VII. Maintenance and Care

1. During prolonged operation of the RO system, fine sediments and

bacteria may settle on the membrane surface and block the flow. It

is therefore advisable to carry out a regular rinse:

a. Manual flushing

b. Rinsing procedure: Open the inlet water valve and allow the device

to rinse for approx. 5 - 10 minutes. Then close the inlet water valve

again.

2. To ensure an excellent quality of ultrapure water, the filters must be

replaced regularly. The lifetime of each filter varies depending on the

quality of the input water. A family of three has on average a daily

water consumption of about 10 liters of drinking water. The filters

should therefore be replaced as follows:

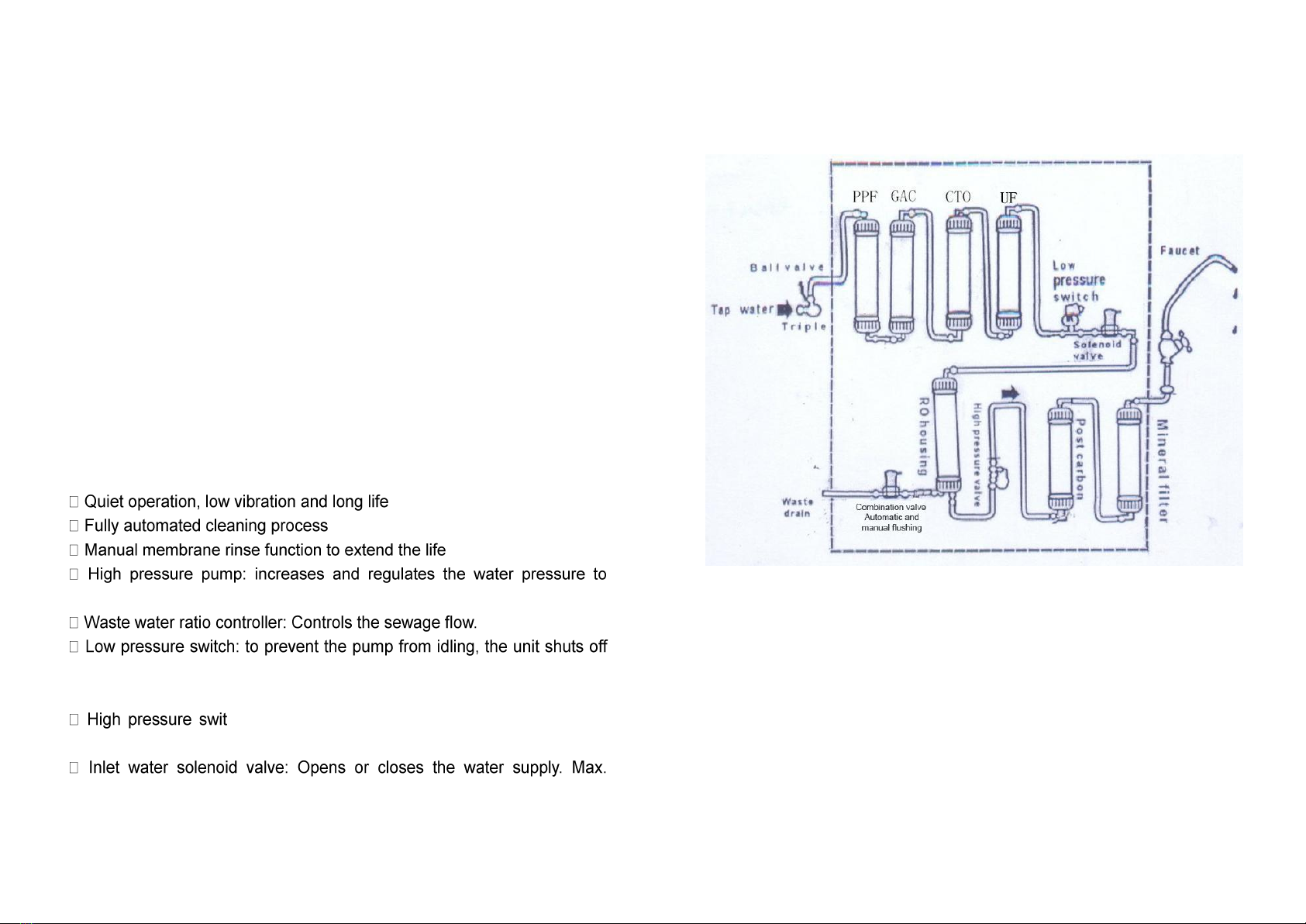

Stage 1 - PP filter 10 microns: about 3 - 6 months

Stage 2 - GAC granular activated carbon filter: approx. 3 - 6 months

Stage 3 - CTO activated carbon block 5 microns: about 3 - 6 months

Stage 4 - UF fine filter 0.02 micron: approx. 6 - 12 months

Stage 5 - RO membrane: approx. 12 - 24 months

Level 6 - T33 post activated carbon filter: approx. 6 - 12 months

Stage 7 - mineralization filter: approx. 6 - 12 months

A change of filters is necessary if the following situations occur:

1. The quality of the ultrapure water deteriorates and the taste

changes

2. The ultrapure water volume decreases noticeably. (ATTENTION: a

reduced volume of ultrapure water production also results from a

change in the temperature of the input water.)

Attention!

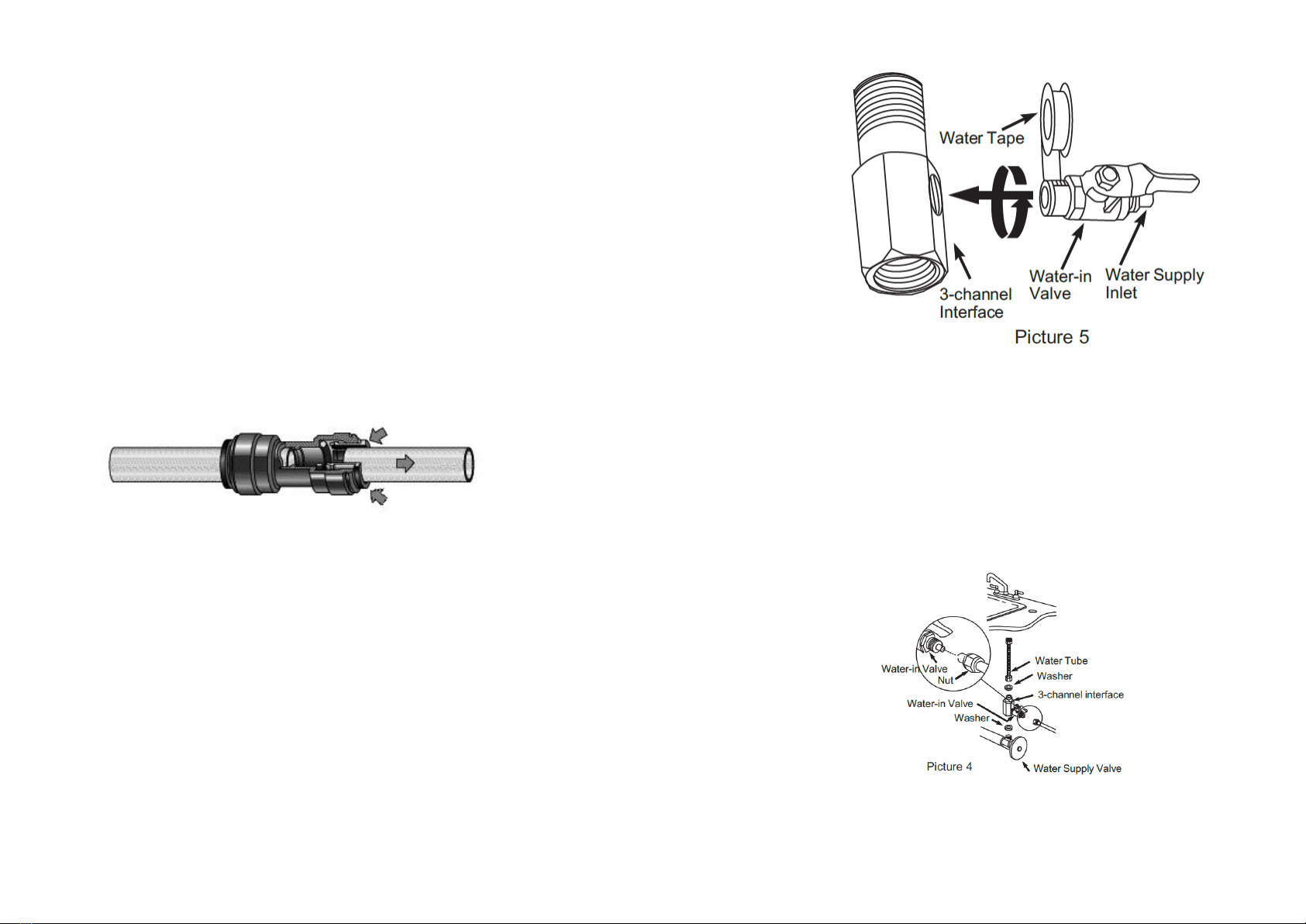

1. We recommend having the installation carried out by a specialist,

as a drill and other power tools are used during assembly. If you

install the reverse osmosis system yourself, please follow exactly

the listed individual steps. Please keep children away from the

device.

2. When drilling, make sure that there are no water and electrical

cables behind it. The device must be connected to a grounded

power outlet. The power adapter must be stored in a

well-ventilated and watertight location.

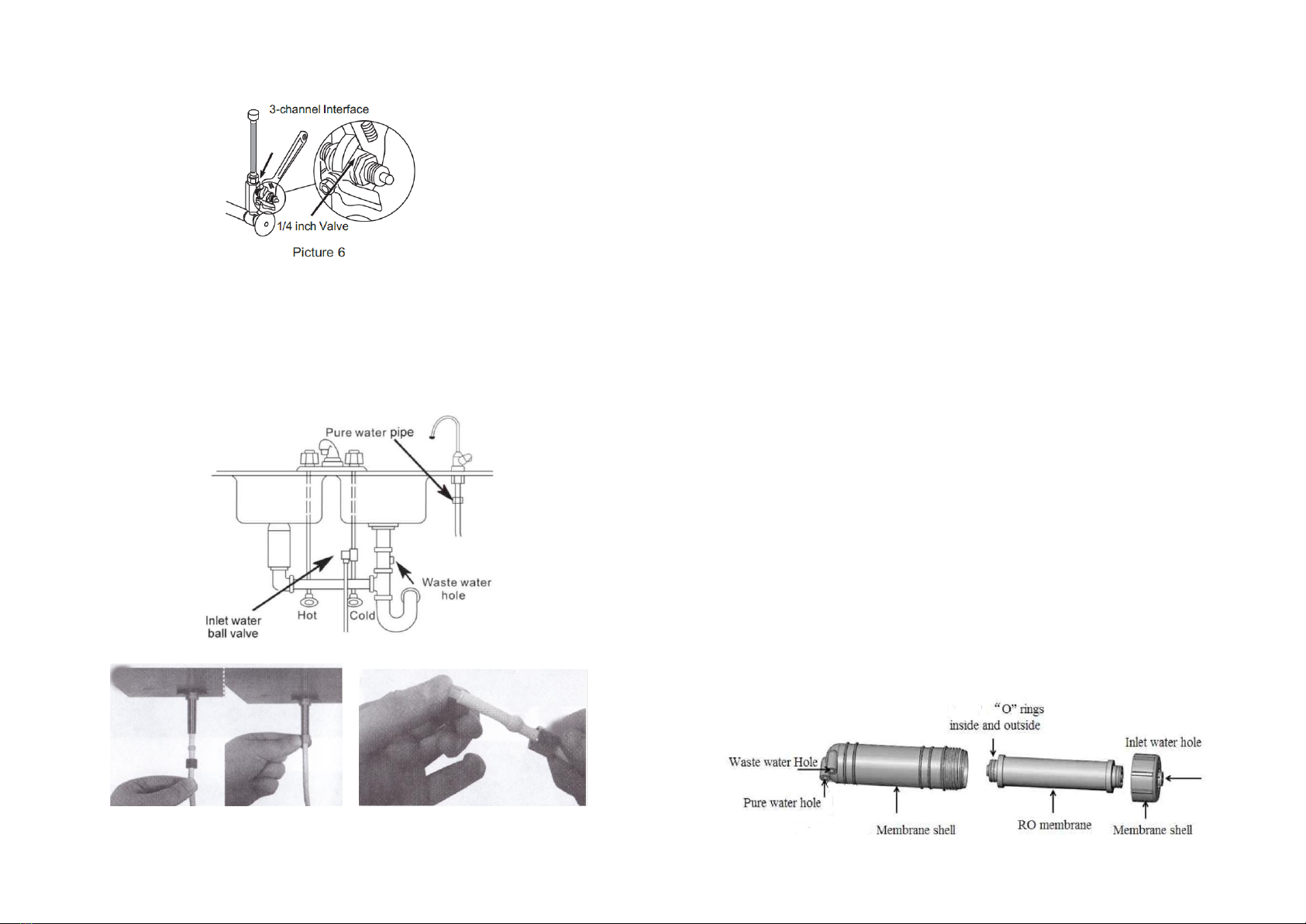

If any of the following occurs, disconnect the unit immediately from

the water supply (close the inlet water ball valve) or disconnect the

power cord and repair:

- if water comes out of the water pipes or other components

- if some of the elements are not working properly

- if some components carry electricity

- if you notice other anomalies or errors on the device