1.0 About your HotZONETM HeatProjector

Congratulations on your purchase of a revolutionary HotZONETM HeatProjector from Radiant Op-

tics. The HeatProjector line of electric infrared heaters are the most efficient spot heaters on the

market today – and not by just a little bit. Our high efficiency heat “projector” is made possible by

the combination of two proprietary and innovative features. Infrared heat is generated with our

unique Inverted Cone IR element and focused using our precision Compound Reflective Lens.

These act to generate, collect, and concentrate heat rays into a beam that can be pointed at a tar-

get area.

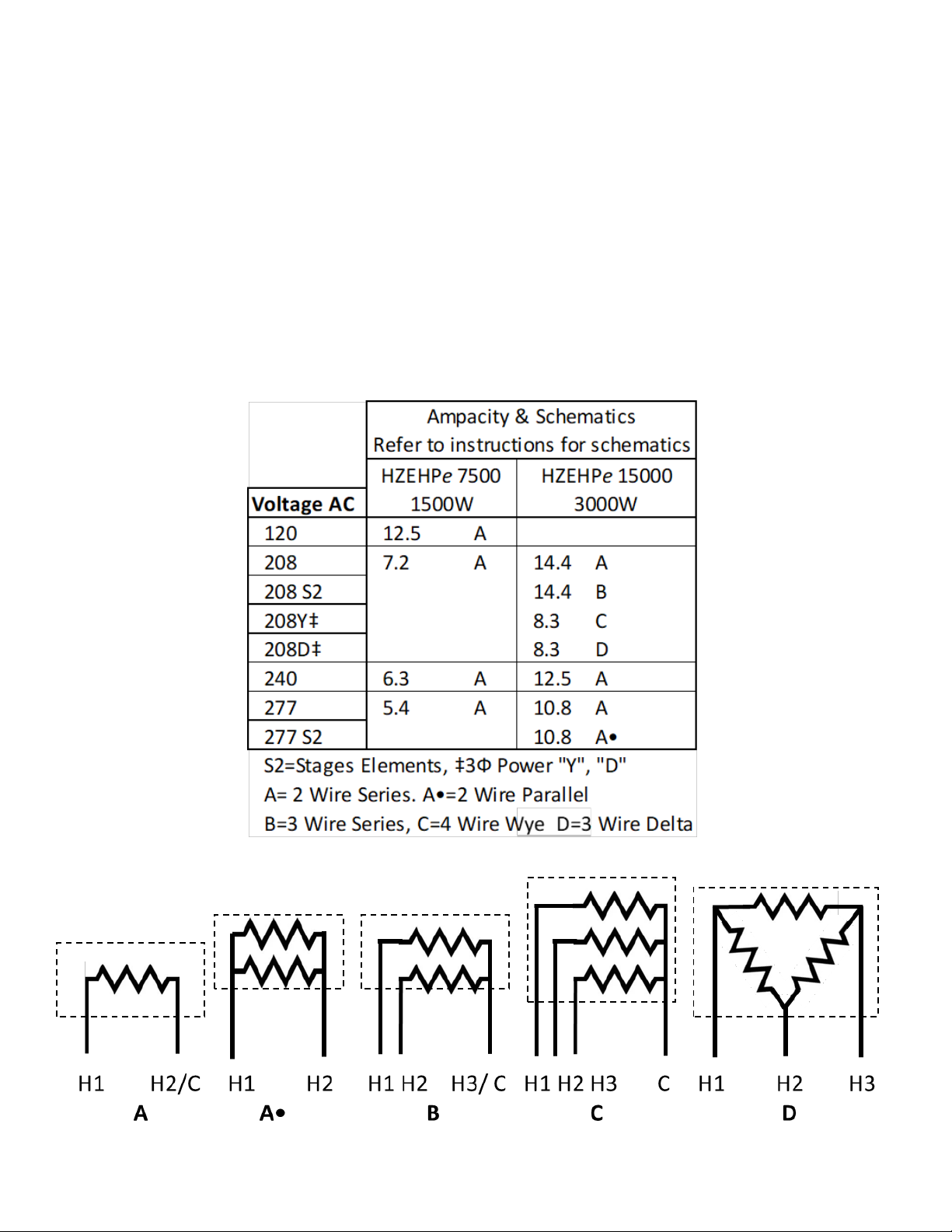

HotZONEM HeatProjectors come in 2 models: HZEHPe7500w and HZEHPe15000w

The e7500 delivers the equivalent energy of a 7500w non-lensed heater with only 1500w input;

The e15000 delivers the equivalent energy of a 15000w non-lensed heater with only 3000w input.

HeatProjectors are very low cost to run, have a smaller carbon footprint and can deliver a beam of

heat to a target over a longer distance and with a defined edge between the heated and unheated

areas.

Plan your installation by identifying the area you want to heat and how much of a temperature

increase is desired. The temperature increase depends on the power of the heater, the mounting

angle, and the distance from the target. See the HZE HeatProjector Product Guide available at

www.radiantoptics.com and refer to the Temperature Increase Map.

HotZone™ electric heaters are listed with ETL and ETLc (for Canada) by Intertek and are approved

for use in dry and wet locations.

Warranty

Radiant Optics Mfg., LLC warrants, to the original purchaser, our products to be free of defects in material or work-

manship for six months from date of purchase. Parts found to be defective will be repaired or replaced at the option

of Radiant Optics Mfg., LLC. This warranty of material and workmanship specifically excludes labor and ordinary and

routine servicing and maintenance associated with the goods sold, including replacement of the element which has

an expected service life of 2000 hours.

What is Not Covered By The Warranty

The warranty does not cover:

(1) Installations not made in accordance with installation instructions;

(2) Where the operation of the product varies substantially from our operating instructions;

(3) Malfunctions resulting from misuse, negligence, alteration, accident or lack of maintenance;

(4) Labor, loss of time, inconvenience, loss of use of the product, or other consequential damages;

(5) Products with the manufacturer nameplate removed.

The above constitutes our sole warranty. THERE IS NO WARRANTY OF MERCHANTABILITY AND

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION OF THE FACE HEREOF.

1