QC Conveyors INDUSTRIAL Series Installation and operating instructions

Other QC Conveyors Accessories manuals

QC Conveyors

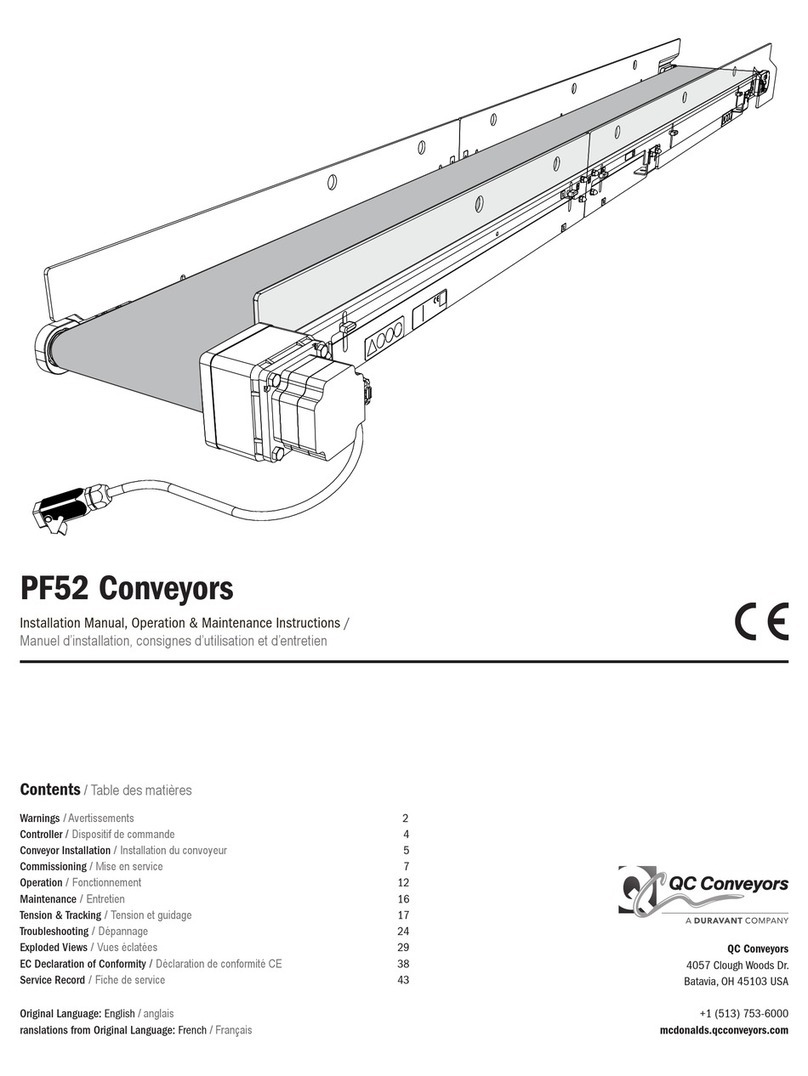

QC Conveyors PF52 Instruction Manual

QC Conveyors

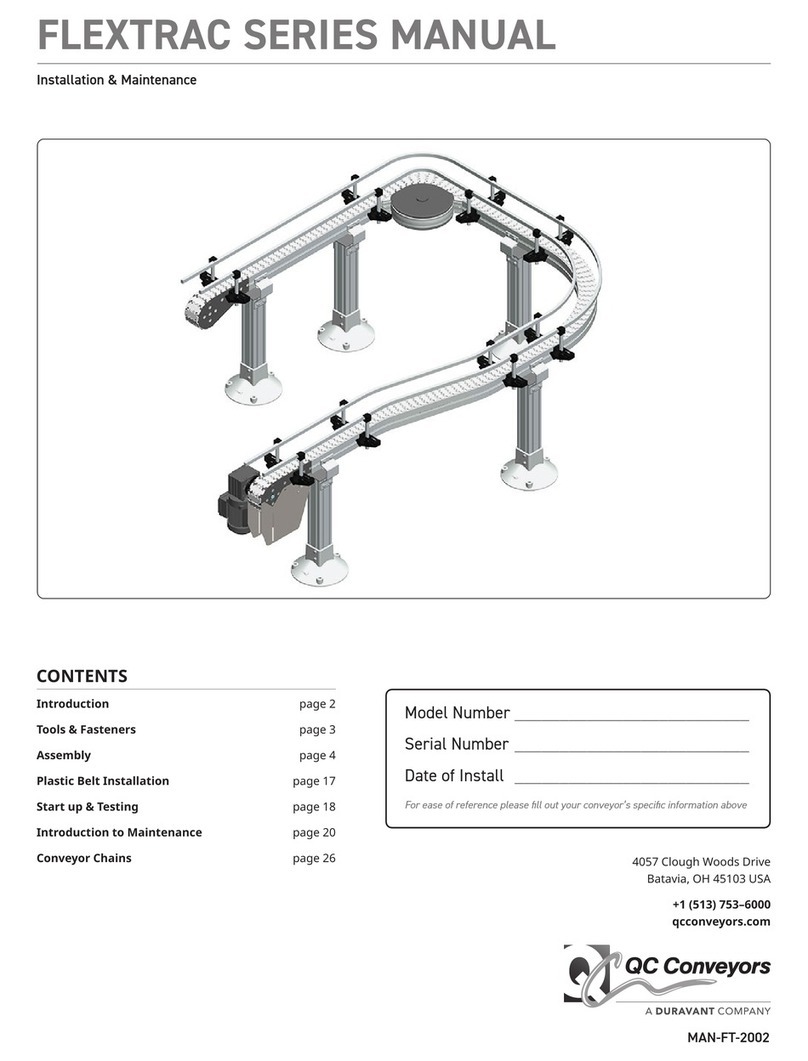

QC Conveyors FLEXTRAC Series User manual

QC Conveyors

QC Conveyors PF52 Instruction manual

QC Conveyors

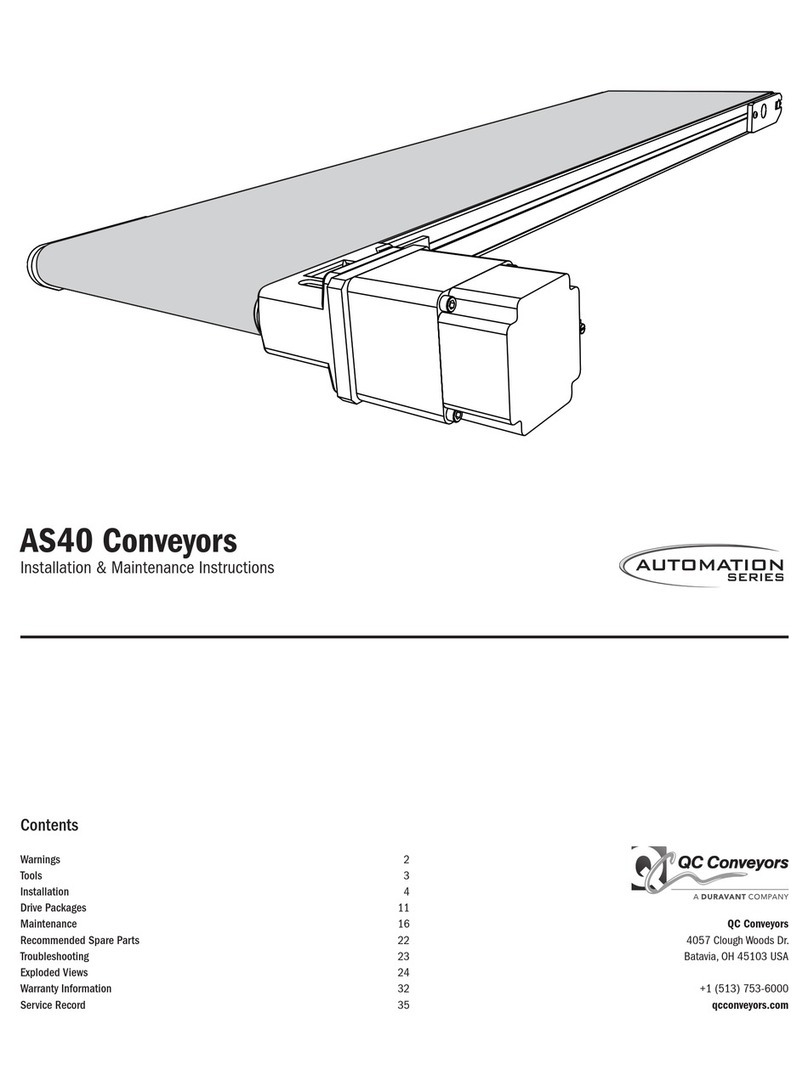

QC Conveyors AS40-CD Installation and operating instructions

QC Conveyors

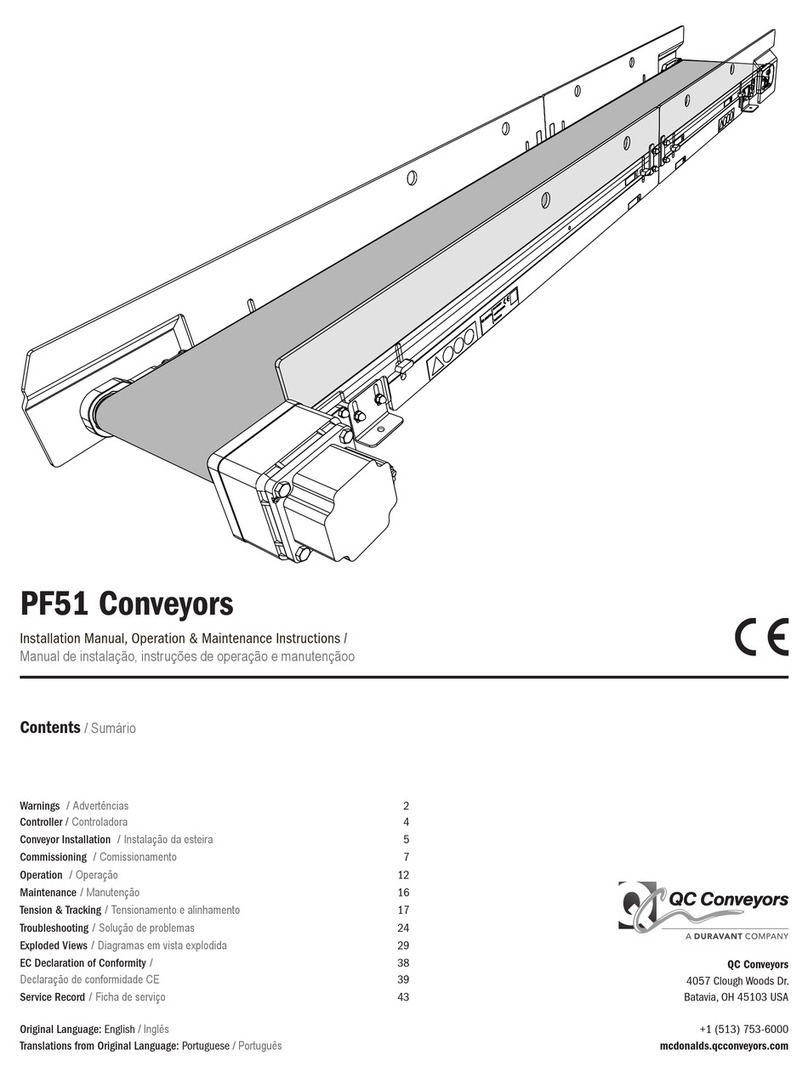

QC Conveyors PF51 Instruction Manual

QC Conveyors

QC Conveyors PF52 Instruction manual

QC Conveyors

QC Conveyors Automation Series Installation and operating instructions