2

1108900-W2-L

CONTENTS

Description...............................................................................................4

Patents and Design Registration..........................................................5

Safety : Warnings ....................................................................................5

Specications ..........................................................................................6

Installation ...............................................................................................7

General................................................................................................. 7

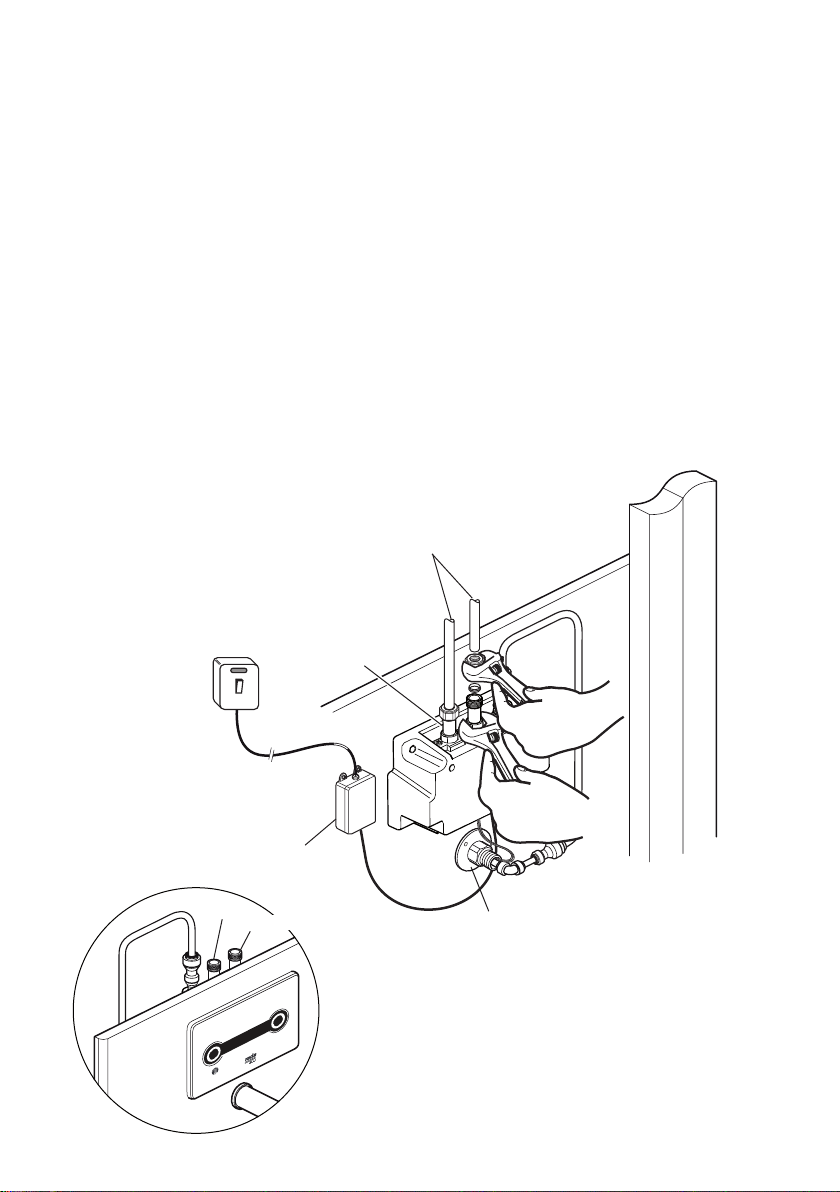

Make the connections to the Rada Acu................................................ 8

Commissioning .......................................................................................9

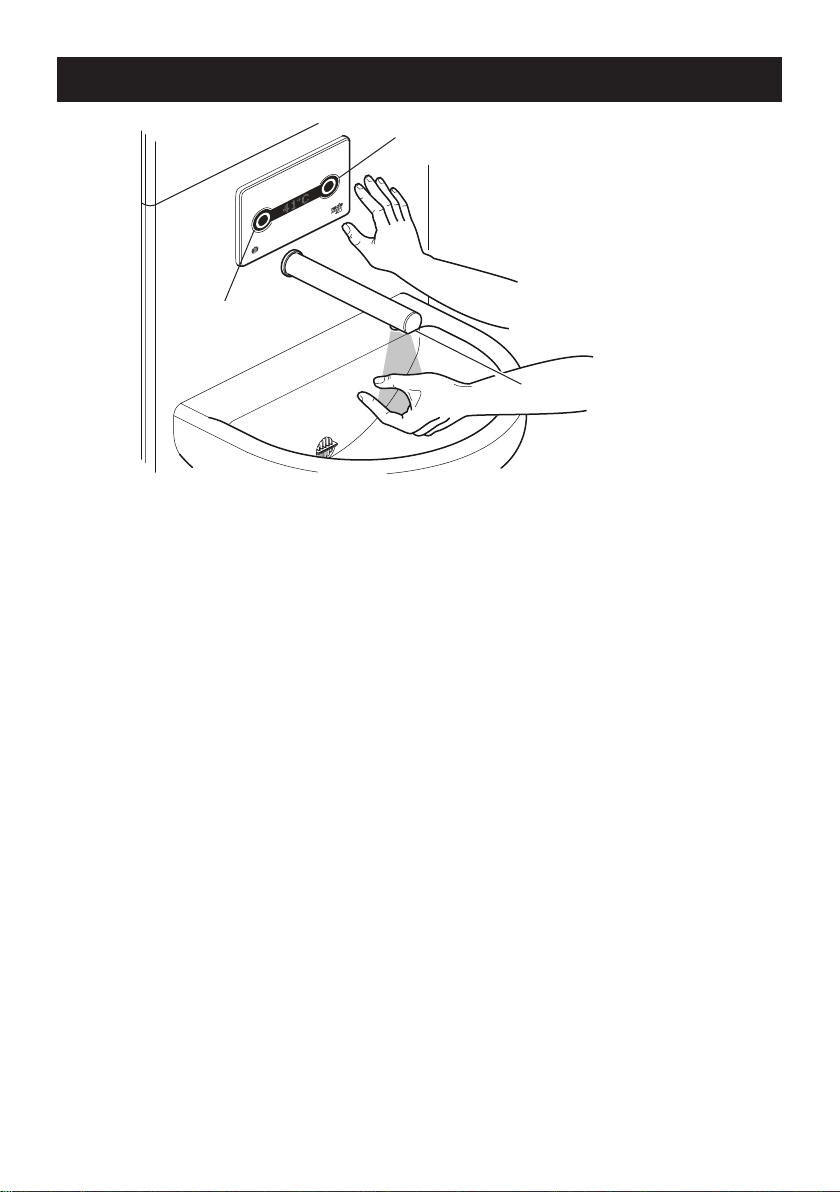

Operation ...............................................................................................10

User Modes........................................................................................10

Programming .........................................................................................13

General...............................................................................................13

Main Menu..........................................................................................15

Settings .............................................................................................. 16

Valve Setup ........................................................................................17

Set Mode............................................................................................18

Flush Setup ........................................................................................19

Set Password .....................................................................................20

Service ............................................................................................... 21

Manual Flush......................................................................................22

Disinfection.........................................................................................23

Commissioning...................................................................................24

Maintenance...........................................................................................25

General...............................................................................................25

Planned Maintenance.........................................................................25

Cleaning ............................................................................................. 26

Duty Flush ..........................................................................................26

Disinfection.........................................................................................26

Pall Filters...........................................................................................26

Filters and Non Return Valves............................................................ 27

Fault Diagnosis......................................................................................30

General...............................................................................................30

Self Diagnostic Errors.........................................................................32

Spare Parts ............................................................................................34