8INTEGRATED SAFETY DEVICE | INSTRUCTION MANUAL

—

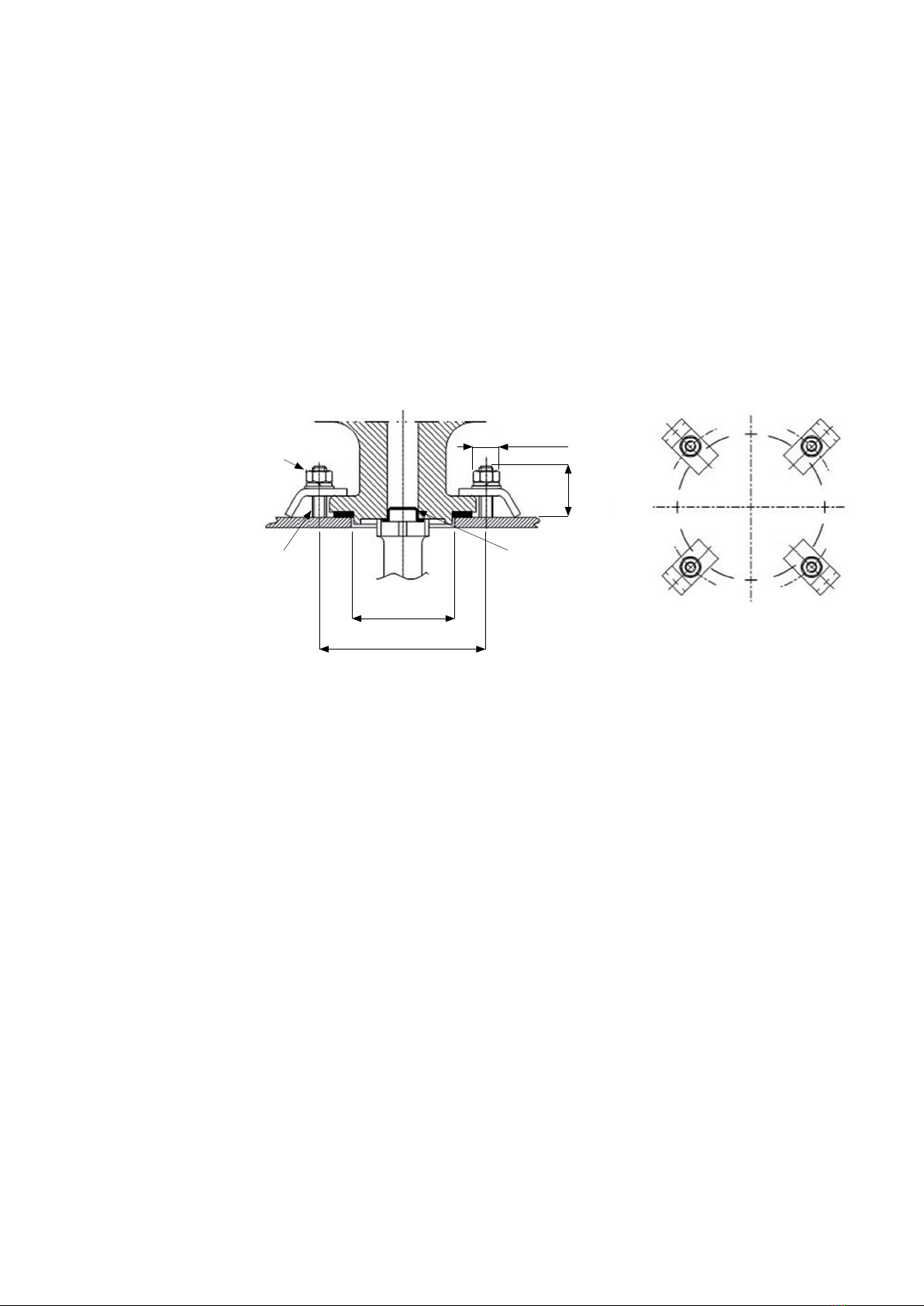

3. Installation

3.2 Installations and operating

instructions

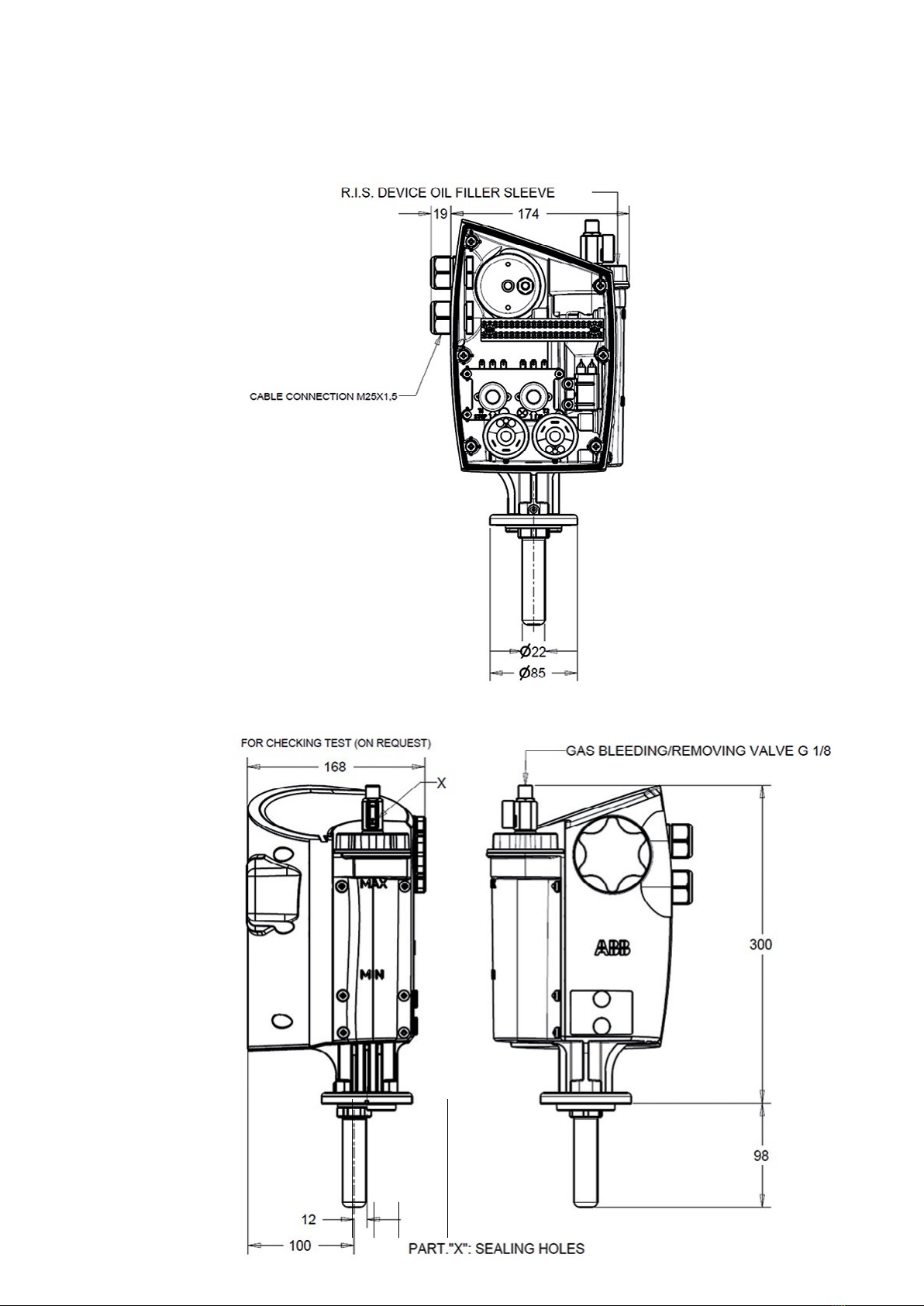

• Before installing the device remove the protective

cap from the oil down flow hole.

• Ensure the bearing surface is smooth and flat.

• A four stud fixing is recommended.

• Protect Comem RIS2 device from any subsequent

paint operation.

• Only install Comem RIS2 after the transformer

drying operation.

• Switch off the supply voltage prior to working on

Comem RIS2

• Operation and maintenance of Comem RIS2 should

only be carried out by skilled personnel.

• ABB disclaim all responsibility for incorrect

installation or improper use.

• On receipt of the goods please check the attached

test certificate.

• The Comem RIS2 is guaranteed against defective

parts for 12 months.

• Do not use powerful solvents or benzene's for

cleaning. A damp cloth should.

• Do not remove float from inside Comem RIS2

3.3 Instructions for topping up

the level on Comem RIS2

Foreword

The device is filled with oil exclusively by the

transformer manufacturer at environment

temperature. At the time of putting into service,

ensure what Comem RIS2 device is completely filled

with oil. For various reasons, the oil may be below

the set level. If the transformer is warm, due to high

environment temperature or to its own operation,

the internal pressure may increase, causing a visible

drop in the oil level in the chamber of the device.

• To solve this problem it is sufficient to remove the

lead seal on the lever of the tap 1 (see diagram),

partly unscrew cap 2, slightly turn the lever of tap

1, thus releasing pressure and causing the oil level

to rise until the device is completely full. After

operation, ensure that cap 2 is closed and clean off

any oil I that may have leaked out of the device.

• When the transformer is cold, due to a long period

of inactivity, and/or an outdoor temperature

below that of the environment, a vacuum may

form inside the transformer, with consequent fall

of the oil level visible on the external chamber of

the device. This problem may be solved by

removing the lead seal on the cap 2, unscrewing

the cap 6 and topping up the oil level slowly with

the aid of a funnel until the device is completely

full, taking care not to let it overflow. Close the

device with the cap 6.

• DO NOT USE THE OIL FILTER ON THE COMEM

RIS2 FOR GENERAL FILLING OF THE

TRANSFORMER, ONLY FOR TOPPING UP THE

DEVICE

• WHEN FILLING THE COMEM RIS2. WITH OIL

MAKE SURE THE BLEED COCK IS OPEN AND

FILL UNTIL FLOAT REACHES THE “MAX”

POSITION.

• AFTER FILLING ENSURE THE BLEED COCK AND

FILLER CAP ARE FULLY CLOSED. HAND

TIGHTEN ONLY, NO TOOLS REQUIRED.

• AFTER SETTING THE THERMOMETER POINTER

ENSURE THE PROTECTIVE WINDOW IS

SECURED, HAND TIGHTEN ONLY.

• CHECK THE CABLE GLAND M25X1,5 IS

SECURELY FITTED.

• THE EVENT OF A MAJOR OIL LEVEL VARIATION

OR HIGH GAS EVOLVEMENT THE FLOAT WILL

REACH “MIN” POSITION, TRIGGERING THE

ALARM SWITCH, IT WILL THEN BE NECESSARY

TO BLEED OFF GAS OR ADD OIL.

WARNING