TCRS AH150TON Service manual

150 TON AHU

OPERATING AND SERVICE MANUAL

STARTING S/N AHU 150-22-00037

REV-

Contact TCRS at 440-658-2020

1

TABLE OF CONTENTS

Page No.

Description

1

Table of Contents

2

Safety Information

5

Technical Data Specifications

6

Operator Control Panel

7

Operation and Service

7

Troubleshooting

8

Electrical Schematic

9

Electrical Panel Layout

10

Structural\Sheet Metal

Contact TCRS at 440-658-2020

2

Important Safety Information

Most accidents that involve product operation, maintenance and repair are caused by failure to observe

basic safety rules or precautions. An accident can often be avoided by recognizing potentially hazardous

situations before an accident occurs. A person must be alert to potential hazards, including human factors

that can affect safety. This person should also have the necessary training, skills and tools to perform these

functions properly.

Improper operation, lubrication, maintenance or repair of this product can be dangerous and could

result in injury or death.

Do not operate or perform any lubrication, maintenance or repair on this product, until you verify

that you are authorized to perform this work, and have read and understood the operation,

lubrication, maintenance, and repair information.

Safety precautions and warnings are provided in this manual and on the product. If these hazard warnings

are not heeded, bodily injury or death could occur to you or to other persons.

The hazards are identified by the “Safety Alert Symbol” and followed by a “Signal Word” such as

“DANGER”, “WARNING” or “CAUTION”. The Safety Alert “WARNING” label is shown below.

The meaning of this safety alert symbol is as follows:

Attention! Become Alert! Your Safety is involved.

The message that appears under the warning explains the hazard and can be either written or pictorially

presented.

A non-exhaustive list of operations that may cause product damage are identified in this publication.

TCRS cannot anticipate every possible circumstance that might involve a potential hazard.

The warnings in this publication and on the product are, therefore, not all inclusive. You must not

use this product in any manner different from that considered by this manual without first satisfying

yourself that you have considered all safety rules and precautions applicable to the operation of the

product in the location of use, including site-specific rules and precautions applicable to the

worksite. If a tool, procedure, work method or operating technique that is not specifically

recommended by TCRS is used, you must satisfy yourself that it is safe for you and for others. You

should also ensure that you are authorized to perform this work, and that the product will not be

damaged or become unsafe by the operation, lubrication, maintenance or repair procedures that

you intend to use.

The information, specifications, and illustrations in this publication are on the basis of information that was

available at the time that the publication was written. The specifications, torques, pressures,

measurements, adjustments, illustrations, and other items can change at any time. These changes can

affect the service that is given to the product. Obtain the complete and most current information before you

start any job.

When replacement parts are required for this

product, TCRS recommends using parts with

equivalent specifications including, but not limited

to, physical dimensions, type, strength and material.

Failure to heed this warning can lead to premature

failures, product damage, personal injury or death.

Contact TCRS at 440-658-2020

3

Universal Warning

Do not operate or work on this equipment unless

you have read and understand the instructions

and warnings in the Operation and Maintenance

Manuals. Failure to follow the instructions or heed

the warnings could result in serious injury or

death.

Electrical Shock

The safety message for electrical shock is located on the control panel.

WARNING! Shock/Electrocution Hazard! Read

and understand the instructions and warnings in

the Operation and Maintenance Manual. Failure to

follow the instructions or heed the warnings

could cause serious injury or death.

Additional Messages

There are several warning labels on this unit. Please be aware of all warning labels.

Make sure that all of the messages are legible. Clean the messages or replace the messages if the words or images are

unreadable. When you clean the messages, use a cloth, water and soap. Do not use solvent, gasoline, or other harsh

chemicals to clean the messages. Solvents, gasoline, or harsh chemicals could loosen the adhesive that secures the

messages. Loose adhesive will allow the messages to fall off.

Replace any message that is damaged, or missing. If a message is attached to a part that is replaced, install a message on

the replacement part.

General Hazard Information Attach a “Do Not Operate” warning tag to the start switch or controls before the

unit is serviced or repaired. Attach the warning tags to the unit and to the operator

control station. When appropriate, disconnect the starting controls. Do not allow

unauthorized personnel on the unit, or around the unit when the unit is being

serviced. Cautiously remove the following parts. To help prevent spraying or

splashing of pressurized fluids, hold a rag over the part that is being removed.

•Gage ports

•Breathers

•Drain plugs

Use caution when cover plates are removed. Gradually loosen, but do not remove

the last two bolts or nuts that are located at opposite ends of the cover plate or the

device. Before removing the last two bolts or nuts, pry the cover loose in order to

relieve any spring pressure or other pressure.

Wear a hard hat, protective glasses, and other protective equipment, as required.

Do not wear loose clothing or jewelry that can snag on parts of the unit.

Ensure that all protective guards and all covers are secured in place on the unit.

Never put maintenance fluids into glass containers. Glass containers can break.

Use all cleaning solutions with care.

Report all necessary repairs.

Contact TCRS at 440-658-2020

4

Unless other instructions are provided, perform maintenance under the following conditions:

The unit is powered down and cannot be started.

The protective locks on the controls are in the locked out position.

Do not attempt any repairs that are not understood. Use the proper tools.

Replace any equipment that is damaged or repair the equipment.

Pressurized Air and Water

Pressurized air and/or water can cause debris and/or hot water to be blown out which could result in personal injury.

The maximum air pressure for cleaning purposes must be reduced to 205 kPa (30 psi) when the air nozzle is deadheaded and

used with effective chip guarding (if applicable) and personal protective equipment. The maximum water pressure for cleaning

purposes must be below 275 kPa (40 psi). When pressurized air and/or pressurized water is used for cleaning, wear protective

clothing, protective shoes, and eye protection. Eye protection includes goggles or a protective face shield. Always wear eye

protection for cleaning the cooling system. Avoid direct spraying of water on electrical connectors, connections, and

components. When using air for cleaning, allow the machine to cool to reduce the possibility of fine debris igniting when

redeposited on hot surfaces.

Fluid Penetration

Always use a board or cardboard when you check for a leak. Leaking fluid that is under pressure can penetrate body

tissue. Fluid penetration can cause serious injury and possible death. A pinhole leak can cause severe injury.

If fluid is injected into your skin, you must get treatment immediately. Seek treatment from a doctor that is familiar with this

type of injury.

Containing Fluid Spillage

Care must be taken to ensure that fluids are contained during performance of inspection, maintenance, testing,

adjusting, and repair of the product. Be prepared to collect the fluid with suitable containers before opening any

compartment or disassembling any component containing fluids. Dispose of all fluids according to local regulations and

mandates.

Dispose of Waste Properly

Improperly disposing of waste can threaten the environment. Potentially harmful fluids should be disposed of according to local

regulations. Always use leak proof containers when you drain fluids. Do not pour waste onto the ground, down a drain, or into

any source of water.

Burn Prevention

Do not service an operating unit. Allow liquids to cool before any maintenance is performed.

Contact TCRS at 440-658-2020

5

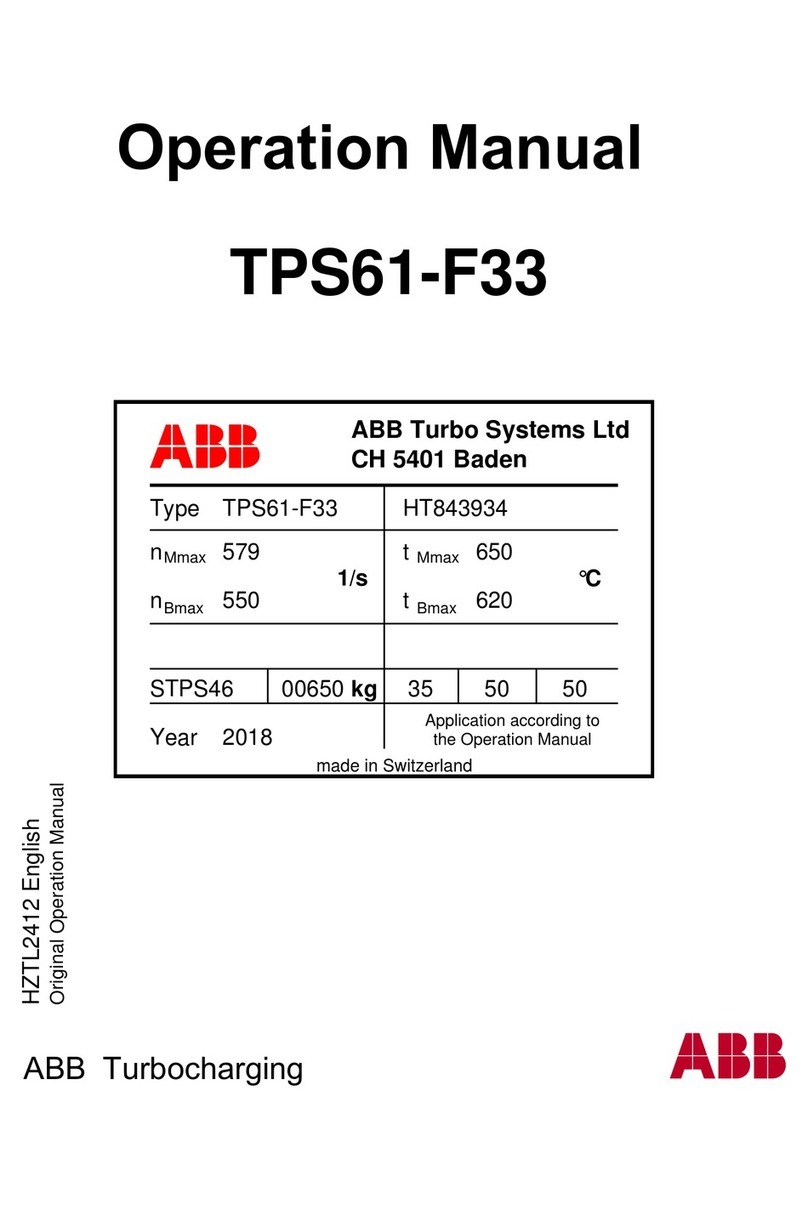

Technical Data Specifications

Model Number

AH150TON

Serial Number

AC150-22-0037

Capacity

150 TON

Voltage

480V 3PH 60Hz

FL Amps - Cooling

27 AMPS

Interrupt Rating

10KAIC

Minimum Circuit

Ampacity

40 AMPS

Enclosure Type

Type 3R

Control

110V

Control

12V DC

Blower Motor

WATTS

4400 WATTS x4

FLA

6.6 AMPS x4

Circuit Protection

10 AMPS

Condensate Pump

H.P.

1/150 HP

FLA

1 AMP

Circuit Protection

2 AMPS

Control Transformer

Rating

500 VA

Primary Fuse

ATDR4

Secondary Fuse

ATDR4

DBA @20’

76 DBA

DBA @20’ with Ducts

66 DBA

Weight

3500 LBS.

Made in USA

Contact TCRS at 440-658-2020

Operator Control Panel

6

7

Operation and Service

Turn on Main Disconnect

Turn BLOWER switch to the ON position. Green BLOWER ON light indicates system is powered.

Turn BLOWER SPEED to desired speed. Blower minimum speed is 30% when blower is on.

Filter and mist eliminator must be kept clean to ensure proper operation.

Troubleshooting

Caution

must be taken when troubleshooting the electrical circuit and should only be performed by a trained service

technician.

INDICATION

POSSIBLE

CAUSE

CORRECTIVE

ACTION

Nothing

operates

Main power

Control power

Check voltage

Check transformer and fusing

Blower Fault

Breaker tripped

Motor failure

Find cause, reset breaker

Verify 480V 3ph is present

Verify 0-10VDC control voltage is present

replace blower motor if not responding

For operation and service concerns please call:

440-658-2020

Contact TCRS at 440-658-2020

8

Electrical Schematic

Contact TCRS at 440-658-2020

Electrical Panel Layout

9

Contact TCRS at 440-658-2020

10

Contact TCRS at 440-658-2020

11

Contact TCRS at 440-658-2020

12

Table of contents

Other TCRS Industrial Equipment manuals