Troubleshooting Guide

for Zone Irrigation Systems

This Troubleshooting Guide will assist you in the location of

fault in an irrigation control system related to power supply

or valve control wires. There are corresponding instructions

on how to use the test tool to accomplish steps that require

their use.

Step 1 Make sure the master water supply is turned on.

Keep in mind the water supply may be controlled

by either a manual or electric master valve.

Step 2 Make sure any shut-off devices, such as a rain

sensor, are disabled or disconnected.

Step 3 Turn the controller on and sequence the clock

through the different stations. If nothing is working,

skip to Step 6. If some of the stations are working,

proceed to Step 4. If all of the stations are work-

ing, then you don’t have any troubleshooting to do

at the controller.

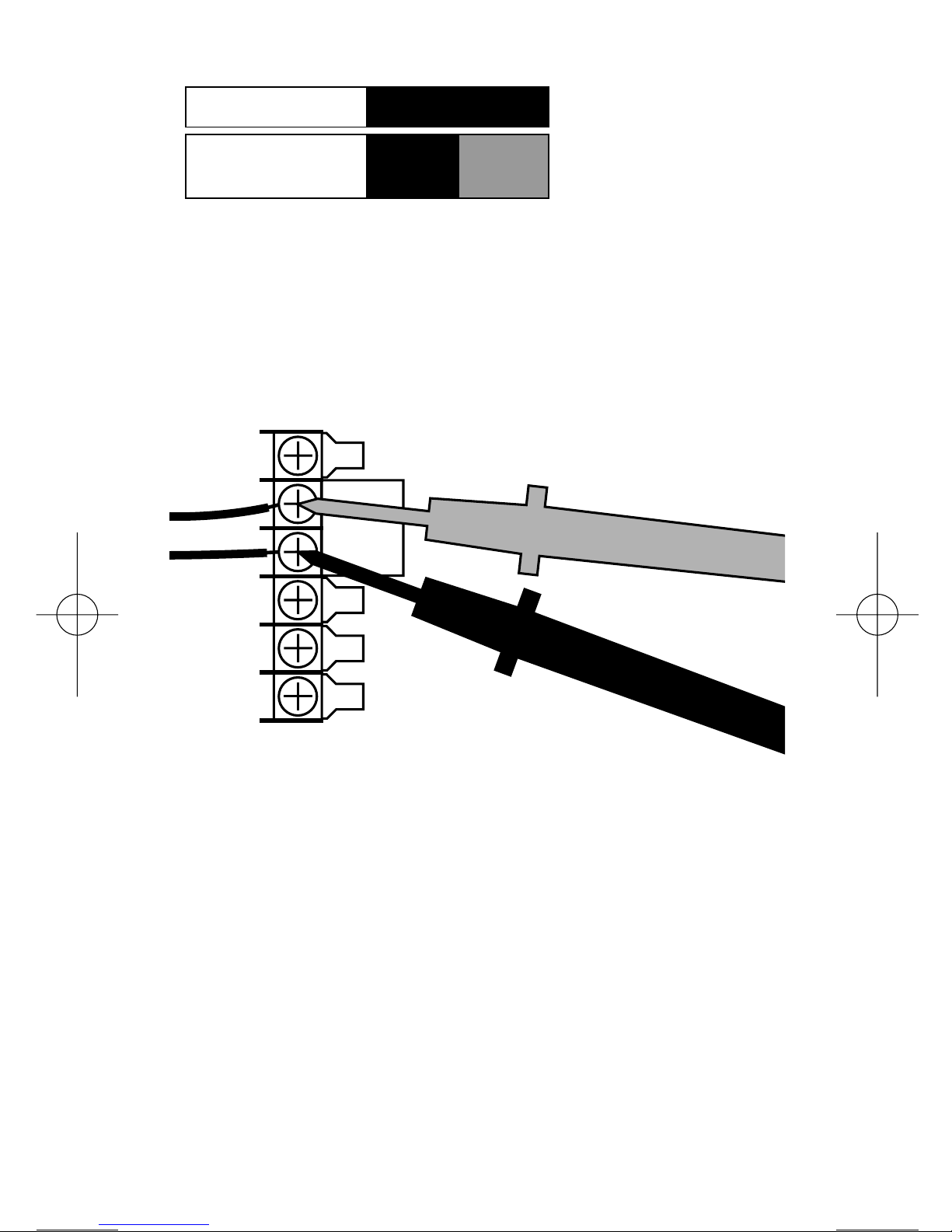

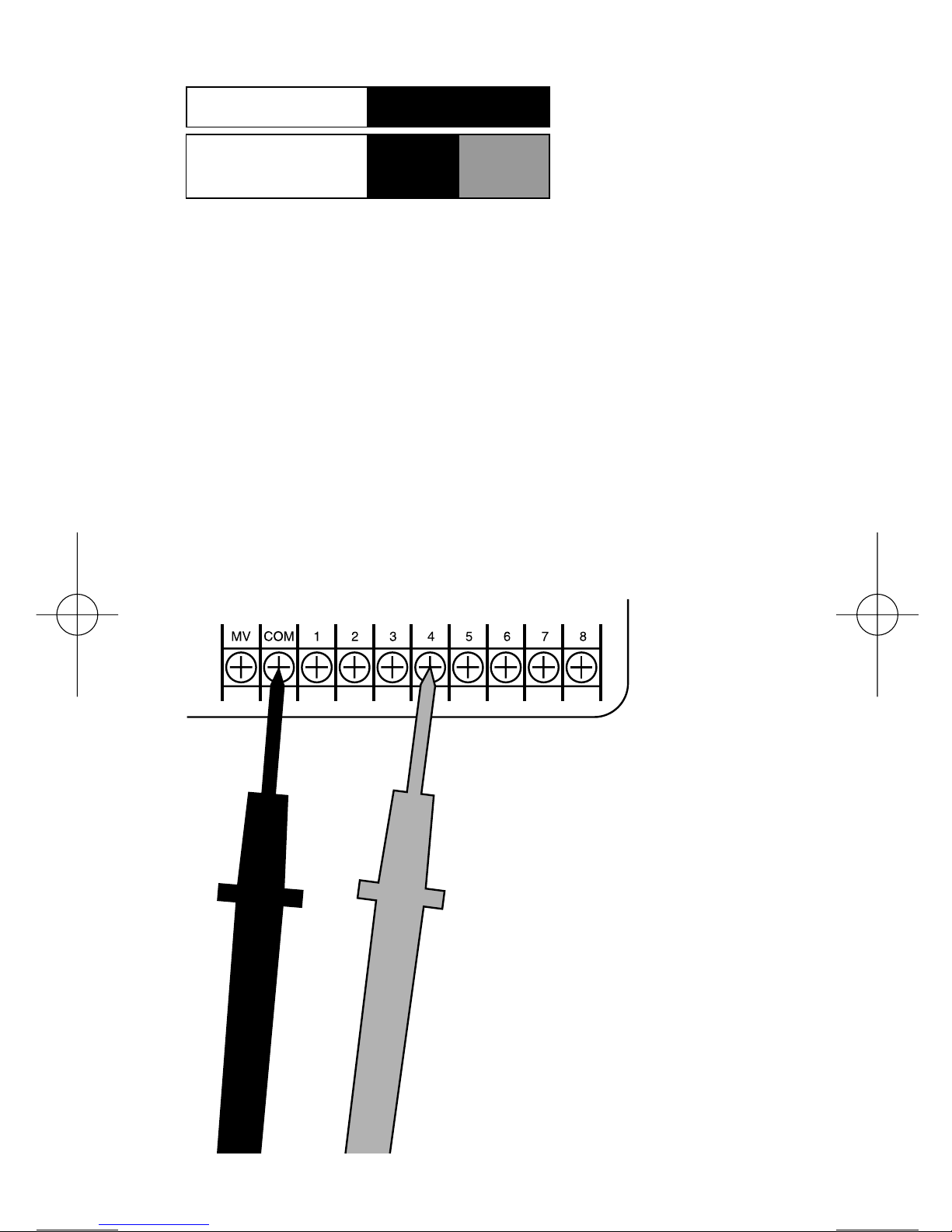

Step 4 Make a list of all of the stations that are not

functioning properly. Measure the output voltage

for each station using a Multi-Meter (Rain Bird

Model TI-DM200, TI-DM400 or TI-DSA500) and

the instructions provided. See Page 9 of this guide.

If the power is in range at every station (24-28

VAC ), proceed to Step 5. If the power is correct

when you test some stations, but not others, you

may need to have your controller repaired. Take

your controller to an authorized distributor.

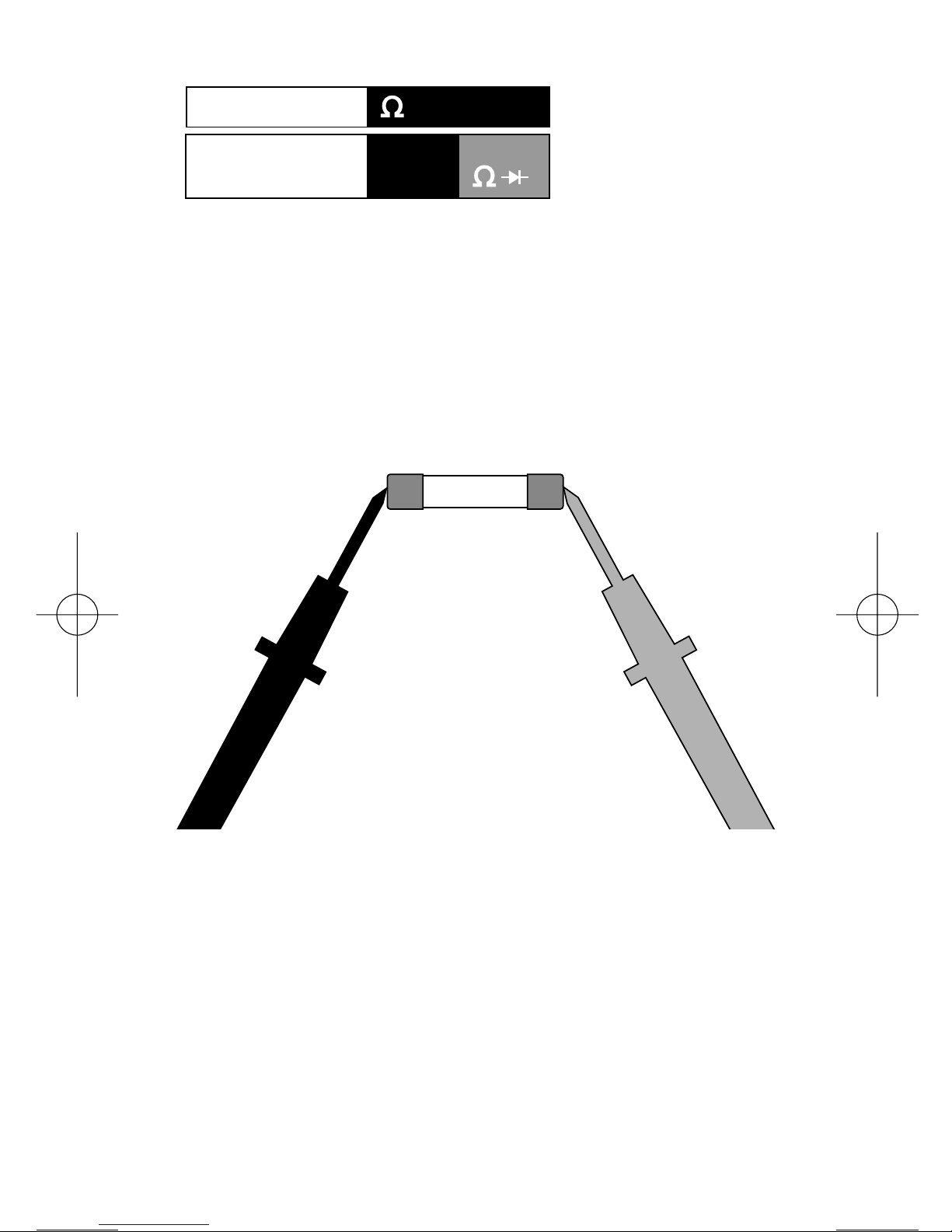

Step 5 Turn the controller off to test the resistance at

each station. Use the following table to diagnose

the problem that each station may have.

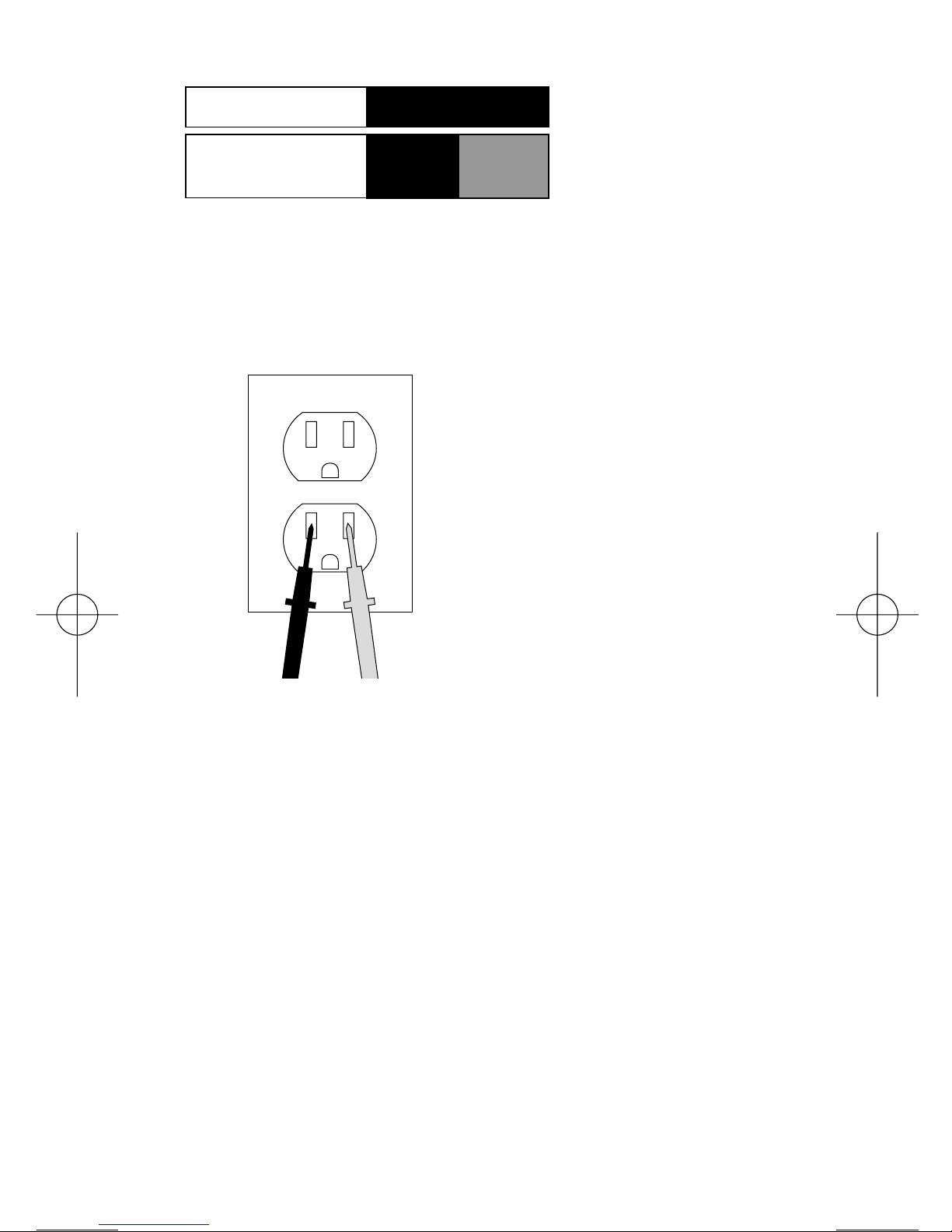

0-5 ohms Fully Shorted Solenoid

8-20 ohms Shorted Solenoid or Multiple Valves

20-60 ohms Normal

> 60 ohms Bad Connection, Splices, Nicked

Wires, Open Solenoid or Broken Wire

-

3

-