ISSUE 2 LAST UPDATED 22/07/2005 PAGE 4 OF 12

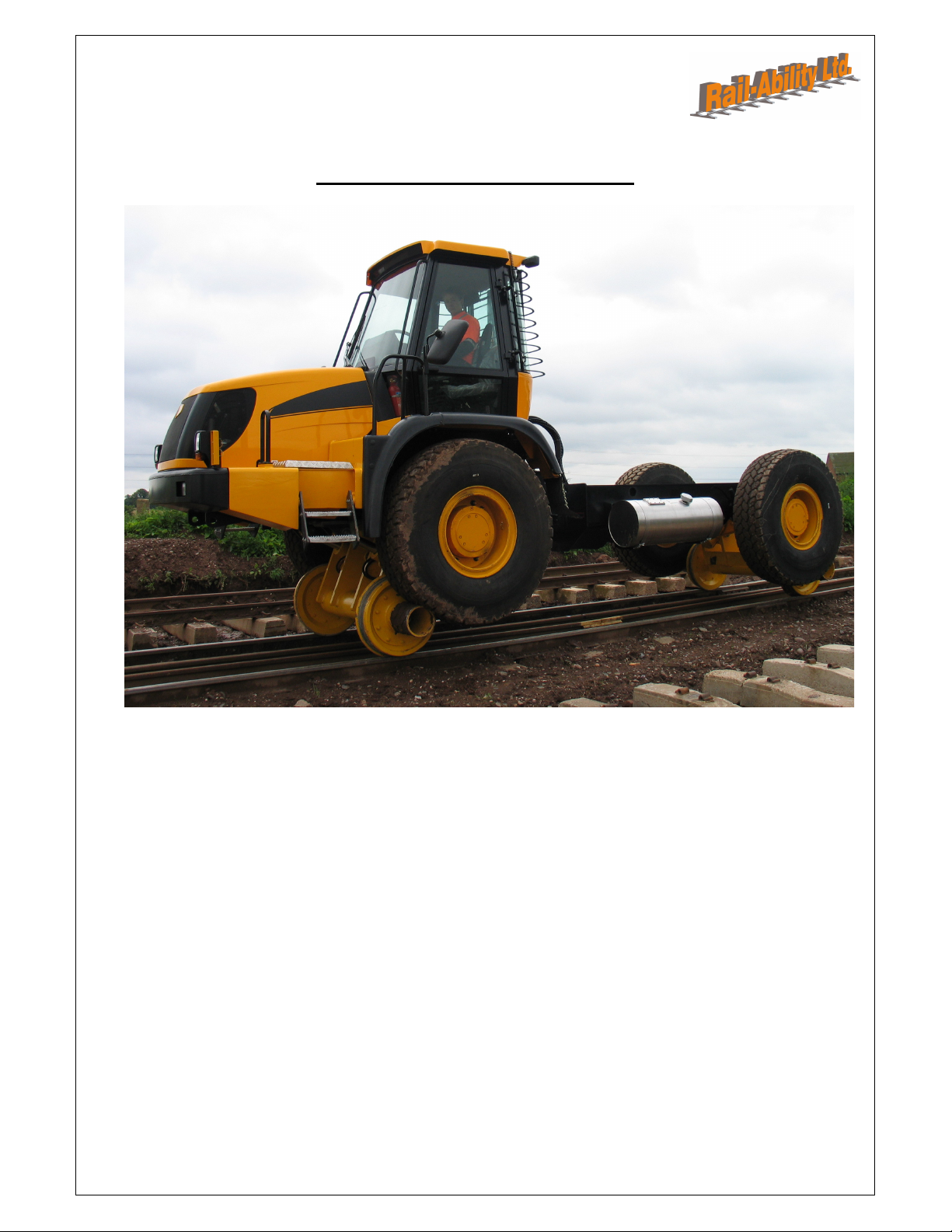

JCB 714 OPERATING CONTROLS

RAIL MASTER SWITCH

THIS SWITCH MUST BE OPERATED FOR ALL RAIL-MOUNTED OPERATIONS.

WHEN OPERATED THE SWITCH MAKES THE RAIL DRIVE AND RAIL AXLE

CONTROL SWITCHES AND STEERING LOCK SYSTEM ACTIVE. IT ALSO

ACTIVATES THE RAIL NAVIGATION LIGHTS AND GEAR RESTRICTION SYSTEM.

[WARNING] NEVER OPERATE THE MACHINE ON TRACK WITH OUT THE RAIL

MODE SWITCH ACTIVE. FAILURE TO ADHERE TO THIS REQUIREMENT WILL

RESULT IN THE RAIL SAFETY SYSTEMS ON THE MACHINE BEING INACTIVE AND

CAN RESULT IN EXCESSIVE SPEED BEING REACHED WHEN TRAVELLING ON

RAIL AND POTENTIAL DE-RAIL OCCURRING RESULTING IN SERIOUS INJURY OR

DEATH AND SEVERE DAMAGE TO THE RAIL INFRASTRUCTURE AND MACHINE.

AUXILIARY CONTROL LEVER

NORMALLY THIS OPERATES THE HYDRAULICS ON THE MODULE ATTACHED TO

THE CHASSIS, I.E. OPERATES THE TIPPING RAM ON THE 3-WAY TIPPER MODULE.

WHEN THE AXLE CHANGEOVER SWITCH IS OPERATED THIS RAISES AND

LOWERS THE SELECTED RAIL GEAR.

AXLE CHANGE-OVER SWITCH

THIS SWITCH CHANGES BETWEEN FORWARD AND REAR RAIL GEAR WHEN

RAISING AND LOWERING THE WHEELS. HOLDING THE LEFT SIDE OF THE

SWITCH DOWN GIVES POWER TO THE FRONT AXLE RAMS AND HOLDING THE

RIGHT SIDE SWITCHES FLOW TO THE REAR AXLE RAMS. WHEN THIS SWITCH IS

IM THE DEFAULT CENTRAL POSITION THE AUXILIARY HYDRAULIC CIRCUIT ITS

ACTIVE

STEERING LOCK SWITCH

ONCE THE STEERING LOCK SWITCH HAS BEEN OPERATED THE LOCK WILL

ONLY TAKE AFFECT ONCE THE CHASSIS IS STRAIGHT. THIS MAY REQUIRE THE

STEERING TO BE MOVED FROM SIDE TO SIDE TO FIND THE LINEAR POSITION

UNTIL THE LOCK ENGAGES.

GEAR SELECTOR

WHEN TRAVELLING ON RAIL THE MACHINE MUST BE IN REVERSE GEAR TO

ACHIEVE FORWARD DRIVE AND CONVERSELY WHEN FORWARD IS

SELECTED THE MACHINE WILL TRAVEL BACKWARDS.

TO OPERATE THE GEAR SELECTOR THE BUTTON ON THE TOP NEEDS TO BE

PRESSED AND HELD IN BEFORE IT WILL SELECT A GEAR. PUSH THE LEVER

FORWARD INTO THE ‘V’ POSITION TO SELECT FORWARD TRAVEL OR PULL

BACK INTO THE ‘R’ POSITION FOR REVERSE TRAVEL.

IN NORMAL USE THE JCB 714 HAS 6 FORWARD GEARS AND 3 REVERSE. IF THE

GEAR LEVER IS JUST PUT IN FORWARDS POSITION IT WILL START IN

AUTOMATIC. TO CHANGE UP OR DOWN GEARS MANUALLY MOVE THE LEVER

TO THE SIDE AS INDICATED ON THE LABEL.

IN RAIL MODE THE VEHICLE IS REDUCED TO 3 FORWARD AND 2 REVERSE

GEARS. WHEN THE VEHICLE IS PUT INTO REVERSE IN RAIL MODE IT WILL