Table of Contents

Table of Contents

Introduction.....................................................................................................................1

Six Button Dash Features............................................................................................1

Package Contents.........................................................................................................1

Optional Items:..............................................................................................................1

Ultra Dash Installation ..................................................................................................3

Selecting a Mounting Location....................................................................................3

Dash Mounting ..............................................................................................................3

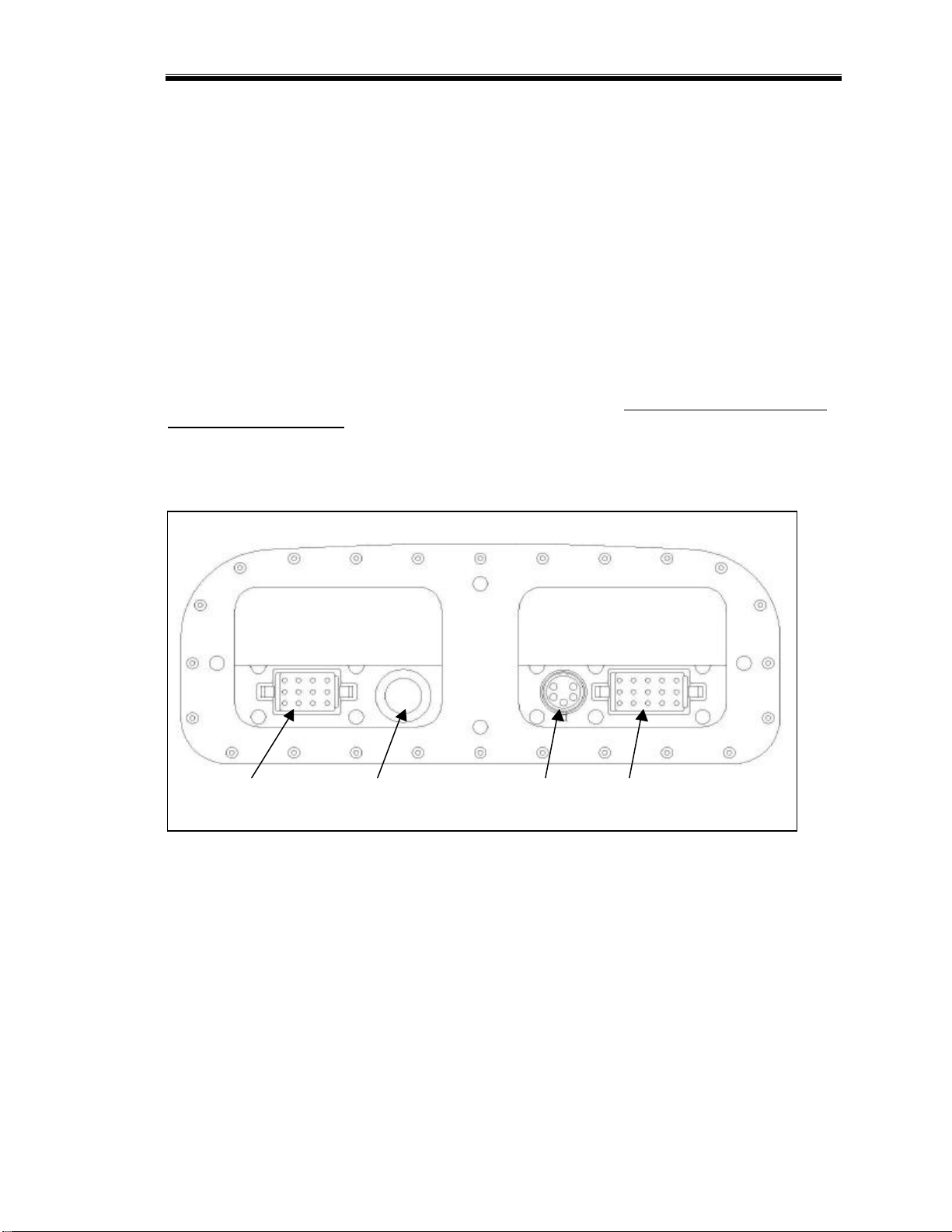

Port Descriptions...........................................................................................................3

Port A Wiring...................................................................................................................4

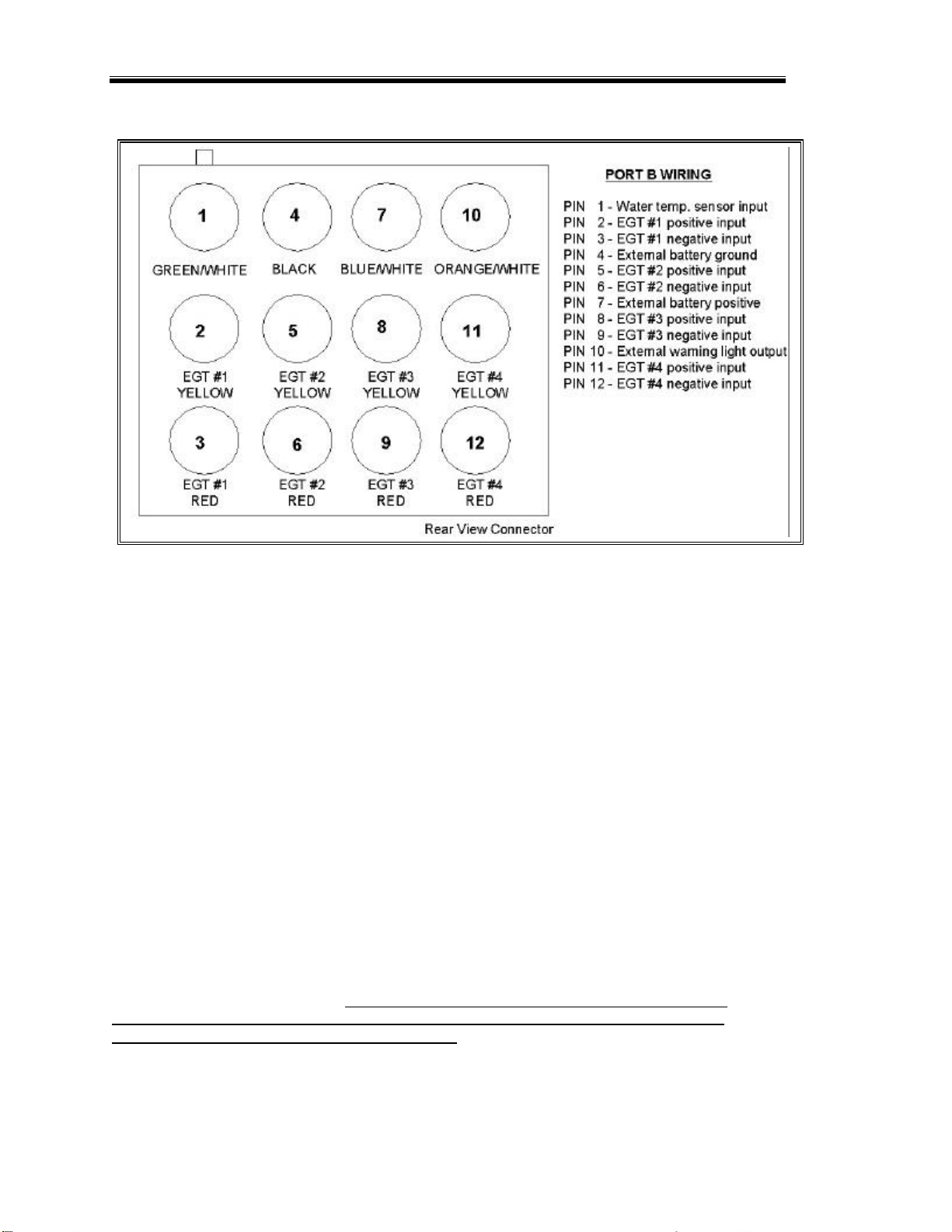

Port B Wiring...................................................................................................................6

Port B Wiring...................................................................................................................6

Sensor Installation.........................................................................................................7

EGT Probe Installation.................................................................................................7

Water Temperature Sensor Installation.....................................................................7

Removing Wires from the Connector and/or changing EGT Probes....................7

Jack Shaft Sensor and Collar Installation.................................................................7

Remote Switch..............................................................................................................8

External Battery.............................................................................................................8

Installing V-Net Channels ............................................................................................9

Programming and Operation Using the Dash Buttons......................................11

How the Buttons Work:..............................................................................................11

Display Modes.............................................................................................................12

Setup Mode..............................................................................................................12

Speedometer Calibration....................................................................................15

Fuel Level Calibration..........................................................................................15

Real-time Mode........................................................................................................16

Scroll Mode...............................................................................................................17

Min –Max Recall Mode..........................................................................................19

Record Mode...........................................................................................................19

Playback Mode.........................................................................................................19

Warning Indicators......................................................................................................20

Clearing Alpha Display Warnings .........................................................................21

Programming Using the DataLink PC software...................................................23

Installing the DataLink Software...............................................................................23