Page | 2

Table of Contents

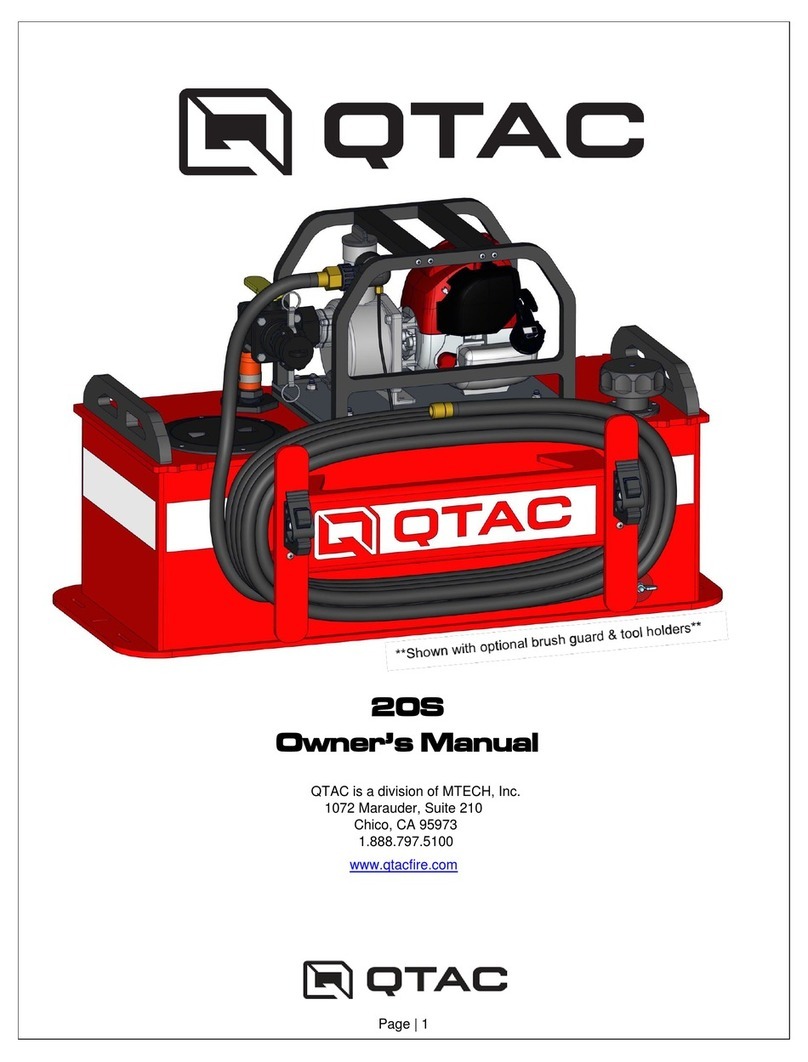

GETTING TO KNOW YOUR QTAC..................................................................................4

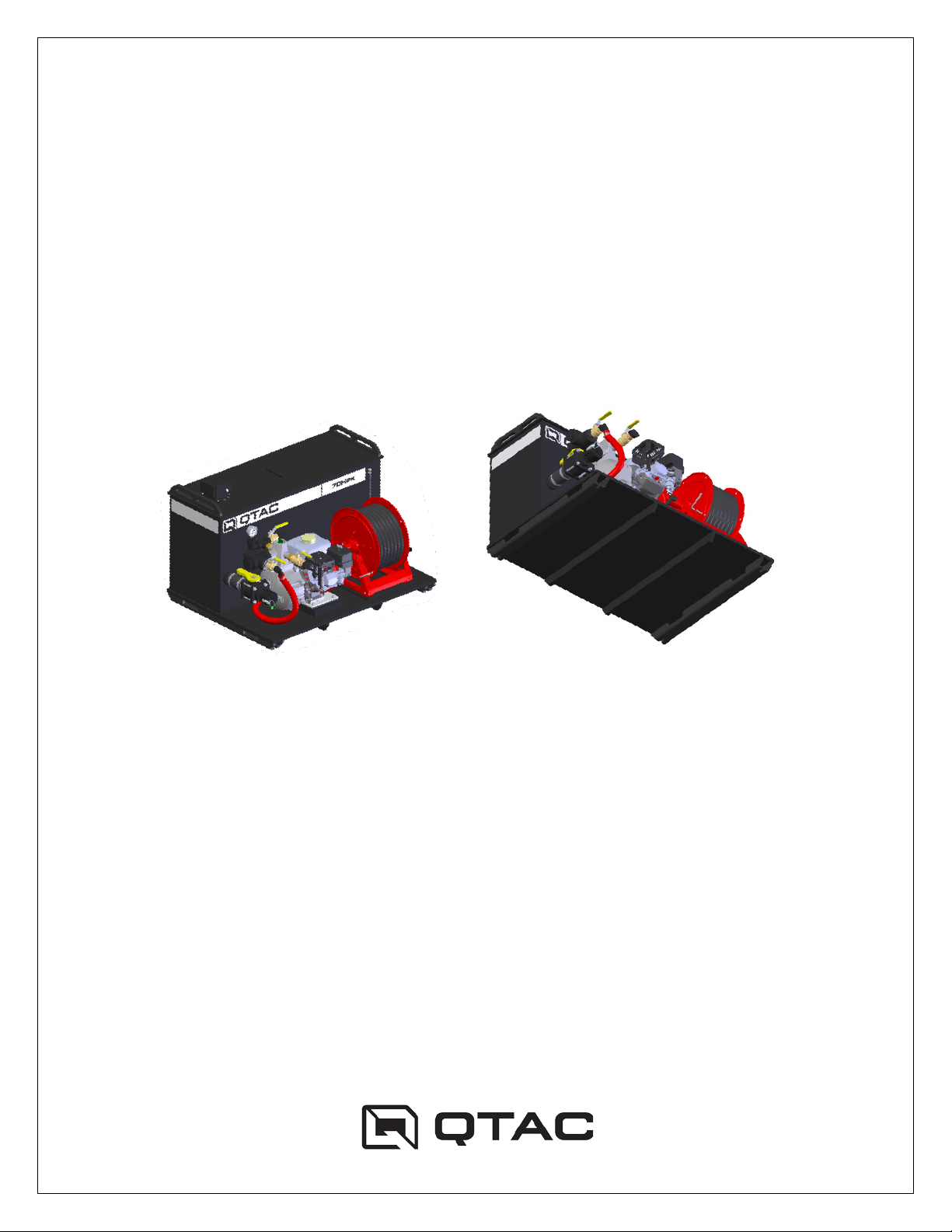

TRANSPORTING YOUR QTAC .......................................................................................7

Gross Vehicle Weight Rating.........................................................................................7

General QTAC Mounting and Fastening........................................................................7

Special Precautions for Carrying a QTAC on Ride-On ATVs or Side-By-Side UTVs ....8

OPERATING YOUR QTAC...............................................................................................9

Before Starting Up Your QTAC......................................................................................9

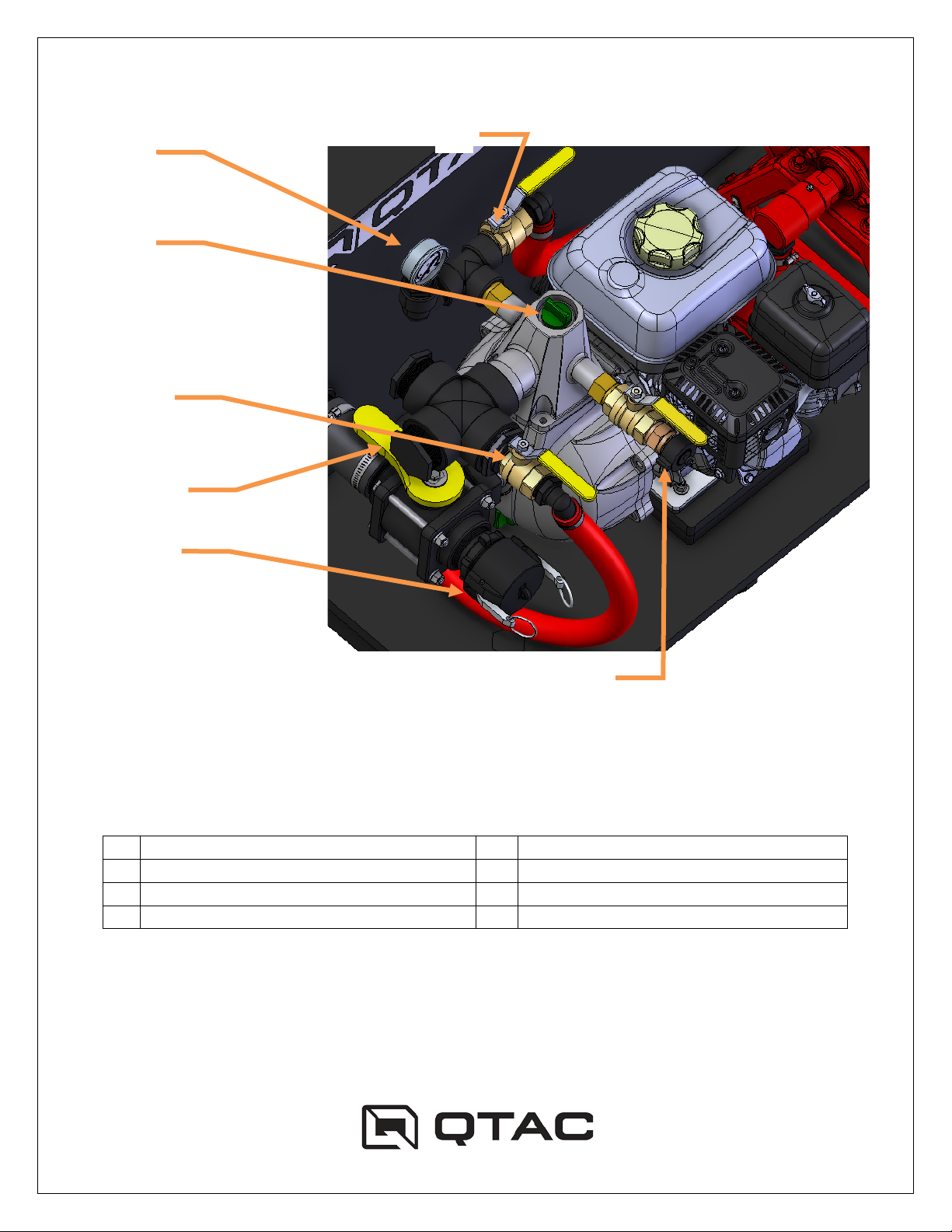

PUMP OPERATION..........................................................................................................9

Priming the Pump after an Extended Period of Use ......................................................9

Tank Fill Requirements:.................................................................................................9

Tank Fill Through the Fill Tower ..................................................................................10

Pumping Using the Tank Water Supply .......................................................................10

Starting the Engine ......................................................................................................11

DRAFT PROCEDURES..................................................................................................11

Drafting From an Auxiliary Water Source ....................................................................11

Connecting the Draft Hose ..........................................................................................11

Drafting to Fill the Water Tank .....................................................................................12

Pumping While Drafting From an Auxiliary Water Source ...........................................13

To Supply Water to the 1” NPSH Discharge................................................................14

STOPPING YOUR QTAC ...............................................................................................14

STORING YOUR QTAC .................................................................................................14

General Storage ..........................................................................................................14

SPECIAL QTAC OPERATION........................................................................................15

Using More Than Water in Your QTAC .......................................................................15

SERVICING YOUR QTAC ..............................................................................................15

Cleaning Your QTAC...................................................................................................15

Protecting Your QTAC.................................................................................................15

Routine QTAC Maintenance........................................................................................16

TROUBLESHOOTING YOUR QTAC..............................................................................16

The Pump Engine Will Not Start ..................................................................................16

The Pump Will Not Build Water Pressure ....................................................................16

Water Will Not Discharge From The Discharge Hose..................................................17