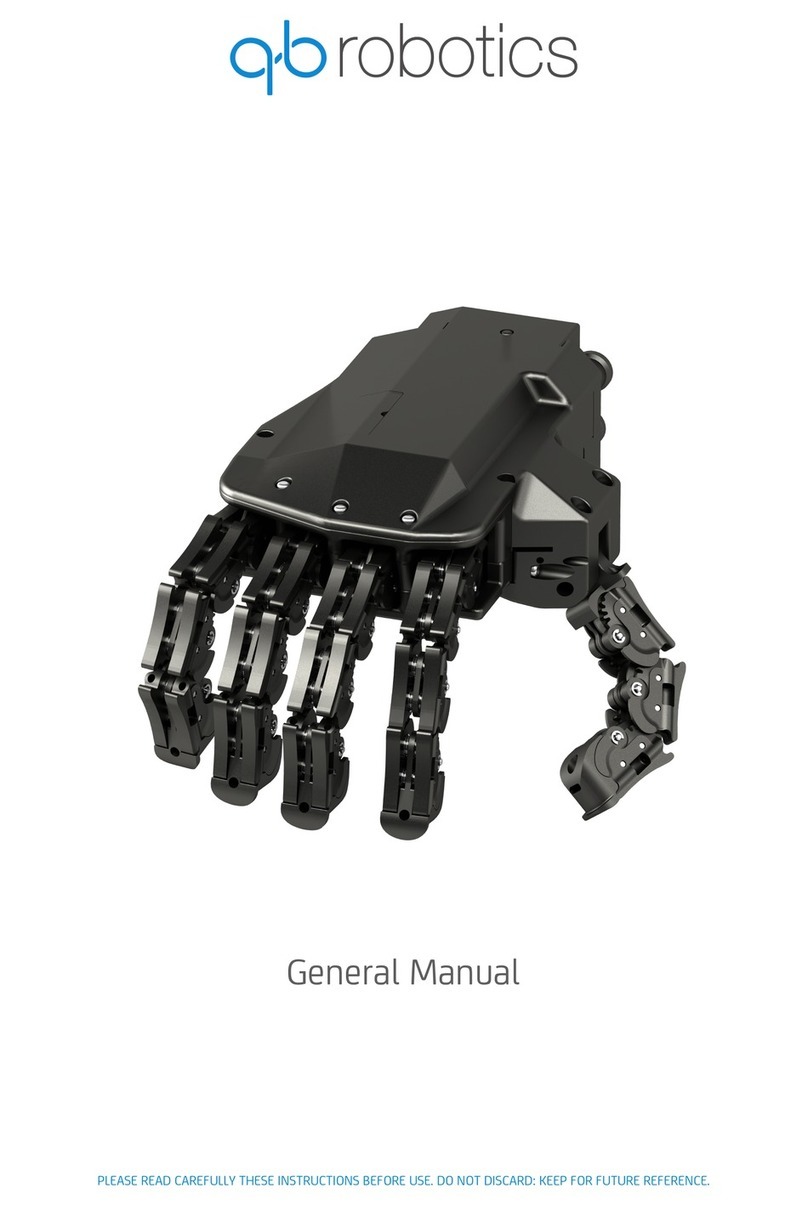

QBSOFTHAND2 RESEARCH USER MANUAL —3

2 Safety

2.1 Intended use

The product design is intended for grasping and manipulating objects in the weight range from 1 to 1700

g.

Fragile, sharp or sharp-edged objects shall not be grasped.

Objects having the ratio between the biggest and the smallest dimensions ≥8 mm and the main dimension

greater than 300 mm shall not be grasped.

The product, as its name suggests, is intended for research and educational use.

The product is intended for installation on robotic arms: the safety features are established only for use

as described in this document.

The safety of the product cannot be guaranteed in case of inappropriate use. One, single, inappropriate

use can result in a permanent damage to the safety of the product.

2.2 Safety instructions

•

•

•

•

•

•

•

•

•

•

•

•

•

•

•

WARNING:

Check that all the content is intact after removing it from the packaging.

The device can be used only by specially trained staff.

Disconnect the power supply before installation, cleaning or maintenance operations.

Make sure that no residual energy remains in the system.

Always operate the product within the specifications defined.

Keep away from children and pets. Always set off or unplug when not in use.

Never use aerosol products, petroleum based lubricants or other flammable products on

or near the end-effectors.

Do not use any damaged power cable, plug, or loose outlet. It may cause damages to the

product or injury to people.

Do not touch electrical components to avoid damages due to electrostatic charges.

Make sure the end-effector is properly and securely bolted in place and cabled.

Do not use if damaged or defective. Do not disassemble.

Do not insert any objects between moving parts of the fingers.

Keep head and face outside the reach of the end-effector.

Do not wear loose clothing or jewelry when working with the end-effector.

Disrespect of these precautions can affect safety of the device.