OPERATING MANUAL 11-2020 6/8

4. STORAGE & TRANSPORT

The products are packed on EURO pallets (1200x800 mm) or in custom containers, as applicable. Store the valves

in clean indoor rooms without bacteriological or chemical contaminants and at a room temperature between -20°C

and 70°C. Protect the paint coat and rubber parts from prolonged exposure to UV radiation. The filters should be

protected against mechanical damage.

Protect the rubber parts from compression by keeping the gate valve wedge closure halfway open. Secure the

products against shifting during shipping and handling. The gate valves shall be handled on slings and secured

from rotating.

5. INSTALLATION

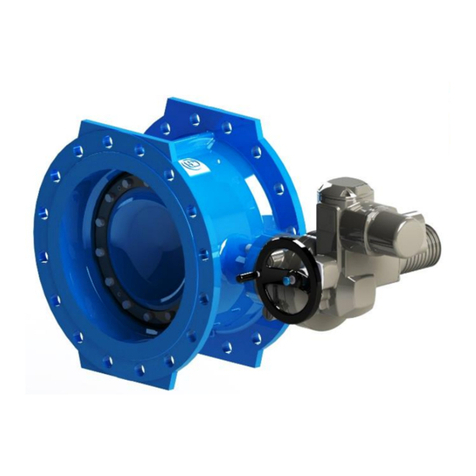

The flanged gate valves with soft seals intended for gas flow isolation in NG pieline systems and other fluid

systems, can be installed in underground pipelines or overground pipeline installations, both horizontal and

vertical, with any direction of flow of the medium. The Type 2312 gas gate valves are intended for installation

between resistance-welded pipeline ends. The Type 2314 gas gate valves are intended for installation between

fusion-welded pipeline ends. Note that the completed installation must not expose the valve to bending or tensile

stress from loading with the unsupported pipeline sections, and the valves must be installed aligned with the piping.

Consider proper compensation of the pipeline dimensional changes from temperature and pressure in the

installation. The gate valve is ready for installation as assembled and adjusted by the manufacturer. Any

dismantling of the gate valve components may result in loss of seal.

Before attempting to install the valve, check the technical and commercial documents delivered with the product

to verify that your media and pipeline operating parameters comply with the manufacturer's declaration. Any

change in the operating conditions must be consulted with the manufacturer beforehand.

Before attempting to assemble the valve, remove the main bore plugs, check the inner surfaces of the valve and

thoroughly flush with water, if necessary. Install the gate valve on a base or a support adequate to the size and

weight of the valve, to prevent strain of the piping with the valve. Use suitable piping flanges, gaskets and bolts

for the valve flange ends. The valve and piping flange holes must be aligned. Tighten the connection flange bolts

crosswise to ensure a proper seal pressure. The gate valve location must prevent exposure to freezing of the

medium flowing through the gate valve. Equip the gate valve with a suitable control, e.g. a spindle handwheel with

a flexible or rigid housing, an electric drive unit and a pedestal. When installing a housing, it is necessary to equip

the unit with a street box founded on a base slab. When using a spindle extension, make sure that the weight of the

extension is not transferred to the gate valve spindle. To prevent the load transfer, use holding pieces, mounted to

the chamber/vault walls. Spindle extensions over 3000 mm long shall be attached via Cardan joints. Having

completed the installation, perform a pressure test at a maximum test pressure equal to 1.5 times the nominal

pressure.

Caution! If the product has mechanical damage, do not install it in the pipeline.

6. OPERATION AND MAINTENANCE

The gate valve shall be operated in accordance with all relevant requirements for stop valves, i.e. kept either in the

fully open or fully closed position. Leaving the gate valve partially opened (or closed) may result in seal failure.

The gate valve can be controlled with:

a handwheel sized according to the Product Specification Sheet and mounted on the gate valve spindle or a

pedestal;

a T-socket wrench, if the spindle neck is in a housing;

an electric or pneumatic drive unit;

other driving gear, e.g. a handwheel with a chain.

Valve control requires a specific driving torque (see table in Section 2) and a specific number of spindle turns. Do

not exceed the maximum driving torque.

To ensure full operational efficiency, carry out a technical inspection and maintenance at least once a year as

follows:

Operate the gate valve from the fully open position to the fully closed position, or vice versa, as the case may

be.

Follow the driving torque limits specified in the table in Section 2.