PAGE 2

A B

C D

FIG. 1

FIG. 2

Set-up

Position unit in its ultimate operating location. Keep a minimum of

2" of airspace around the unit and a minimum of 10" above the

unit. The port holes at the top of the unit will expel a small amount

of warm air through natural convection. This port can also be used

as an access for an external temperature probe to verify the

chamber's temperature or the chamber's contents directly.

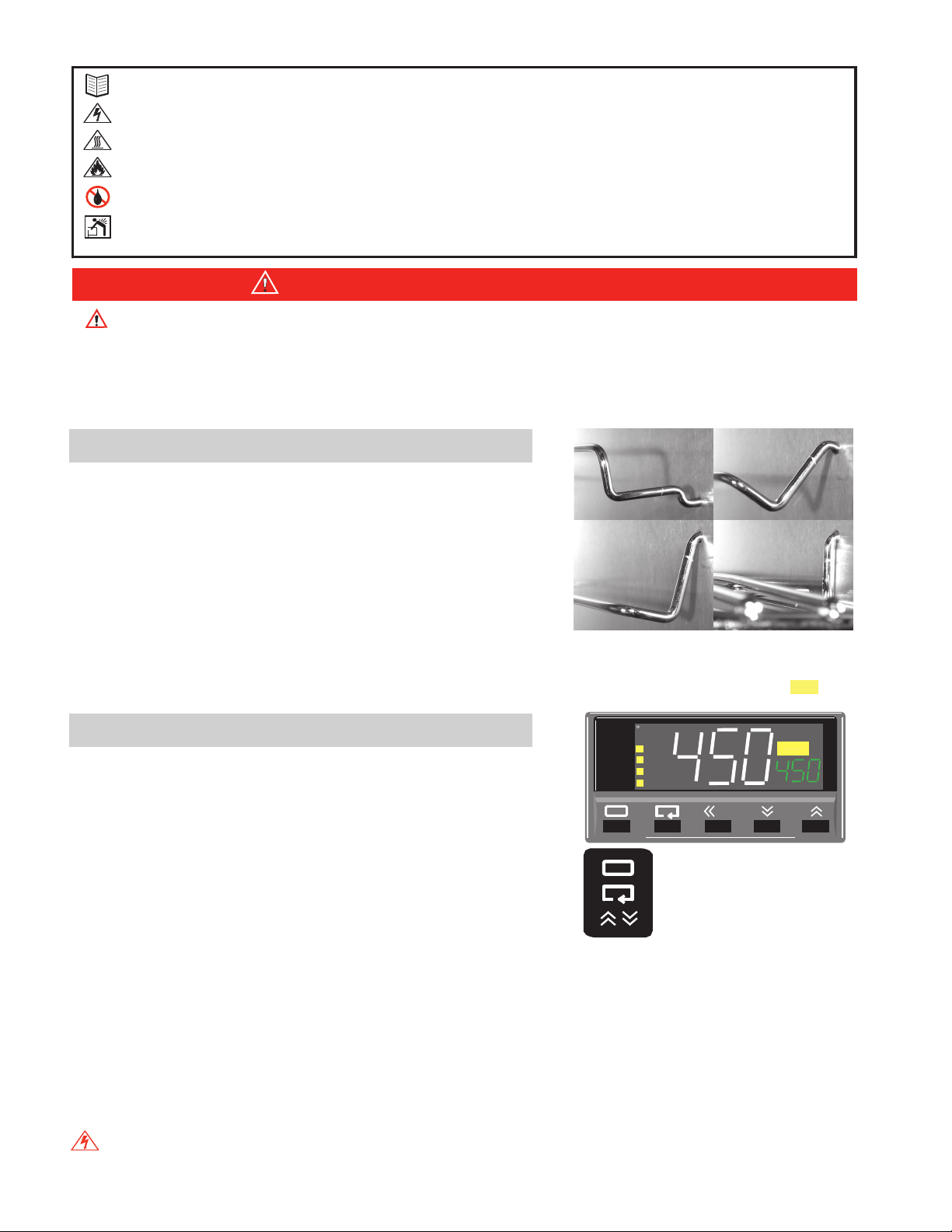

Install adjustable shelf by placing the ends of the wire shelf bracket

into the corresponding holes located on the inner sides of the oven

at the desired height. Push the ends of the

bracket into the holes until the first bends in the bracket are

against the wall, then rotate the bracket down. Place the shelf on

the brackets. (FIG 1)

Plug the unit into a grounded outlet for your unit's rated voltage.

General Operation

The unit is ready for your immediate use. All control parameters,

calibration and tuning has been done at the factory, no adjustments

are necessary.

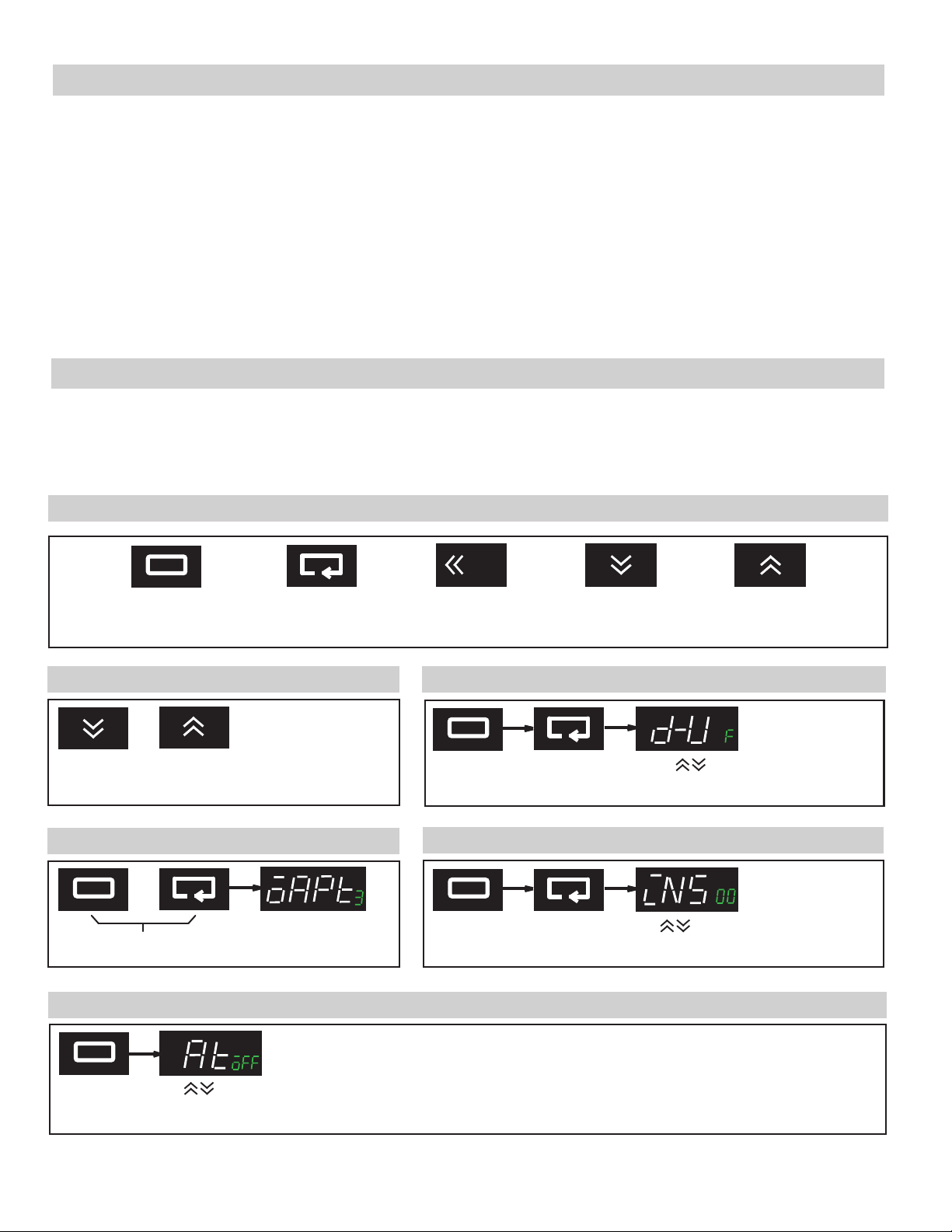

Push the illuminated power button. All LED's on the temperature

control will light-up and display the current chamber temperature

and the set temperature.

Set temperature is constantly displayed in the lower right-hand

corner of the display. To change the set temperature, simply press

either the up arrow key or the down arrow key, until desired set

temperature is reached. (FIG. 2) The temperature control is set at

the factory to read in 1/10th degree F, or Fahrenheit units.

To change Controller functions see: Menu Level Functions Guide

Read Operating Instructions Thoroughly Prior to Operation

The GCE Series lab ovens are not designed for use with any flammable solvents or gases or for materials

that may contain flammable solvents or gases. Use only a grounded outlet that is rated for your model's

electrical requirement. Oven exterior walls and doors may become hot to the touch when operating at higher

set temperatures. Do not leave the oven unattended during operation, especially when processing materials

that have flash point temperatures lower than the model oven's maximum operating range. Do not modify the

oven or control parameters to operate the oven above the stated maximum operating temperature.

Safety Precautions

Once the unit nears the desired temperature allow the unit to cycle for 20 minutes at set point before temperature

becomes fully stable. NOTE: Upon each initial powering-up, the control may typically overshoot the set temp by 3 or 4

degrees especially if the temperature set point is close to the operating ambient temperature. After equilibrium is

achieved the control will hold set temperature within 1 unit degree.

READ INSTRUCTIONS THOROUGHLY BEFORE OPERATING OVEN

DO NOT USE WITH FLAMMABLE LIQUIDS OR GASES

EXTERIOR SURFACES MAY BECOME HOT DURING OPERATION

WARNING:

WARNING:

CAUTION:

RISK OF ELECTRICAL SHOCK. DISCONNECT UNIT FROM POWER SOURCE BEFORE REMOVING COVER

WARNING:

NOT FOR USE WITH OPEN LIQUIDS

WARNING:

CARE SHOULD BE TAKEN WHEN CARRYING/LIFTING UNIT INTO PLACE. LARGER

UNITS ARE HEAVY AND MAY REQUIRE TWO PEOPLE TO TRANSPORT OR INSTALL.

WARNING:

Unit Safety Reset- If the unit exceeds its maximum temperature, an internal safety “snap disc” will cut power to the

unit until it is manually reset. To do this, unplug the unit, lay it on its back and remove the bottom cover. Locate the round

safety “snap disc” and push in the button to reset.

RISK OF ELECTRICAL SHOCK. DISCONNECT UNIT FROM POWER SOURCE BEFORE REMOVING COVER.

FAILURE TO COMPLY COULD RESULT IN SERIOUS INJURY OR DEATH.

WARNING:

(page 3).