Page 4of 20

railfanmodels.com

Final Truck Assembly

1. Loosen the un-glued Sideframes from the Centers, but do not completely remove.

IMPORTANT –You should practice Steps 3 –5 without using glue a time or two before proceeding with

Step 2.

2. Find a small piece of scrap styrene or plastic (cardboard will also work). Deposit a small

amount of CA to the material. You will use a toothpick to apply CA from here in the next

steps.

3. Insert Wheelsets into the axle bearing points on the glued

Sideframe. Move the opposite ends into the loose Sideframe.

You will have to wiggle the Sideframe slightly, but try not to

remove it completelt from the Center piece. (The sideframed in

the picture are for demonstration purposes, your parts will be painted.)

4. Hold the Wheelsets in place with one hand. With your free

hand, use a toothpick to pick up a small amount of CA. Apply

the CA inside the gap between the Sideframe and Center.

5. Press the Sideframe against the Center, making sure the

Wheelsets are seated correctly in both Sideframes as the parts

are pressed together.

6. The first Truck is now complete. Repeat for the remaining 5 Trucks.

Assembling Trucks to Span Bolsters

1. At this time set aside the Center Trucks (the ones with oval centers). These get installed at the

very end of the build.

2. Carefully remove the contents of Bag B. There should be 4 screws and 4 springs.

3. Place a screw through bottom of the Truck.

4. Place a spring over the exposed threads of the screw.

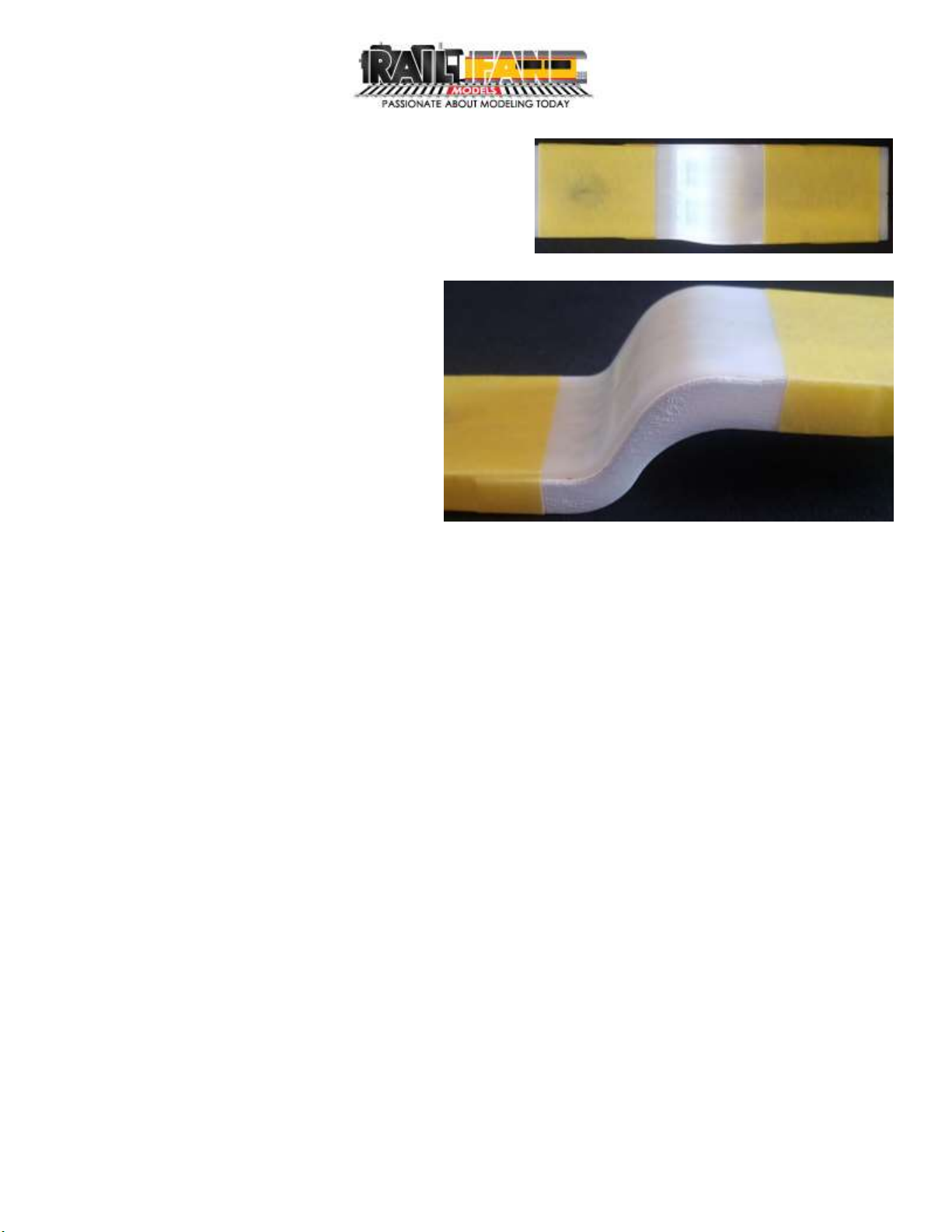

5. Align the notch in the top of the Truck to the notch near the end of the Span Boster.

6. Place the screw into the hole near the notch.

7. Turn the screw counter clockwise (loosening) while applying a little pressure to the screw until

you feel a bump. Turn the screw clockwise (tightening) until the screw bottoms out into the

Span Boster. The holes are pre-threaded, and this process is the easiest way to get the screw

aligned with the threads. When the screw is seated correctly, the Truck will move about 1/16”

between the Span Bolster and screw head. DO NOT OVER TIGHEN THE SCREWS! As shown in

the picture, the springs are pushing the

Trucks up against the screw heads, but

the Trucks will push down against the

Span Bolster leaving a gap between

the screw and Truck center.

8. Repeat for the 3 remaining Trucks.