RR8 Build Tips & Tricks

Differentials

Note: Several steps of the assembly have been omitted.

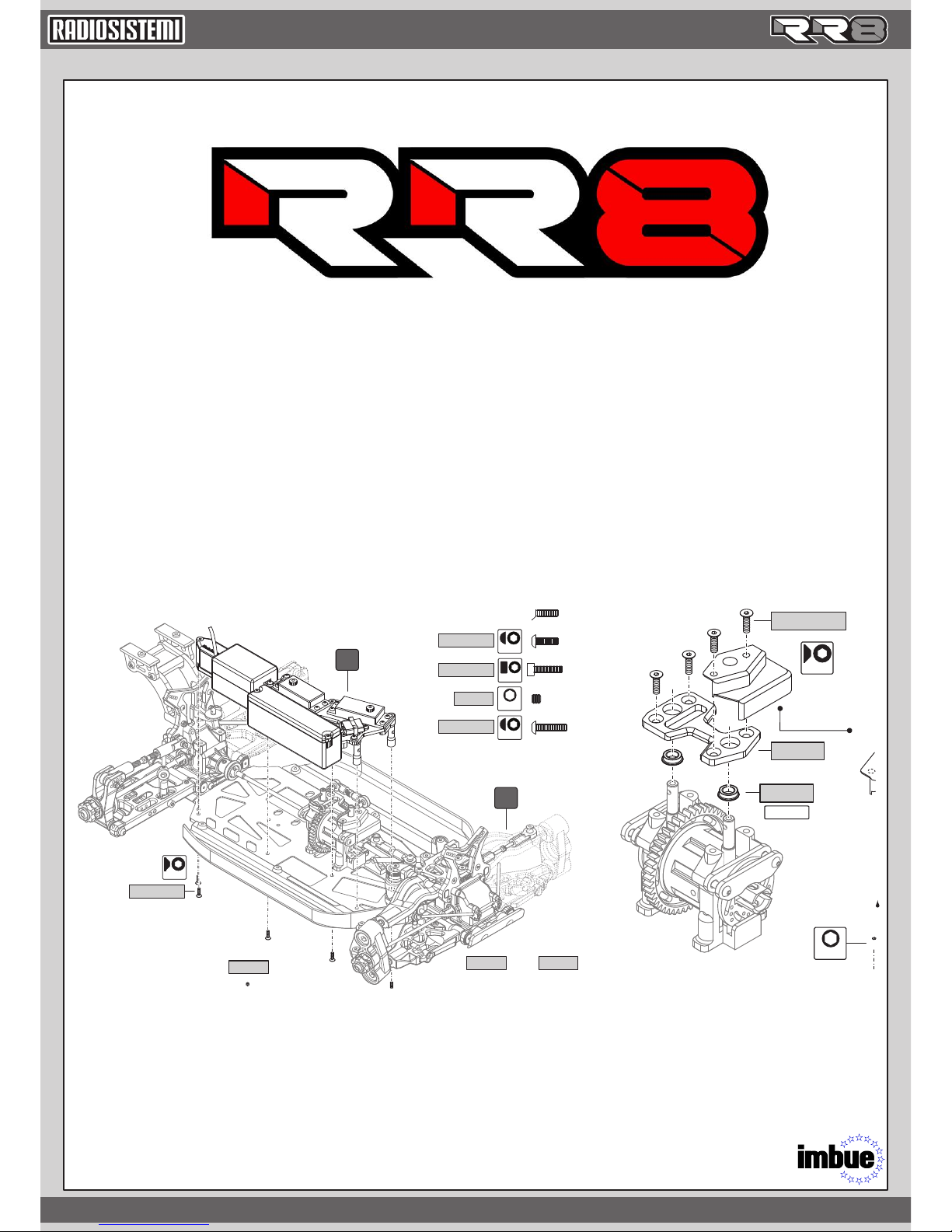

Quickly check and set backlash by

assembling the diff case and the bevel gear.

Make sure to use the blue diff gasket so the

gear and case will be the correct assembled

width. Do not install any internals yet.

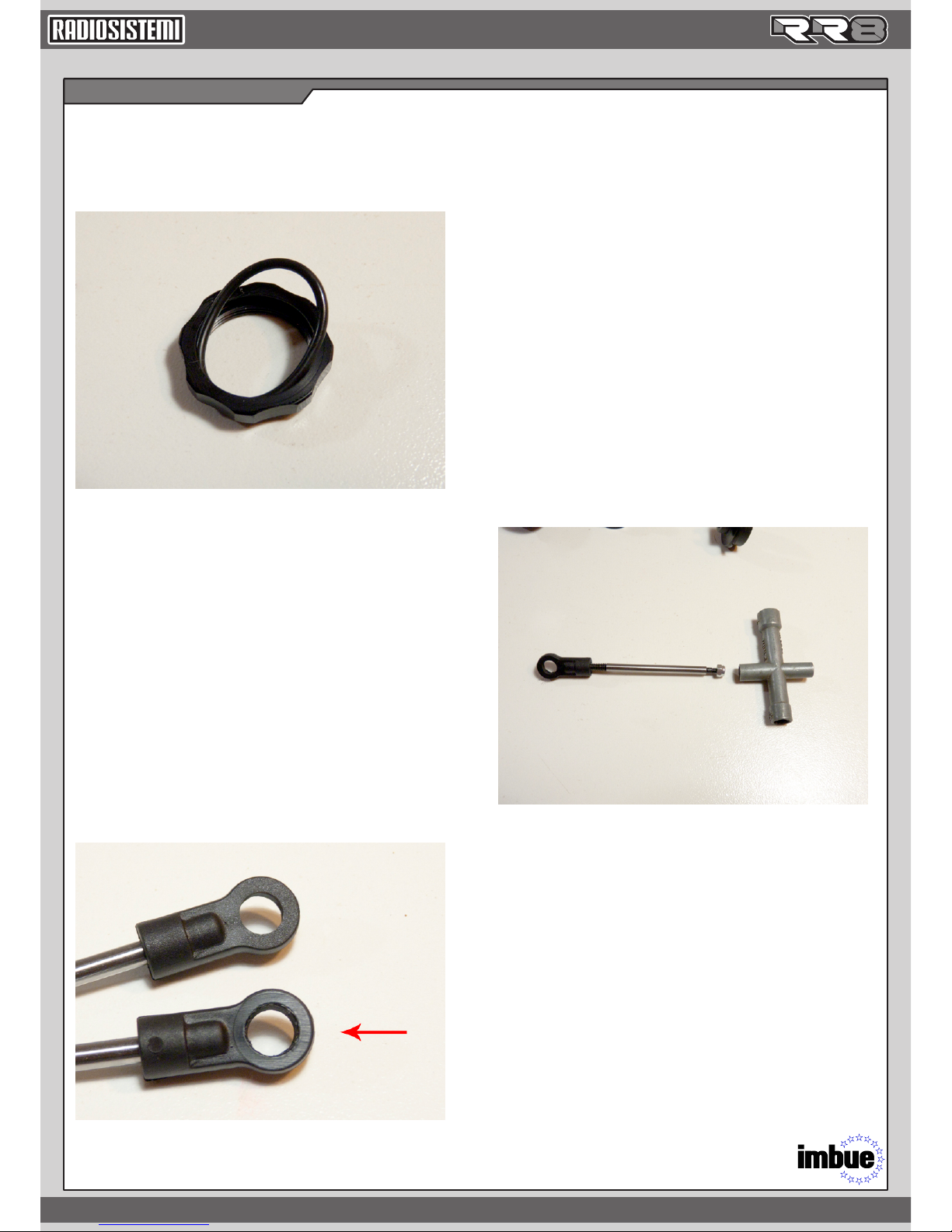

Add shims and the 8x14 bearings to the diff.

You also need to install the 8x16 bearings and

the pinion gear into the bulkhead.

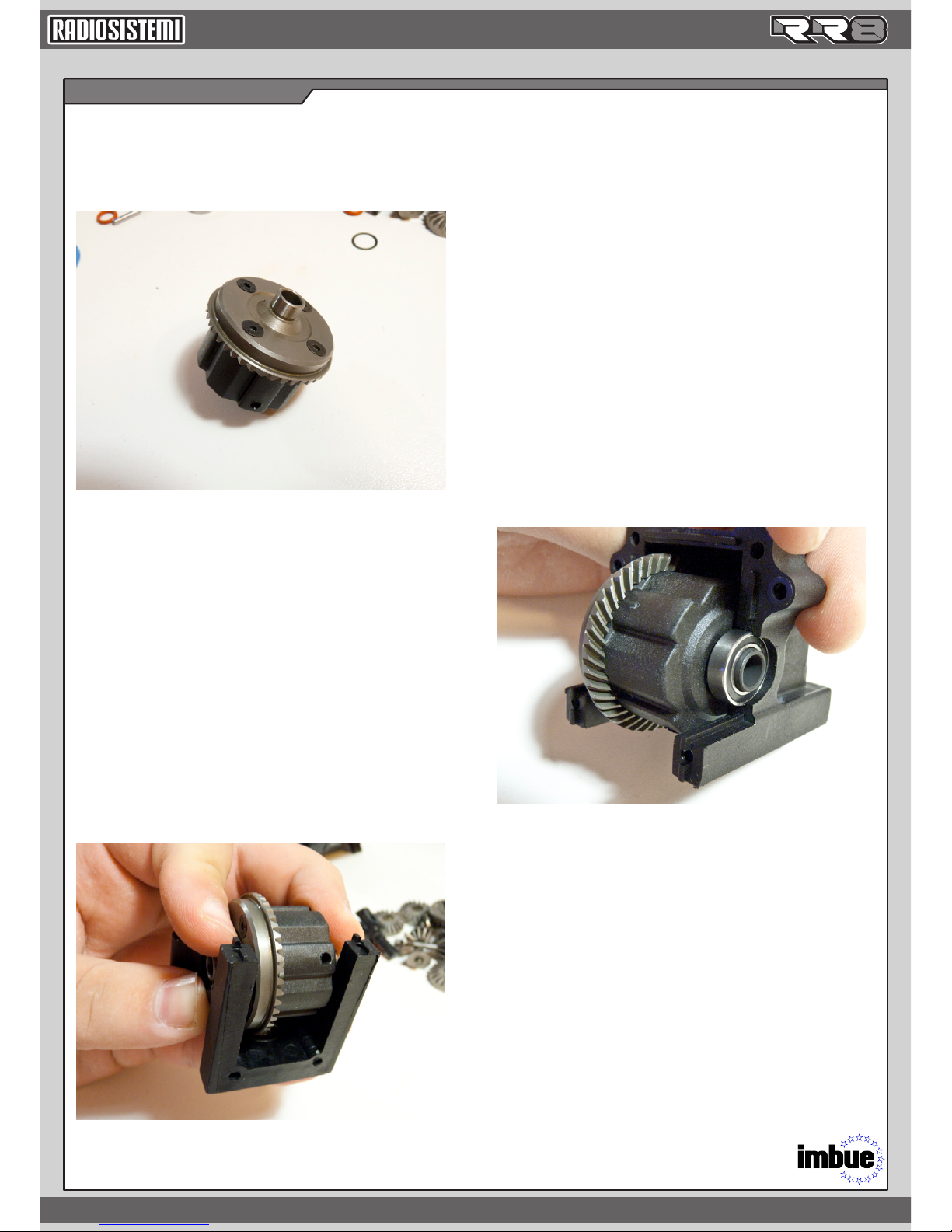

With the pinion and diff installed into the

bulkhead, press on the bearings with your

fingers (holding the gears tight) and check

backlash. You want the gears to rotate

smoothly, with no notchiness and minimal

play. I used one .2mm shim on the gear side,

no shim on the case side. If you need to add

or change the shimming, you can do so now

without having to disassemble the entire

diff. DO THIS FOR BOTH F & R DIFFS.