5

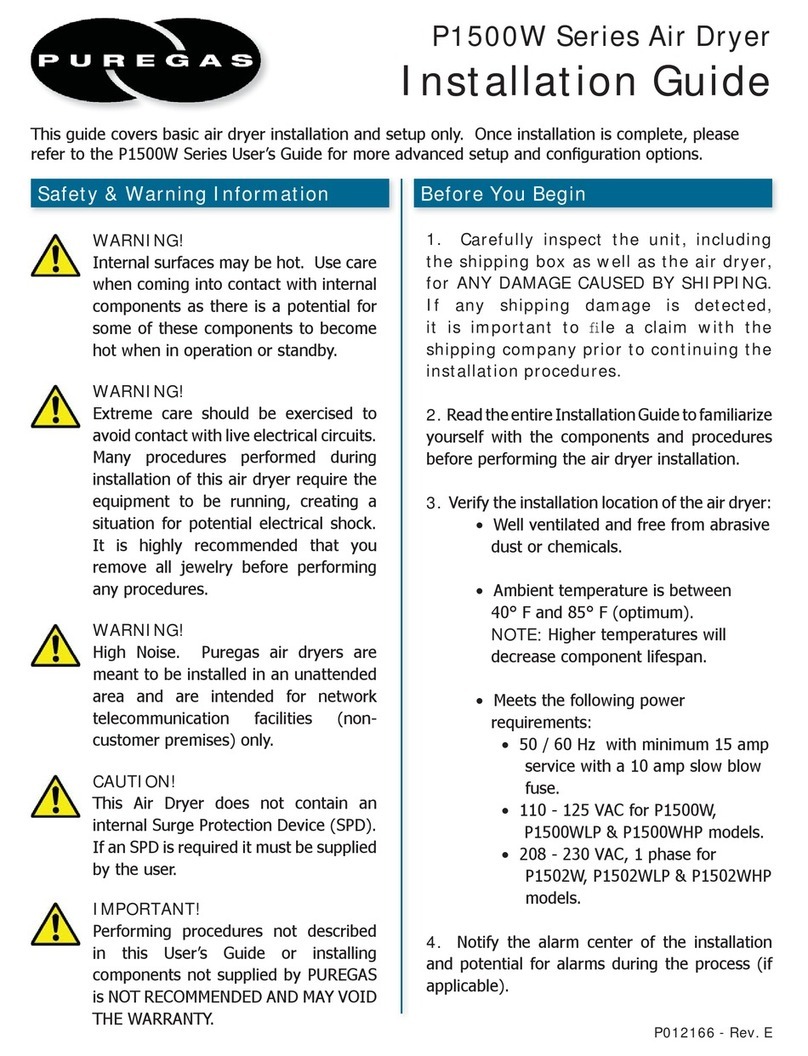

ELECTRICAL INSTALLATION– The dryer data label lists the electrical power requirements for the air dryer. The user must

confirm that the line voltage matches the voltage listed on the data label. (Warning– Operating the air dryer with improper line

voltage will void the warranty.) Provide the proper size wire, disconnect switches and fuses in accordance with applicable

codes. Field wiring must comply with local and national fire safety and electrical codes. Standard dryer’s enclosures and controls are

designed to meet NEMA 1 Type 1 electrical standards. All wiring is complete. Connect power leads as indicated in the electrical

schematic. Ground the frame properly. Once power is connected turn the power on to the dryer.

MAXIMUM WORKING PRESSURE - 232 psig.

CAUTION:

BREATHING AIR APPLICATIONS– This dryer has not been tested for breathing air applications. The owner is advised to do its

own testing and use for breathing air applications at own risk.

DRYER CONTROLS

1. On/Off switch– Turns the refrigerant compressor on/off.

2. Power On Light– Indicates there is power to the dryer.

3. Digital Dew-Point Temp. Indicator– indicates the approximate dew point temp of the compressed air.

4. Refrigerant Suction Pressure Gauge

5. Hot Gas Bypass Valve– Controls the evaporator pressure

6. Fan Cycling Switch– Cycles the condenser fan on and off based on the condensing pressure. (See Figure 1)

7. High Pressure Shutdown w/Manual reset– Cut Out 300 PSIG

8. Low Pressure Shutdown– Cut Out 10 psig / Cut In 25 psig

9. Programmable Electronic Auto-Drain Valve– Automatically controls the draining of liquid condensate removed by the dryer.

START UP

The following procedure must be followed to start your air dryer. Failure to follow this start up procedure will void your warranty. If

problems occur during start up, contact your distributor.

1. Turn off the On/Off switch.

2. Verify the main electrical supply voltage matches the voltage specified on the data label.

3. Do not turn the dryer on during this warm up period.

4. Check the proper connection and support of the compressed air lines to the dryer .

5. Check dryer bypass and isolation valve system.

6. Confirm that the inlet and ambient air temperature, pressure and flow to the dryer meet specified requirements.

7. Confirm that the condensate drain lines from the separator are properly piped to an environmentally approved disposal system.

INITIAL RUN PROCEDURE

After start up and checks are complete and after the main electrical power to the dryer has been turned on

1. Turn ON the dryer On/Off switch.

2. After 15 seconds observe the refrigerant suction pressure gauge. It should start to pull down immediately.

3. Let the dryer run for 15 minutes.

4. Check the refrigerant suction pressure gauge

Should Read: On R134a dryers ( 28 psig to 34 psig)

6. Check the DEWPOINT TEMP INDICATOR. After about 15 min it should read 35°F to 39°F.

7. Verify that the condenser fan motor is operating. The fan will cycle on and off.

8. Allow compressed air to flow through the dryer.

9. Confirm that condensate is discharging from the condensate drain. This may take 30-60 min.

10. Make sure bypass valves are closed and 100% of the air from the compressor is flowing through the dryer.