QWICK KURB®, INC. Long Term Installation Manual

REMOVAL

........................................................................................................................................25

TRAFFIC CONSIDERATIONS..................................................................................................................25

REMOVING THE MARKERS/BOLLARDS............................................................................................25

REMOVING THE L65 REFLECTIVE ARCS............................................................................................25

DISASSEMBLING THE L60 SEPARATOR UNITS ................................................................................25

UNBOLTING FROM THE ROADWAY - ASPHALT ............................................................................26

PICKING UP THE L60 SEPARATOR ......................................................................................................26

DO NOT DRAG THE L60 SEPARATOR UNITS..................................................................................26

MAINTENANCE .............................................................................................................................27

STORAGE .........................................................................................................................................28

TRANSPORT....................................................................................................................................29

CUSTOMER

SER

VIC

E

...................................................................................................................30

REPLACEMENT PARTS............................................................................................................................30

MEASUREMENTS ......................................................................................................................................30

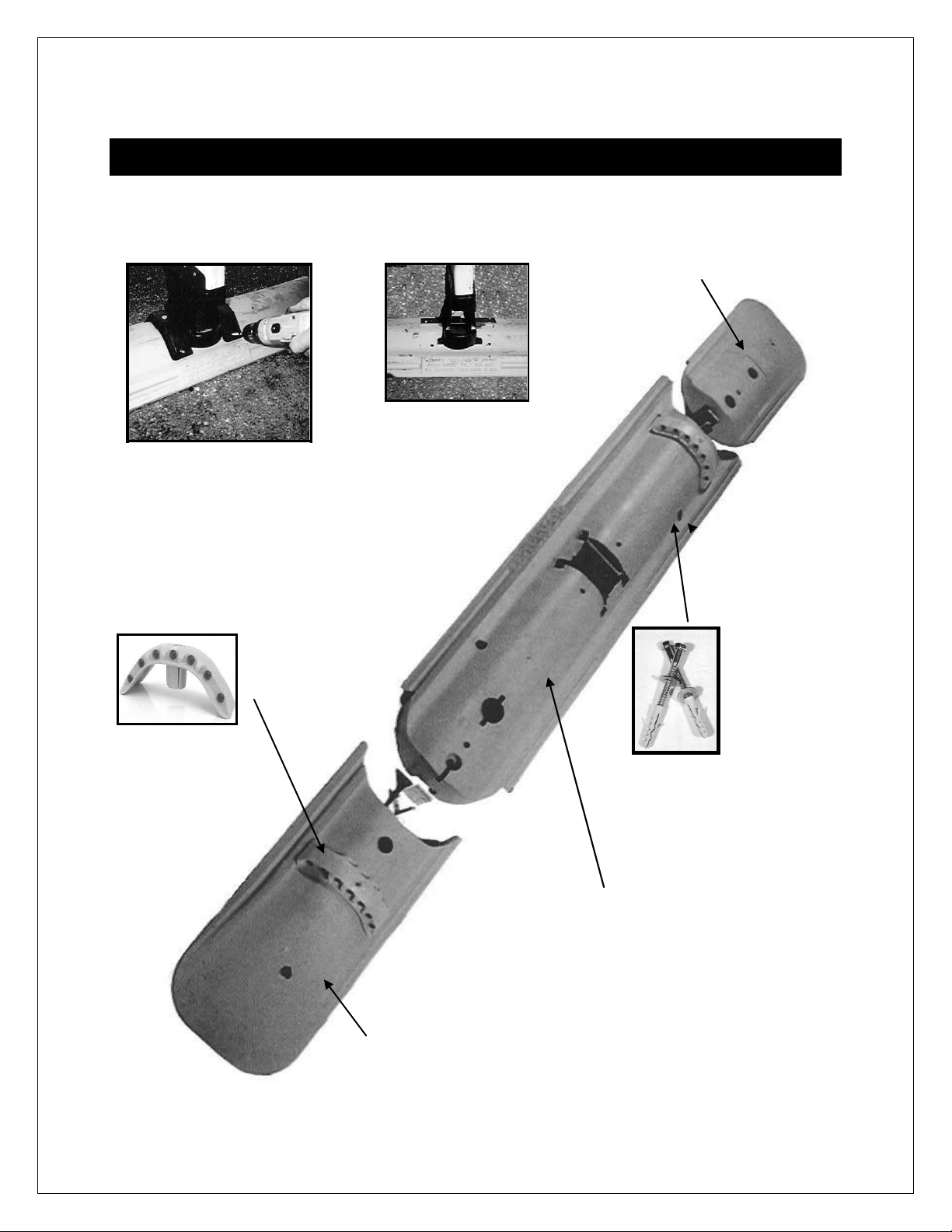

APPENDIX A - Q640 PANEL

PULLER

........................................................................................31

QWICK INSTALLATION ..........................................................................................................................31

APPENDIX B - INSTALLING NEW MARKERS/BOLLARDS TO THE

REBOUNDABLE FLEX

B

OO

T

......................................................................................................34

TRAFFIC CONSIDERATIONS..................................................................................................................34

REMOVING THE OLD MARKER/BOLLARD FROM THE REBOUNDABLE FLEX BOOT..........34

PREPARING THE NEW MARKER/BOLLARD FOR INSTALLATION ON THE

REBOUNDABLE FLEX BOOT ..................................................................................................................34

APPENDIX C – PARTS

SPEC

IFICATION

S

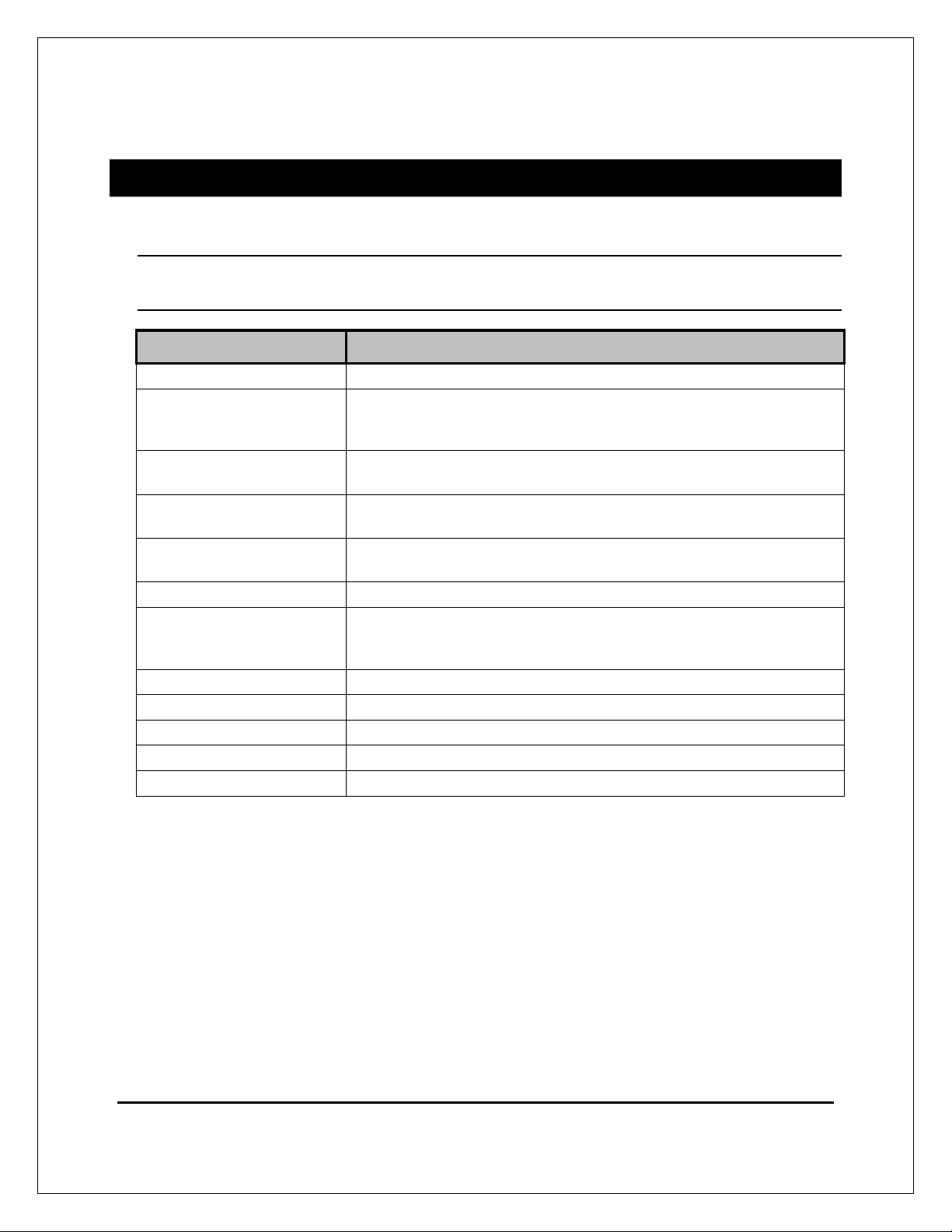

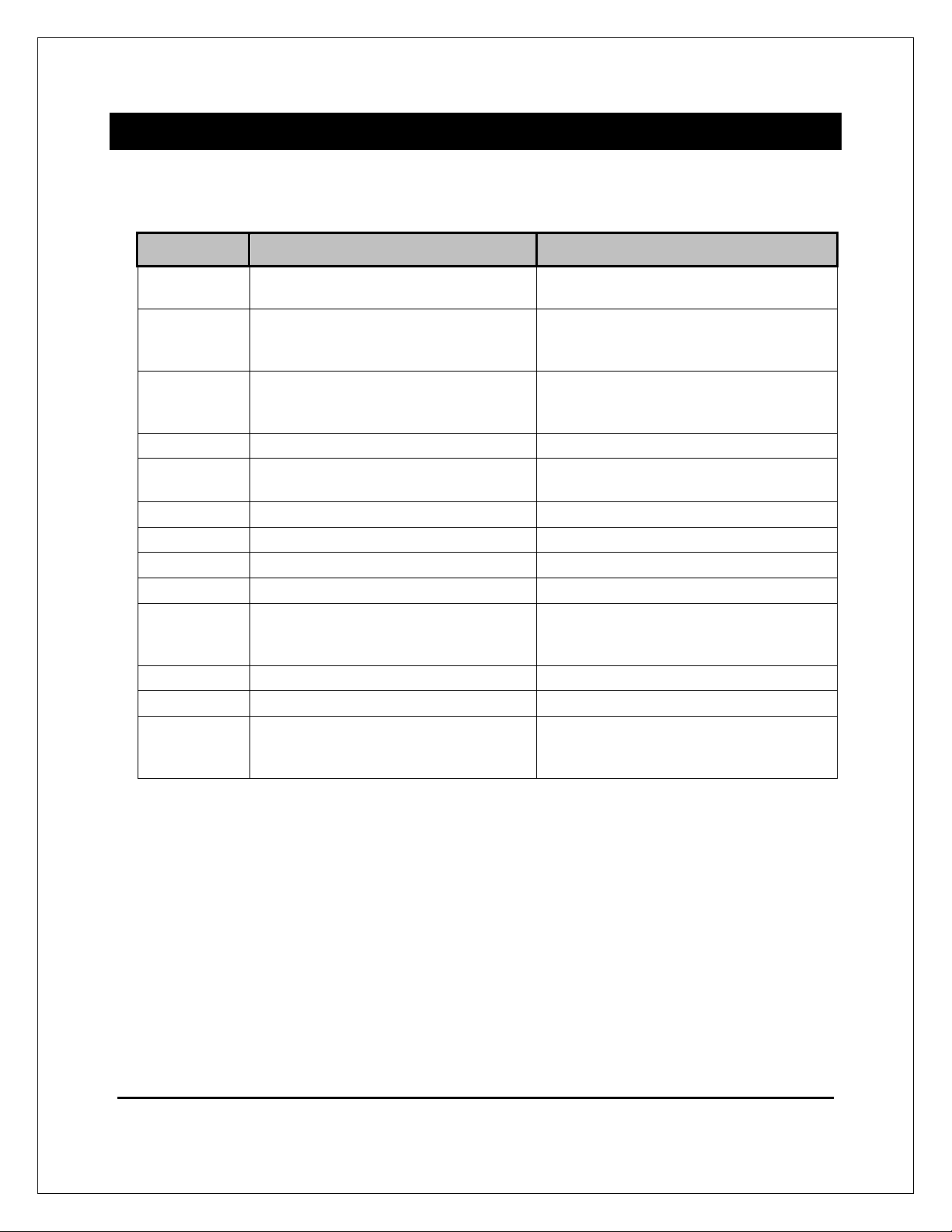

...............................................................................36

L60 SEPARATOR UNIT .............................................................................................................................36

L61 MALE END UNIT................................................................................................................................37

L62 FEMALE END UNIT...........................................................................................................................38

L65 REFLECTIVE MARKER......................................................................................................................39

S65 SECURING ARC ..................................................................................................................................40

L84 FLAT MARKER/BOLLARD..............................................................................................................41

L104 MEGA MARKER®/BOLLARD.......................................................................................................42

Phone: 800-324-8734 Fax: 813-645-4856 www.qwickkurb.com

1/21/2016

4