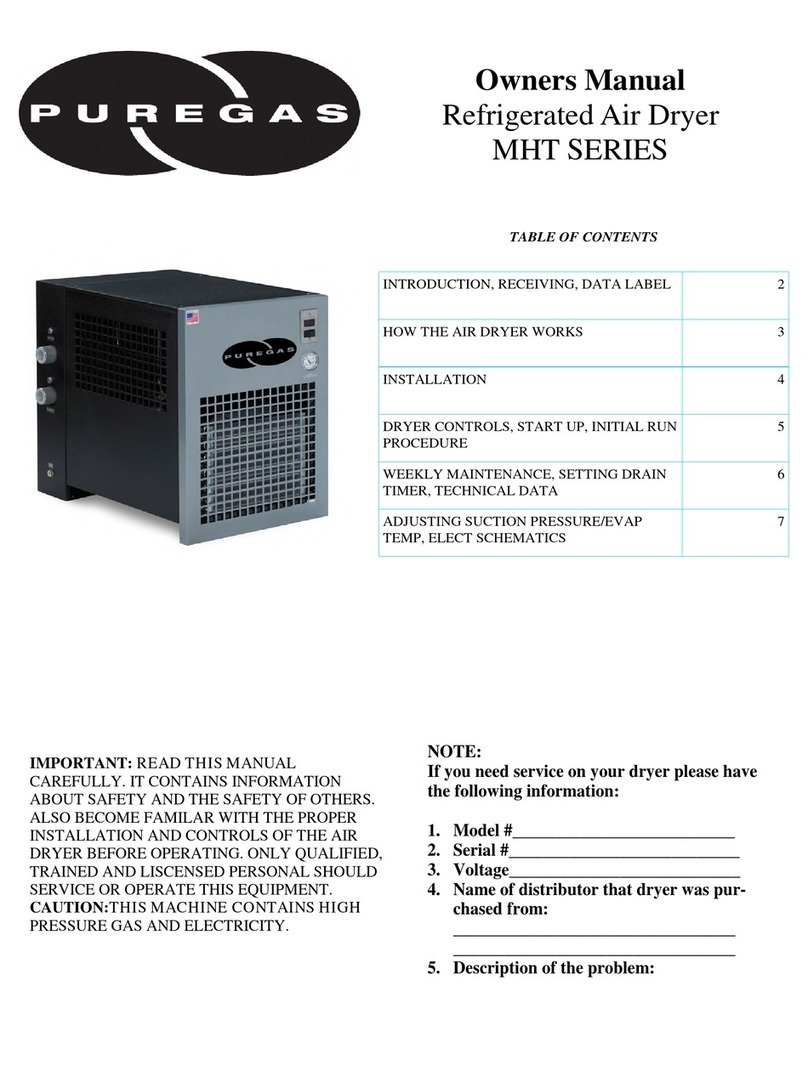

PUREGAS INSTRUCTION MANUAL

MODEL P4200DCO3A AIR DRYER

TABLE OF CONTENTS

SECTION 1 – GENERAL................................................................................... 1

1.1 Scope of Manual .....................................................................................................1

1.2 Initial Inspection.....................................................................................................1

1.3 Warranty.................................................................................................................1

SECTION 2 – DESCRIPTION........................................................................... 2

SECTION 3 – PRINCIPLES OF OPERATION................................................ 3

3.1 Air System...............................................................................................................3

3.2 Air Compressor ......................................................................................................3

3.3 Heatless Dryer.........................................................................................................4

3.3.1 Tower #1....................................................................................................... 4

3.3.2 Tower #2....................................................................................................... 4

3.4 Humidity Sensing Tube..........................................................................................5

3.5 Capacity Control Valve..........................................................................................5

3.6 Pressure Switch and Storage Tank........................................................................5

3.7 Pressure Regulator and Shut-Off Valve ................................................................5

3.8 High/Low Pressure Switch.....................................................................................5

3.9 Alarm Summary.....................................................................................................5

3.9.1 High Pressure Alarm – HIGH PRESSURE..................................................... 5

3.9.2 Low Pressure Alarm – LOW PRESSURE ...................................................... 5

3.9.3 Air Compressor Maintenance Alarm - COMP. RUN TIME ALARM............. 5

3.9.4 Humidity Condition – HUMIDITY, -COND.-................................................ 6

3.9.5 Humidity Alarm – HUMIDITY ALARM....................................................... 6

3.10 Humidistat .............................................................................................................6

3.11 Desiccant................................................................................................................6

3.12 Logic Scan LED.....................................................................................................6

3.13 Alarm LED ............................................................................................................6

SECTION 4 – INSTALLATION AND START-UP........................................... 7

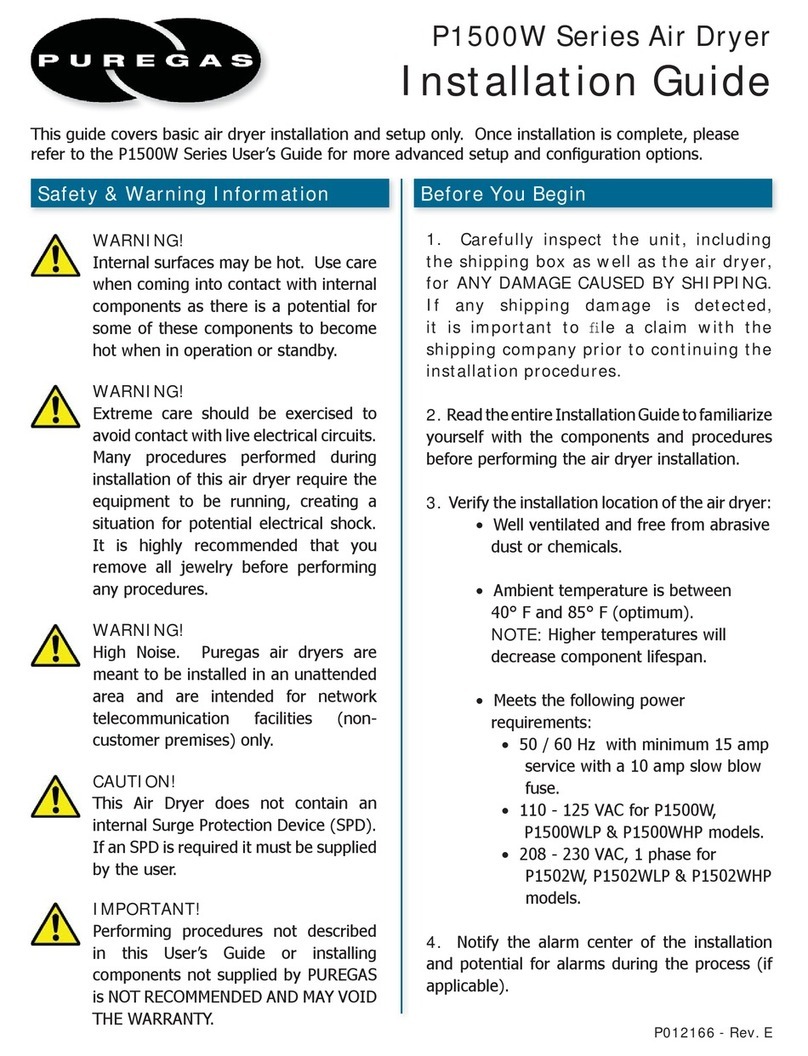

4.1 Inspection................................................................................................................7

4.2 Installation Procedure.............................................................................................7

4.3 Location ...................................................................................................................7

4.4 Electrical Hook-Up..................................................................................................7

4.5 Start-Up ...................................................................................................................8

SECTION 5 – TEST PROCEDURES................................................................. 9

5.1 Low Pressure Alarm Test........................................................................................9

5.2 High Pressure Alarm Test.......................................................................................9

5.3 Humidity Condition Test.........................................................................................9

5.4 Humidity Alarm Test ............................................................................................10

5.5 Compressor Performance Test.............................................................................. 11

SECTION 6 – MAINTENANCE .......................................................................12

6.1 Routine Maintenance ............................................................................................ 12

6.2 Maintenance Matrix..............................................................................................13

6.3 Recommended Spare Parts List............................................................................14

6.4 Air Compressor Safety Valves ..............................................................................15