1

Statement

This document is a guide to simple and convenient hardware installation. Please read it carefully before installation, to

prevent bodily injury or device damage.

The device installation personnel must be well trained before installation, to master correct installation operations and safety

precautions.

Device installation shall follow local safety regulations. Precautions listed in this document are suppliments to local safety

regulartions. Raisecom shall not be reliable to any accident if common safety operation requirements are violated, or design,

manufacturing, or usage security standards for devices are violated.

Lightning safety

Device installation is prohabited in lightning and thunderstorm conditions to prevent bodily injury and device damage.

High-voltage safety

DO NOT install or remove the device when it is powered on, to prevent unpredictable bodily injury.

Use special tools instead of common tools when conducting operations in high voltage and AC power conditions.

Prevent the device from being rotted. Once the device is rotted, power off it immediately.

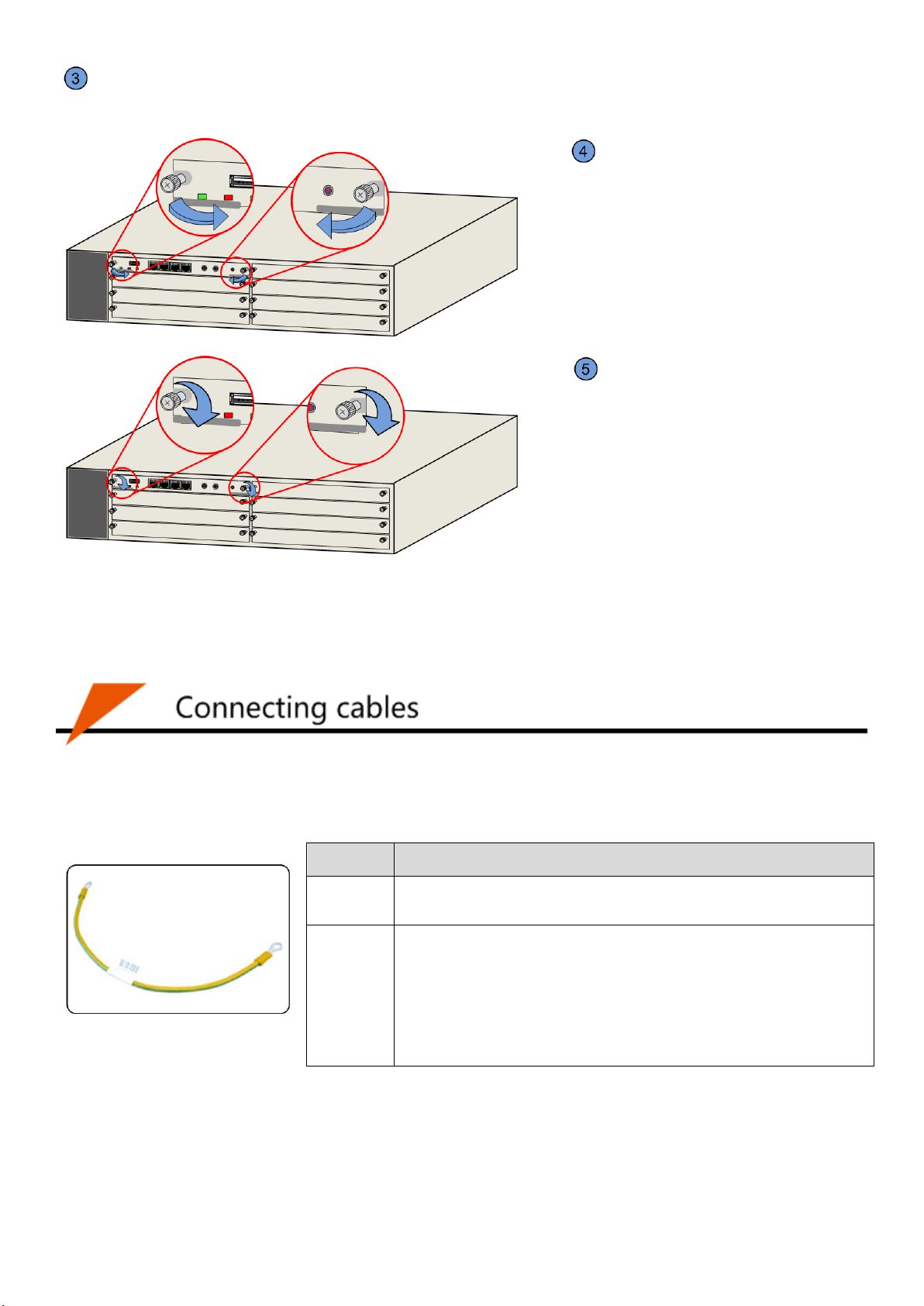

Electrostatic discharge safety

Any time when contacting the device, you must wear an Electro-Static Discharge (ESD) wrist strap in good contact with skin

and have the other end of the ESD wrist grounded.

Grounding safety

Before connecting cables, ensure that the device is fixed and is well grounded. Do not connect other cables if the device is

not grounded.

Laser safety

Before cutting or welding fiber, disconnect the fiber and the optical source. DO NOT stare into the optical interface to

prevent eye injury.