4

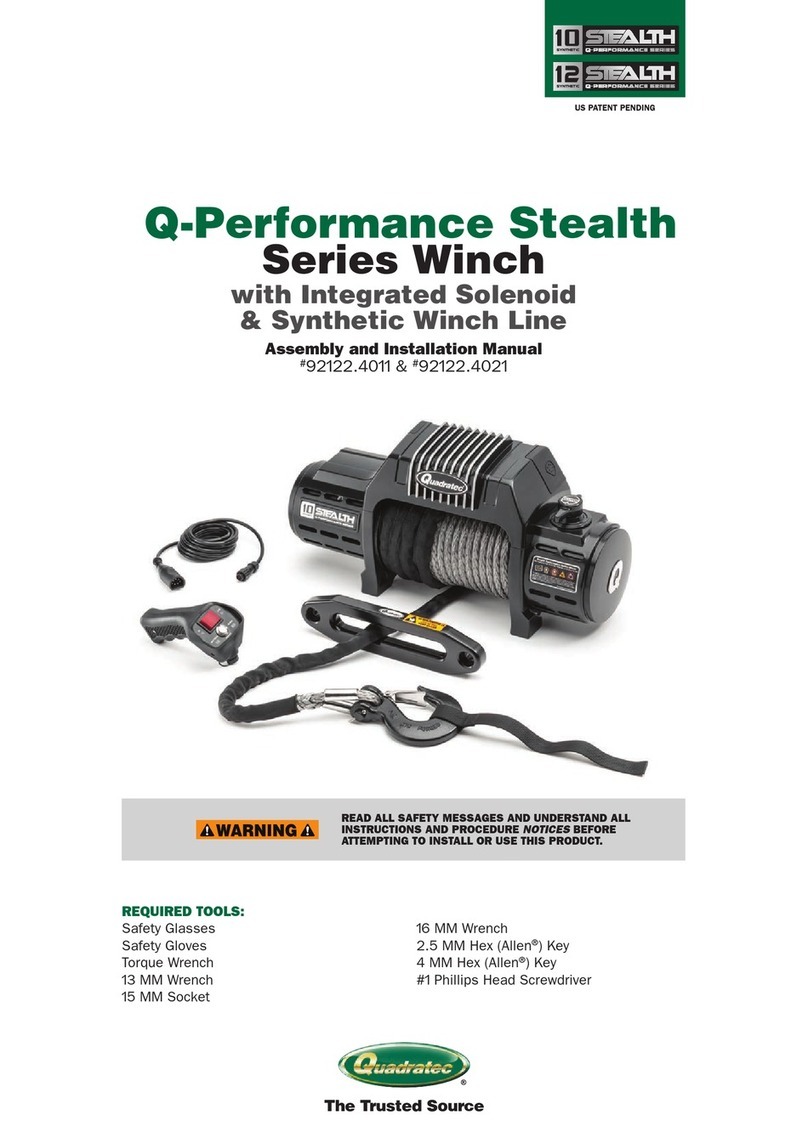

Winch Mounting:

Mount the supplied Hawse Fairlead to

the Mounting Frame (not included) using

supplied Bolts and Nuts.

The winch MUST be properly secured to

a winch mount bumper or an approved

winch mount plate with the included

10mm nuts and bolts (qty 4/each).

There are machined pockets at each of

the four inside base corners that fit a

flange head whiz nut. Place a nut into

each pocket and center the winch over

the mounting base holes. Tip: a touch

of bearing grease can hold the 4 nuts in

place prior to fastening the flange head

whiz bolts. In some rare mounting

situations drilling for bolt holes may be

required. Using a 15mm socket, thread

the four 10mm x 1.5 x 35mm bolts

through the bottom of the winch mount

plate or bumper and into the whiz nuts.

Use a torque wrench and 10mm socket

and torque each mounting bolt to

50Ft-lbs.

Synthetic Winch Line Pre-Tensioning:

The winch line must be pre-tensioned

prior to use. Do NOT use winch line

without pre-tensioning it.

First, place clutch in Free Spool position

and slowly pull all of the winch line from

the drum. Remove the line fastener at the

drum using a 4mm allen key at the drum

and remove the line.

Thread the winch line through the

fairlead and re-attach the line to the

winch drum. You now need to pre-stretch

winch line to ensure even stretching. To

stretch winch line, begin with 5 or 6 snug

wraps around the drum and set up a

secureanchor point. Pull vehicle (in

Assembly and Installation (Continued)

Flange

Head Nut

(10mm x

1.5mm)

Flange Head Whiz Bolt

(10mm x 1.5mm x 35mm)

Winch Mount

Plate or Bumper

BATTERY CABLES SHOULD NOT BE DRAWN TAUT. LEAVE SLACK

FOR SOME CABLE MOVEMENT. THE BATTERY CABLES SHOULD BE

SECURE, OUT OF THE WAY OF MOVING PARTS, ROAD DEBRIS, OR ANY

POSSIBILITY OF BEING DAMAGED BY OPERATION OR MAINTENANCE

OF VEHICLE. FOR EXAMPLE, THE BATTERY CABLES MAY BE ROUTED

UNDER THE VEHICLE, ATTACHING THEM TO THE FRAME USING

SUITABLE FASTENERS SUCH AS CABLE TIES (NOT INCLUDED).

DO NOT ATTACH BATTERY CABLES TO THE EXHAUST SYSTEM, DRIVE

SHAFT, EMERGENCY BRAKE CABLE, FUEL LINE, OR ANY OTHER

COMPONENTS WHICH MAY CAUSE DAMAGE TO THE BATTERY CABLES

THROUGH HEAT OR MOTION, OR CREATE A FIRE HAZARD. IF A

HOLE IS DRILLED THROUGH THE BUMPER OR ANY OTHER PART OF

THE VEHICLE, MAKE SURE TO INSTALL A RUBBER GROMMET (NOT

INCLUDED) IN THE HOLE TO PREVENT FRAYING OF THE BATTERY

CABLES AT THAT POINT. THE USE OF AT LEAST A 650 COLD CRANKING

AMPS (CCA) BATTERY IS HIGHLY RECOMMENDED.