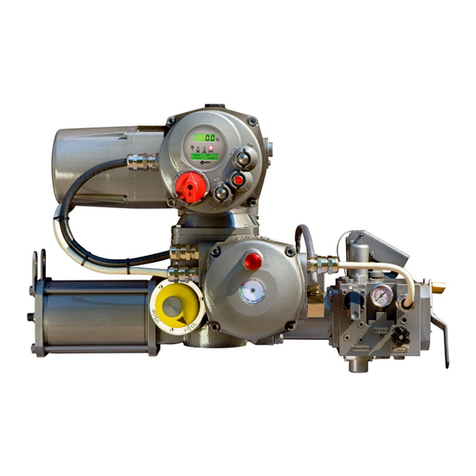

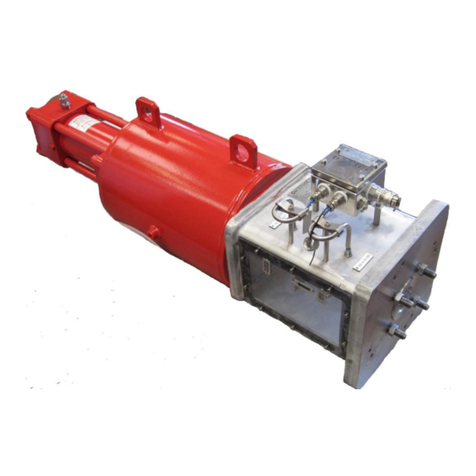

1.3 Introducing the Actuator

PLA Double-Acting Pneumatic Low-Pressure Linear Actuators, are suitable for the

operation of linear valves (wedge gate valves, through conduit gate valves) for ON-OFF and

modulating heavy-duty service.

The actuator is made up of a pneumatic cylinder and a mounting pedestal complete with

a joint for the coupling to the valve stem of actuator output stem. The valve is actuated in

opening and in closing position by the actuator pneumatic cylinder that is pressurized in

one or in the other direction.

The linear stroke of the valve is adjustable by means of the external mechanical stop for

upward position and by the adjustment of the coupling of valve stem to actuator joint for

the downward position.

The actuator pedestal has a ange with threaded holes to x the actuator to the valve.

Bif can supply different types of control system following Customer’s requirements.

The expected lifetime of actuator is approximately 25 years .

Figure 2 Identication of actuator parts

Manual handpump MHP (optional)

Pneumatic cylinder

Lifting eyelets

MHP (optional) Hydraulic cylinder (for MHP models)

Valve coupling

Valve position indicator

4

June 2020

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4

Section 1: General Warnings

General Warnings

1.4 Data sheet

Supply uid Air, Nitrogen or sweet gas

Operating temperature Standard: from –30 °C to +100 °C

Optional: from –60 °C to +140 °C

Supply pressure 10.5 bar max.

Manual override

Stroke (mm)

Cylider diameter (mm)

Max. allowable thrust (N)

Double-Acting actuator

PLA 250k 585 300 MHP

5

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4 June 2020

Section 2: Installation

Installation

Section 2: Installation

2.1 Checks Upon Actuator Receipt

• Check that the model, the serial number of the actuator and the technical data

reported on the identication plate correspond with those of order conrmation,

see Section 1.2.

• Check that the actuator is equipped with the ttings as provided for by

order conrmation.

• Check that the actuator was not damaged during transportation: if necessary renovate

the painting according to the specication reported on the order conrmation.

• If the actuator is received already assembled with the valve, its settings have

already been made at the factory.

• If the actuator is delivered separately from the valve, it is necessary to check,

and if required, to adjust, the settings of the mechanical stops, (refer to

Section 3.4) and of micro-switches (if any) refer to Section 3.5.

2.2 Actuator Handling

NOTICE

The lifting and handling should be made by qualied staff and in compliance with the laws

and provisions in force.

! WARNING

The fastening points are appropriate for the lifting of the actuator alone and not for the

valve + actuator assembly. Avoid that during the handling, the actuator passes above the

staff. The actuator should be handled with appropriate lifting means. The weight of the

actuator is reported on the delivery bill.

For a correct lifting procedure, please refer to following Figures.

Figure 3 Lifting Points for PLA Actuators

1 = Lifting points

(obligatory)

6

June 2020

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4

Section 2: Installation

Installation

Figure 4 Positioning by chains and by slings

1. Point of support

2. Don’t lay the actuator on tie-rods of cylinder

3. Don’t lay the actuator on accessories

(manual handpump, manual jackscrew, pneumatic control group etc.)

2.3 Storage

If the actuator needs storage, before installation follow these steps:

• Place it on a wood surface in order not to deteriorate the area of valve coupling.

• Make sure that plastic plugs are present on the hydraulic and electrical

connections (if present).

• Check that the protection of the control system and of the limit switch box

(if any) are properly closed.

If the storage is long-term or outdoor:

• Keep the actuator protected from direct weather conditions.

• Replace plastic plugs of hydraulic and electrical connections (if any) with metal

plugs that guarantee perfect tightness.

• Coat with oil, grease or protection disc, the valve coupling area.

• Periodically operate the actuator, refer to Section 3.3.

7

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4 June 2020

Section 2: Installation

Installation

2.4 Actuator Assembly on the Valve

2.4.1 Types of Assembly

The adapter pedestal in fabricated carbon steel is specically designed for adaptation to

any type of valve with provision for local indicator, limit switches and other accessories

(on request).

Lift the actuator by safety-hook for chains using the lifting-points (see Section 2.2)

on the top of actuator for handling, transporting and assembling in vertical position

(see Figure 3). For handling, transporting and assembling the actuator in horizontal

position by safety-hook for chains use the lifting-points on the top of cylinder head-ange

and on coupling ange (see Figure 4).

2.4.2 Assembly Procedure

! WARNING

Failure to comply with the following procedures may impair product warranty.

Installation, commissioning and maintenance and repair works should be carried out by

qualied staff. A non-conforming assembly could be the source of serious accidents.

For actuator assembly on the valve:

NOTICE

Check that the assembly position, as shown on the documentation, complies with

system’s geometry. Check the consistency of the parts of actuator-valve coupling.

8

9

8

7

6

5

4

2

1

3

June 2020

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4

Section 2: Installation

Installation

A. To assemble the actuator onto the valve by bracket with threaded joint proceed

as follows:

Table 1. Parts list

Item Description

1Nut

2Stud bolt

3Support joint

4Index

5 Screw

6Connecting joint

7 Screw

8Bushing

9Flange

Figure 5 Pedestal with threaded coupling joint

9

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4 June 2020

Section 2: Installation

Installation

1.

Check that the coupling dimensions of the valve ange and stem, or of the

relevant extension, meet the actuator coupling dimensions (valve stem and

ange). Lubricate the valve stem with grease in order to make the assembly easier.

2. Connect a sling to the support point of the actuator and lift it. To make easier the

assembly, the valve stem has to be in perfect vertical position.

NOTICE

The eyebolt is sized for the lifting of the only actuator (NOT ACTUATOR+VALVE).

Proper lifting points have to be foreseen for the valve.

3.

Screw the actuator coupling joint onto the valve by rotating the actuator, or screw

down the valve stem stroke-ring with Red Loctite 542 and x the half bearings.

When the threaded holes of the actuator ange are in correspondence with the

holes on the valve ange screw the proper stud bolts. Screw the nuts on the stud

bolts and tighten up the valve ange is in contact with the actuator ange.

4. Tighten the nuts of the connecting stud bolts evenly with the torque prescribed

in the table. The stud bolts must be made of ASTM A320 L7 steel, the nuts must

be made of ASTM A194 grade 2 steel as minimum.

10

9

8

7

6

5

4

3

2

1

10

June 2020

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4

Section 2: Installation

Installation

B. To assemble the actuator onto the valve by bracket with shell joint,

perform the following operations:

Table 2. Parts list

Item Description

1Stud bolt

2Nut

3Nut

4Screw

5 Pedestal

6Actuator joint

7 Stem valve joint

8Shell joint

9Spacer

10 Screw

Figure 6 Pedestal with shell coupling joint

11

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4 June 2020

Section 2: Installation

Installation

1.

Check that the coupling dimensions of the valve ange and stem, or of the

relevant extension, meet the actuator coupling dimensions (valve stem and

ange). Lubricate the valve stem with grease in order to make the assembly easier.

2. To make easier the assembly, the valve stem has to be in perfect vertical position.

3. Disassemble the two halves of actuator pedestal shell joint (item 8) by unscrewing

the retaining screws (item 4), therefore disassemble the valve stem joint (item 7).

4. Lift the actuator by utilizing the proper lifting eyelets, and unscrew the nuts and

the stud bolts from the actuator pedestal.

5. Assemble the actuator onto the valve, and arrange it in its correct vertical

position proper to connection between valve stem and actuator cylinder rod.

6. Screw the valve stem joint (item 7) on valve stem up to reach the proper position

which allow the reassembly of the two halves of shell joint (item 8), tighten the

joint fastening screws (item 4).

7. Screw the stud bolts (item 1) into the actuator pedestal ange, and screw the

nuts on the stud bolts.

8. Tighten according to the nut (item 2) size torque requirements.

To operate refer to following Table:

The screwing values in Table 3 were calculated considering the materials ASTM A320 L7

for screws or tie rods and ASTM A194 gr.2H for the nuts.

Table 3. Nuts Tightening Torque

Threading Tightening torque (Nm)

M8 20

M10 40

M12 70

M14 110

M16 160

M20 320

M22 420

M24 550

M27 800

M30 1100

M33 1400

M36 1700

12

June 2020

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4

Section 2: Installation

Installation

2.5 Pneumatic Connections

! WARNING

Check that the values of pneumatic supply available are compatible with those reported

on the identication plate of the actuator.

NOTICE

The connections should be made by qualied staff. Use pipes and connections appropriate

as for type, material and dimensions.

• Properly deburr the ends of rigid pipes.

• Properly clean the interior of pipes sending through them plenty of the supply uid

used in the system.

• Mould and fasten the connection pipes so that no irregular strains at entries or

loosening of threaded connections occur.

• Make the connections according to the operating diagram.

• Check the absence of leakages from pneumatic connections.

2.6 Electrical Connections (If Any)

! WARNING

Use components appropriate as for type, material and dimensions. The connections

should be made by qualied staff. Before carrying out any operation, cut line power off.

Safety provisions:

2006/95/EC: Directive for low voltage equipment (until 19 April 2016)

2014/35/EU from 20 April 2016

2004/108/EC: Directive for the electromagnetic compatibility (until19 April 2016)

2014/30/EU from 20 April 2016

94/9/CE:

Directive and safety instructions for use in hazardous Area (until 19 April 2016)

2014/34/EU from 20 April 2016.

Remove plastic plugs from cables entries

• Screw rmly the cable glands.

• Introduce connection cables.

• Make the connections in compliance with applicable wiring diagrams on the

documentation supplied.

• Screw the cable gland.

• Replace the plastic plugs of unused entries with metal plugs.

13

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4 June 2020

Section 2: Installation

Installation

2.7 Commissioning

! WARNING

Installation, commissioning and maintenance and repair works should be made by

qualied staff.

Upon actuator commissioning please carry out the following checks:

• Check that paint hasn't been damaged during transport, if necessary repair the

damages to paint coat.

• Check that the pressure and quality of the gas supply (ltering degree, dehydration)

are as prescribed. Check that the feed voltage values of the electric components

(solenoid valve coils, micro-switches, pressure switches, etc.) are compatible with

those reported on the identication plate of the actuator (Figure 1) and to specic

data-plate on electric components.

• Check that the setting of the components of the actuator control unit (pressure

regulator, pressure switches, ow control valves, etc.) meet the plant requirements.

• Carry out all kinds of operations and check their proper execution (Section 3.3).

• Check the absence of leakages in the pneumatic connections.

• If necessary tighten the nuts of the pipe-ttings.

• Check proper operation of all the due signalling (valve position, gas supply pressure etc.).

• Make a complete functional test in order to verify all the operations are executed

according to operating schematic diagram supplied.

14

June 2020

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4

Section 3: Operation and Use

Operation and Use

Section 3: Operation and Use

3.1 Operation Description

The supply gas pressurizes the pneumatic-cylinder chamber relevant to the operation to

carry out (opening or closing) (see following pages). This pressure starts the linear motion

of the piston and the consequent motion of the valve stem that is coupled.

For local or remote operations, please refer to technical documentation furnished

with actuators.

The power and control systems are supplied on specic customer demand.

NOTICE

For all the relevant information please refer to the specic documentation supplied.

Figure 8 Double-Acting function with jackscrew manual override type MHW

(direct action) or MSJ (that it can be engaged/disengaged by hand-lever)

Figure 7

15

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4 June 2020

Section 3: Operation and Use

Operation and Use

Figure 9 Double-Acting function with jackscrew manual override type MHP

3.2 Residual Risks

! WARNING

It is recommended to pipe exhaust gas.

The actuator has parts under pressure.

Use the due caution.

Use individual protections provided for by the laws and provisions in force.

3.3 Operations

3.3.1 Local Pneumatic Operation

! WARNING

Use the proper safety measures to protect from any pressurized gas not piped

and from excessive and harmful noise. Refer to applicable control schematic in

supplied documentation.

16

June 2020

Installation, Operation and Maintenance Manual

MAN 619 Rev. 4

Section 3: Operation and Use

Operation and Use

Figure 10 PLAS MHP without control system

Pressurize the pneumatic-cylinder chamber, this pressure starts the linear motion of the

piston and the consequent motion of the valve stem that is coupled.

The valve is actuated in opening and in closing position by the actuator pneumatic

cylinder in one direction and by the spring unit in the other direction. Check the correct

operation of the actuator through the visual position indicator.

3.3.2 Electric Remote Control to Open and to Close

When actuator is furnished of control system (panel or cabinet) remote operations

were possible:

• From the control room send the electric signal corresponding to the operation to

carry out: energize solenoid valve during all the valve stroke.

• Solenoid valve must be de-energized at the end of actuator operation.

3.3.3 Emergency Manual Operation by MSJ / MHW

(when sufcient line pressure is not available)

• Engage the manual override by rotating it’s handle.

• Turn by the lever the manual override clockwise to close, or counterclockwise to open.

• Check the correct operation of the actuator through the visual position indicator.

• If no other manual operation is carried out, disengaged the manual override to allow

the operation with pneumatic supply.

(see Section 7.2, Table 14: sectional drawing for Manual Jackscrew MSJ.)

Table of contents

Other BIFFI Controllers manuals

BIFFI

BIFFI RPS Series User manual

BIFFI

BIFFI GIGS 0.3 User manual

BIFFI

BIFFI FCB Series Operating instructions

BIFFI

BIFFI HLAS-C Series User manual

BIFFI

BIFFI COMPACT Series User manual

BIFFI

BIFFI ALGAS-MHP User manual

BIFFI

BIFFI EFS2000v4 Parts list manual

BIFFI

BIFFI GIL MAN 725 User manual

BIFFI

BIFFI OLGA-H User manual

BIFFI

BIFFI ALGAS-QA Series Manual

BIFFI

BIFFI RPD Series User manual

BIFFI

BIFFI ECU 1000 Manual

BIFFI

BIFFI RPHD User manual

BIFFI

BIFFI GILS User manual

BIFFI

BIFFI ALGA-EAC Series User manual

BIFFI

BIFFI ALGAS-MHW User manual

BIFFI

BIFFI HLAS User manual

BIFFI

BIFFI OLGA Series User manual

BIFFI

BIFFI ALGAS-QA EAC User manual

BIFFI

BIFFI OLGAS User manual