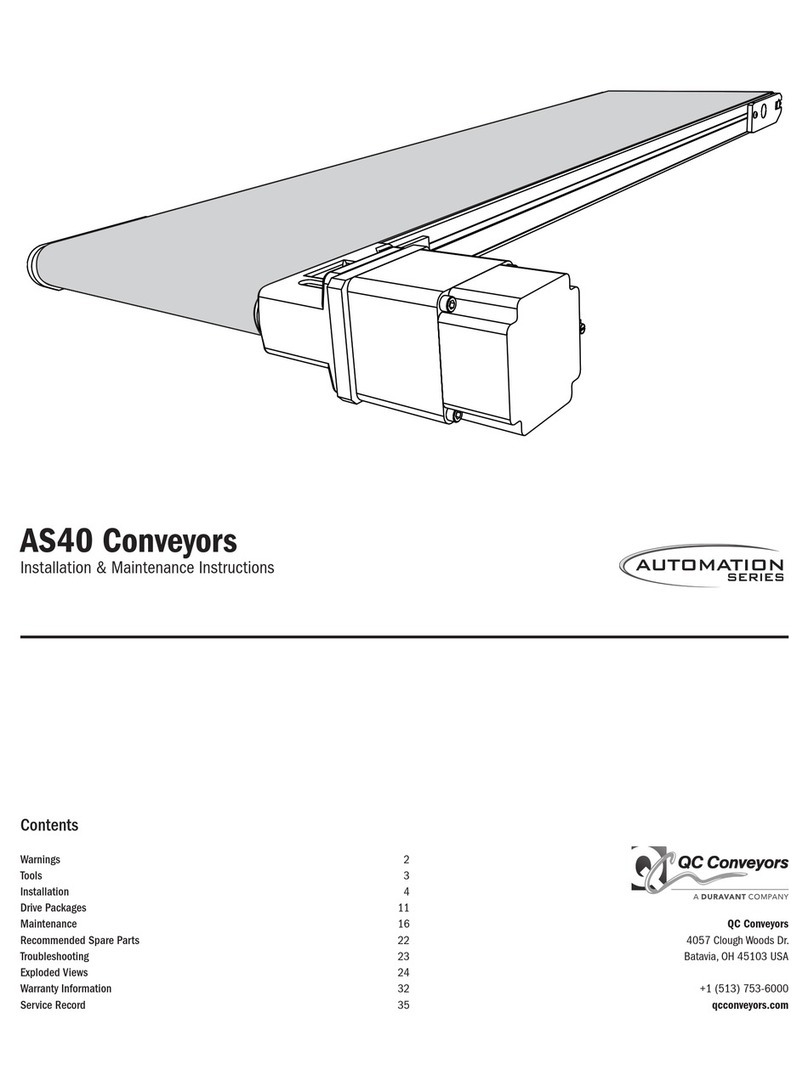

6AS40-CD Conveyors | Installation & Maintenance Instructions

uStand Height Adjustment

1Loosen four screws in each

stand bracket using a 5mm

allen wrench.

2Adjust stand height by

turning bolt using a 3/4”

wrench. Turn clockwise to lower or

counter-clockwise to raise. Ensure

conveyor is level.

3Tighten jam nut against top

plate of stand. 4Tighten four screws in each

stand bracket using a 5mm

allen wrench.

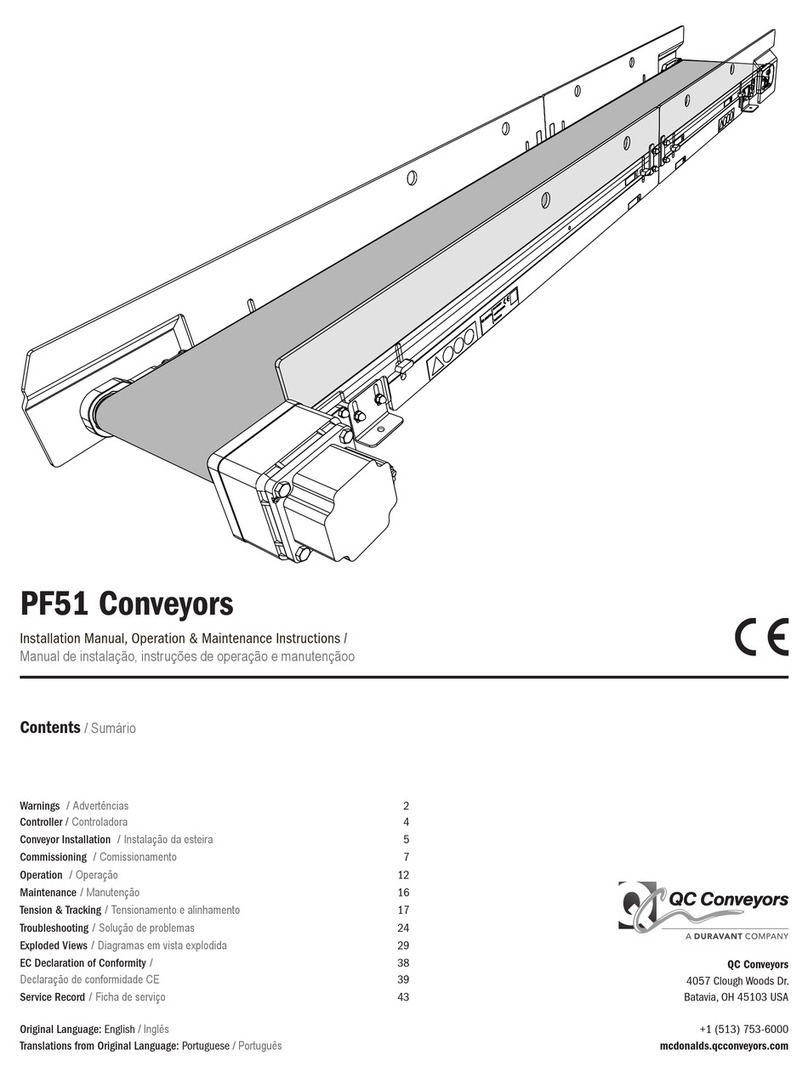

uInstalling Cross Ties

For applications using a single cross tie, the cross tie should be installed between the cross bars of the stands. For applications using two cross ties, the cross ties should

be installed between the uprights of the stands.The installation process is the same for each.

4

x2

x

1Using a 5mm allen wrench,

loosen two socket head cap

screws in each cross tie adjustment

plate.

2Slide adjustable cross tie

pieces to fit between stands. 3Loosen triangular Quick Clamp

on each end of cross tie. 4Ensuring the socket head cap

screw is facing you, slide Quick

Clamp into tee slot at desired mount-

ing position.

4

x

5Using a 5mm allen wrench,

tighten Quick Clamp. 6Using a 5mm allen wrench,

tighten two socket head cap

screws in each cross tie adjustment

plate.