JCB 714 Super-Boss Road/Rail Conversion SB002 Operator’s Manual

Issue 1, R2 Last Updated 5 April 2017 Page 2 of 43

Contents

Introduction.....................................................................................5

Description and Intended Use.......................................................5

Limitations ......................................................................................5

Manuals...........................................................................................6

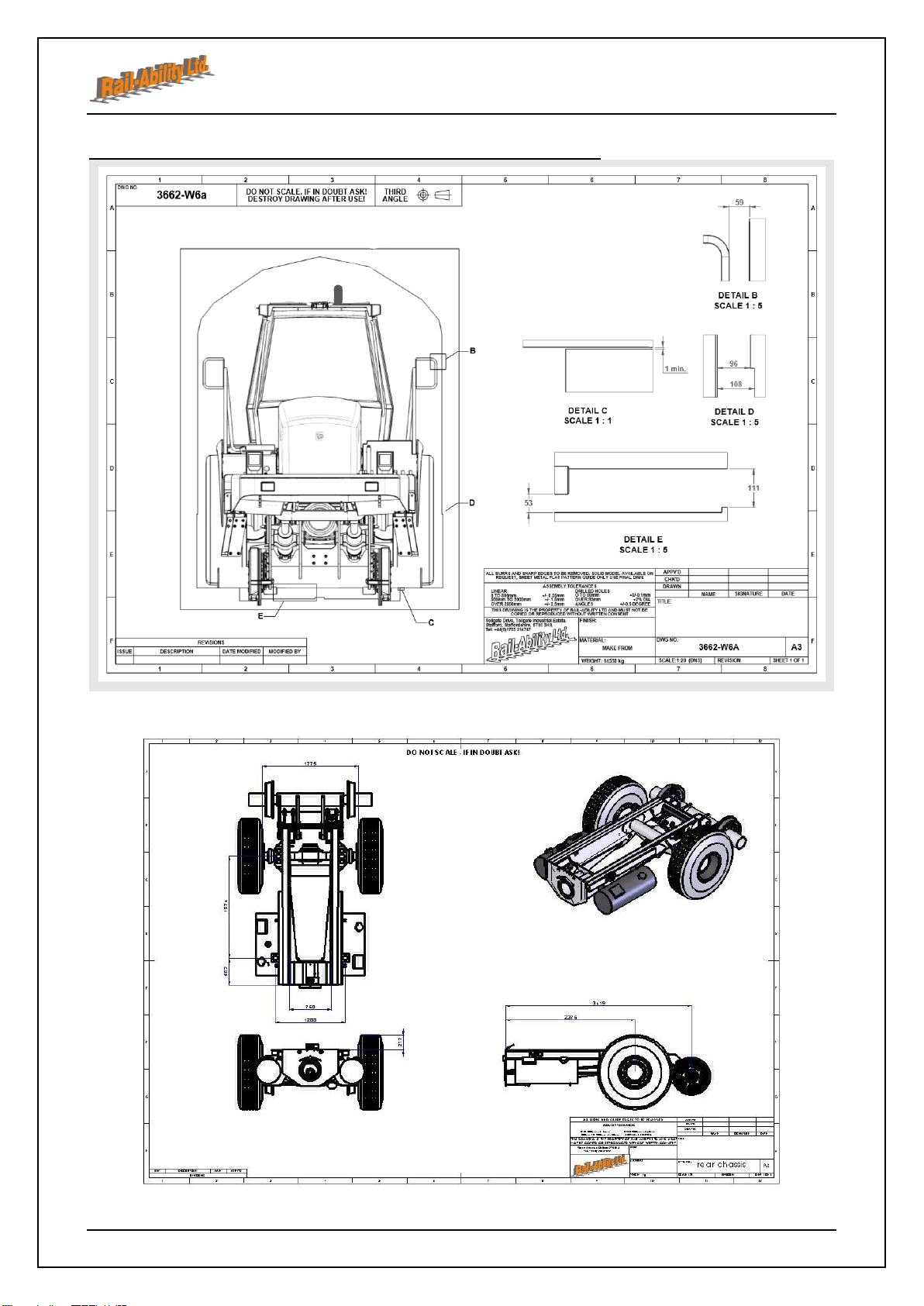

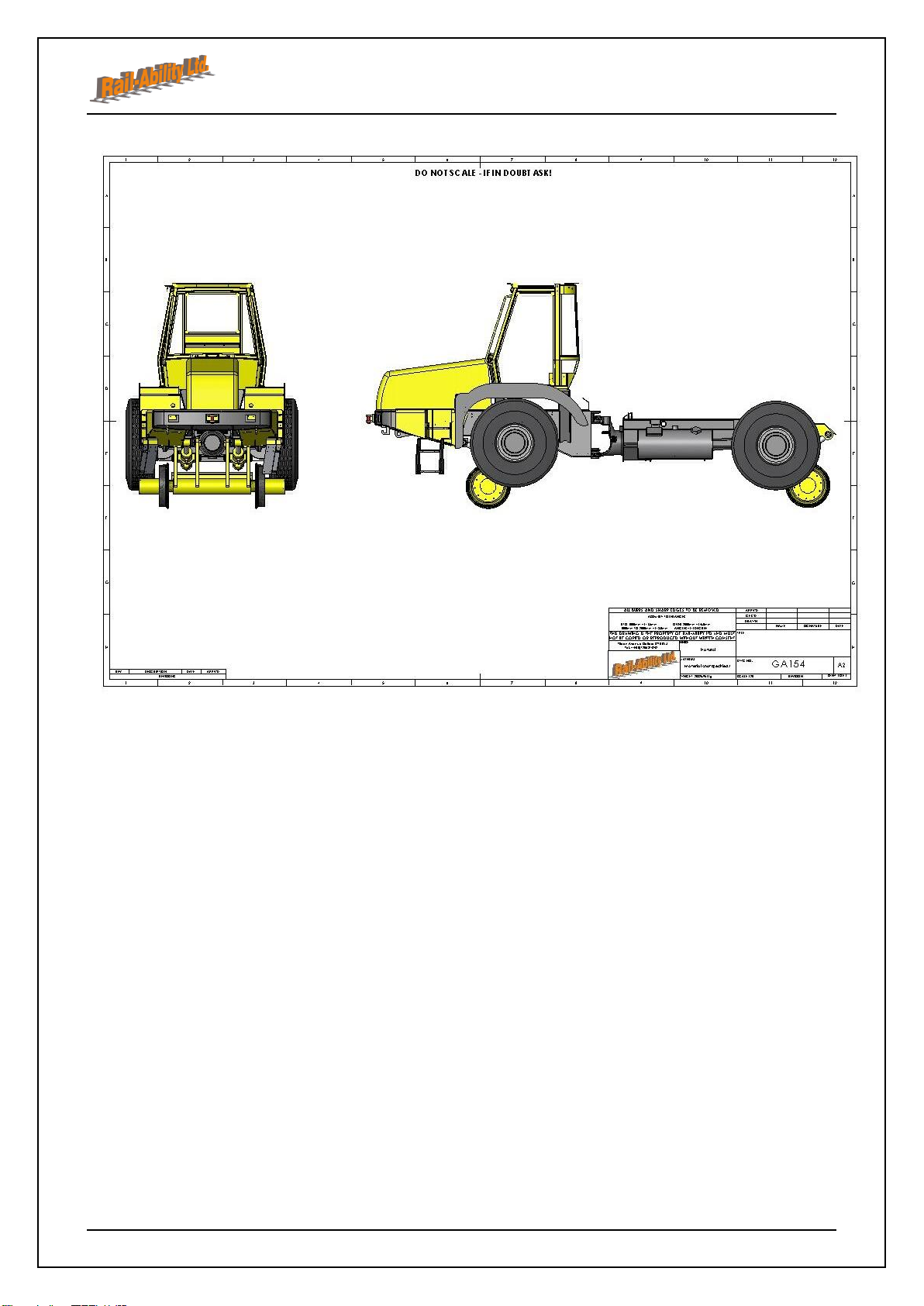

Specification - Principal Dimensions ...........................................7

Specifications.................................................................................9

General Safety Rules ...................................................................11

Electrocution Hazards ..............................................................................11

Collision Hazards .....................................................................................12

Crushing Hazards..................................................................................... 13

Component Damage Hazards.................................................................. 13

Explosion and Fire Hazards......................................................................13

Damaged Machine Hazards..................................................................... 13

Bodily Injury Hazards................................................................................ 14

Burn Hazards ........................................................................................... 14

Electrocution Hazards ..............................................................................14

Lifting Hazard...........................................................................................15

Decal Legend................................................................................15

Rail Safety Rules ..........................................................................16

On / Off-Tracking the Machine - general points........................................16

Travelling on the Rail................................................................................16

Emergency Off-Tracking...........................................................................17

Pre-operation Inspection.............................................................18

Fundamentals...........................................................................................18

Checks..................................................................................................... 19

Maintenance..................................................................................21

Check the Engine Oil Level ......................................................................21

Check the Hydraulic Oil Level...................................................................21

Check the Batteries.................................................................................. 21

Check the Tyre Pressures........................................................................22

Check for Fuel Leaks................................................................................ 22

Scheduled Maintenance...........................................................................23

Operational....................................................................................24

Safety Precautions ...................................................................................24

Control Layout.......................................................................................... 25

JCB 714 Operating Control Principles...................................................... 26

Rail Systems GUI Screen.......................................................................................... 26

Auxiliary Control Lever .............................................................................................. 26

Axle Select Change-Over.......................................................................................... 26

Steering Lock ............................................................................................................ 26