Note: If it is in Turbine Mode, there is no special Low Idle sound in Neutral.

After the Air Pumps start, you can also use the direction switch to blow the Horn or turn on or off the Bell8.

Note: If you are in Turbine Mode, you will be able to hear the long Air Let-off but you may not be able to hear the Air Pumps over the sound of the

Turbine.

If you cannot enter Neutral, or have difficulties with any of the operations, you may need to program your locomotive for optimal use with your

particular DC power pack (see Analog Programming in next section).

Changing the Locomotive’s Direction without Turning off the Sound

You can use the power pack’s direction switch while the locomotive is in Neutral to change the locomotive’s direction.

Put the locomotive in Neutral by bringing the throttle down below V-start and wait for the locomotive to stop9.

Flip the direction switch after you hear the Short Air Let-off but before you hear the Long Air Let-off and the Air Pump sounds turn on.

During this short time (3 seconds) the Horn will not blow when you flip the direction switch.

Turn up the throttle anytime thereafter to operate the locomotive in the opposite direction.

If you have waited until the Air Pumps start in Neutral and now wish to change direction, you can either:

1. Turn the power all the way off, change the direction switch and turn the power back on, or,

2. Flip the direction switch (the Horn will come on) and then turn up the throttle. When the locomotive starts to move in the opposite

direction, the Horn will stop automatically.

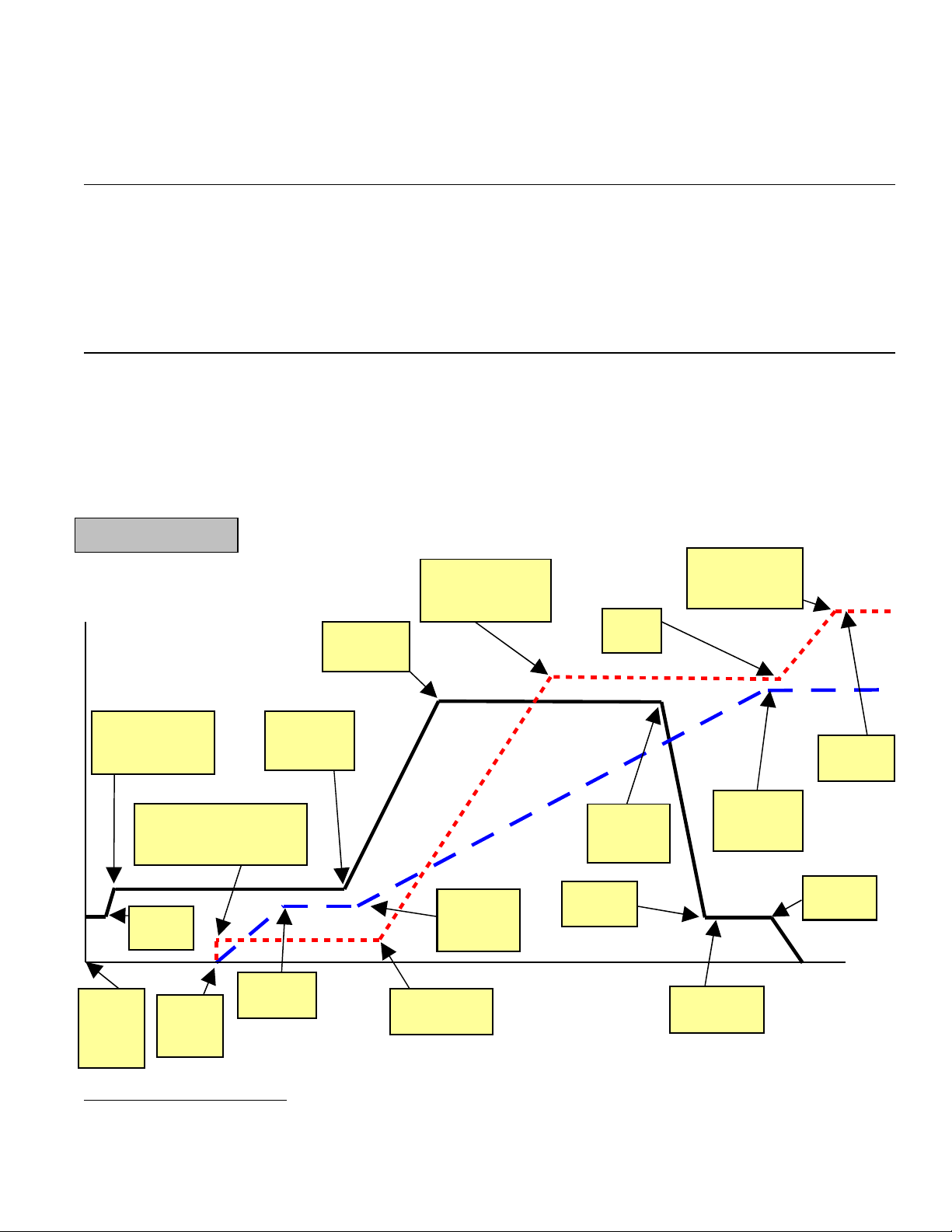

Standard Throttle Control™ (STC™) and Regulated Throttle Control™ (RTC™)

Quantum locomotives have two types of Analog throttle control available, Standard and Regulated. Both Standard Throttle Control (STC) and

Regulated Throttle Control (RTC) will apply more power to the motor as a function of increasing track voltage beginning at the V-Start setting.

RTC includes an Inertial Control™ feature that prevents the locomotive from reacting quickly to changes in voltage or minor impediments to

motion such as misaligned track joints, tight curves, rough turn-outs, etc. A locomotive under STC may come to an unrealistic halt from a raised

track joint or a drop in voltage10 while the same locomotive under RTC, with its Inertial Control, will continue at the same speed. RTC operates

your locomotive as though it has the mass and inertia of a prototype locomotive; your locomotive will resist changes in speed once it is moving

and will resist starting up quickly if at rest. You will be able to operate your locomotive at very slow prototypical speeds without having to adjust

your throttle voltage continually to maintain speed.

While small obstacles will not affect the locomotives speed under RTC, a continual force will slow your train down, just like the prototype. For

instance, if your diesel locomotive encounters an upward grade under RTC, it will eventually slow down. Providing more throttle will slowly

accelerate it back to speed. The same locomotive under STC would quickly slow down or stop if it encountered an upward grade.

The type of throttle control also affects how your locomotive decelerates. Under STC, your locomotive will respond quickly to a reduction in track

voltage. Under RTC, your locomotive will decelerate slowly as you bring the throttle down. If you bring the throttle down below V-Start, the

locomotive will slowly come to a stop. You can however, force a locomotive to slow down rapidly under RTC by bringing the throttle down

quickly; this action reduces the power available to the motor inertial control circuit and forces the speed to decrease faster than RTC would

normally allow. Once the locomotive slows down and regains normal RTC operation, it will continue to decelerate slowly according to its built-in

inertia and Load setting. For instance, if your locomotive was running at top speed and you quickly reduced the track voltage to just below V-

Start (where the locomotive would normally be stopped) the locomotive would at first slow down rapidly as you reduced the available power to

the motor. After this initial rapid slow down, the locomotive would decelerate at a rate determined by RTC Inertial Control and Load and finally

coast to a stop.

STC and RTC are selected under Analog Programming (see next section). The default for the Gas Turbine is STC.

Note: RTC will have different performance with different power packs. In particular, if your power pack operates at voltages in excess of 12 volts11, you will

want to reprogram V-Max (see Analog Programming) to a higher value. Also see the

Quantum Analog Reference Manual (Version 3)

from

http://www.qsindustries.com.

Note: The Gas Turbine in Diesel Mode under RTC will initially start and operate as a standard diesel locomotive except that the top speed is limited to 25

smph or less to model the limited speed of the prototype locomotive when operated with the small 250 hp Cummings diesel. You will need to change to

Turbine Mode to achieve full power, just like the prototype.

8In Neutral, the mechanical Bell feature has a distinctive turn-on effect as the pneumatic clapper gains full motion to strike the bell. The Bell may also have a shut-down effect

where each strike becomes less loud as the clapper slows its motion.

9On some power packs that have high internal resistance, the track voltage may rise slightly as the locomotive slows down and requires less power to operate. With these power

packs, as the locomotive slows, you may need to reduce the throttle a little more to remain below V-Start.

10 For instance, blowing the Horn takes power and can reduce track voltage substantially and quickly. Under STC at low speeds, blowing the Horn can stop your locomotive.

Under RTC blowing the Horn will not cause your locomotive to stop or slow abruptly

11 Most MRCTM Power Packs have a maximum voltage anywhere from 16 to 20 volts, which is above the recommended NMRA standard of 12 volts.

Gas Turbine Locomotive Q1R Operation Manual Version 3.0 5/26 14 March 2006