caV032rewoP 50/60Hz

Maximum power About 1KW

Line fuse F1 3,15 A delayed

Logic circuit fuse F2A 500 mA

Accessories fuse F3 1,6A

Motor output 230V ac

Electrical lock output 12Vac 15W

Accessories output 24Vac 500mA

Logic circuit input 5Vdc

Operating temperature -20°C / +70°C

IP protection rate IP 55

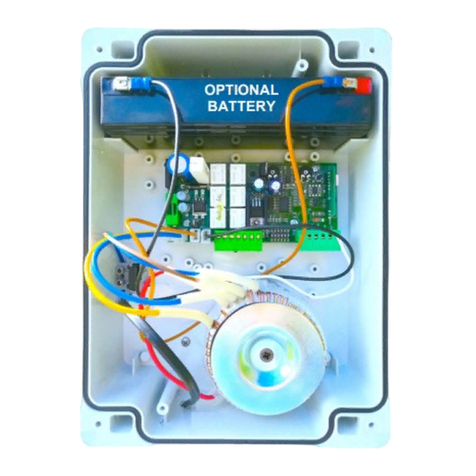

INSTALLATION

-Position the control board as near as possible the gear motor, in order to avoid over long connection

cables;

-Use power cables (power input, motors, earth and flashing light) of at least 1.5 mm

2

conductor, taking

into consideration the amperage, voltage drop and length. This requirement doesn’t apply to the

connection cables of the auxiliary control devices such as key switch and photocell, whose cross-section

can reduced to 0,5 mm

2

;

-Ensure connections to the terminal board are made not to alter the level of protection offered by the

housing, which must be installed in a dry and suitable place according to the IP rating;

-PLEASE REMEMBER TO PROPERLY EARTH THIS PRODUCT AND TO OBSERVE THE SAFETY

REGULATIONS IN FORCE IN THE COUNTRY OF INSTALLATION.

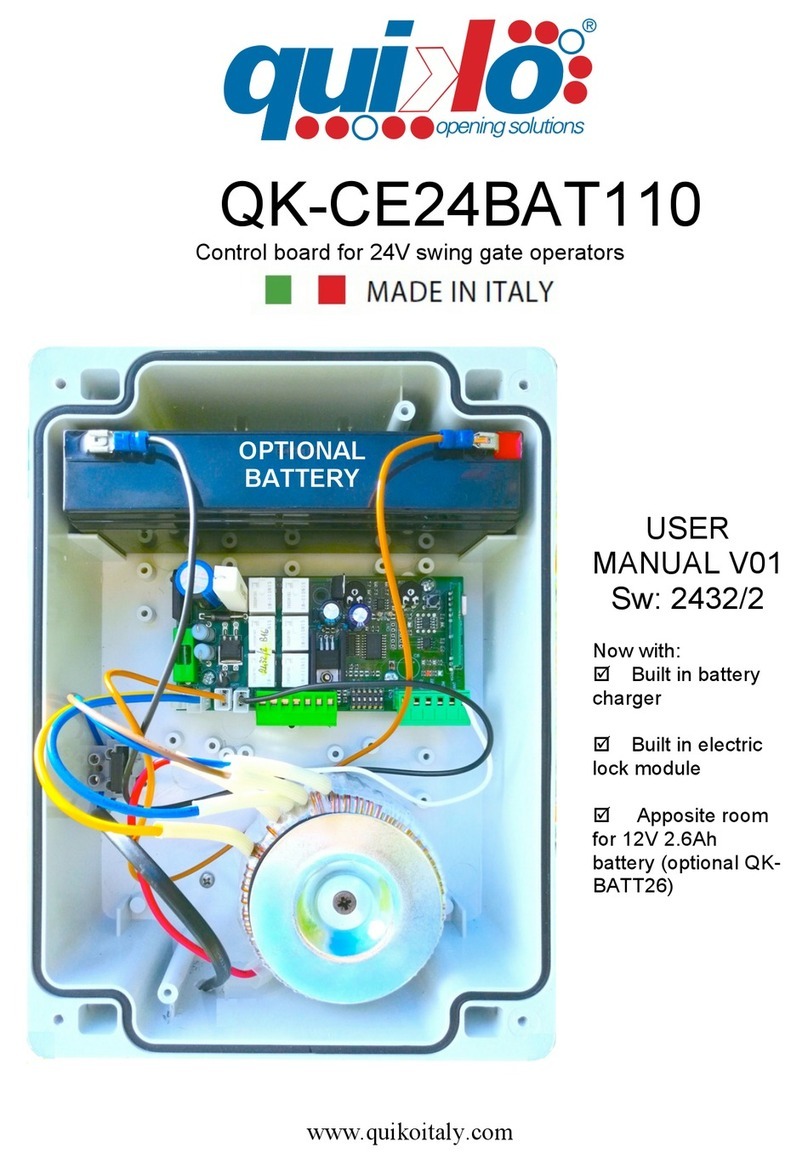

QK-CE220BATRLEcontrol unit has been designed to control electromechanical gear motors such as swing gates.

Any other use is considered improper and is consequently forbidden by current laws. The automation system you

are going to install is classified as “machine construction” and is therefore included in the application of European

directive 2006/42/EC (Machinery Directive).

The above mentioned directive includesfollowing prescriptions:

-only trained and qualified personnel should install the equipment;

-the installer must first make a “riskanalysis” of the machine;

-the equipment must beinstalled incompliance with the regulations inforce;

-after installation, the machine owner must be given the “declaration of compliance”.

Quiko Italy observes all security standards in any phase of the product’s production process (see the attached

declaration of compliance) and the installer must therefore observe the same standards when installing the system.

Should he ignore such regulations, he will be fully responsible for any damage caused by the system. For this

reason we suggest to read all instructions in this manual in advance.

MAIN FEATURES OF THE CONTROL BOARD

-Motor torque adjustment

-Built-in flashing light circuit with opening (fast) / closing (slow) / pause (always on) differentiated flashing

-Built-in radio receiver with 200 memories (2 channel: channel 1 START, channel 2 PEDESTRIAN

START)

-Input status LEDs

-Protection fuses

-2

nd

“pedestrian entry” function

-Soft start/stop function

-Plug and play technology

TECHNICAL DATA

INTRODUCTION

This manual is enclosed with control unit QK-CE220BATRLEand may not be used for different products. Moreover it

has been especially writtenfor use by qualified fitters.

Important note:

disconnect the panel before operating on the control unit.

3

E

N

G

L

I

S

H