128-8191

5 of 10

Page 5

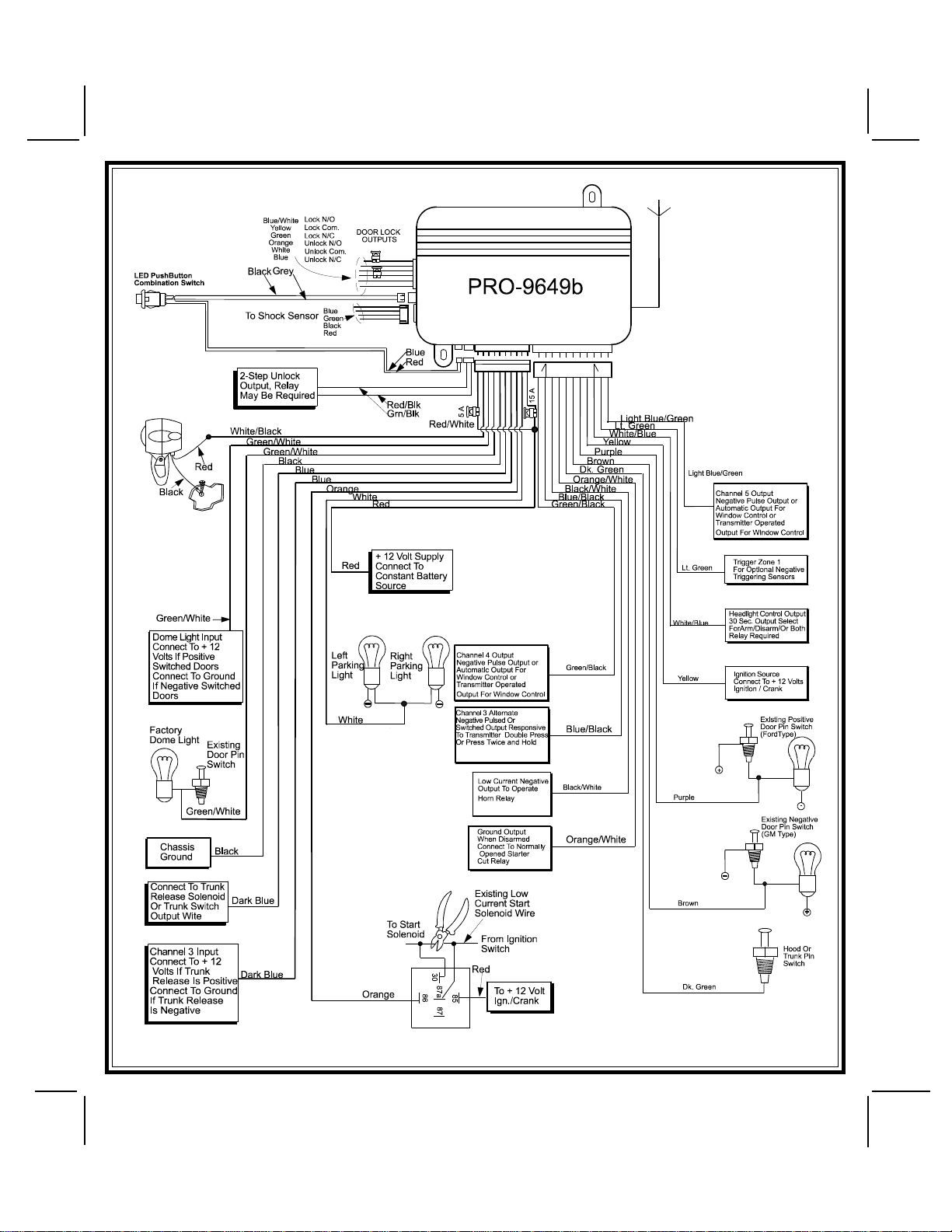

Note: This is a normally closed starter cut arrangement, and when power is removed from the

security system, the starter disable feature will not operate, allowing the vehicle to start.

Audiovox does not recommend using the Orange wire to interrupt anything but the

starting circuit of the vehicle.

White Wire: +12 VDC Pulsed Parking Light Output (15 Amp Max.)

Thiswireis provided to flash the vehicle’s parking lights. Connectthewhitewiretothepositive side of one

ofthevehicle’sparking lights.

Mini 11 Pin Edge Connector :

Dark Green w/ Black Trace Wire: Latching Output / Channel 4

This wire latches to ground via an independent RF channel from the keychain transmitter. This is a

transistorized, low current (300 mA) output, and should only be used to drive an external relay coil.

This wire provides an immediate ground signal, and stays at ground for as long as the button(s) on the

keychaintransmitterremainpressed.

WARNING ! Connecting this wire to the high current switched output of trunk release circuits will

damage the control module.

Connect this output to terminal 86 of the AS 9256 relay (or an equivalent 30 Amp automotive relay), and

wire the remaining relay contacts to perform the selected function of channel 4.

Dark Blue w/Black Trace Wire:Alternate Channel 3 Output (Dbl. Push Required)

This wire is controlled from the transmitter button programmed to the receiver's channel 3. By double

pressing this the transmitter button, this output will become active for 1 second. This is a transistorized,

low current (300 mA) output, designed to provide an output only when the transmitter is intentionally

operated, such as is the case with remote start add on modules. If you require more than 300mA drive

from this output, you must drive an external relay coil, and arrange the relays contacts to preform the

specifiedfunction.

Note: Pressingthetransmitter button, then immediately pressing and holding it willcause this outputto

be active as long as the transmitter button is depressed.

Black w/ White Trace Wire: 300 mA Horn Output

The black w/ white trace wire is provided to beep the vehicle’s horn. This is a transistorized low current

output, and should only be connected to the low current ground output from the vehicle’s horn switch.

Ifthevehicleusesa+12VDChornswitch,thenconnecttheblackw/ white trace wire to terminal 86 of the

AS 9256 relay (or an equivalent 30 Amp automotive relay) and connect relay terminal 85 to a fused +12

VDC battery source. Connect relay terminal 87 to the vehicle’s horn switch output, and connect relay

terminal 30 to a fused +12 VDC battery source.

Orange w/ White Trace Wire: 300 mA GROUND OUTPUT WHEN DISARMED - N. O. STARTER

DISABLE (Optional Relay Required).

Thiswireisprovided to control the startercut relay.Connecttheorange w/white wire to terminal 86 of the

relay. Connect relay terminal 85 to an ignition wire in the vehicle that is live when the key is in the on and

crank positions, and off when the key is in the off position. (This is where the yellow wire from the alarm

shouldbeconnected).

Cut the low current starter solenoid wire in the vehicle, and connect one side of the cut wire to relay

terminal 87. Connect the other side of the cut wire to relay terminal 30.

Note: This is a normally opened starter cut arrangement, and when power is removed from the

security system, the starter disable feature will remain operational, and the vehicle will

not start. Audiovox does not recommend using the Orange w/ White trace wire to

interrupt anything but the starting circuit of the vehicle.

Dark Green Wire: (- ) INSTANTTRIGGER ZONE

Thisis aninstantonground triggerwire.It must beconnectedto the previouslyinstalledhood and trunkpin

switches.