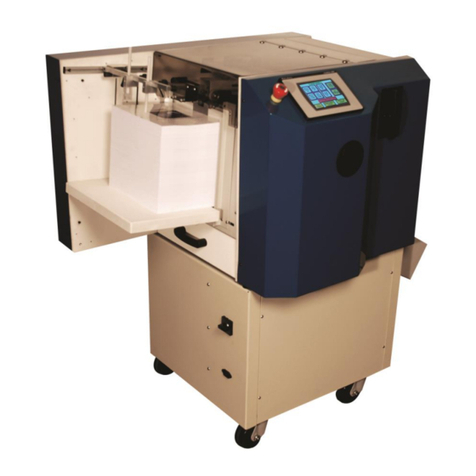

SPECIFICATIONS PARTS DIAGRAM

FKR-200 FRK-300 FKR-400

Seal Length 10mm 10mm 10mm

Power 110V / 300W 110V / 400W 110V / 500W

Length 8” 12” 16”

Temperature Up to 300⁰F(150⁰C)

Wei

ht 4lbs

OPERATING INSTRUCTIONS

1. Insert power plug into socket.

2. Allow the sealer to heat up approximately 5 minutes

(warm-up time will vary with the thickness of the bag to be

sealed). Choose either the low setting for a light material

or a the high setting for thicker materials. We recommend

starting at the lowest setting and gradually moving up as

needed.

3. After a suitable temperature has been reached, put the

bag edge between the heated sealing bars and press

down for 3 seconds. If the seal weld holds, continue this

way. *If the welding appears to damage the bag, apply

pressure on the sealing bar for less than 3 seconds. If the

PARTS LIST

No Description QTY No Description QTY

1 Lever (up) 1 15 Expoxy Washer 16

2 Lever Cover (up) 1 16 Aluminum 8

3 Insulation Plate 1 17 Nylon Nut 4

welding appears incomplete, apply pressure for more

than 3 seconds.

5 Below Board 1 19 Lever (down) 1

6 Supporter 2 20 Spring 1

7 Heating Bar (down) 1 21 Plate Board 1

8Heater 4 22 Lever Cover 1

9M10Bolt 4 23 Volume 1

10 Shaft 1 24 Bimetal 1

11 Plain Washer 2 25 Heating Bar (up) 1

12 M6 Bolt 2 26 Code Rock 1

13 Stainless Steel Bolt 4 27 Stainless Steel Nut 8

14 Plain Washer (SUS) 16