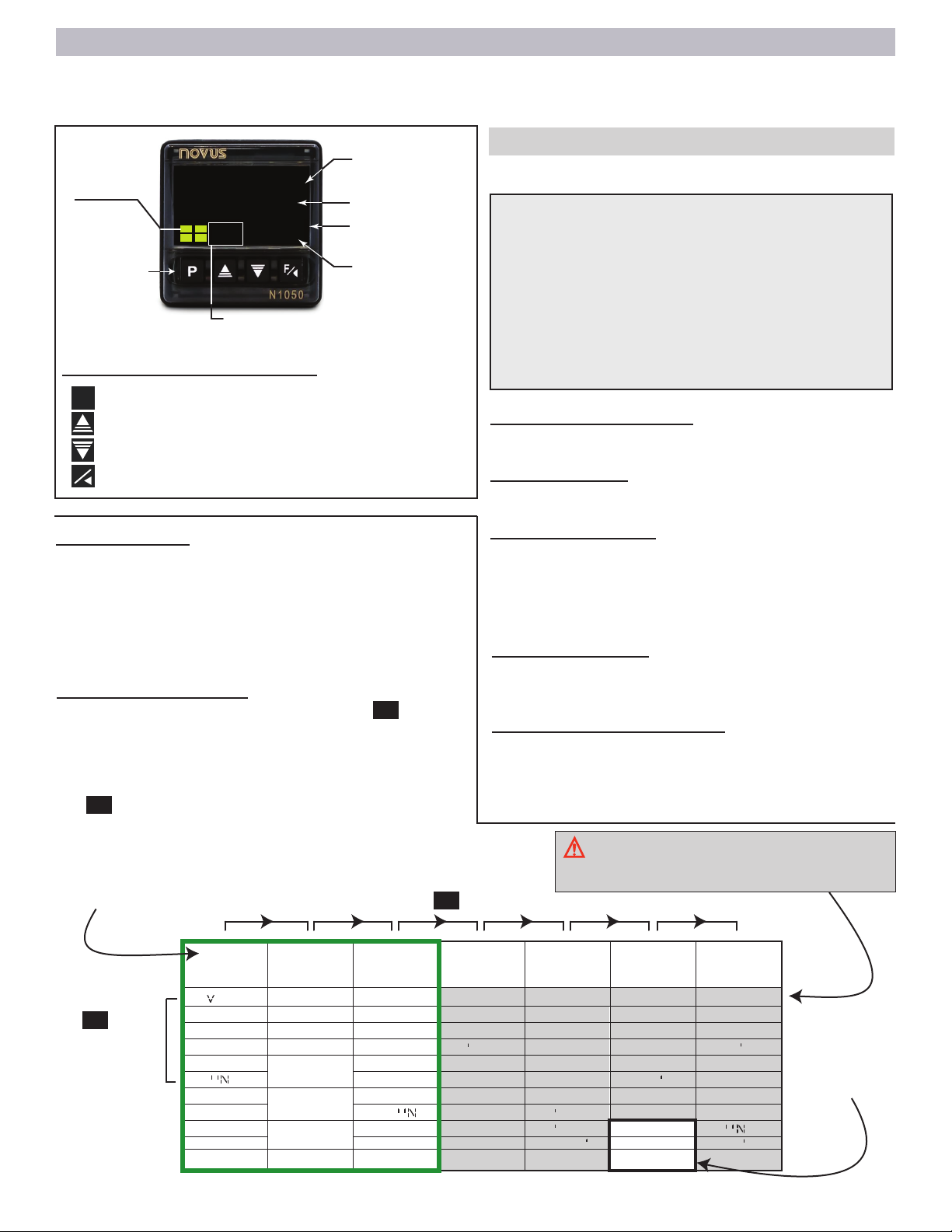

Press and hold until you see T.STR

Basic Count Down Timer Function (Menu 3)

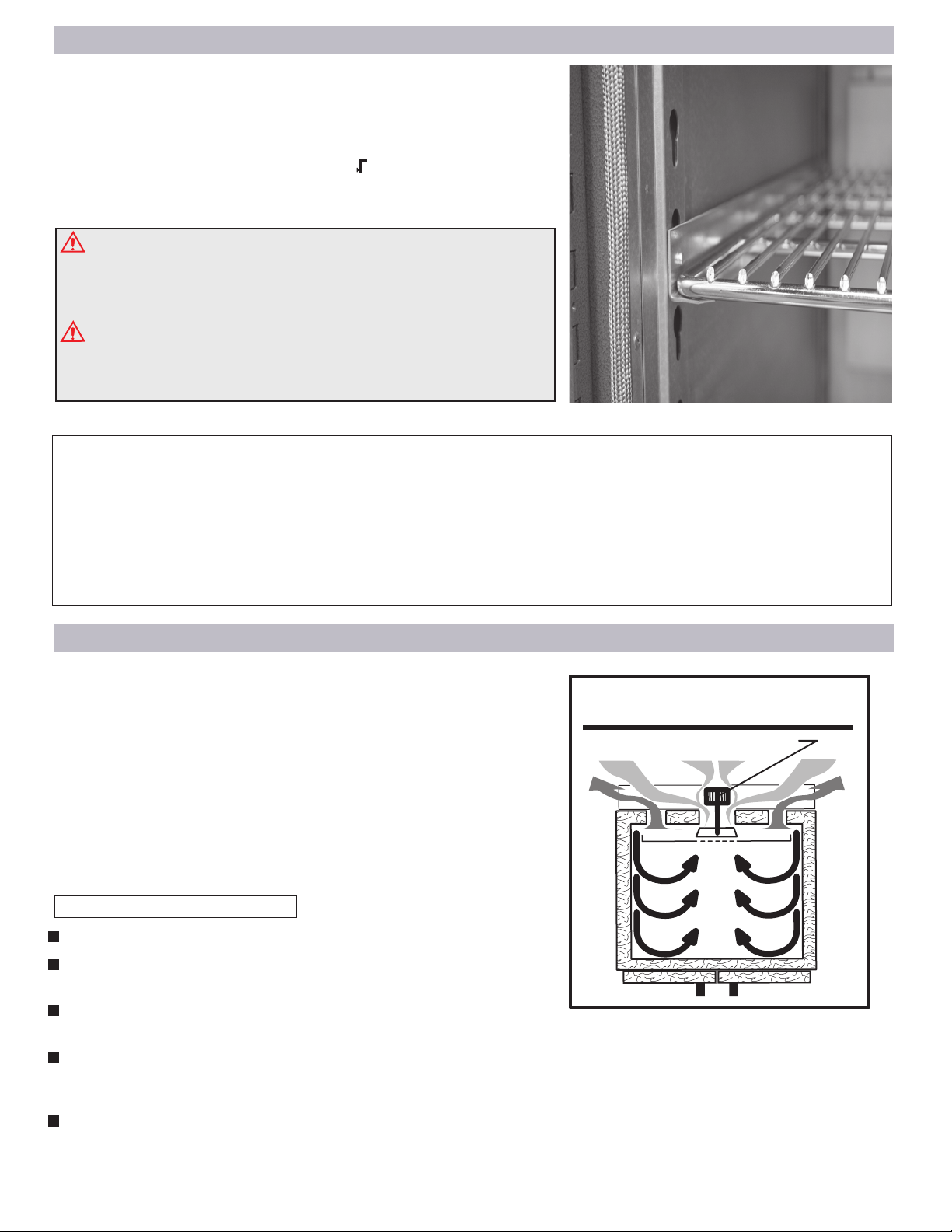

Control Calibration to Match Independent Device

IMPORTANT

The most accurate calibra�on possible for any digital unit is at

the center of the chamber (with the chamber empty). Therefore,

calibrate the control to the center of the chamber using an accu-

rate temperature measuring device.

Calibra�ng the actual chamber temperature to the temperature

displayed on the controller should only be done if the chamber’s

temperature, as measured by a known accurate device, is off by

more than the stated tolerance of your Bench Oven.

Your oven’s controller offset value has been input at the factory to match

your oven’s true chamber temperature when measured at the center of

the oven using an NIST (National Institute of Standard and Technology)

traceable temperature box (FIG.11). Over time this offset value may need

to be adjusted. If an offset needs to be performed in the field, place a

temperature probe at the center of the oven and adjust as needed.

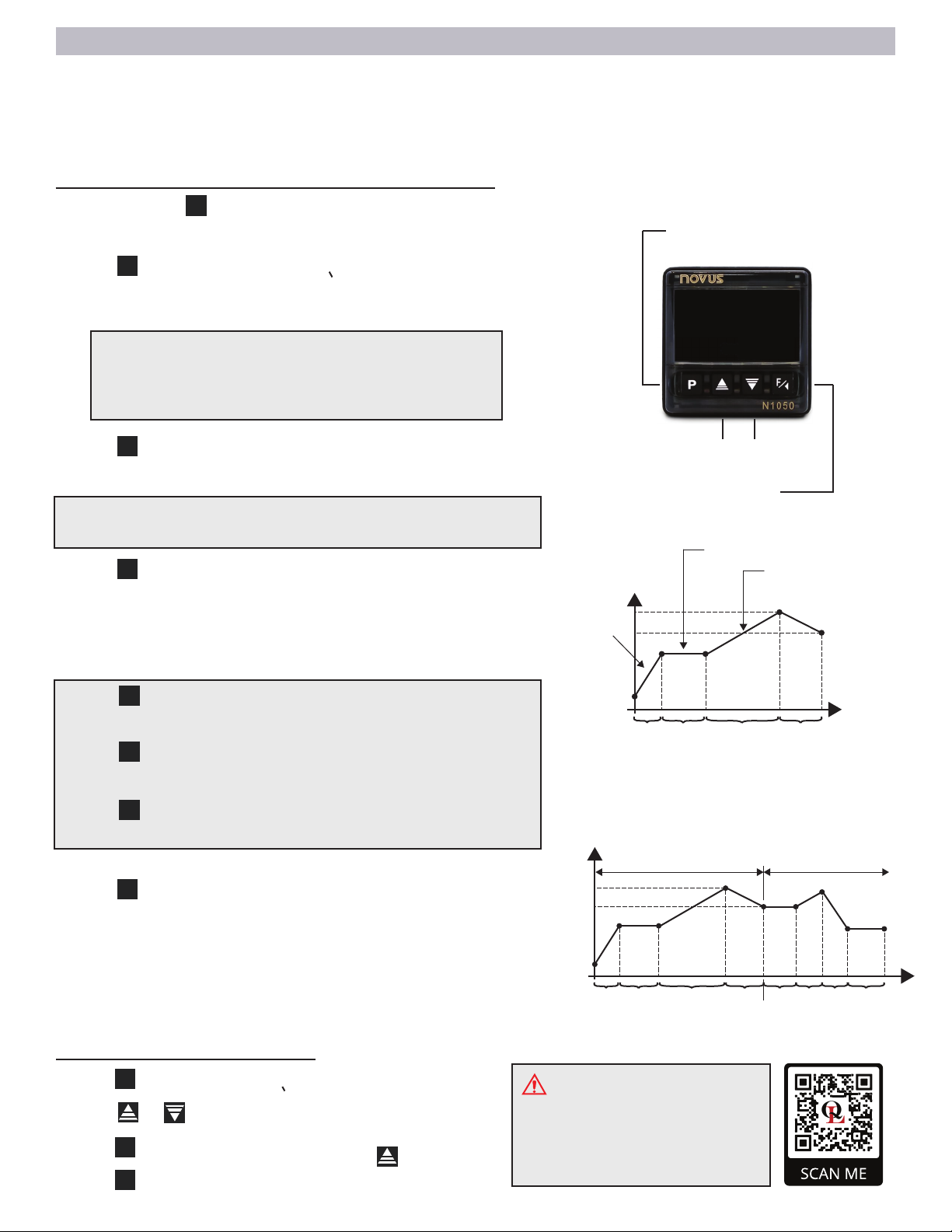

CALIBRATION EXAMPLE:

In the example shown in (FIG.12), the digital controller process value

reads 150°F (white LEDs) and the independent temperature probe

placed at the center of the oven shows a reading of 155°F. Note the

difference of 5 degrees F between the temperatures. On the controller’s

OFFS parameter, for this example, we add the 5°F difference to the

offset value already present. This value change will adjust the process

value on the controller to match the chamber temperature of 155°F.

OFFS

0

PF

PF

Press 3 times to

see OFFS

Press up or down

to input difference

PFPress 3 times to

return.

Once a temperature adjustment has been made, allow the oven some

time to stabilize before making any subsequent adjustments.

The temperature difference between the controller and your independent

probe can be a positive or negative number.

OFFSET VALUE

150°F

155°F

Independent temperature

measuring device.

Independent temperature probe

ACCESS THE OFFSET PARAMETER BY:

Your oven’s controller is equipped

with a timer feature that allows

you to use a count down timer by

manual activation.

For additional timer options see

Timer on pg2 of the QR-code pdf.

T.STR

F

T.DIR

DN

T.TB

: SS

Time Start Mode (T.STR)

The (F) value allows the timer to be

manually activated by pressing once

steps are completed.

Time Count Direction (T.DIR)

F

MM

Time Base Setting ( T.TB)

Access this parameter and choose the

desired timer base setting.

T1

T.PU

ON

Time Interval Adjustment (T1)

Acess this parameter and input the

desired timer value using the UP or

DOWN arrow keys .

T.PU Behavior at end of timer

This parameter allows the unit to continue

or stop with the heating operation after the

timer option is finished. Choose one of the

following:

00:00

HH:MM - Time intervals are diplayed in

hours and minutes.

MM:SS - Time intervals are diplayed in

minutes and seconds.

T1.E

Set this parameter to NO. Continue to next timer parameter.

T. END

Set this parameter to OFF. Continue with the next timer parameter.

T2

Set this parameter to 0000. Continue with the next timer parameter.

N

N

ON - Temperature controller continues

to operate.

OFF - End controller heating operation

at the end of the timer.

If the OFF option is selected, at the end of the timer

the RUN function will need to be enable to YES for

oven to heat again. See RUN FUNCTION on page 6.

Step 1

Step 2

Starting the timer

Once timer is set, you can start, pause,

and stop/cancel the timer count by doing

the following:

F

Step 6

Setting the count down timer

Start - Press once.

Pause - Press once.

F

Stop / Cancel - Press for 3 seconds.

F

When the timer has activated, the indica-

tor (A3) will flash continuously.

When the timer is interrupted the indica-

tor (A3 or A4) will flash quickly.

P

(Press to advance to Step 2)

P

This tells the controller to count in a down

direction.

Step 3

and press to select F

T1.E

As you are pressing and holding you may go pass

T.STR , if this happens, simply continue to press

and hold until parameter T.STR is reached.

P

P(Press once more to complete set-up and return to

temperature display)

P

Press to select DN

Press to advance to Step 3 or to return to previous

PF

Using the or keys and select a desired

time base to apply to the timer.

Press to advance to Step 4 or to return to previous

PF

Step 4

Press to advance to Step 5 or to return to previous

PF

Using the or keys and select a desired

time.

Step 5

Set the following (3) parameters as follows and

press to advance :

Press to advance to Step 6 or to return to previous

PF

P

Using the or key select what happens

at the end of the timer.

There are other timer options available,

but only Fwill work as a count down timer.

Digital

controller

process

value

PAGE 7

FIG. 11

FIG. 12