Dynalyzer – Digital Display/Printer OPERATION MANUAL

1

Contents

Important ..............................................................................................................................................................2

Introduction..........................................................................................................................................................2

Description.........................................................................................................................................................2

Construction ......................................................................................................................................................3

Measured Quantities.....................................................................................................................................3

Predicted Maximum mAs Reading Inaccuracy for Selected Exposure Times .............................................6

Calculated Quantities....................................................................................................................................6

Operation..............................................................................................................................................................8

Operation..............................................................................................................................................................9

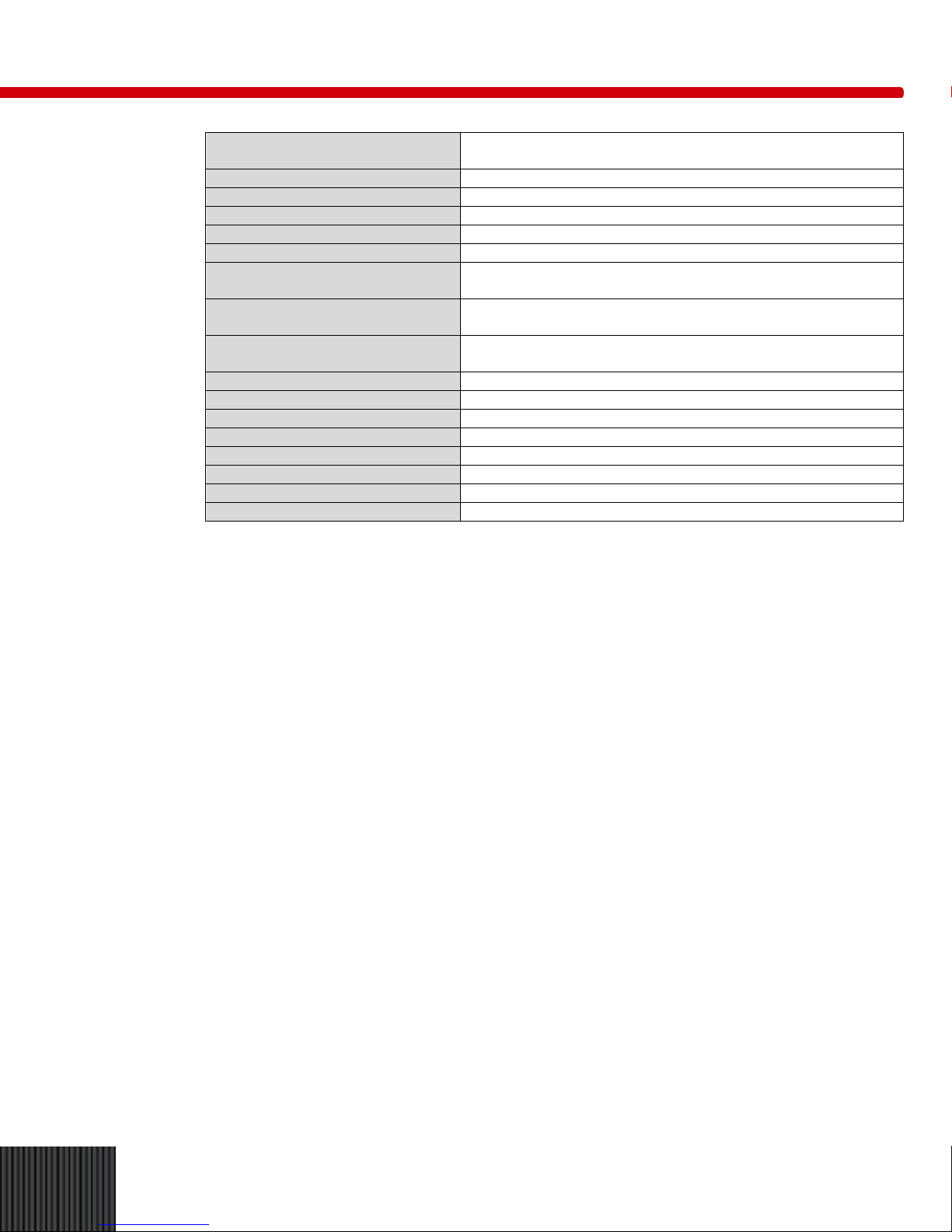

Specifications ....................................................................................................................................................9

Printer............................................................................................................................................................9

RS-23-2 Connector.......................................................................................................................................9

Initial Setup and Self Test .................................................................................................................................9

Triggering Sources..........................................................................................................................................10

External Trigger...........................................................................................................................................11

Auto Trigger ................................................................................................................................................11

Manual Trigger............................................................................................................................................11

KV and MA Trigger Mode Operation ..........................................................................................................11

Trigger Level ...................................................................................................................................................12

kV Measurement Delay...................................................................................................................................15

Fluoroscopic Current Measurements (0-20 mA).............................................................................................16

Window Delay Mode Operation.......................................................................................................................16

Exposure Number Window and Recall Button................................................................................................18

Clear Reading .................................................................................................................................................18

Reset...............................................................................................................................................................18

Coefficient of Variation Measurement.............................................................................................................18

Applications .......................................................................................................................................................20

Typical Operating Sequence...........................................................................................................................20

Recommended Procedure for Verification of X-ray Equipment Calibration....................................................21

X-Ray Tube KVP (A + C), Transformer Balance A & C, and Exposure Timer Verification........................21

X-ray Tube Milliampere Station Verification................................................................................................21

Grid Pulse System Measurement ...................................................................................................................21

Printer .................................................................................................................................................................23

Loading Paper into the Printer.........................................................................................................................23

Changing the Printer Ribbon...........................................................................................................................23

Output Port.........................................................................................................................................................24

RS232 Port Settings........................................................................................................................................24