PTronik E10 User manual

This quick start guide provides the user very basic information required to make the E10

controller pulse solenoid valves and to make changes to the time and pressure settings. The

user is referred to the E10 manual for detailed connection and setup information and all

safety and warning instructions. The E10 should only be installed by a suitably qualified

person and all local electrical standards must be observed.

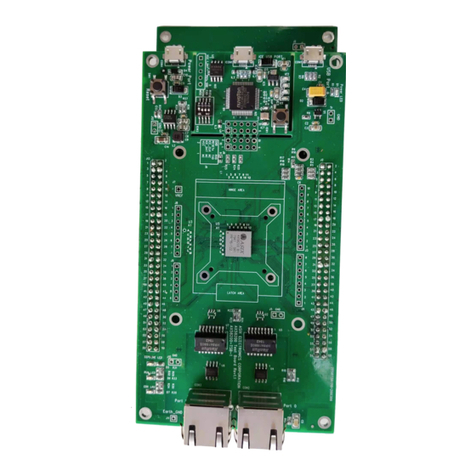

Top Board Layout

Bottom Board Layout

LC Screen

Three Button

Interface

Input Sensors

Output Relays

Modbus RTU and/or

extension cards

Solenoid

Valve

Outputs

110/240

VAC

Input

24V C Input

Or Output

Fuse (AC

version)

Cleanup

24V C connections

for tube cleaning valves

Quick Start Guide

E10 Master Controller

Connecting Power and Solenoid alves

If the E10 has been purchased as a complete unit then undo the 4 dome nuts and remove

the face plate. Remove the PCB from the brass spacers to access the bottom of the board.

DO NOT double up solenoid valves, only connect one solenoid valve per position.

DO NOT mix commons between the main and extension cards if extension cards are connected.

oing both these will cause the E10 to detect valve faults.

DC SOLENOID VERSION - AC input power and 24VDC

solenoid output

For this configuration the AC input voltage can be

between 100-240VAC, but the output voltage is fixed

at 24V C

1. Connect the 100 to 240V AC incoming power

supply to terminal marked ENA (terminal J103).

This plug is removable to assist the installation

process.

2. Connect the 24V C solenoid coils to terminal

marked SOLENOIDS (terminal J306). This plug is

removable to assist the installation process.

DC SOLENOID VERSION - DC input power and DC

solenoid output

For this configuration the C input voltage can be

between 10-30V C and the output voltage to the coils

is identical to the input voltage. So 10V C in, 10V C

out. 24V C in, 24V C out etc.

1. Connect the C incoming power supply to

terminal marked CVI (terminal J104)

2. Connect the 24V C solenoid coils to terminal

marked SOLENOI S (terminal J306). This plug is

removable to assist the installation process.

AC SOLENOID VERSION - AC power input and identical

AC solenoid output

For this configuration the AC input voltage can be

between 100-240VAC and the output voltage to the

coils is identical to the input voltage. So 240V in, 240V

out. 110V in, 110V out etc.

1. Connect the 100 to 240V AC incoming power

supply to terminal marked ENA (terminal J103).

This plug is removable to assist the installation

process.

2. Connect the 100 to 240V AC solenoid coils to

terminal marked SOLENOI S (terminal J306). This

plug is removable to assist the installation process.

2

2

2

Main Run Page

The main run page gives the user a snap shot of the current status of the dust collector.

There is a lot of information on this screen so please take a minute to read this section.

MODEL OF PTronik

CONTROLLER

Indicates the model of the PTronik controller. Visually the E10, E10

and E10 look very similar.

2 COUNT DOWN TIME Indicates the time in seconds until the next valve pulses.

3 NEXT VALVE Indicates the next valve that will pulse. This will be a number

between 1 and 240 depending on setup and how many extension

cards are connected.

4 ALARM STATE Indicates the alarm status for alarms 1 to 8 (the screen will toggle

between A1IA2IA3-A4+ and A5IA6-A7-A8-).

• I = Interrupt

• - = alarm disabled

• + = alarm enabled

• * = alarm enabled and ON (activated)

5 SOLENOID STATE Indicates the last solenoid valve that fired and what the result of the

valve as (whether the coil of the last valve is faulty or not).

• OK = NO Fault

• OC = Open Circuit

• SC = Short Circuit

6 MANUALLY STOPPING THE

DUST COLLECTOR

Indicates the current state of the controller. The dust collector can

be manually halted if required.

• Halt = The dust collector has been halted either manually or

by the differential pressure cleaning mode

• Pulse = The dust collector is pulsing

If any of the three buttons are pressed the following screen will appear. This allows the user

to change between pulsing or halting and allow the user to enter the Menu section.

2

3

4

5

6

7 PULSE OR HALT Press on the left button to manually change the state between

Halted and Pulsing.

8 MENU Press on the middle button to check alarms, enter maintenance

mode or to alter the settings of the controller.

Accessing the Settings Area

From the main screen, continue pressing the middle button unit the Enter CODE page

appears

To enter the code, select the left DOWN or right UP buttons. The

password code for all controllers is set to 4.

When this has been entered enter the middle SET button.

Timer Settings

This menu allows the user to change the settings of the controller such as number of valves,

sequencing, the pulse on and off times. Keep pressing NEXT until the TIMER Setup page is

displayed.

To modify the controller timer settings, enter the middle Select

button.

2

This page specifies the number of valves connected to the E10.

To alter the number of valves connected to the system use the left

DOWN or right UP buttons. When the desired number of valves has

been entered enter the middle SET button.

3

Keep pressing the set button to skip the next few pages until the

user gets to OnTime page.

This page modifies the length of the pulse duration.

The pulse duration is user selectable in milli seconds (ms) and can be

between 1ms to 999ms in length.

7

8

To alter the on time OnTime select the left DOWN or right UP

buttons. When the desired on time has been entered enter the

middle SET button. In this example the on time is 150 milli seconds.

4

This page modifies the length of time between pulses. The interval

between pulses is user selectable in seconds (sec) and can be

between 1s to 999s in length.

OffTime - This is the off time used during normal

operation when the differential pressure is between Low

and Fast settings (see O C section following)

To alter the off times, select the left DOWN or right UP buttons.

When the desired off time has been selected enter the middle SET

button. In this example the off time 1 is 15 seconds.

Maintenance Mode

Maintenance mode allows the user to manually pulse and test the valves. Keep pressing

NEXT until the Maintenance page is displayed.

To enter maintenance mode, select the middle SELECT button

2

This page allows the user to select the valve to test.

To select the valve to pulse, select the left DOWN or right UP

buttons. When the valve to be tested has been selected hit the

middle PULSE button to test the valve

3

This page shows the test result of the valve just pulsed.

The test result of the coil will be shown to the right of the PULSED!

text and will be one of the following three possibilities

OK – The solenoid valve is functioning correctly

SC – The solenoid valve is showing a short circuit. This could

mean the

OC – The solenoid valve is showing an open circuit. This

could mean the valve is not connected or the coil has burnt

out.

Enter DONE to return to the main menu or NEXT to test and pulse

another valve

Further Assistance Required?

If a full manual or further assistance is required then please contact PTronik

Tel: +61 2 4578 9611

Website: https://www.ptronik.com/contact-us

Email: [email protected]

This manual suits for next models

9

Other PTronik Controllers manuals