Troubleshooting

Decoders

General Information

Calculate expected “At Rest” current

draw on each wire path and each

LDI or SDI interface.

• FD-101 = 0.5 mA

• FD-102 = 0.5 mA

• FD-202 = 1.0 mA

• FD-401 = 1.0 mA

• FD-601 = 1.0 mA

Prior to troubleshooting when using

a clamp meter, make sure you know

the static current draw of the wire

path or sections of wire path you will

be troubleshooting. (1) To calculate

the static current draw at an individual

wire path section, add the number of

decoders that are downstream from the

test point, and multiply it by the current

draw of each decoder to determine

the total calculated current draw of

the wire section after the test point. (2)

To calculate the static current draw of

an entire wire path, add the number

of decoders on the entire wire path,

and multiply it by the current draw of

each decoder to determine the total

calculated current draw of the wire path.

(3) To calculate the static current draw of

an entire interface, add up all calculated

wire path current draws that are

connected to the interface.

NOTE: If the wire path has been looped,

you must break the loop in order to

properly troubleshoot current draw

using a clampmeter.

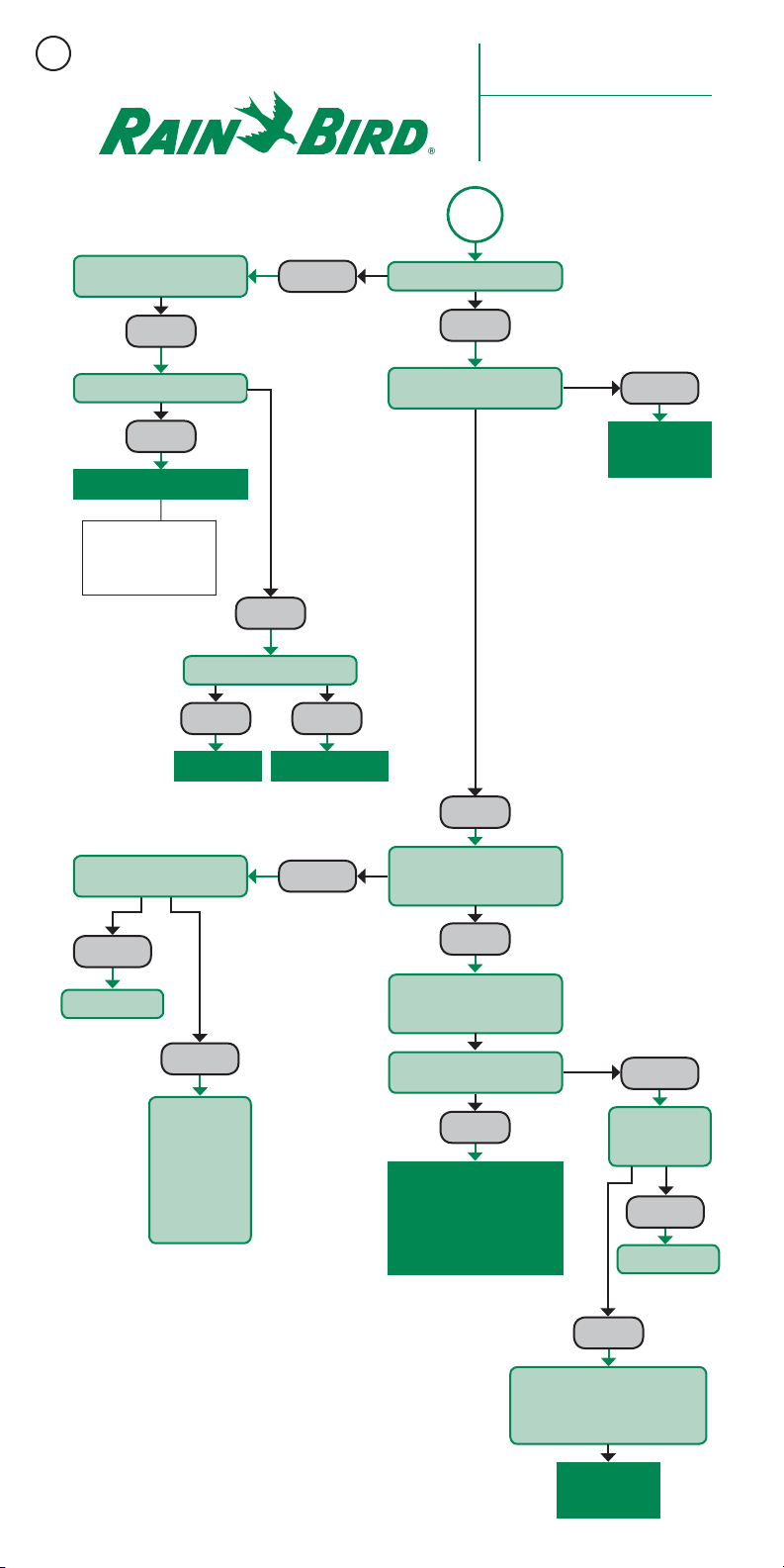

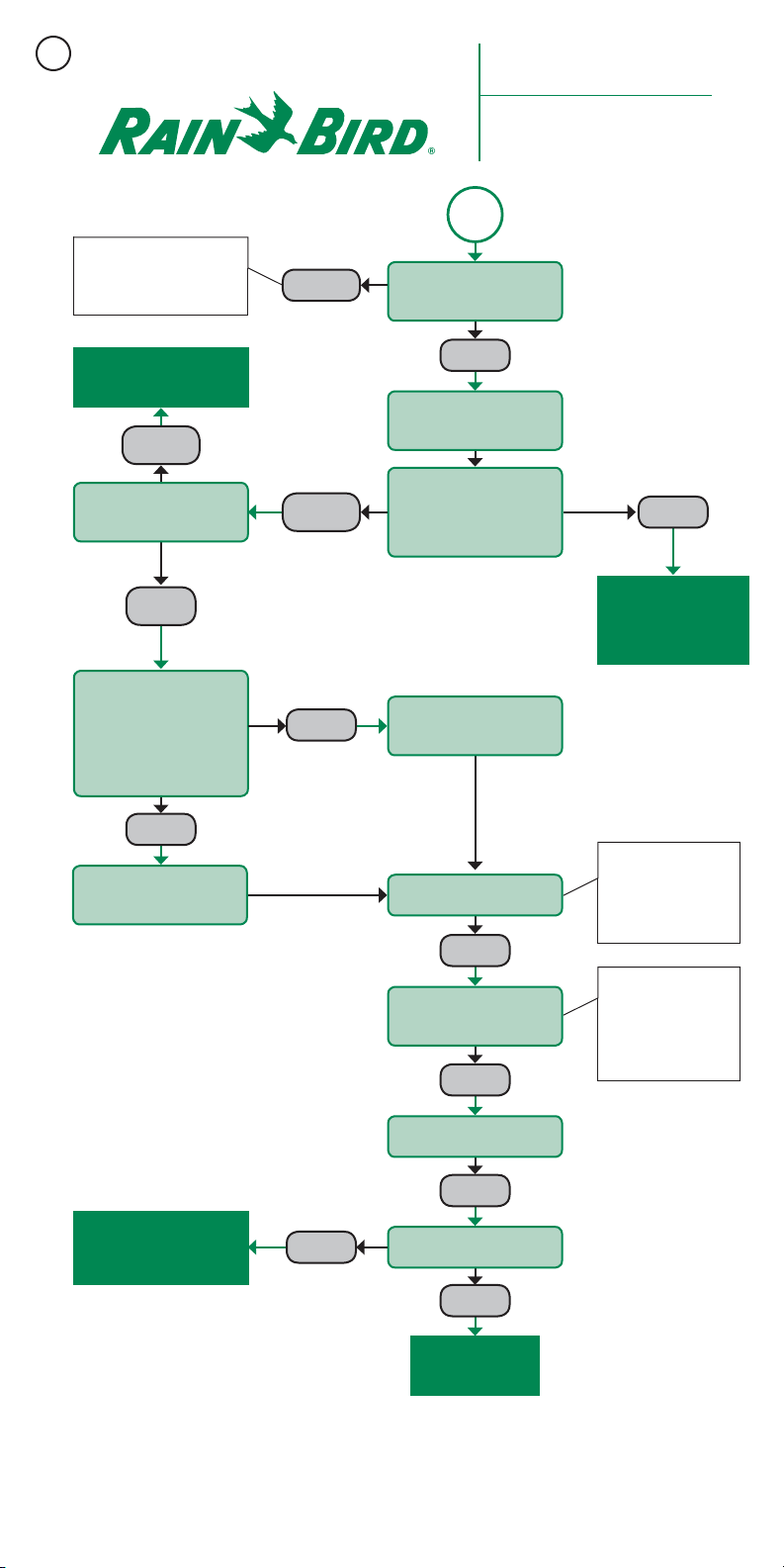

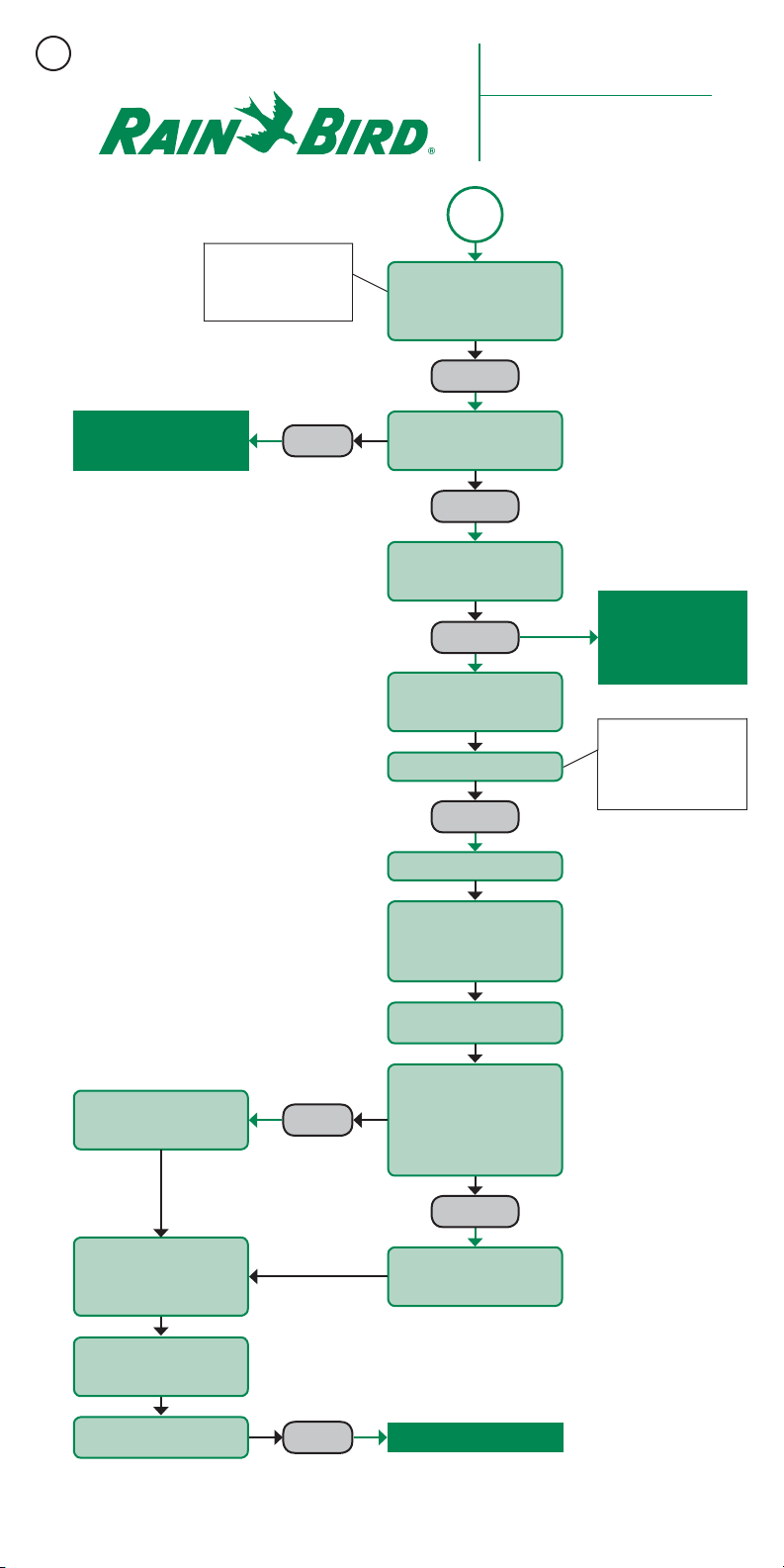

(see Locating A Bad Decoder on page 4).

Example:

BLUE WIRE

• 100 FD-101 x 0.5 mA = 50 mA

• 25 FD-202 x 1.0 mA = 25 mA

• 10 FD-401 and FD-601 = 10 mA

• Total Blue Wire current = 85 mA

RED WIRE

• 80 FD-102 x 0.5 mA = 40 mA

• 20 FD-202 x 1.0 mA = 20 mA

• 15 FD-401 and FD-601 = 15 mA

• Total Red Wire current = 75 mA

• Total Current for LDI or SDI = 85 +

75 = 160 mA

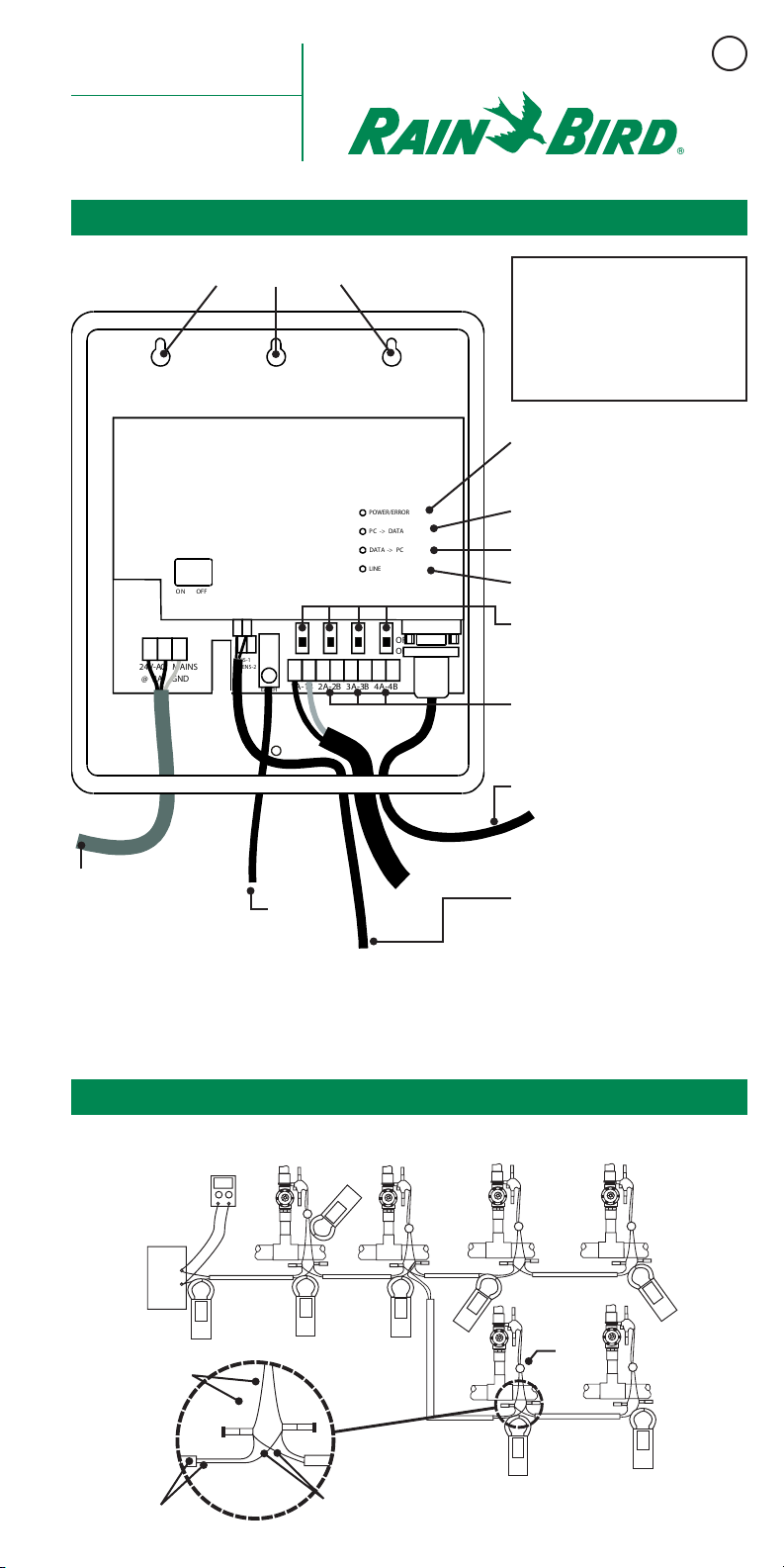

Tool List

• Spare Decoders

• Clamp Meter (current specifications are

available by calling 1-866-GSP-XPRT)

• Digital Multi-Meter

• Direct Bury Wire Splice Kits

• Maxi Wire Strippers

• Wire Strippers

• Linesman Pliers

• Extra Maxi Wire

• Updated “As-Built” drawing (“As Built”

should show wire path colors, decoder locations,

expected current draw per wire path and expected

current draw per LDI/SDI.)

2