I128 User Manual

PTC2-2120709629-4038 Version: 2.0 Page 6 of 127

2 Figures

Figure 1. Serial adaptor cable .................................................................................................................................. 12

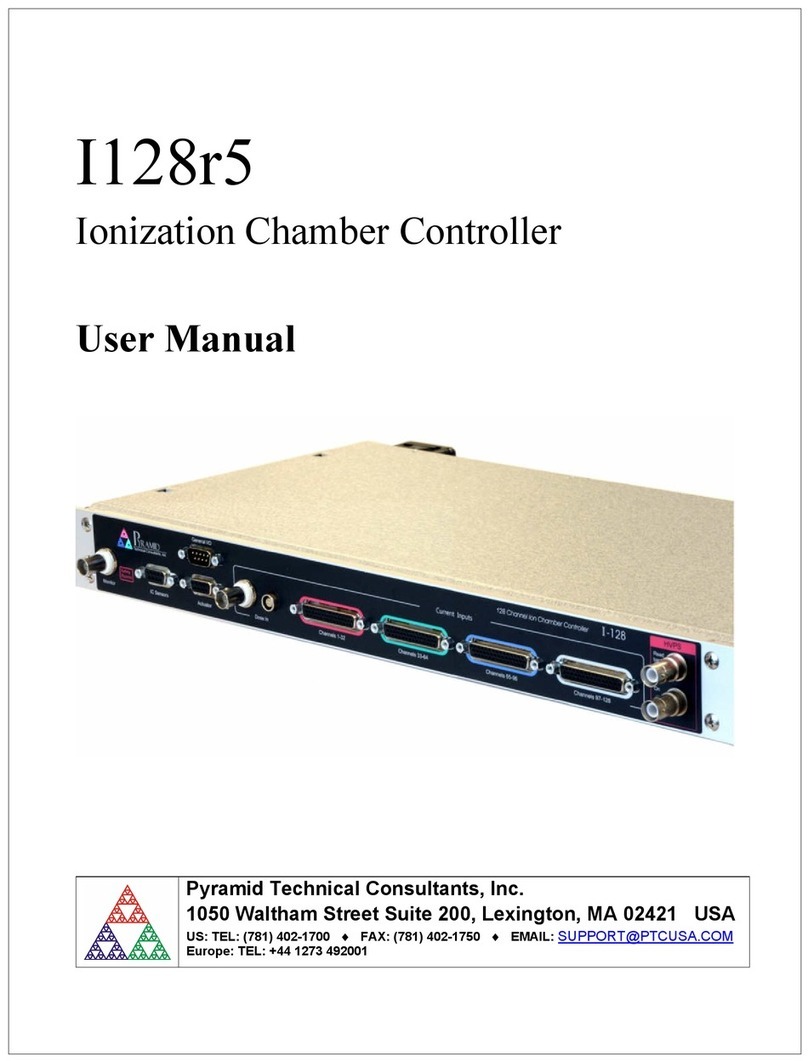

Figure 2. I128 front and rear panels. Dimensions mm. ....................................................................................... 21

Figure 3. I128 case plan and side views. Dimensions mm. ................................................................................... 22

Figure 4. Schematic example: basic I128 installation ............................................................................................ 25

Figure 5. Schematic example: I128 installation for dual IC128-25 ionization chambers ................................... 26

Figure 6. Current return path: ionization chamber bias provided by HV module in the I128 ......................... 28

Figure 7. Current return path: ionization chamber bias provided separate HV module .................................. 29

Figure 8. Multichannel electrometer input (one of 128 identical parallel inputs, ch1 to 128) ........................... 30

Figure 9. HCC (integral plane, ch0) electrometer input ....................................................................................... 31

Figure 10. High voltage loopback arrangement ..................................................................................................... 33

Figure 11. Schematic example: I128 control of remote devices ............................................................................ 34

Figure 12. PTC DiagnosticG2 installation .............................................................................................................. 37

Figure 13. Direct Ethernet connection. ................................................................................................................... 38

Figure 14. Configuring the IP address on the host computer. .............................................................................. 38

Figure 15. Ping test of the Ethernet connection. .................................................................................................... 39

Figure 16. Discover devices in progress .................................................................................................................. 40

Figure 17. Ready to connect to the I128 .................................................................................................................. 40

Figure 18. Opening the I128 window ...................................................................................................................... 41

Figure 19. HCC graphic displayed .......................................................................................................................... 43

Figure 20. Data analysis display – I128 and PTC DiagnosticG2 calculations ..................................................... 44

Figure 21. IC Device Support ................................................................................................................................... 45

Figure 22. Pixelated device setup screen .................................................................................................................. 47

Figure 23. Measured parameters from pixelated data ........................................................................................... 47

Figure 24. Pixelated Display Options ....................................................................................................................... 48

Figure 25. MLFC setup ............................................................................................................................................. 49

Figure 26. MLFC Energy Display ............................................................................................................................ 50

Figure 27. Setup - Measuring sub-tab ................................................................................................................... 50

Figure 28. Setup - Trigger sub-tab ........................................................................................................................ 51

Figure 29. Setup - HCC sub-tab ............................................................................................................................ 52

Figure 30. Calibration source control ..................................................................................................................... 53

Figure 31. Current input calibrations ..................................................................................................................... 53

Figure 32. Interlock test functions ........................................................................................................................... 54

Figure 33. Firmware versions .................................................................................................................................. 55

Figure 34. Communication settings ......................................................................................................................... 56

Figure 35. IP Configuration control ........................................................................................................................ 56

Figure 36. Graphics display with HCC display enabled. ...................................................................................... 57

Figure 37. Scope mode capture of a pulse............................................................................................................... 58

Figure 38. Strip chart data display showing cursor. .............................................................................................. 59

Figure 39. Increasing the low pass filtering of the displayed data. ....................................................................... 60

Figure 40. Zero correction of displayed data ......................................................................................................... 61

Figure 41. I128 physical layout. ............................................................................................................................... 62

Figure 42. I128 block schematic. ............................................................................................................................. 64

Figure 43. High voltage jumper settings ................................................................................................................. 68

Figure 44. Data feed into samples............................................................................................................................ 70

Figure 45. Contiguous data number of samples as a function of input data rate ............................................... 73

Figure 46. Signal and trigger used for custom trigger examples .......................................................................... 74

Figure 47. Time-varying signal seen in internal mode .......................................................................................... 75

Figure 48. Time-varying signal seen in custom buffered mode ............................................................................ 75

Figure 49. Using trigger signals and burst size to capture a portion of the signal .............................................. 76

Figure 50. Examples of monitor output pulse: TTL (left), transformer-coupled (right).................................... 78

Figure 51. I128 actuator control circuit. ................................................................................................................. 79

Figure 52. Actuator connections for 24 VDC solenoid. ......................................................................................... 79

Figure 53. Interlock relays in series on multiple devices wired for current loop (top) or 24 V logic (bottom). 81