4

Warning!

Products manufactured by us are safe provided they are installed, used and maintained

in good working order in accordance with our instructions and recommendations.

Caution!

1. Read all of these instructions.

2. Retain this guide for later use.

3. Pass on this guide in the event of change of ownership of the installation site.

4. Follow all warnings, cautions and instructions contained in this guide.

5. The plumbing installation must comply with the requirements of UK Water

Regulations/Bye-laws (Scotland), Building Regulations or any particular

regulations and practices, specied by the local water supplier. The installation

should be carried out by a plumber or contractor who is registered or is

a member of an association such as:

i) Institute of Plumbing (IOP), throughout the UK.

ii) National Association of Plumbing, Heating and Mechanical Services

Contractors (NAPH & MSC), England and Wales.

iii) Scottish and Northern Ireland Plumbing Employers’ Federation (SNIPEF),

Scotland and Northern Ireland.

6. Anyone who may have difculty understanding or operating the controls of any

appliance should be attended whilst operating. Particular consideration should

be given to the young, the elderly, the inrm, or anyone inexperienced in the

correct operation of the controls.

The use of the word “failsafe” to describe the function of a thermostatic mixing valve

is both incorrect and misleading. In keeping with every other mechanism it cannot

be considered as being functionally infallible.

Provided that the thermostatic mixing valve is installed, commissioned, operated

within the specication limits and maintained according to this Manual, the risk of

malfunction, if not eliminated, is considerably reduced.

Malfunction of thermostatic mixing valves is almost always progressive in nature

and will be detected by the use of proper temperature checking and maintenance

routines.

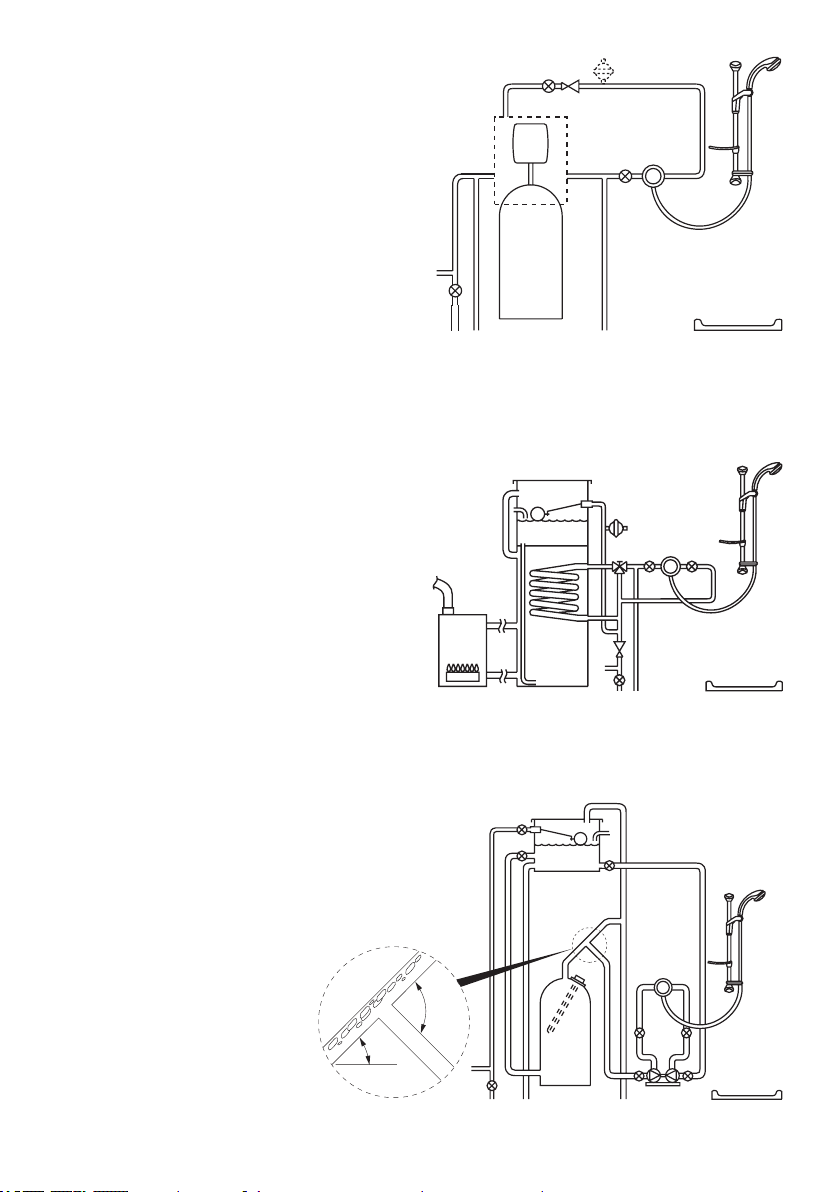

Certain types of system can result in the thermostatic mixing valve having excessive

‘dead-legs’ of pipework. Others allow an auxiliary cold water supply to be added

to the mixed water from the mixing valve. Such systems can disguise the onset of

thermostatic mixing valve malfunction.

Ultimately, the user or attendant must exercise due diligence to make sure that the

delivery of warm water is at a stable, safe temperature. This is particularly important

in such healthcare procedures as supervised bathing of patients unable to respond

immediately to unsafe temperatures.

SAFETY : WARNINGS